The global grinding equipment market, a critical enabler of precision manufacturing in specialized trades like custom knife making, is experiencing steady expansion driven by rising demand for high-tolerance metalworking solutions. According to Grand View Research, the global industrial grinding machines market was valued at USD 7.8 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2030. This growth is fueled by advancements in abrasive technologies, increased adoption in small-batch and artisanal manufacturing, and the rising popularity of custom cutlery. As knife makers increasingly prioritize consistency, edge retention, and material efficiency, the role of high-performance grinders has become indispensable. This list highlights the top 10 knife making grinder manufacturers that combine innovation, durability, and precision—backed by market trends and user-reported performance—to meet the exacting standards of modern blade craftsmen.

Top 10 Knife Making Grinder Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Beaumont Metal Works

Domain Est. 2001

Website: beaumontmetalworks.com

Key Highlights: Beaumont Metal Works is the leading manufacturer of industrial belt grinders and machinery. We have produced the KMG belt grinder for over 20 years using ……

#2 Tru Grit, Inc.

Domain Est. 1998 | Founded: 1978

Website: trugrit.com

Key Highlights: Tru-Grit has been family owned and operated since 1978. We offer the best quality abrasives and knifemaking supplies in the industry….

#3 Reeder Products, Inc.

Domain Est. 2015

Website: reederproducts.com

Key Highlights: The Reeder Grinder 2×72 belt grinder is the perfect machine for your project. The applications are endless. With over 65 years of experience in machine design….

#4 HouseMade Industrial

Domain Est. 2019

Website: housemade.us

Key Highlights: Free deliveryFamily-run and USA-made, HouseMade offers DIY kits & plans to build workshop tools like belt grinders & forges, as well as kitchen tool kits….

#5 Knife Grinders

Domain Est. 1998

Website: knifemaking.com

Key Highlights: Shop grinders, sanders, buffers, and accessories to outfit your knife making shop. Top brands include Burr King, Baldor, Kalamazoo, and Bader….

#6 USA Knife Maker

Domain Est. 2007

Website: usaknifemaker.com

Key Highlights: We carry everything for building your own grinder, we also carry complete grinders, supplies and more. Shop Grinders & Sanders · Folding Knife Parts. All the ……

#7 amktactical.com, 2×72 belt grinder, disc grinder, knifegrinder

Domain Est. 2013

Website: amktactical.com

Key Highlights: Our mission is supply you with items that are unique and innovative gun, archery, and knife making products. Every product is made in the USA….

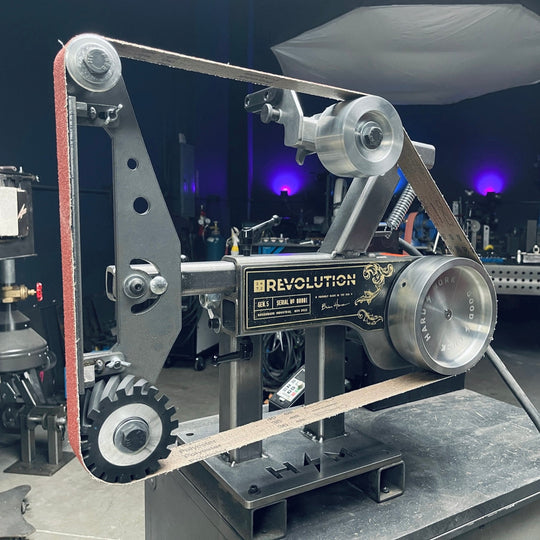

#8 Black Fox Knife Works engineering the ideal 2×72 inch belt grinders

Domain Est. 2017

Website: blackfoxknifeworks.com

Key Highlights: Explore Black Fox Grinders — premium 2×72 belt grinders and surface grinding kits built for knife makers, metalworkers, and serious fabricators. Precision….

#9 Origin Blade Maker

Domain Est. 2018

Website: originblademaker.com

Key Highlights: 4.3 12 · 30-day returnsMar 7, 2025 · Knife Making Belt Grinder Angle Grind Guide (Large) & Large Tool Rest · Featured, Measuring & Guiding, USPS-L. $182.95. portaband v.7.5 (saw…

#10 Hardcore Grinders & Products: Precision USA

Domain Est. 2024

Website: hardcoregrinderproducts.com

Key Highlights: Hardcore Products offers top-quality, USA-made grinders engineered for precision and durability. With over 30 years of expertise, we provide tooling to ……

Expert Sourcing Insights for Knife Making Grinder

2026 Market Trends for Knife Making Grinders

Rising Demand in Artisanal and Custom Knife Production

The global resurgence in craftsmanship and handmade goods is significantly influencing the knife-making industry. By 2026, demand for high-quality knife making grinders is expected to grow, driven by a surge in artisanal blacksmiths, custom knife makers, and at-home hobbyists. Platforms like YouTube, Instagram, and Etsy have empowered skilled individuals to build businesses around hand-forged blades, increasing the need for reliable, precision grinding equipment. As consumers value unique, durable, and personalized cutlery, small-scale producers will continue investing in advanced grinders to improve efficiency and blade quality.

Technological Advancements in Grinder Design

By 2026, knife making grinders are anticipated to incorporate smart technologies and enhanced ergonomic features. Expect to see increased integration of variable speed controls, digital readouts, and motor efficiency improvements. CNC-assisted grinding systems may become more accessible to mid-tier workshops, enabling consistent bevels and edge geometries. Additionally, manufacturers are likely to focus on dust extraction innovations and noise reduction to improve workshop safety and user experience—key selling points for both professional and amateur knife makers.

Expansion of the DIY and Home Workshop Sector

The do-it-yourself (DIY) trend continues to expand, with more individuals exploring metalworking as a hobby. This shift is fueling demand for compact, affordable, and user-friendly knife making grinders tailored to home use. In 2026, entry-level and mid-range grinders with modular setups—such as bench grinders with specialized jigs and tool rests—are expected to dominate sales. Online communities and instructional content will further lower the barrier to entry, encouraging broader adoption of grinding equipment in personal workshops.

Sustainability and Material Efficiency Focus

Sustainability concerns are influencing equipment design and usage patterns. Knife makers are increasingly prioritizing material conservation and energy efficiency. By 2026, grinder manufacturers may emphasize eco-friendly motors, longer-lasting abrasive belts, and systems that minimize metal waste during grinding. Water-cooled grinding options could gain traction as a way to reduce heat-related warping and extend tool life, aligning with both performance and environmental goals.

Regional Market Growth and Supply Chain Shifts

Asia-Pacific and North America are expected to lead in market growth for knife making grinders by 2026. Japan, the U.S., and Germany remain hubs for high-end blade craftsmanship, while emerging markets in Southeast Asia and Eastern Europe show rising interest in metalworking hobbies. Supply chains are adapting to localized production, reducing lead times and import dependencies. This regional diversification supports faster innovation cycles and customized product offerings.

E-Commerce and Direct-to-Consumer Sales Surge

Online retail platforms will play a crucial role in the distribution of knife making grinders. By 2026, direct-to-consumer (DTC) models and specialized e-commerce sites catering to knife makers are expected to outpace traditional retail channels. Enhanced product videos, customer reviews, and bundled accessory kits (e.g., belts, jigs, safety gear) will improve online purchasing confidence and drive conversion rates.

Conclusion

The 2026 market for knife making grinders reflects a convergence of craftsmanship revival, technological innovation, and digital accessibility. As both professionals and hobbyists demand precision, safety, and sustainability, manufacturers will respond with smarter, more adaptable grinding solutions. The knife making grinder market is poised for steady growth, underpinned by a passionate global community and evolving production needs.

Common Pitfalls When Sourcing a Knife Making Grinder (Quality and Intellectual Property)

Sourcing a knife making grinder—especially from overseas or lesser-known suppliers—can present significant challenges related to both product quality and intellectual property (IP) risks. Being aware of these pitfalls is crucial for protecting your investment, ensuring consistent production, and safeguarding your brand.

Poor Build Quality and Inadequate Materials

Many low-cost grinders, particularly those from unverified manufacturers, use substandard components such as inferior bearings, thin steel housings, or low-grade motors. These issues can lead to premature wear, inconsistent grinding results, vibration, and frequent breakdowns, ultimately increasing downtime and maintenance costs.

Misleading or Inaccurate Specifications

Some suppliers exaggerate key performance metrics like motor power (RPM, torque), belt speed, or dust extraction efficiency. Units may be listed with inflated horsepower ratings or incompatible power requirements (e.g., 220V vs. 110V), leading to integration issues and underperformance in your workshop.

Lack of Precision and Consistency

High-quality knife grinding requires precision tooling and consistent contact wheels, platen alignment, and tension systems. Budget grinders often lack the fine adjustability and rigidity needed for repeatable, professional results, resulting in inconsistent bevels and edge geometry that compromise blade performance.

Inadequate After-Sales Support and Spare Parts Availability

Many overseas or generic brands offer little to no technical support, warranty service, or access to replacement parts. If a critical component fails, sourcing replacements can take weeks or months, halting production and impacting business operations.

Risk of Copying or Counterfeit Designs (IP Infringement)

A significant intellectual property concern is sourcing grinders that replicate patented or trademarked designs from reputable brands (e.g., Wolverine, KMG, Tormek). Purchasing or using such equipment may inadvertently involve you in IP violations, exposing your business to legal risk, especially if you market your workshop as using “professional-grade” or branded-equivalent tools.

Use of Unlicensed Branding or Trademarked Names

Some suppliers falsely label their grinders with names, logos, or model numbers that closely resemble well-known brands to imply endorsement or equivalence. This not only misleads buyers but also raises legal red flags if your business is associated with counterfeit or cloned equipment.

No IP Protection in Supplier Agreements

When working with OEMs or custom manufacturers, failure to secure proper IP agreements (e.g., ownership of custom designs, non-disclosure, non-compete clauses) can result in your unique grinder modifications or designs being replicated and sold to competitors.

Solution: Due Diligence and Verified Sourcing

To avoid these pitfalls, conduct thorough research, request product certifications, inspect units in person if possible, and prioritize suppliers with transparent documentation, verifiable track records, and clear IP policies. Consider partnering with reputable domestic distributors or manufacturers who respect quality standards and intellectual property rights.

Logistics & Compliance Guide for Knife Making Grinders

Overview and Purpose

This guide outlines essential logistics and compliance considerations for knife making grinders—individuals or businesses engaged in grinding and shaping knife blades as part of the custom or commercial knife-making process. Whether operating independently or as part of a larger manufacturing chain, understanding legal requirements, shipping protocols, and safety standards is crucial for smooth operations and regulatory compliance.

Legal Classification of Knives and Grind Products

The legal status of knives and knife components varies significantly by jurisdiction. Grinders must be aware that the finished or semi-finished blades they produce may be classified as controlled items depending on local, state, or national laws. Key considerations include:

- Blade Type and Design: Certain grinds (e.g., switchblade-style, ballistic, or gravity knife profiles) may trigger legal restrictions.

- Intended Use: While most custom blades are for utility, hunting, or collection, grinders should avoid producing blades clearly intended for prohibited uses.

- Jurisdictional Variations: Laws differ widely—what is legal in one state or country may be restricted elsewhere. Research destination regulations before shipping.

Safety and Workplace Compliance

Grinders must adhere to occupational health and safety standards to protect themselves and employees:

- OSHA Compliance (U.S.): Follow guidelines for machine guarding, ventilation, hearing protection, and eye safety when operating grinding equipment.

- Dust and Fume Control: Metal grinding generates fine particulates and fumes; use local exhaust ventilation (LEV) systems and respirators where needed.

- Fire Safety: Grinding can create sparks; keep flammable materials away and maintain fire extinguishers rated for metal fires (Class D).

- Personal Protective Equipment (PPE): Mandate use of safety glasses, face shields, hearing protection, gloves, and flame-resistant clothing.

Shipping and Logistics of Knife Components

Transporting knife blades—even unfinished or pre-handle blanks—requires adherence to carrier policies and regulations:

- Domestic Shipping (USA):

- USPS: Prohibits mailing sharp objects unless properly packaged and declared. Blanks or tangs may be allowed if securely wrapped and not easily accessible.

- UPS and FedEx: Permit shipment of blades if adequately packaged and labeled. Check specific service restrictions (e.g., no knife shipments to certain states like New Jersey without compliance).

-

Packaging: Use rigid, non-metallic packaging with padding. Clearly mark contents as “Blade Components” or “Metal Parts” without emphasizing weapon-like features.

-

International Shipping:

- Highly restricted. Many countries prohibit import of knife components entirely.

- Always check destination country customs regulations.

- Avoid shipping to regions with strict knife laws (e.g., UK, Australia, Canada) without verifying legality and required documentation.

- Use commercial invoices clearly stating the item is a “knife blank” or “tool component” for crafting, not a finished weapon.

Export Controls and ITAR Considerations

While most knife grinders are not subject to export controls, certain high-performance or tactical blades may fall under regulation:

- EAR (Export Administration Regulations): Most civilian knife components are EAR99 (low concern), but verify if your product includes advanced materials (e.g., certain alloys or coatings) that could be controlled.

- ITAR (International Traffic in Arms Regulations): Only applies if blades are specifically designed for military/law enforcement use and listed on the USML. Most custom knife grinders are not ITAR-controlled, but caution is advised.

Recordkeeping and Traceability

Maintain detailed records to demonstrate compliance and support business operations:

- Customer Documentation: Keep records of buyer information, especially when shipping to regulated areas. This supports due diligence if questioned.

- Work Logs: Track blade types, materials, and grinding specifications for quality control and liability protection.

- Compliance Certifications: Retain safety training records, equipment maintenance logs, and ventilation system inspections.

Environmental Regulations

Grinding operations may generate hazardous waste:

- Metal Dust and Sludge: Depending on the alloy, grinding waste may be classified as hazardous. Check local EPA or environmental agency rules.

- Coolants and Lubricants: Used grinding fluids may require proper disposal as hazardous waste. Use recycling systems where possible.

- Spill Prevention: Store oils and coolants in secondary containment to prevent environmental contamination.

Intellectual Property and Design Rights

When grinding to custom or proprietary designs:

- Respect Copyrights and Trademarks: Do not reproduce patented grinds or branded knife profiles without permission.

- Client Agreements: Use contracts to clarify ownership of designs, especially when working with custom knife makers or designers.

Conclusion

Operating a knife making grinding service involves navigating complex logistics and compliance landscapes. By staying informed about legal restrictions, safety standards, shipping rules, and environmental obligations, grinders can protect their business, ensure customer satisfaction, and contribute responsibly to the knife-making community. Always consult legal counsel or regulatory experts when uncertain about specific requirements.

Conclusion: Sourcing a Knife-Making Grinder

Sourcing a high-quality grinder for knife making is a critical step in establishing an efficient, precise, and professional bladesmithing operation. Whether for hobbyist use or commercial production, selecting the right grinder involves evaluating several key factors—such as motor power, wheel size, variable speed control, build quality, dust extraction, and cooling systems. While budget is an important consideration, investing in a durable and well-designed grinder can significantly improve consistency, safety, and efficiency in tasks like beveling, shaping, and finishing blades.

After assessing various options—ranging from bench grinders to custom-built knife-making setups like the Wolverine system or dedicated knife jigs—it becomes clear that purpose-built knife grinders or well-modified industrial models offer the best value in the long term. Brands like Kalamazoo, Tormek, Baldor, and DIY configurations with variable-speed motors provide reliable performance tailored to the precision demands of knifemaking.

Ultimately, the ideal grinder should align with the maker’s skill level, production needs, and workflow preferences. Proper sourcing ensures not only superior control and repeatability but also enhances the overall quality and craftsmanship of each knife produced. By carefully evaluating available options and prioritizing functionality and longevity, knife makers can make an informed investment that supports their artistry for years to come.