The global kitting services market is experiencing robust growth, driven by rising demand for customized packaging, increased efficiency in supply chain operations, and expanding applications across industries such as healthcare, electronics, and e-commerce. According to Grand View Research, the global kitting services market size was valued at USD 4.3 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 7.2% from 2023 to 2030. This surge is fueled by the growing need for lean manufacturing processes and just-in-time inventory systems, which rely heavily on precise component assembly and timely delivery. Additionally, Mordor Intelligence forecasts similar momentum, citing automation advancements and increasing outsourcing of logistics and assembly tasks to specialized providers as key market drivers. As companies seek to streamline operations and reduce fulfillment times, the role of professional kitting manufacturers has become increasingly critical. In this evolving landscape, identifying top-tier kitting companies with proven capabilities in scalability, quality control, and industry-specific expertise is essential for businesses aiming to maintain a competitive edge.

Top 10 Kitting Companies Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Kitting Solutions

Domain Est. 1997 | Founded: 1977

Website: specialtybolt.com

Key Highlights: Specialty Bolt & Screw is your reliable partner for fasteners, custom hardware, and inventory solutions. Proudly supporting manufacturers worldwide since 1977….

#2 Custom Kitting Services for Packaging Efficiency

Domain Est. 1998

Website: millwoodinc.com

Key Highlights: Millwood, Inc. delivers high-quality kitting services that help businesses reduce costs, shorten lead times and improve inventory management….

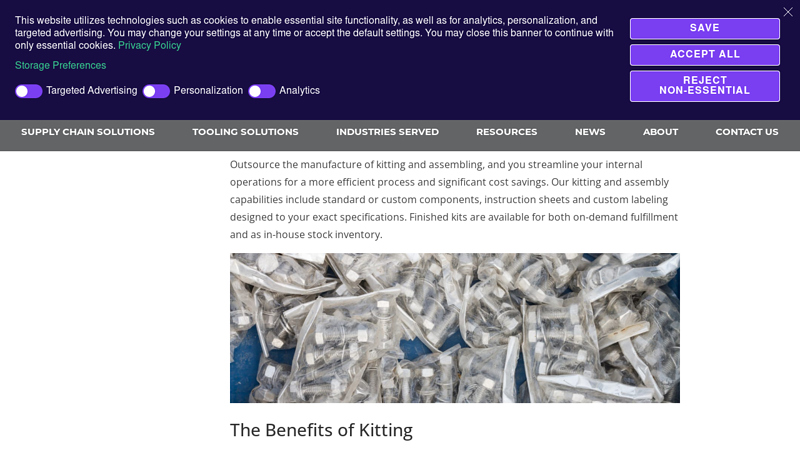

#3 Kitting & Assembly Services

Domain Est. 1996

Website: afcind.com

Key Highlights: Our kitting and assembly capabilities include standard or custom components, instruction sheets and custom labeling designed to your exact specifications….

#4 Kitting Services

Domain Est. 1996

Website: kpak.com

Key Highlights: We offer tailored kitting services to meet the unique needs of your business, whether it’s for retail, e-commerce, promotional materials, or other purposes….

#5 Kitting & Assembly Services

Domain Est. 1997

Website: geodis.com

Key Highlights: Get expert kitting and assembly services from GEODIS, a trusted third-party logistics provider. We produce over 50 million kits a year across the automotive ……

#6 Custom Kitting

Domain Est. 1997

Website: halo.com

Key Highlights: We take the stress out of swag by walking you through every step of the kitting process. From product selection and package design to logistics and delivery….

#7 Kitting

Domain Est. 1998

Website: joncoind.com

Key Highlights: Kitting is a process where warehouse workers take multiple components with different stock keeping units (SKUs) and package them as a single SKU….

#8 Kitting

Domain Est. 2000

Website: incora.com

Key Highlights: Our Kitting Services answer that need and are suitable for a wide range of manufacturing, assembly, aftermarket, and MRO requirements….

#9 Kitting / Fulfillment Services

Domain Est. 2000

Website: bakerindustries.org

Key Highlights: We build both promotional and product kits to meet every requirement. Services include box building, counting, collating, inserting, organizing, placing, ……

#10 Kitting Services

Domain Est. 1997

Website: newstreaming.com

Key Highlights: Outsourcing kitting and packaging services to a 3PL empowers you to focus on your core competencies while increasing customer satisfaction….

Expert Sourcing Insights for Kitting Companies

2026 Market Trends for Kitting Companies

As we approach 2026, kitting companies are poised for significant transformation driven by technological innovation, evolving customer expectations, and supply chain dynamics. Kitting— the process of assembling individual components into a single packaged unit for simplified logistics, retail, or manufacturing use—continues to expand beyond traditional sectors into e-commerce, healthcare, technology, and customized consumer goods. This analysis explores the key market trends shaping the kitting industry in 2026.

Rising Demand in E-Commerce and Direct-to-Consumer Models

The exponential growth of e-commerce remains a primary driver for kitting services. In 2026, retailers and brands are increasingly leveraging kitting to enhance unboxing experiences, bundle complementary products, and reduce shipping costs. Direct-to-consumer (DTC) brands are investing in customized kits—such as beauty sample sets, subscription boxes, or seasonal gift bundles—requiring agile and scalable kitting operations. Third-party logistics (3PL) providers with integrated kitting capabilities are seeing higher demand as businesses outsource to meet seasonal spikes and reduce overhead.

Automation and Smart Warehousing

Advancements in automation, robotics, and warehouse management systems (WMS) are revolutionizing kitting efficiency. By 2026, leading kitting companies are deploying AI-powered picking systems, collaborative robots (cobots), and vision-guided automation to minimize errors and speed up assembly. Real-time tracking and IoT-enabled inventory systems support just-in-time kitting, reducing overstock and waste. The integration of digital twins and predictive analytics allows kitting centers to simulate workflows and optimize labor usage, enhancing scalability and responsiveness.

Sustainability and Eco-Conscious Packaging

Environmental regulations and consumer demand for sustainability are reshaping kitting practices. In 2026, kitting companies are prioritizing recyclable, biodegradable, or reusable packaging materials. Minimalist packaging designs and right-sized kits are reducing material usage and shipping volume, contributing to lower carbon footprints. Brands are also requesting “eco-kits” that emphasize sustainability in both content and packaging, pushing kitting providers to partner with green-certified suppliers and obtain sustainability certifications.

Growth in Healthcare and Medical Kitting

The healthcare sector is a rapidly expanding market for specialized kitting services. In 2026, medical device manufacturers, hospitals, and home healthcare providers rely on sterile and non-sterile kitting for surgical trays, diagnostic kits, and telehealth care packages. Regulatory compliance (e.g., FDA, ISO standards) is critical, and kitting companies with cleanroom facilities and traceability systems are gaining competitive advantage. Personalized patient care kits—pre-packed with medications, devices, and instructions—are rising due to trends in remote care and chronic disease management.

Customization and Mass Personalization

Consumers and B2B clients alike are demanding greater customization. In 2026, kitting companies are adopting modular assembly processes and digital order management platforms to support mass personalization. AI-driven recommendation engines allow dynamic bundling based on customer behavior, enabling real-time kit configuration. Industries such as electronics, automotive, and education are using kitting to deliver tailored product bundles, training kits, or repair packages, increasing customer satisfaction and reducing return rates.

Supply Chain Resilience and Nearshoring

Global supply chain disruptions have prompted a shift toward regionalized and nearshored kitting operations. In 2026, many companies are relocating kitting centers closer to end markets to improve delivery speed and reduce dependency on long-haul logistics. This trend supports faster fulfillment, especially for time-sensitive kits in retail and healthcare. Kitting providers with multi-regional footprints and flexible labor models are better positioned to support clients navigating geopolitical and logistical uncertainties.

Data Integration and End-to-End Visibility

Kitting companies are becoming key data hubs in the supply chain. By 2026, integrated platforms that connect kitting operations with ERP, CRM, and e-commerce systems are standard. Real-time data on kit status, inventory levels, and fulfillment metrics enables proactive decision-making. Blockchain technology is being piloted for high-value or regulated kits to ensure authenticity, track provenance, and enhance transparency across stakeholders.

Conclusion

The kitting industry in 2026 is defined by agility, intelligence, and sustainability. Companies that invest in automation, embrace customization, and align with environmental and regulatory trends will lead the market. As supply chains grow more complex and customer expectations evolve, kitting is no longer a back-end function but a strategic value driver—enhancing efficiency, brand experience, and operational resilience across industries.

Common Pitfalls When Sourcing Kitting Companies (Quality, IP)

Sourcing a reliable kitting company is critical for maintaining product integrity, operational efficiency, and protecting your brand. However, businesses often encounter significant challenges, especially concerning quality control and intellectual property (IP) protection. Being aware of these common pitfalls can help mitigate risks and ensure a successful partnership.

Quality Inconsistencies and Lack of Oversight

One of the most frequent issues when outsourcing kitting is inconsistent product quality. Some kitting providers may use substandard materials, skip quality checks, or fail to follow assembly specifications precisely. Without clear quality benchmarks, regular audits, or defined acceptance criteria in the contract, companies risk receiving kits that damage their reputation or cause downstream issues in manufacturing or distribution.

Inadequate Process Documentation and Traceability

Many kitting companies lack standardized operating procedures or traceability systems. This makes it difficult to identify the root cause of defects, track components used, or verify compliance with industry standards. Without proper documentation, resolving quality disputes becomes challenging and time-consuming.

Intellectual Property Exposure

Outsourcing kitting often requires sharing sensitive product designs, component lists, or proprietary assembly methods. A major pitfall arises when companies fail to establish strong IP protections through contracts. Without a comprehensive Non-Disclosure Agreement (NDA) and clear IP ownership clauses, there’s a risk of design theft, reverse engineering, or unauthorized use of proprietary information by the kitting provider or its subcontractors.

Insufficient Vetting of Subcontractors

Some kitting companies outsource portions of the work to third-party facilities without the client’s knowledge. These subcontractors may not adhere to the same quality or security standards, increasing both quality risks and IP vulnerability. Lack of transparency in the supply chain can leave businesses exposed.

Poor Communication and Responsiveness

Delayed responses, lack of proactive updates, or unclear reporting can hinder issue resolution and project management. When quality problems arise or design changes are needed, inefficient communication can lead to costly delays and misunderstandings.

Absence of Scalability and Flexibility

Choosing a kitting partner that cannot scale with your business or adapt to changing requirements can result in bottlenecks. Companies may face difficulties during peak demand or when introducing new product variants, especially if the provider lacks the infrastructure or agility to respond quickly.

To avoid these pitfalls, thoroughly vet potential kitting companies, conduct on-site audits, demand transparency in processes and subcontracting, and ensure strong contractual protections for both quality standards and intellectual property.

Logistics & Compliance Guide for Kitting Companies

Understanding Kitting Operations

Kitting involves assembling individual products into a single package or bundle for sale or distribution. This process enhances customer experience, streamlines inventory management, and can increase perceived product value. For kitting companies, efficient logistics and strict compliance are essential to ensure accuracy, timeliness, and legal adherence.

Supply Chain and Inventory Management

Effective supply chain management is foundational for successful kitting operations. Companies must maintain accurate inventory levels of all component parts and finished kits. Implementing an integrated inventory management system helps track stock in real time, prevent stockouts, and reduce overstocking. Consider vendor-managed inventory (VMI) agreements with suppliers to ensure timely replenishment and minimize lead times.

Warehouse Layout and Workflow Optimization

Design your warehouse to support efficient kitting workflows. Organize storage areas based on kit component frequency and compatibility. Use designated kitting stations equipped with packaging materials, barcode scanners, and work instructions. Optimize picking routes to minimize travel time and reduce errors. Incorporate quality checkpoints at various stages of the kitting process.

Packaging and Labeling Standards

All kitted products must be securely packaged to prevent damage during transit. Use appropriate materials such as bubble wrap, dividers, or custom inserts. Labels must clearly display the kit name, SKU, barcode, contents, and any required warnings or certifications. Ensure compliance with carrier-specific packaging requirements to avoid shipping delays or penalties.

Regulatory Compliance

Kitting companies must adhere to various regulatory standards depending on the product type and destination market. This includes:

– Consumer Product Safety Commission (CPSC) regulations for children’s products

– FDA guidelines for kits containing food, cosmetics, or medical items

– FCC rules for electronics included in kits

– REACH and RoHS directives for products shipped to the European Union

Ensure all components and final kits meet relevant safety, labeling, and chemical restrictions.

Import/Export Compliance

For international kitting operations, comply with customs regulations in both origin and destination countries. Accurately classify kits using Harmonized System (HS) codes. Maintain detailed records of component sourcing and final assembly locations to support country-of-origin declarations. Utilize Automated Export System (AES) filings when required and ensure proper documentation, including commercial invoices and packing lists.

Product Liability and Insurance

Kitting companies assume responsibility for the safety and integrity of assembled products. Obtain comprehensive product liability insurance to protect against claims related to defective kits. Conduct regular quality audits and maintain traceability records—knowing which batch of components went into each kit can be critical during recalls.

Data Security and Customer Privacy

If handling customer-specific kitting (e.g., subscription boxes), safeguard personal data in compliance with regulations like GDPR or CCPA. Use secure systems for storing and transmitting customer information. Limit access to authorized personnel and implement data encryption protocols.

Sustainability and Environmental Compliance

Adopt eco-friendly practices in packaging and operations. Use recyclable or biodegradable materials where possible. Comply with local and international environmental regulations, such as waste disposal laws and extended producer responsibility (EPR) schemes. Clearly label recyclable components and provide disposal instructions when applicable.

Recordkeeping and Audit Preparedness

Maintain detailed records of all kitting activities, including inventory receipts, assembly logs, quality checks, shipping manifests, and compliance certifications. These records support internal audits and regulatory inspections. Regularly review and update standard operating procedures (SOPs) to reflect current best practices and legal requirements.

Partnering with Carriers and 3PLs

Collaborate with reliable logistics partners experienced in handling kitted goods. Clearly communicate kit dimensions, weights, and any special handling instructions. If using a third-party logistics provider (3PL), ensure they comply with your quality and compliance standards through service level agreements (SLAs) and regular performance reviews.

By following this guide, kitting companies can streamline operations, reduce risks, and ensure compliance across the entire supply chain—from component sourcing to final delivery.

In conclusion, sourcing kitting companies requires a strategic approach that balances cost-efficiency, quality, reliability, and scalability. By clearly defining your kitting needs—such as product type, volume, customization level, and delivery timelines—you can identify potential partners that align with your operational goals. Thorough evaluation of suppliers based on experience, capabilities, quality control processes, technology integration, and customer service is essential to ensure seamless fulfillment and customer satisfaction.

Additionally, conducting site visits, requesting samples, and starting with pilot projects can help verify the competence and reliability of a kitting partner before committing to long-term collaboration. Leveraging both domestic and international suppliers, where appropriate, allows for flexibility and risk mitigation in the supply chain.

Ultimately, a well-chosen kitting partner not only streamlines packaging and assembly operations but also enhances order accuracy, reduces labor costs, and improves turnaround times—contributing significantly to overall supply chain efficiency and customer experience. Continuous communication, performance monitoring, and relationship management are key to maintaining a successful, long-term partnership in your kitting operations.