The global kiting industry, long associated with recreation and cultural traditions, has seen a resurgence driven by innovations in materials science and rising demand for high-performance, durable kites. According to a report by Mordor Intelligence, the global kite market is projected to grow at a CAGR of 5.2% from 2023 to 2028, fueled by increasing participation in outdoor sports, advancements in aerial technology, and expanding applications in education and renewable energy (e.g., kite power systems). A key enabler of this growth is the evolution of kite-making materials—ultra-lightweight yet robust fabrics, precision-engineered frames, and weather-resistant coatings—that enhance flight stability, longevity, and design versatility. As demand rises, manufacturers specializing in advanced textiles like ripstop nylon, carbon fiber spars, and laminated films are playing a pivotal role in shaping the next generation of kites. This list highlights the top 10 manufacturers leading the charge in supplying high-performance materials essential to modern kite construction, selected based on innovation, material quality, industry reputation, and market reach.

Top 10 Kite Making Materials Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

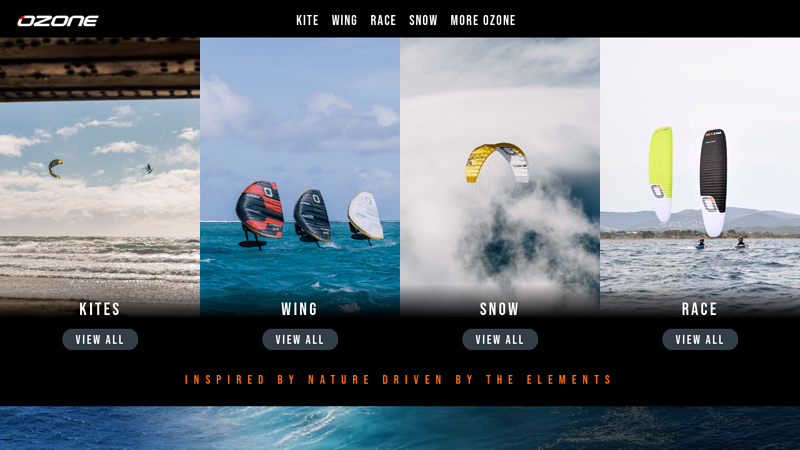

#1 Ozone Kites

Domain Est. 2000

Website: ozonekites.com

Key Highlights: Ozone is one of the world’s leading manufacturers of Kites and Paragliders, created around a dedicated team of passionate riders and pilots that share the ……

#2 Into The Wind : Known and Flown for over 30 years

Domain Est. 1996 | Founded: 1981

Website: intothewind.com

Key Highlights: Complete online kite store makes it easy to shop from hundreds of kites. Or request our free 48 page print catalog, the #1 kite catalog since 1981….

#3 Cool Materials

Domain Est. 1996

Website: prismkites.com

Key Highlights: DIY Materials … CAD modeling and 3-D printing let us refine shapes and test materials so your kite not only flies great, but goes together with ease….

#4 Kites In The Sky

Domain Est. 2004

Website: kitekits.com

Key Highlights: Kite Kits for Children & Adults. Kite Kits for all skill levels & event sizes. Ready To Fly Kite Kits. Do It Yourself Kite Kits. Kite making kits are fun!…

#5 All Products

Domain Est. 2006

#6 Kite Culture

Domain Est. 2011

Website: kiteculture.sg

Key Highlights: Browse our various models of DIY kites. Design and colour them with markers or simply just fly them. Highly recommended for schools and community events….

#7 Fly Market Kitemaking Supply

Domain Est. 2014

Website: flymarketkites.com

Key Highlights: Fly Market helps you fly. From kite parts to fabric, LARP weapons, drones, R/C boats and planes, or even theatrical sets, we’ve got just the thing you need….

#8 Kite Building Materials

Domain Est. 2016

Website: goodkites.com

Key Highlights: Email or call (210) 570-5766 for wholesale orders, and local pickup. Products. Kite Kits · Nylon Kites · Building Materials · Accessories · Books · All….

#9 Your kite for every style

Domain Est. 2018

Website: duotonesports.com

Key Highlights: Every DUOTONE Kite is built from premium materials with a focus on durability, safety, and performance. As a global leader in kitesurfing innovation, DUOTONE ……

#10 kite making workshop kits for teachers and children

Website: lekite.com.au

Key Highlights: Our make-you-own kite kits provide teachers with all of the materials and supporting resources they need to enable very successful class workshops….

Expert Sourcing Insights for Kite Making Materials

2026 Market Trends for Kite Making Materials

The kite making materials market is poised for significant evolution by 2026, driven by technological advancements, shifting consumer preferences, and growing environmental awareness. Key trends shaping the industry include:

Rising Demand for Sustainable and Eco-Friendly Materials

Consumers and manufacturers alike are increasingly prioritizing sustainability. By 2026, biodegradable films such as PLA (polylactic acid) and recycled polyester (rPET) are expected to gain substantial market share. Natural fiber reinforcements like bamboo and organic cotton string will see increased use, particularly in premium and educational kite kits. Regulatory pressures and corporate ESG (Environmental, Social, and Governance) goals will accelerate this shift, pushing suppliers to innovate with compostable coatings and recyclable packaging.

Advancements in High-Performance Synthetic Materials

Despite the green shift, technical innovation in synthetic materials continues. Lightweight, high-tensile strength films such as ultra-thin ripstop nylon and advanced Mylar variants will dominate performance kiting segments, including sport, traction, and aerial photography kites. Nanocoated fabrics offering enhanced UV resistance, water repellency, and tear strength will become more accessible, improving kite durability without adding weight. These materials are critical for professional and enthusiast markets demanding reliability and longevity.

Growth in Customization and DIY Kite Kits

The maker movement and educational STEM initiatives are fueling demand for customizable kite materials. By 2026, suppliers will offer modular material packs with pre-cut films, color-fast dyes, and easy-assembly frames tailored for schools, hobbyists, and craft fairs. Online platforms enabling personalized design uploads and on-demand cutting services will expand, allowing consumers to create unique kites using durable, print-ready substrates.

Expansion of Smart Kite Technologies

Integration of lightweight electronics into kites—such as LED lighting, GPS trackers, and small cameras—will drive demand for conductive threads, flexible solar films, and EMI-shielding materials. These “smart kites” will appeal to tech-savvy users and commercial applications like aerial monitoring, requiring materials that balance conductivity with aerodynamic efficiency and low weight.

Regional Market Diversification

Asia-Pacific, particularly China and India, will remain dominant in manufacturing and consumption due to cultural traditions and growing middle-class leisure spending. However, North America and Europe will see growth in niche segments like eco-kites and high-end recreational products. Emerging markets in Latin America and Southeast Asia will present new opportunities for affordable, durable kite kits made from weather-resistant materials.

Supply Chain Resilience and Local Sourcing

Post-pandemic supply chain disruptions have prompted a shift toward regional sourcing and inventory diversification. By 2026, more kite material suppliers will establish local partnerships to reduce lead times and transportation emissions, supporting just-in-time production for seasonal demand spikes, especially during festivals and holidays.

In summary, the 2026 kite making materials market will be defined by a dual focus on sustainability and performance, with innovation catering to both eco-conscious consumers and tech-driven enthusiasts. Manufacturers who adapt to these trends will capture growing market segments in education, recreation, and commercial applications.

Common Pitfalls Sourcing Kite Making Materials (Quality, IP)

Sourcing materials for kite making—whether for hobbyists, artisans, or commercial producers—can involve several hidden challenges, particularly concerning material quality and intellectual property (IP) considerations. Avoiding these pitfalls ensures both performance and legal compliance.

Poor Material Quality and Inconsistency

One of the most frequent issues is receiving substandard or inconsistent materials, especially when sourcing from unfamiliar suppliers or low-cost manufacturers. Lightweight ripstop nylon, polyester films (like Mylar), carbon fiber spars, or dacron sailcloth may vary significantly in weight, tensile strength, or UV resistance. Inconsistent material properties can lead to poor flight performance, premature tearing, or structural failure. Always request samples, verify specifications (e.g., denier count, coating type), and prioritize suppliers with proven track records in technical fabrics or aerospace-grade components.

Misrepresentation of Material Specifications

Suppliers may exaggerate or mislabel material characteristics—such as wind resistance, waterproofing, or durability—leading to kites that underperform in real-world conditions. For example, a fabric advertised as “UV-resistant” might degrade quickly under prolonged sunlight if the claim is unsubstantiated. Conduct independent testing or rely on third-party certifications to validate material claims before bulk ordering.

Intellectual Property Infringement Risks

Using designs, patterns, or branded materials without proper authorization can lead to IP violations. This includes printing copyrighted artwork, using patented kite frame designs, or replicating signature patterns from well-known kite makers. Even sourcing materials with embedded logos or proprietary weaves (e.g., branded sailcloth with a distinctive pattern) can pose legal risks if used commercially. Always confirm licensing rights and avoid replicating protected designs.

Unlicensed Use of Branded Components

Some high-performance materials (e.g., branded ripstop fabrics or carbon fiber rods) are trademarked or sold under specific usage agreements. Unauthorized commercial use or resale of products made with these components may breach the supplier’s terms. Check licensing terms and, when in doubt, opt for generic or openly licensed alternatives.

Supply Chain Transparency and Ethical Sourcing

Lack of visibility into the origin of materials can expose makers to ethical or reputational risks—such as using fabrics produced under poor labor conditions or non-sustainable practices. Increasingly, consumers value eco-friendly and ethically sourced components. Partnering with suppliers who provide traceability and sustainability documentation helps mitigate these concerns and supports responsible kite making.

By proactively addressing these quality and IP-related pitfalls, kite makers can ensure their creations are both high-performing and legally sound.

Logistics & Compliance Guide for Kite Making Materials

Overview

This guide outlines the essential logistics and compliance considerations when sourcing, shipping, storing, and using materials commonly used in kite making. Whether you’re a hobbyist, small business, or manufacturer, understanding these factors ensures smooth operations, legal adherence, and product safety.

Regulatory Classification & Import/Export Compliance

Kite making materials may fall under various international trade classifications depending on composition and origin. Key compliance points include:

- HS Codes (Harmonized System Codes): Identify appropriate codes for materials such as ripstop nylon (5407.71), carbon fiber rods (7015.90), wooden dowels (4407.29), or plastic films (3920.62). Accurate classification prevents customs delays and ensures correct duty rates.

- Import Restrictions: Some countries restrict or tax certain textiles, plastics, or composites. Verify local regulations with customs authorities before shipping.

- Export Controls: Materials with potential dual-use (e.g., high-tensile carbon fiber) may require export licenses under frameworks like the Wassenaar Arrangement.

- Documentation: Maintain commercial invoices, packing lists, and certificates of origin. For commercial shipments, include material safety data sheets (MSDS) where applicable.

Transportation & Handling

Proper handling ensures materials arrive in optimal condition:

- Perishable/Environmental Sensitivity: Avoid exposure to moisture, extreme temperatures, or UV light during transit. Store ripstop fabric and adhesives in sealed, climate-controlled conditions.

- Fragile Components: Carbon fiber spars, wooden dowels, and plastic frames should be packed with padding to prevent breakage. Use rigid outer packaging for long rods.

- Roll & Sheet Goods: Transport fabrics and plastic films on cores or in tubes to prevent creasing and warping.

Storage Requirements

- Textiles (Nylon, Polyester, Ripstop): Store in dry, cool environments away from direct sunlight to prevent degradation and mildew.

- Adhesives & Tapes: Keep in temperature-controlled areas (typically 15–25°C). Check shelf life and rotate stock using FIFO (First In, First Out).

- Carbon Fiber & Fiberglass Rods: Store horizontally to avoid bending or warping. Protect from impacts.

- Dyes & Paints: If using pigments or fabric dyes, store according to flammability and toxicity guidelines (e.g., in ventilated cabinets if volatile).

Safety & Environmental Compliance

- Chemical Handling: Follow SDS guidelines for adhesives, dyes, and solvents. Use personal protective equipment (PPE) such as gloves and masks when applicable.

- Waste Disposal: Dispose of fabric scraps, plastic trimmings, and chemical waste in accordance with local environmental regulations. Recycle where possible.

- Fire Safety: Keep flammable materials (e.g., aerosol adhesives) away from ignition sources. Ensure storage areas have appropriate fire suppression systems.

Labeling & Product Standards

- Material Labels: Clearly label all materials with content type, batch number, and date received for traceability.

- Consumer Safety (if selling kites): Comply with toy safety standards such as ASTM F963 (U.S.) or EN 71 (EU), particularly regarding small parts, string strength, and chemical content.

- String & Line Regulations: Some regions regulate kite line composition (e.g., banning metallic or abrasive lines) due to safety hazards. Ensure compliance with local aviation or public safety laws.

Best Practices Summary

- Verify material compliance with destination country regulations before shipping.

- Use durable, protective packaging tailored to material type.

- Maintain organized inventory with environmental monitoring.

- Train personnel in safe handling and emergency procedures.

- Keep records of suppliers, shipments, and compliance documentation.

Adhering to this guide supports efficient logistics and legal compliance, enabling safe and sustainable kite production across regions.

In conclusion, sourcing materials for kite making requires a thoughtful balance between durability, weight, cost, and availability. Lightweight yet strong fabrics such as ripstop nylon or polyester, along with flexible yet resilient frame materials like fiberglass or carbon fiber, are ideal for optimal flight performance. Natural materials such as bamboo can offer sustainability and traditional appeal, while modern synthetics provide consistency and weather resistance. Local craft stores, specialized kite shops, online retailers, and even upcycled household items can all serve as viable sources depending on the project’s scale and purpose. Ultimately, the choice of materials should align with the kite’s intended use—whether for recreation, education, or art—ensuring both functionality and enjoyment. Careful sourcing not only enhances the kite’s performance but also supports creativity, sustainability, and cost-effectiveness in the building process.