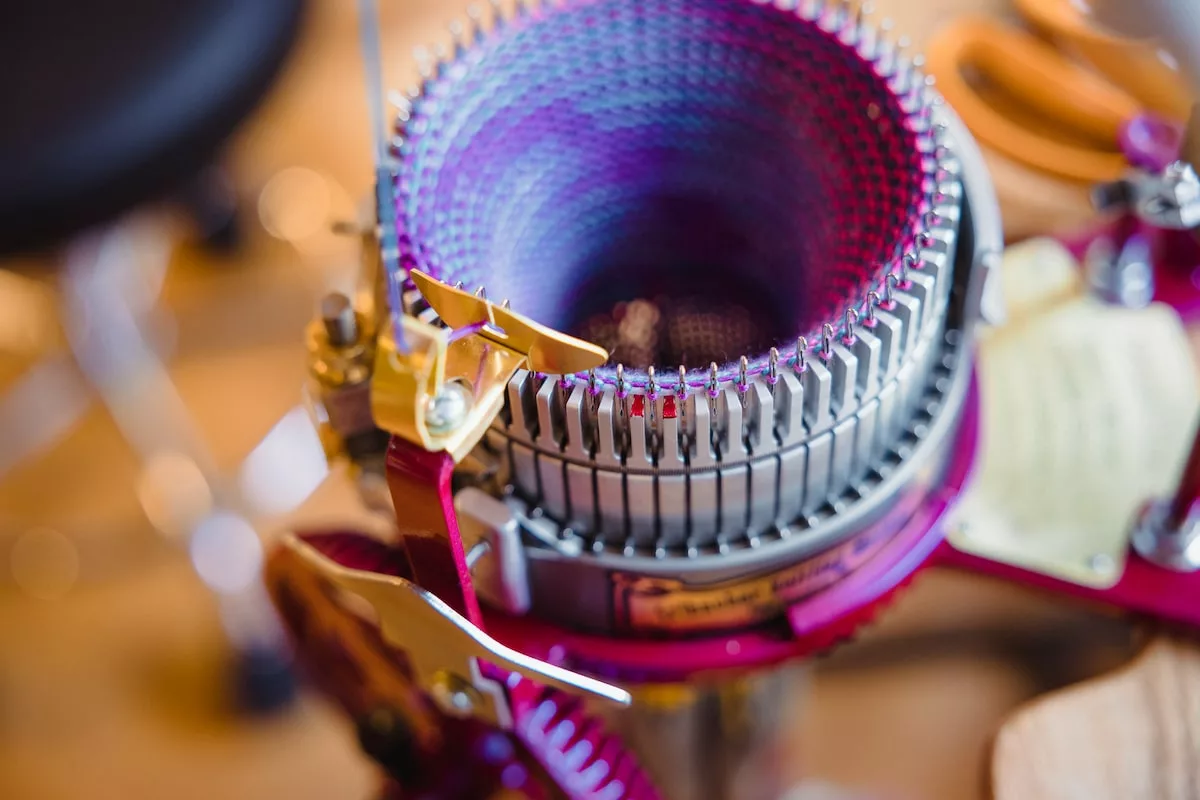

The global knitting machinery market is experiencing steady growth, driven by rising demand for technical textiles, automation in garment manufacturing, and the resurgence of niche products like machine-knitted socks. According to Grand View Research, the global circular knitting machines market size was valued at USD 1.1 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by increasing investment in advanced textile manufacturing technologies, particularly in Asia-Pacific, where countries like China, India, and Turkey dominate production. As sock demand continues to grow—spurred by activewear trends, health-focused compression hosiery, and customization—manufacturers are turning to high-efficiency, precision knitting machines to boost output and reduce waste. Based on production capacity, stitch quality, automation level, and industry adoption, we’ve identified the top 9 knitting machine manufacturers that are shaping the future of sock production worldwide.

Top 9 Knitting Machine For Socks Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

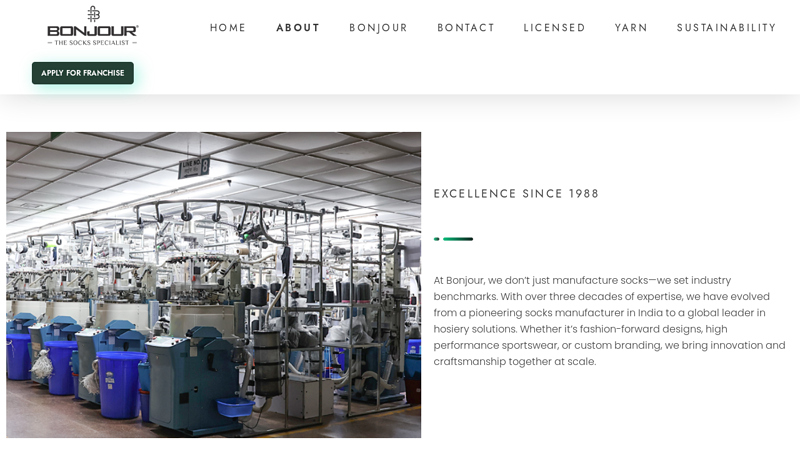

#1 About Page

Domain Est. 2004

Website: bonjourgroup.net

Key Highlights: With over three decades of expertise, we have evolved from a pioneering socks manufacturer … Having received specialised training on circular knitting machines ……

#2 S.Labo, an experimental sock making space.|SOUKI

Domain Est. 2015

Website: slabo.souki-knit.jp

Key Highlights: S.Labo is the sock making laboratory presented by SOUKI, aiming to become the most exciting sock factory for everyone from kids to the grown-ups….

#3 Sock Factory

Domain Est. 2022

Website: uet-intl.com

Key Highlights: UET Socks is the only knitting Company in the Philippines that using the top of the line machines in manufacturing our knitted product such as Socks, Beanies, ……

#4 Sock World Hokitika

Domain Est. 2005

Website: autoknitter.com

Key Highlights: New Zealand’s largest online wool / yarn and sock store. The home of NZ Autoknitter (NZAK) Circular Sock Machines, quality yarns, socks and accessories….

#5 Nester Hosiery

Domain Est. 2005

Website: nesterhosiery.com

Key Highlights: Nester Hosiery expands their capabilities of sock manufacturing with 54 needle Moreni and 84 needle Crawford knitting machines. … officially launched at the ……

#6 Crescent Sock Company

Domain Est. 2010

Website: crescentsockco.com

Key Highlights: Crescent Sock Co is the oldest continually operating sock mill in the United States, still family owned after 119 years!…

#7 Circular Sock Knitting Machine Society

Domain Est. 2013

Website: cskms.org

Key Highlights: a CSM community to share knowledge about these great machines — how best to make your machine knit well; the fascinating history of CSMs; pattern ideas ……

#8 Wisdom

Domain Est. 2023

Website: wisdomsocksmachinery.com

Key Highlights: We are the one of first manufacture who produced fully computerized socks knitting machine in China. We welcome people from all circles to give the guidance ……

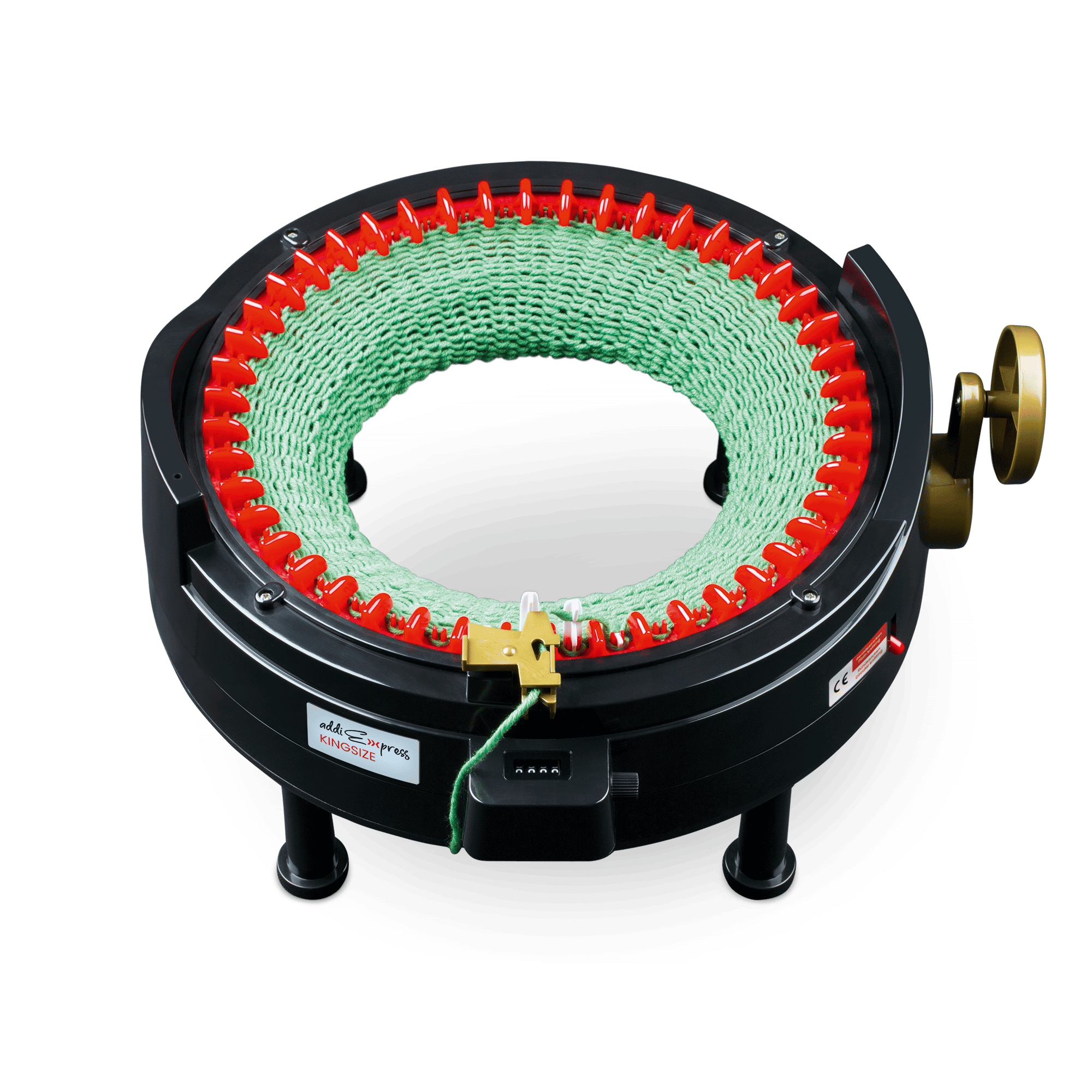

#9 addiExpress Kingsize Knitting Machine » addi.de

Website: addi.de

Key Highlights: The addiExpress Kingsize knitting machine boasts 46 needles, allowing for quick knitting in rounds or straight by simply turning the crank….

Expert Sourcing Insights for Knitting Machine For Socks

2026 Market Trends for Knitting Machines for Socks

The global market for knitting machines for socks is poised for significant transformation by 2026, driven by technological innovation, shifting consumer preferences, and evolving manufacturing demands. Key trends shaping the landscape include:

Advancements in Automation and Smart Manufacturing

By 2026, automation will be a cornerstone of sock knitting operations. Manufacturers are increasingly integrating Industry 4.0 principles, with sock knitting machines featuring IoT connectivity, real-time monitoring, and predictive maintenance capabilities. These smart machines reduce downtime, optimize production efficiency, and enable remote diagnostics. Fully automated production lines—from yarn feeding to sock finishing—are becoming more common, especially among large-scale producers aiming to reduce labor costs and enhance consistency.

Rising Demand for Customization and On-Demand Production

Consumers are driving demand for personalized and niche sock designs, prompting investment in flexible knitting technologies. Computerized circular knitting machines with enhanced digital control allow for rapid design changes, small batch runs, and mass customization. By 2026, digital knitting platforms that support direct-to-consumer (DTC) models and on-demand manufacturing are expected to gain traction, minimizing inventory waste and enabling greater design diversity.

Sustainability and Eco-Friendly Innovations

Environmental concerns are reshaping the sock knitting industry. There is growing demand for machines that support sustainable practices, such as reduced energy consumption, waterless dyeing compatibility, and the ability to process recycled or biodegradable yarns. Machine manufacturers are responding with energy-efficient motors, optimized stitch formation, and integration with closed-loop recycling systems. By 2026, eco-certifications and low-impact production capabilities will be key differentiators in the knitting machine market.

Growth in Technical and Performance Socks

The expanding market for athletic, medical, and compression socks is fueling demand for high-precision knitting machines capable of producing complex structures and functional textiles. Machines with multi-gauge capabilities and advanced tension control are essential for crafting performance-oriented socks with targeted compression, moisture-wicking, and durability. This trend is particularly strong in North America and Europe, where health and wellness markets continue to grow.

Regional Shifts and Supply Chain Resilience

Geopolitical factors and supply chain disruptions are prompting a reevaluation of manufacturing locations. By 2026, there is an increasing trend toward regionalization, with investment in sock production capacity in Eastern Europe, Southeast Asia, and Latin America. This shift is encouraging localized machine sales and service networks. Additionally, dual sourcing and nearshoring strategies are leading some brands to invest in compact, modular knitting machines suitable for smaller, agile production facilities.

Integration of AI and Machine Learning

Artificial intelligence is beginning to play a role in optimizing sock knitting processes. By 2026, AI-driven software will be more widely used for pattern generation, quality inspection via machine vision, and predictive analytics for yarn usage and machine performance. These technologies enhance precision, reduce material waste, and support faster time-to-market for new sock designs.

In conclusion, the 2026 market for knitting machines for socks will be defined by smarter, more sustainable, and highly adaptable technologies. Manufacturers and brands that embrace automation, customization, and environmental responsibility will be best positioned to succeed in this dynamic and competitive landscape.

Common Pitfalls When Sourcing Knitting Machines for Socks: Quality and Intellectual Property Concerns

Logistics & Compliance Guide for Knitting Machines for Socks

Product Classification and HS Code

Accurate classification is crucial for international shipping and customs clearance. Knitting machines for socks typically fall under HS Code 8447.20 (“Circular knitting machines”). Confirm the exact code with your local customs authority, as variations may exist depending on machine specifications (e.g., computerized vs. mechanical). Proper classification ensures correct duty calculation and compliance with trade regulations.

Import/Export Regulations

Compliance with both origin and destination country regulations is mandatory. Exporters must adhere to export control laws, including potential licensing requirements for dual-use machinery. Importers must verify if the destination country imposes import restrictions, quotas, or special certifications for textile machinery. Always consult with customs brokers or trade compliance experts to ensure adherence to bilateral trade agreements and sanctions lists.

Packaging and Handling Requirements

Knitting machines are sensitive industrial equipment requiring robust packaging. Use wooden crates with internal foam or foam-in-place cushioning to protect moving parts and electronic components. Clearly label packages with “Fragile,” “This Side Up,” and handling instructions. Include moisture barrier wrapping to prevent corrosion during sea freight. Secure all loose components and document contents for customs inspections.

Transportation Modes and Freight Options

Choose the transportation method based on cost, speed, and machine size. For large or heavy sock knitting machines, sea freight (FCL/LCL) is cost-effective for bulk shipments. Air freight is suitable for urgent, lightweight, or replacement parts. Ensure the freight forwarder has experience with industrial machinery to manage loading, securing, and transit risks. Use Incoterms (e.g., FOB, CIF, DDP) clearly defined in contracts to allocate responsibilities.

Customs Documentation

Provide complete and accurate documentation to avoid delays. Essential documents include:

– Commercial Invoice (with value, description, and HS code)

– Packing List (itemizing contents and weights)

– Bill of Lading or Air Waybill

– Certificate of Origin (may be required for preferential tariffs)

– Import/Export Licenses (if applicable)

Ensure all documents match and are signed where required.

Electrical and Safety Compliance

Verify that the knitting machine meets electrical standards of the destination country (e.g., CE marking for the EU, UL listing for the U.S.). Voltage and plug types must align with local power supply (e.g., 220V/50Hz vs. 110V/60Hz). Include multilingual safety manuals and compliance certificates (such as EMC or RoHS) to satisfy regulatory inspections.

After-Sales Support and Warranty Logistics

Plan logistics for spare parts, technical support, and warranty service. Maintain an inventory of critical components in key markets or arrange expedited shipping agreements. Provide customers with clear warranty terms and support channels. Ensure technicians are trained and authorized to comply with local service regulations.

Environmental and Disposal Regulations

Adhere to environmental standards for packaging materials (e.g., ISPM 15 for wooden crates). Be aware of regulations governing the disposal of industrial machines at end-of-life, especially in regions with strict WEEE (Waste Electrical and Electronic Equipment) directives. Offer take-back programs or recycling guidance where required.

Risk Management and Insurance

Insure shipments against loss, damage, or delay. Choose all-risk cargo insurance that covers transit across all modes. Conduct a risk assessment for high-value shipments, including piracy-prone regions or areas with unstable infrastructure. Retain insurance documentation for claims processing.

Final Compliance Checklist

Before shipping, verify:

– Correct HS code and tariff classification

– All required certifications and labels are present

– Documentation is complete and consistent

– Packaging meets international standards

– Incoterms and responsibilities are clearly defined

– Import permits/licenses are secured (if needed)

Consult local regulatory authorities or a customs broker to ensure full compliance with evolving trade laws.

Conclusion: Sourcing a Knitting Machine for Socks

In conclusion, sourcing the right knitting machine for sock production requires a careful evaluation of several key factors, including production volume, desired sock quality, automation level, technical support, and overall cost-effectiveness. Whether opting for circular sock knitting machines like single-cylinder or double-cylinder models, it is essential to align machine specifications with the intended yarn types, stitch patterns, and target market requirements.

Sourcing from reputable manufacturers—domestic or international—should be done with due diligence, considering after-sales service, spare parts availability, and training support. While advanced, computerized machines offer higher efficiency and design flexibility, they come with higher initial investment, making them more suitable for medium to large-scale operations. On the other hand, semi-automatic machines may be more appropriate for small businesses or startups seeking to minimize upfront costs.

Ultimately, the decision should balance initial investment with long-term productivity, quality output, and scalability. A well-chosen knitting machine not only enhances production efficiency but also ensures consistent product quality, helping to build a competitive presence in the dynamic hosiery market. Proper research, supplier vetting, and a clear understanding of business needs will lead to a successful and sustainable investment in sock knitting machinery.