The global kitchen hood fire extinguishing system market is experiencing robust growth, driven by increasing fire safety regulations in commercial kitchens, rising construction of restaurants and food service establishments, and growing awareness of preventative fire protection. According to Grand View Research, the global kitchen fire suppression systems market was valued at USD 1.3 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 7.2% from 2023 to 2030. This growth is further reinforced by stringent codes from organizations like the National Fire Protection Association (NFPA), particularly NFPA 96, which mandates automatic fire suppression systems in commercial cooking operations. As demand surges across hospitality, healthcare, and institutional sectors, manufacturers are innovating with advanced detection mechanisms, eco-friendly suppressants, and smart system integrations. In this competitive landscape, a select group of companies are leading the charge in reliability, compliance, and technological advancement—here are the top 10 kitchen hood fire extinguishing system manufacturers shaping the industry’s future.

Top 10 Kitchen Hood Fire Extinguishing System Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 CaptiveAire

Domain Est. 1997

Website: captiveaire.com

Key Highlights: CaptiveAire is the nation’s leading manufacturer of commercial kitchen ventilation systems, and now provides a complete solution of fans, heaters, ductwork, ……

#2 PYRO

Domain Est. 1998

Website: pyrochem.com

Key Highlights: PYRO-CHEM offers a comprehensive line of products for commercial and industrial applications, each designed and manufactured to the highest industry standards….

#3 Guardian Safety Solutions International Inc.

Domain Est. 2008

Website: guardianssi.com

Key Highlights: Guardian Fire Suppression Systems provide superior fire suppression of kitchen fires on residential ranges in commercial occupancies….

#4 ANSUL

Domain Est. 1995

Website: ansul.com

Key Highlights: ANSUL is a fire suppression company that designs and engineers specail hazard fire suppression systems and solutions for many different industries and many ……

#5

Domain Est. 1996

Website: buckeyef.com

Key Highlights: Buckeye Fire offers a line of handheld and wheeled fire extinguishers, suppressing foam concentrates & hardware, and kitchen suppression systems….

#6 Kitchen Hood Fire Suppression

Domain Est. 1998

Website: koorsen.com

Key Highlights: Koorsen Fire & Security provides sales, inspections, installation, and maintenance of kitchen fire suppression systems for restaurants and businesses….

#7 StoveTop FireStop

Domain Est. 1999

Website: stovetopfirestop.com

Key Highlights: StoveTop FireStop puts out kitchen fires automatically, so you and your loved ones will be protected whether you are in the kitchen or not….

#8 Tyco Fire Suppression & Fire Safety Solutions

Domain Est. 2001

Website: tyco-fire.com

Key Highlights: We have innovative and industry-leading fire safety and fire suppression solutions to protect your people and property. From sprinkler systems to valves, ……

#9 Kidde Fire Systems

Domain Est. 2002

Website: kiddefenwal.com

Key Highlights: Our fire protection solutions include conventional & intelligent detection and control systems which complement a complete line of fire suppression systems….

#10 Denlar Fire Protection

Domain Est. 2010 | Founded: 2007

Website: denlarhoods.com

Key Highlights: Denlar Fire Protection has been engineering, manufacturing, and selling FAIL-SAFE fire suppression range hoods and control systems since 2007….

Expert Sourcing Insights for Kitchen Hood Fire Extinguishing System

H2: 2026 Market Trends for Kitchen Hood Fire Extinguishing Systems

The global market for kitchen hood fire extinguishing systems is poised for significant transformation by 2026, driven by evolving safety regulations, technological advancements, and increased awareness of fire hazards in commercial and high-end residential kitchens. As urbanization accelerates and the foodservice industry expands—especially in emerging economies—the demand for reliable and automated fire suppression systems continues to grow. The following key trends are expected to shape the kitchen hood fire extinguishing system market in 2026:

-

Stringent Fire Safety Regulations Driving Adoption

Governments and regulatory bodies worldwide are tightening fire safety codes, particularly for commercial kitchens in restaurants, hotels, and institutional facilities. Standards such as NFPA 96 (Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations) are being more rigorously enforced, mandating the installation of certified kitchen hood suppression systems. In regions like Asia-Pacific and the Middle East, where commercial construction is booming, regulatory compliance is becoming a primary growth catalyst. -

Rise of Smart and IoT-Enabled Systems

By 2026, smart fire suppression systems integrated with IoT (Internet of Things) technology are expected to gain prominence. These systems offer real-time monitoring, remote diagnostics, automatic alerts, and integration with building management systems (BMS). Such features enhance operational efficiency and ensure rapid response, making them highly attractive to facility managers and safety officers. -

Growth in the Foodservice and Hospitality Sectors

The expansion of quick-service restaurants (QSRs), cloud kitchens, and food delivery infrastructure is increasing the number of commercial cooking operations. This growth necessitates reliable fire protection solutions. Additionally, luxury residential complexes and multi-family housing with communal kitchens are increasingly adopting commercial-grade suppression systems, blurring the line between commercial and residential applications. -

Emphasis on Environmentally Friendly Agents

There is a growing shift away from traditional wet chemical agents toward more eco-friendly and non-toxic fire suppressants. Manufacturers are investing in R&D to develop clean agents that minimize environmental impact, reduce cleanup time, and are safer for kitchen staff. This trend is particularly strong in Europe and North America, where sustainability regulations are more stringent. -

Increased Demand in Emerging Markets

Countries in Southeast Asia, India, and Latin America are witnessing rapid urban development and a surge in modern hospitality and foodservice infrastructure. As these regions adopt international safety standards, the demand for certified kitchen hood fire extinguishing systems is expected to rise significantly by 2026. -

Product Innovation and Modular Designs

Manufacturers are focusing on compact, modular, and easy-to-install systems that can be retrofitted into existing kitchen hoods. This flexibility reduces installation costs and downtime, appealing to a broader customer base, including small and medium-sized enterprises (SMEs). -

Focus on Maintenance and Service Contracts

With the complexity of modern systems, there is an increasing trend toward bundled maintenance and service agreements. Providers are offering predictive maintenance through sensor data, ensuring systems remain operational and compliant—a key consideration for businesses aiming to avoid downtime and regulatory penalties.

In conclusion, the kitchen hood fire extinguishing system market in 2026 will be characterized by innovation, regulatory compliance, and digital integration. As safety becomes non-negotiable in commercial kitchen environments, stakeholders across the value chain—from manufacturers to facility operators—will need to adapt to these dynamic trends to remain competitive and ensure public safety.

Common Pitfalls in Sourcing Kitchen Hood Fire Extinguishing Systems (Quality & IP)

Sourcing a Kitchen Hood Fire Extinguishing System is a critical decision for any commercial kitchen. While price and availability are often primary considerations, overlooking quality and intellectual property (IP) aspects can lead to significant safety risks, compliance failures, and operational disruptions. Below are key pitfalls to avoid:

1. Prioritizing Lowest Cost Over Certified Quality

One of the most frequent mistakes is selecting a system based solely on price. Extremely low-cost systems often cut corners in materials, design, and manufacturing, leading to:

- Substandard Components: Use of inferior nozzles, fusible links, or cylinder materials prone to corrosion or failure.

- Inadequate Testing: Lack of rigorous factory or third-party testing to verify performance under real-world fire conditions.

- Non-Compliance: Systems may not meet essential safety standards (e.g., UL 346, EN 13501, local fire codes), rendering them illegal to install or ineffective when needed.

- Solution: Always verify certification marks from recognized testing laboratories (e.g., UL, FM, LPCB) and insist on documented test reports. Invest in systems from reputable manufacturers with proven track records.

2. Ignoring Intellectual Property (IP) Infringement Risks

Sourcing from suppliers offering “compatible” or “generic” replacements for major brands can lead to IP violations:

- Counterfeit Components: Use of unlicensed copies of patented nozzles, detection links, or control panels that mimic original designs but lack performance validation.

- Design Infringement: Replicating proprietary system layouts, nozzle placement patterns, or chemical formulations protected by patents.

- Legal & Safety Consequences: Using infringing systems can result in legal action against the end-user or installer, void insurance coverage, and compromise system reliability due to untested designs.

- Solution: Source directly from authorized distributors of established brands or ensure the supplier can provide proof of licensing for any third-party components. Avoid “knock-off” products.

3. Overlooking Compatibility and Integration Requirements

A fire system must work seamlessly with the kitchen’s specific hood, cooking appliances, and ventilation:

- Improper Nozzle Coverage: Generic systems may not account for unique hood geometry or high-risk appliance locations (e.g., deep fryers, griddles), leaving critical areas unprotected.

- Incompatible Shut-Offs: Failure to integrate with gas/electric shut-off valves for all connected appliances compromises safety.

- Ventilation Interlock Issues: Incorrect integration with exhaust fans can prevent proper smoke removal or hinder extinguishing agent dispersion.

- Solution: Provide detailed kitchen layout and equipment specifications to the supplier. Ensure the proposed system includes a site-specific design and hydraulic calculation report.

4. Accepting Insufficient Documentation and Support

Poor documentation and lack of after-sales support can hinder compliance and maintenance:

- Missing Manuals & Certificates: Failure to receive operation manuals, as-built drawings, or compliance certificates creates audit and inspection issues.

- Lack of Technical Support: Inability to get timely assistance for installation queries or troubleshooting.

- Unavailability of Spare Parts: Risk of prolonged downtime if replacement parts (especially for infringing or obscure systems) are not readily available.

- Solution: Require comprehensive documentation as part of the purchase agreement. Choose suppliers with strong local technical support and a reliable supply chain for parts.

5. Relying on Unverified Supplier Claims

Some suppliers make exaggerated claims about performance, certifications, or global approvals:

- Fabricated Certifications: Presenting fake or expired certification documents.

- Misrepresented Standards: Claiming compliance with standards the system hasn’t been tested to.

- Unproven Performance: Promising extended coverage or faster response without test data.

- Solution: Independently verify certifications with the issuing body. Request access to full test reports and conduct due diligence on the supplier’s reputation and history.

By proactively addressing these quality and IP-related pitfalls, organizations can ensure they procure a reliable, compliant, and legally sound kitchen hood fire suppression system that effectively protects lives, property, and business continuity.

Logistics & Compliance Guide for Kitchen Hood Fire Extinguishing System

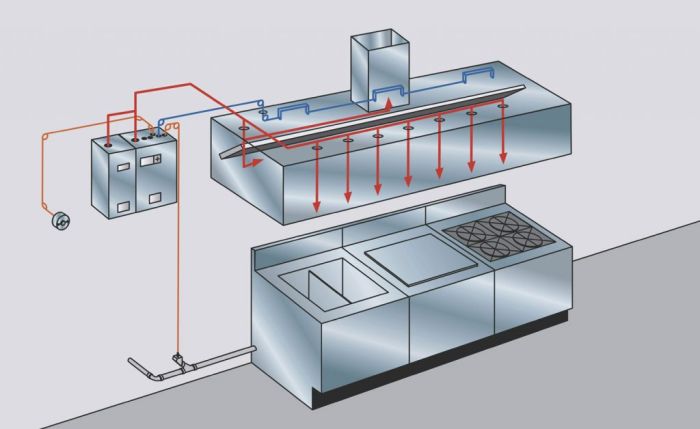

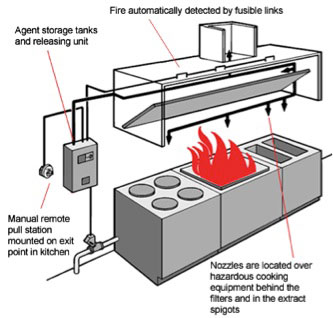

System Overview and Purpose

A Kitchen Hood Fire Extinguishing System is a specialized suppression system designed to detect and extinguish fires originating in commercial cooking equipment, such as fryers, grills, and ranges, located beneath exhaust hoods. Its primary purpose is to protect life, minimize property damage, and prevent fire spread by rapidly suppressing flames before they extend into the ductwork or building structure.

Regulatory Standards and Code Compliance

Compliance with national and local fire safety codes is mandatory. Key standards include:

– NFPA 96: Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations (published by the National Fire Protection Association).

– UL 300: Standard for Wet Chemical Extinguishing Systems for Protection of Commercial Cooking Equipment.

– Local building and fire codes (e.g., International Fire Code – IFC).

Systems must be listed and labeled by a nationally recognized testing laboratory (e.g., UL, FM Global) and installed in accordance with manufacturer instructions and applicable regulations.

System Components and Installation Requirements

Essential components include:

– Nozzles: Strategically placed above cooking appliances and within exhaust plenums.

– Detection System: Fusible links or thermally-activated detectors that trigger discharge.

– Extinguishing Agent Cylinders: Typically containing wet chemical agents.

– Piping Network: Connects cylinders to nozzles; must be corrosion-resistant.

– Manual Pull Station: Allows manual activation, usually located near exits.

– Alarm Devices: Audible and visual signals to indicate system discharge.

Installation must be performed by certified fire protection technicians, following approved design drawings and jurisdictional requirements.

Inspection, Testing, and Maintenance (ITM) Schedule

Regular ITM is critical for system reliability:

– Monthly: Visual inspection by kitchen staff for physical damage, obstructions, and tampering.

– Semi-Annual (Every 6 Months): Comprehensive inspection, testing of detection elements, and operational check by a certified service provider.

– Annual: Full system test, including simulated discharge verification, cylinder weight check, and nozzle flow test.

All maintenance must be documented and records retained for inspection by authorities having jurisdiction (AHJ).

Kitchen Operations and System Interfacing

To ensure system effectiveness:

– Automatic Shutoffs: The system must be interlocked with gas and electrical supplies to cooking appliances, cutting off fuel and power upon activation.

– Hood and Duct Cleaning: Grease buildup in exhaust systems can impair suppression performance. Hoods, ducts, and fans must be cleaned at regular intervals (frequency based on usage—typically monthly to quarterly).

– Equipment Changes: Any modification to cooking appliances requires a system re-evaluation and possible redesign to maintain code compliance.

Training and Staff Awareness

Personnel must be trained on:

– Proper use of portable fire extinguishers (Class K) for initial fire response.

– Location and operation of the manual pull station.

– Actions to take after system activation (e.g., evacuate, call emergency services, secure utilities).

– Reporting of system tampering or maintenance needs.

Training records should be maintained, and refresher sessions conducted annually or after staff turnover.

Documentation and Recordkeeping

Maintain a compliance file including:

– As-built system drawings and equipment specifications.

– Certificate of installation and commissioning.

– Service inspection reports and maintenance logs.

– Records of staff training.

These documents must be accessible for review by fire marshals, insurance auditors, or health inspectors.

Penalties and Consequences of Non-Compliance

Failure to comply with NFPA 96 and local codes may result in:

– Fines or citations from fire departments or health authorities.

– Business closure or operational restrictions.

– Voided insurance coverage in the event of fire.

– Increased liability in case of injury or property damage.

Regular compliance audits are recommended to avoid penalties.

Emergency Response and Post-Discharge Procedures

After system activation:

– Evacuate the area and contact emergency services.

– Do not re-enter until cleared by fire officials.

– Secure gas and electrical supplies.

– Contact a certified technician to inspect, recharge, or replace system components before resuming kitchen operations.

A post-incident report should be prepared for internal review and regulatory submission if required.

Modifications and System Upgrades

Any changes to the kitchen layout or cooking equipment necessitate a system reassessment. Modifications must be:

– Reviewed and approved by a qualified fire protection engineer.

– Implemented by certified technicians.

– Re-inspected and tested before being placed back into service.

Never bypass or disable system components during renovations.

Conclusion

Proper logistics, ongoing maintenance, and strict adherence to compliance standards are essential for the reliable operation of a kitchen hood fire extinguishing system. By following this guide, facility managers and kitchen operators can ensure safety, regulatory compliance, and business continuity.

Conclusion:

Sourcing a kitchen hood fire extinguishing system is a critical step in ensuring the safety, compliance, and operational efficiency of commercial kitchens. Given the high risk of grease fires in such environments, investing in a reliable, certified, and properly installed fire suppression system is not only a regulatory requirement but also a vital component of risk management.

After evaluating various suppliers, system types (e.g., wet chemical, pre-engineered systems), and key factors such as certification (e.g., UL300), ease of maintenance, compatibility with kitchen equipment, and service support, it is evident that a well-sourced system significantly reduces fire hazards and minimizes potential downtime and property damage.

It is recommended to partner with reputable suppliers who provide compliant, tested systems backed by strong technical support and maintenance services. Additionally, regular inspection, employee training, and adherence to local fire codes are essential to ensure the long-term effectiveness of the system.

In conclusion, a thoughtful and informed sourcing process for a kitchen hood fire extinguishing system enhances safety, ensures regulatory compliance, and contributes to the sustainable operation of any foodservice establishment.