The global kitchen fixtures market has experienced steady expansion over the past decade, driven by rising residential and commercial construction, urbanization, and increased consumer focus on kitchen hygiene and plumbing efficiency. According to a report by Mordor Intelligence, the global plumbing fixtures market size was valued at USD 165.8 billion in 2022 and is projected to grow at a CAGR of 5.2% from 2023 to 2028. Within this sector, P traps—critical components in kitchen sink drainage systems—play a vital role in preventing sewer gases, minimizing clogs, and ensuring smooth wastewater flow. With growing emphasis on water efficiency and durable materials like PVC, stainless steel, and brass, demand for high-performance P traps has surged. As of 2023, North America and Europe account for over 45% of global P trap consumption, while Asia-Pacific is emerging as the fastest-growing region due to rapid urbanization and infrastructure development. This increasing demand has fostered a competitive landscape among manufacturers, leading to innovations in design, corrosion resistance, and ease of installation. Based on market presence, product quality, and technological advancements, we’ve identified the top 9 kitchen sink P trap manufacturers shaping the industry today.

Top 9 Kitchen Sink P Trap Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Symmons

Domain Est. 1996

Website: symmons.com

Key Highlights: Symmons is renowned for its wide range of durable, reliable commercial-grade plumbing products for Educational, Healthcare, Hospitality, Industrial, and ……

#2 Sioux Chief: Rough Plumbing Products

Domain Est. 1997

Website: siouxchief.com

Key Highlights: We are an American manufacturer. Sioux Chief believes in making our products right here in America. American manufacturing is important….

#3 Chicago Faucets

Domain Est. 1997

Website: chicagofaucets.com

Key Highlights: Chicago Faucets has been a trusted manufacturer of industry-leading fittings for over 120 years. We engineer the most durable faucets and fittings in the ……

#4 Decorative Lavatory Traps – P

Domain Est. 1998

Website: mountainplumbing.com

Key Highlights: Mountain Plumbing Products is a leading manufacturer of High-Performance Water Appliances “made better by design”. We offer same day shipping of our market- ……

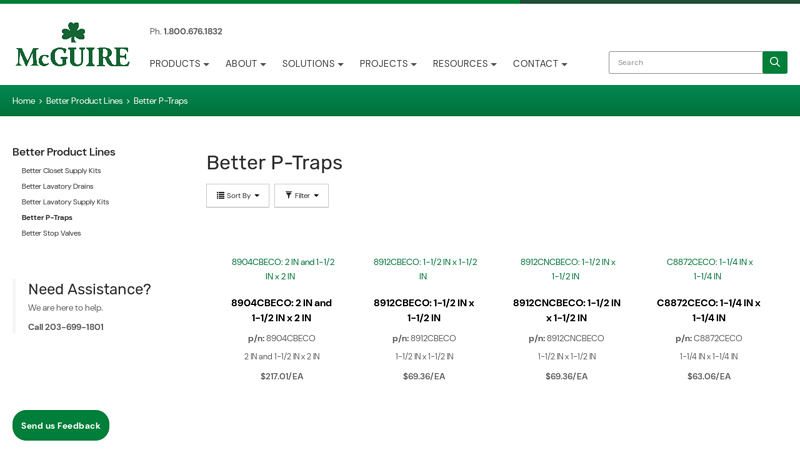

#5 Better P

Domain Est. 1999

Website: mcguiremfg.com

Key Highlights: McGuire Manufacturing Co., Inc. has been providing high quality, commercial plumbing for over 70 years….

#6 Sinks

Domain Est. 1996

Website: justmfg.com

Key Highlights: Stainless Steel 16-3/4″ x 15-1/2″ x 13″ Single Bowl Wall Hung Hand Wash Sink w/Faucet + Drain + P-trap · Download Spec Sheet….

#7 Oatey® 1

Domain Est. 1996

Website: oatey.com

Key Highlights: P-Trap allows for a faster and easier install with no nuts, washers, tools or glue needed. The simple push to install, press to release connections of 1-1/2 in….

#8 Sink P

Domain Est. 2010

Website: fergusonhome.com

Key Highlights: Free delivery over $49Shop Ferguson Home for sink p-traps, parts, and more! Can’t find what you’re looking for? Call or chat in to our online product experts ……

#9 Solid Brass Kitchen Sink P Trap

Domain Est. 2011

Website: maidstonesupply.com

Key Highlights: Features a beautiful fluted exterior that adds a touch of sophistication to any bathroom decor · Generously sized at 71 inches, offering ample space for a ……

Expert Sourcing Insights for Kitchen Sink P Trap

2026 Market Trends for Kitchen Sink P-Trap

The kitchen sink P-trap market in 2026 is poised for steady evolution, driven by advancements in materials, shifting consumer priorities, and broader trends in home improvement and sustainability. While traditionally a utilitarian component, the P-trap is seeing subtle but significant changes that reflect the modernization of plumbing systems and heightened awareness of hygiene and environmental impact.

Material Innovation and Durability Focus

By 2026, there is a noticeable shift away from basic PVC toward higher-grade materials. Homeowners and contractors increasingly favor ABS (Acrylonitrile Butadiene Styrene) and chromed brass P-traps for their superior durability, resistance to warping, and aesthetic appeal. Additionally, antimicrobial additives in plastic traps are gaining traction, especially in health-conscious households, reducing bacterial buildup and odors. This trend aligns with a broader demand for long-lasting, low-maintenance plumbing components.

Sustainability and Eco-Conscious Design

Environmental concerns are influencing P-trap design and material sourcing. Recycled plastics are being incorporated into manufacturing processes, and brands are highlighting recyclability at end-of-life. Furthermore, water-efficient designs that minimize standing water without compromising seal integrity are being explored, supporting broader green building initiatives. Consumers in 2026 are more likely to choose eco-certified plumbing products, including P-traps, as part of sustainable kitchen renovations.

Smart Plumbing Integration and Leak Prevention

Although still emerging, the integration of P-traps into smart home systems is beginning to take shape. Leak-detection sensors embedded near or within P-trap assemblies are becoming more common, especially in high-end kitchens. These sensors connect to home monitoring apps, providing real-time alerts for potential leaks or condensation issues, helping prevent water damage. While not standard, this trend signals a move toward proactive maintenance and smart infrastructure.

Design and Aesthetic Customization

The visibility of under-sink plumbing in modern open-cabinet designs has elevated the importance of P-trap aesthetics. In 2026, consumers seek P-traps that complement kitchen finishes—brushed nickel, matte black, and satin brass options are increasingly available. Modular and adjustable P-traps also gain popularity, allowing for easier installation in tight or non-standard spaces, appealing to DIY renovators and professional installers alike.

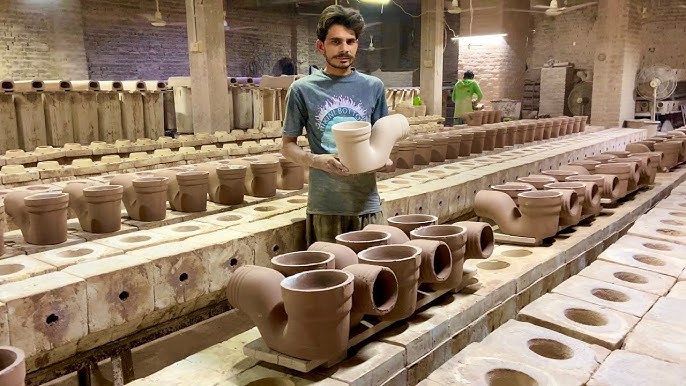

Supply Chain Resilience and Regional Manufacturing

Ongoing global supply chain dynamics continue to influence the P-trap market. In response, North American and European manufacturers are expanding local production to reduce dependency on overseas sourcing. This shift supports faster delivery times, reduced carbon footprint, and greater responsiveness to regional plumbing codes, which is especially important as regulations around emissions and materials tighten.

In summary, the 2026 kitchen sink P-trap market reflects a convergence of durability, sustainability, and smart functionality. While the core purpose remains unchanged, innovations in materials, design, and integration are transforming this once-overlooked component into a more intelligent and environmentally responsible part of the modern kitchen.

Common Pitfalls Sourcing Kitchen Sink P-Trap (Quality, IP)

Sourcing the right kitchen sink P-trap is essential for reliable plumbing performance, leak prevention, and compliance with health standards. However, buyers often encounter several pitfalls related to quality and intellectual property (IP). Being aware of these issues can help avoid costly mistakes, safety hazards, and legal complications.

Poor Material Quality

One of the most frequent issues is receiving P-traps made from substandard materials. Low-quality plastic (such as recycled or non-impact-resistant ABS) or thin-gauge metal can crack, warp, or corrode prematurely. Inferior rubber seals in slip-joint connections may degrade quickly, leading to leaks. These materials often fail under thermal stress from hot water or physical pressure during installation.

Inaccurate Dimensions and Poor Fit

Many sourced P-traps—especially from generic or unbranded suppliers—have inconsistent or inaccurate measurements. Even minor deviations in diameter (e.g., 1.25″ vs. 1.5″) or curvature can prevent a proper fit with the sink tailpiece or drainpipe, resulting in misalignment, stress on joints, and chronic leaks. Poor tolerances also make installation frustrating and time-consuming.

Non-Compliance with Plumbing Codes

Some P-traps are manufactured without adherence to local plumbing codes (e.g., IPC, UPC in the US, or EN standards in Europe). This includes incorrect trap seal depth (must be at least 2 inches), lack of proper venting compatibility, or failure to support required wastewater flow rates. Using non-compliant parts can lead to failed inspections, safety hazards, and liability issues.

Misrepresentation of IP and Brand Authenticity

Counterfeit or cloned P-traps often mimic well-known brands (e.g., Oatey, Danco, Waste King) in design and packaging. These products infringe on intellectual property rights and may falsely claim certifications (like UPC or NSF). Sourcing such items exposes buyers to legal risks and supports unethical manufacturing practices.

Lack of Certified Testing and Documentation

Reputable P-traps undergo third-party testing for durability, chemical resistance, and pressure performance. Many low-cost suppliers cannot provide test reports or certifications (e.g., ASTM D2665 for plastic drains). Without proof of compliance, there’s no assurance the product meets safety or performance standards.

Inadequate Packaging and Corrosion Protection

Poor packaging—especially for metal P-traps—can lead to damage during shipping. Chrome-plated traps may arrive with scratches or dents, compromising both appearance and corrosion resistance. Unprotected metal components may begin to rust even before installation, shortening product life.

Overlooking Long-Term Support and Warranty

Low-cost suppliers often offer no warranty or after-sales support. If a defect appears months later, replacement or recourse may be impossible. Branded manufacturers typically offer warranties and technical support, which are crucial for commercial or large-scale residential projects.

Avoiding these pitfalls requires sourcing from reputable suppliers, verifying certifications, inspecting samples, and ensuring compliance with both technical standards and intellectual property laws.

Logistics & Compliance Guide for Kitchen Sink P-Trap

Product Overview

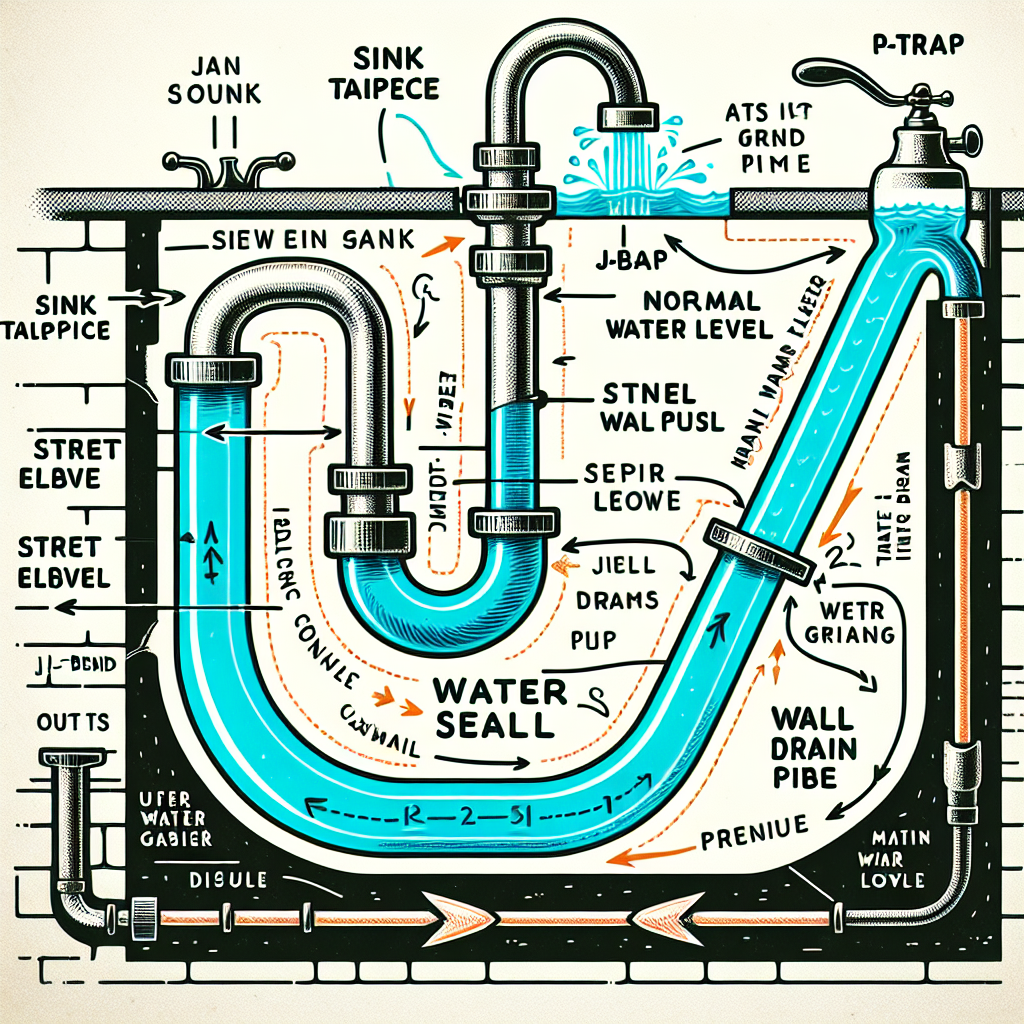

The Kitchen Sink P-Trap is a plumbing fixture designed to connect the kitchen sink drain to the waste pipe system. It prevents sewer gases from entering the home by maintaining a water seal, while also capturing debris to reduce clogs downstream. This guide outlines key logistics and compliance considerations for the import, distribution, and installation of P-Traps in residential and commercial settings.

2.1 Regulatory Compliance Requirements

Plumbing Codes

- International Plumbing Code (IPC): P-Traps must comply with IPC Section 1002, which specifies materials, dimensions, slope, and water seal depth (minimum 2 inches, maximum 4 inches).

- Uniform Plumbing Code (UPC): Requires traps to be self-cleaning, resistant to corrosion, and installed with proper venting (UPC Chapter 10).

- Local Jurisdictions: Always verify with municipal or state plumbing authorities, as some regions may have additional requirements (e.g., freeze protection, seismic bracing).

Material Standards

- ASME A112.1.2 / CSA B125.1: Governs performance and testing of plumbing trap devices.

- NSF/ANSI 14 & 61: Required if P-Trap is made of plastic (e.g., PVC, ABS); certifies material safety and resistance to chemicals in potable water systems.

- Lead-Free Compliance (SDWA): Metal traps (e.g., brass) must meet ≤ 0.25% weighted average lead content under the U.S. Safe Drinking Water Act.

Product Certification

- Look for third-party certification marks:

- IAPMO R&T (for UPC compliance)

- NSF International (for material safety)

- CSA Group (for Canadian markets)

- Certified products are listed in public databases (e.g., IAPMO PMG Listing, NSF Certified Products List).

2.2 Logistics and Supply Chain Considerations

Packaging and Handling

- P-Traps should be individually packaged or bundled to prevent deformation or thread damage.

- Use moisture-resistant packaging to avoid corrosion (especially for chrome-plated brass models).

- Label packages with:

- Product name and model

- Compliance marks (e.g., NSF, UPC)

- Country of origin

- Handling instructions (e.g., “Do Not Stack,” “Protect from Freezing”)

Storage Conditions

- Store in a dry, temperature-controlled environment (10–30°C / 50–86°F).

- Avoid direct sunlight to prevent UV degradation of plastic components.

- Keep off concrete floors using pallets to reduce moisture exposure.

Transportation

- Secure loads to prevent shifting during transit.

- Avoid extreme temperature exposure (e.g., unheated trailers in winter).

- For international shipments:

- Provide HS Code (e.g., 7320.10 for iron/steel traps, 3926.10 for plastic).

- Include necessary documentation: Commercial Invoice, Packing List, Certificate of Conformity.

Inventory Management

- Track shelf life for rubber gaskets and plastic components (typically 5–10 years).

- Rotate stock using FIFO (First In, First Out) to ensure fresh product deployment.

2.3 Installation and Field Compliance

Installation Best Practices

- Ensure proper slope (1/4 inch per foot) from sink to trap and trap to drain.

- Use approved fittings and avoid offset configurations that may siphon the water seal.

- Tighten connections hand-tight plus 1/4 to 1/2 turn with wrench—over-tightening can crack fittings.

Inspection and Testing

- Post-installation, perform a water test: Fill sink and drain rapidly to check for leaks and proper venting.

- Inspect for siphoning (gurgling sounds indicate poor venting).

- Verify local inspector approval where required (e.g., for new construction or remodels).

Documentation for Contractors

- Provide installation manual and compliance data sheet with each unit.

- Include QR code linking to product certifications and warranty information.

2.4 Environmental and Safety Compliance

Waste and Recycling

- Metal traps (brass, stainless steel) are recyclable; plastic traps should be disposed of per local e-waste or plastic recycling rules.

- Discarded traps may retain wastewater; clean before disposal.

Worker Safety

- Installers should wear gloves and eye protection when cutting or fitting pipes.

- Ensure adequate ventilation when using solvent cements for plastic traps.

Sustainability

- Prefer P-Traps made from recycled materials (e.g., recycled brass or post-consumer plastics).

- Manufacturers should disclose environmental product declarations (EPDs) where available.

2.5 Import and Market Access (International Considerations)

North America

- USA: Comply with IPC/UPC, NSF/ANSI 61, and lead-free laws. CBP may inspect for proper labeling.

- Canada: Must meet CSA B64 Series and be certified by accredited body (e.g., CSA, cUPC).

European Union

- CE marking not typically required for standalone traps, but must comply with EN 274 (discharge fittings) if part of a sanitary system.

- REACH and RoHS apply to material content (e.g., restriction of hazardous substances).

Australia / New Zealand

- Must comply with AS/NZS 3500.2 (Plumbing and Drainage – Sanitary Plumbing).

- WaterMark Certification is mandatory.

Summary

To ensure compliance and efficient logistics for Kitchen Sink P-Traps: verify product certifications (NSF, UPC, CSA), maintain proper storage and handling, follow local code requirements during installation, and prepare documentation for international shipments. Always prioritize certified, lead-free, and sustainably manufactured products to meet regulatory and market demands.

In conclusion, sourcing a kitchen sink P-trap requires careful consideration of size, material, compatibility, and local plumbing codes. Whether opting for PVC, ABS, or stainless steel, it’s essential to ensure the P-trap fits your sink configuration and drain setup. Purchasing from reputable suppliers or hardware stores—either in person or online—can provide access to quality products and helpful guidance. Taking accurate measurements and verifying the correct connector types will help ensure a leak-free installation. Ultimately, selecting the right P-trap not only supports efficient drainage but also prevents odors and maintains the overall hygiene of your kitchen plumbing system.