The global radiator manufacturing market is experiencing steady growth, driven by increasing demand for efficient heating solutions in residential, commercial, and industrial sectors. According to Grand View Research, the global heating equipment market was valued at USD 63.5 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. Radiators, as a critical component of hydronic heating systems, are benefiting from rising construction activities, energy efficiency regulations, and the modernization of HVAC infrastructure—particularly in Europe and North America. Additionally, Mordor Intelligence projects continued expansion in the HVAC market, citing advancements in smart thermostatic controls and sustainable materials as key growth enablers. In this evolving landscape, a select group of radiator manufacturers have emerged as industry leaders, combining innovation, scalability, and global reach to capture significant market share. The following analysis highlights the top 8 radiator manufacturers shaping the future of thermal comfort and energy-efficient heating.

Top 8 Key Radiator Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Radiator Key

Domain Est. 1998

Website: monument-tools.com

Key Highlights: Monument Tools manufacturers a number of radiator keys for different applications. 2058J Radiator Key for Bleed and Balancing, 2059M 4 Way Radiator Key….

#2 Radiator Supply House

Domain Est. 2004

Website: radiatorsupplyhouse.com

Key Highlights: Radiator Supply House is a complete manufacturing facility for metal replacement radiators, steel tanks, all aluminum radiators, oil coolers, and charge air ……

#3 Kelvion

Domain Est. 2005

Website: kelvion.com

Key Highlights: Kelvion, your manufacturer for heat exchangers & cooling & heating solutions: plate heat exchangers, cooling heat exchangers & more!…

#4 PWR Advanced Cooling Technology

Website: pwr.com.au

Key Highlights: PWR group, including our Australian, US and UK sites provide design, manufacture, full system integration and testing of cooling systems for the defence sector….

#5 Radiator Keys

Domain Est. 1999

#6 Mishimoto: Page

Domain Est. 2004

Website: mishimoto.com

Key Highlights: We built our Performance Aluminum Radiator specifically to eliminate those weak points and give these trucks the cooling foundation they deserve. Read more »….

#7 Plumbing Tools

Domain Est. 2008

Website: cwhco.com

Key Highlights: In stock 15-day returnsDurable zinc construction · Designed for hot water radiators · Used to bleed out trapped air in the radiator system · Includes 1 air valve key….

#8 Radiator Key

Domain Est. 2018

Expert Sourcing Insights for Key Radiator

H2: 2026 Market Trends Analysis for Key Radiator

As we approach 2026, the global heating, ventilation, and air conditioning (HVAC) market—particularly the radiator segment—is undergoing significant transformation driven by technological innovation, regulatory shifts, and evolving consumer preferences. For Key Radiator, a company specializing in heating solutions, understanding these dynamics is critical to maintaining competitiveness and capturing market share. Below is an analysis of key trends expected to shape the market in 2026.

1. Sustainable and Energy-Efficient Solutions

By 2026, energy efficiency will be a top priority for both residential and commercial consumers. Governments across Europe, North America, and parts of Asia are enforcing stricter energy performance standards (e.g., EU Energy Performance of Buildings Directive, U.S. ENERGY STAR updates). Key Radiator can capitalize on this trend by expanding its product line to include low-temperature radiators compatible with heat pumps and condensing boilers. Demand for radiators with enhanced thermal efficiency, smart thermostatic controls, and reduced material use will grow significantly.

2. Integration with Smart Home Ecosystems

The rise of smart home technology will accelerate through 2026. Consumers increasingly expect heating systems to integrate seamlessly with platforms like Google Home, Amazon Alexa, and Apple HomeKit. Key Radiator should consider embedding or partnering with smart thermostatic radiator valves (TRVs) that allow room-by-room temperature control, remote scheduling, and AI-driven usage optimization. Offering IoT-enabled radiators will differentiate the brand and appeal to tech-savvy homeowners and property developers.

3. Shift Toward Electrification and Decarbonization

With global net-zero targets looming, there is a growing shift away from gas-fired heating toward electrified systems. Radiators are central to this transition, especially when paired with heat pumps. Key Radiator should position itself as a partner in low-carbon heating by promoting radiators designed for lower flow temperatures (e.g., 55°C or below), ensuring compatibility with renewable energy sources. Collaboration with heat pump manufacturers could open new distribution channels and co-branding opportunities.

4. Regional Market Diversification

While Europe remains a strong market due to renovation mandates and energy crises, emerging opportunities in North America and Asia-Pacific should not be overlooked. In the U.S., government incentives under the Inflation Reduction Act (IRA) are boosting adoption of high-efficiency heating systems. Meanwhile, urbanization in countries like India and South Korea is increasing demand for modern, space-efficient radiators. Key Radiator may consider localized product adaptations and regional partnerships to enter these high-growth markets.

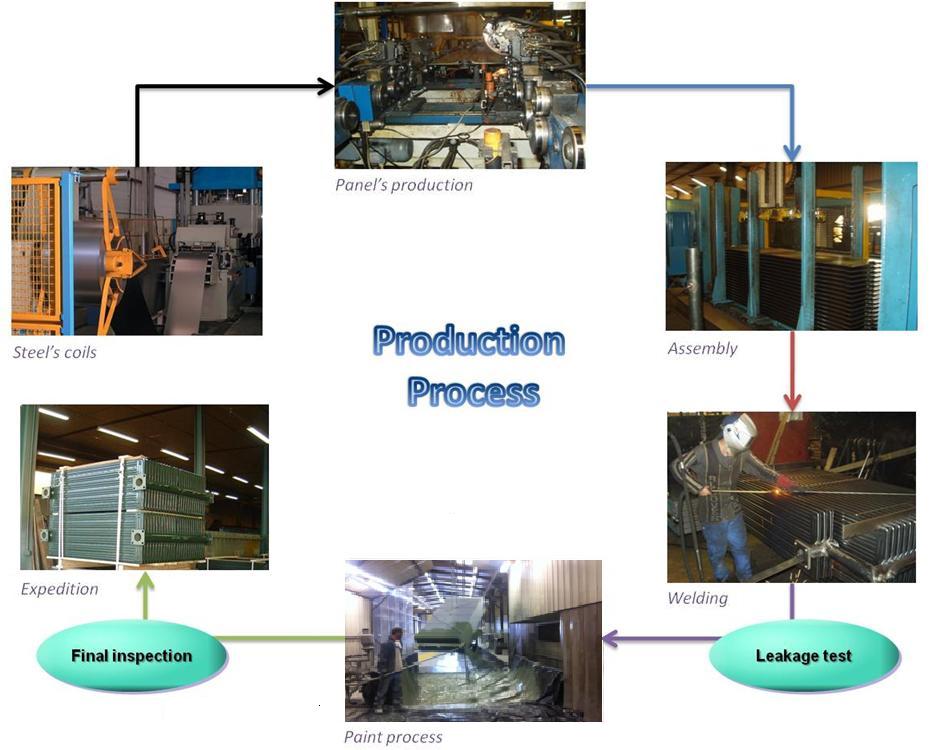

5. Circular Economy and Sustainable Manufacturing

Consumers and regulators are increasingly focused on lifecycle sustainability. By 2026, companies that demonstrate circular economy practices—such as using recycled steel, offering product take-back programs, and designing for disassembly—will gain competitive advantage. Key Radiator can enhance its brand image by publishing environmental product declarations (EPDs), achieving B Corp certification, or joining green building initiatives like LEED or BREEAM.

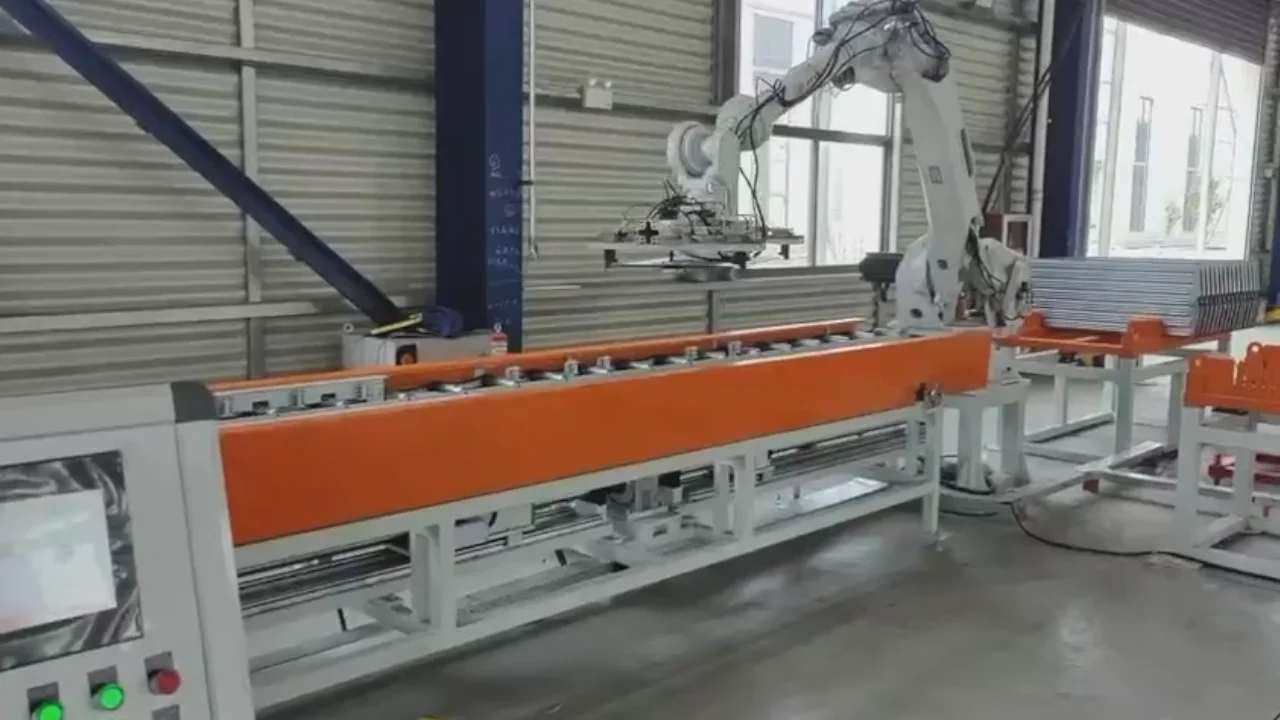

6. Supply Chain Resilience and Localization

Ongoing geopolitical tensions and supply chain disruptions have prompted a reevaluation of sourcing strategies. In 2026, there will be stronger emphasis on nearshoring and supply chain transparency. Key Radiator should assess its supply chain for vulnerabilities, consider localizing component manufacturing, and invest in digital supply chain tools to improve responsiveness and reduce lead times.

Conclusion

The 2026 market landscape for Key Radiator will be defined by sustainability, digital integration, and energy transition. To thrive, the company must innovate beyond traditional radiator designs and position itself as a provider of intelligent, eco-friendly heating solutions. Strategic investments in R&D, smart technology partnerships, and sustainable manufacturing will be essential to align with market demands and regulatory frameworks. By embracing these trends proactively, Key Radiator can strengthen its market presence and drive long-term growth.

Common Pitfalls Sourcing Key Radiator (Quality, IP)

Sourcing a key radiator—especially for specialized applications like electronics cooling, automotive systems, or industrial machinery—can present several challenges, particularly concerning quality and intellectual property (IP). Below are common pitfalls to be aware of:

Quality-Related Pitfalls

Inconsistent Material Standards

Suppliers may use substandard materials (e.g., lower-grade aluminum or copper) to cut costs, leading to reduced thermal efficiency and durability. Without clear material specifications and third-party verification, the radiator may fail prematurely under operational stress.

Poor Manufacturing Tolerances

Inaccurate fin spacing, uneven tube alignment, or improper brazing can significantly impair heat dissipation. These defects are often hard to detect without rigorous inspection and performance testing.

Lack of Performance Validation

Some suppliers provide theoretical thermal performance data without real-world testing. This can result in radiators that underperform in actual operating conditions, leading to overheating and system failure.

Inadequate Corrosion Protection

In environments with high humidity or exposure to chemicals, insufficient surface treatments (e.g., coating or plating) can lead to corrosion, reducing lifespan and efficiency.

Insufficient Quality Control Processes

Suppliers without certified quality management systems (e.g., ISO 9001) may lack consistent inspection protocols, increasing the risk of defective units reaching the end customer.

Intellectual Property (IP) Risks

Design Infringement

Sourcing from manufacturers who replicate patented radiator designs—intentionally or not—can expose your company to legal liability. This is especially common with copycat products from regions with lax IP enforcement.

Reverse Engineering by Suppliers

When sharing proprietary radiator designs with third-party manufacturers, there’s a risk of unauthorized duplication or resale to competitors. This is particularly concerning when working with overseas vendors lacking strong contractual IP protections.

Lack of IP Ownership Clarity

Contracts may not clearly assign ownership of custom designs or improvements made during production. This can lead to disputes over who holds rights to the radiator design, especially if modifications are made during manufacturing.

Inadequate Non-Disclosure Agreements (NDAs)

Without robust NDAs and confidentiality clauses, sensitive technical specifications may be disclosed to other clients or used to develop competing products.

Mitigation Strategies

- Conduct thorough supplier audits, including on-site visits and quality certifications review.

- Require performance test reports and material certifications for each batch.

- Use legally binding contracts that clearly define IP ownership and confidentiality obligations.

- Work with trusted partners in jurisdictions with strong IP protection laws.

- Consider dual sourcing or maintaining in-house design control to reduce dependency and risk.

Avoiding these pitfalls ensures not only a reliable, high-performing radiator but also protects your company’s innovation and market position.

Logistics & Compliance Guide for Key Radiator

This guide outlines the essential logistics and compliance procedures for handling the transportation, storage, and regulatory requirements associated with Key Radiator products. Adherence to these guidelines ensures safe, efficient operations and compliance with international and local regulations.

Product Handling and Storage

Key Radiator units are precision-engineered heating components that require careful handling to prevent damage. Always use appropriate lifting equipment when moving radiators, and avoid impact or deformation of fins and casings. Store radiators in a dry, indoor environment protected from moisture, dust, and extreme temperatures. Units should be stacked horizontally on pallets with sufficient support to prevent warping. Label all stored items clearly with model number, batch, and date.

Packaging and Labeling Standards

All Key Radiator shipments must be packaged according to ISO 11607 standards for medical device packaging (if applicable) or equivalent industrial standards. Use robust, recyclable materials that provide shock and moisture resistance. Each package must be labeled with:

– Product name and model number

– Batch/serial number

– Net and gross weight

– Handling symbols (e.g., “Fragile,” “This Way Up”)

– Country of origin

– Safety warnings (e.g., sharp edges)

Ensure barcodes or QR codes are scannable and linked to product traceability records.

Transportation Requirements

Transport Key Radiator products via certified carriers compliant with ADR (for road), IMDG (for sea), or IATA (for air) regulations where applicable. Though radiators are generally non-hazardous, compliance with general freight safety standards is mandatory. Secure cargo to prevent movement during transit. For international shipments, ensure temperature-controlled vehicles are used if ambient conditions exceed -10°C to +40°C. Maintain a temperature and shock log for high-value or sensitive consignments.

Customs and Import Compliance

Prepare accurate and complete documentation for all cross-border shipments, including:

– Commercial invoice

– Packing list

– Certificate of Conformity (CE, UKCA, or other applicable marks)

– Bill of Lading or Air Waybill

– Import licenses (if required by destination country)

Ensure Harmonized System (HS) code 7322.11 or 7322.19 is correctly applied for radiators made of iron or steel. Verify destination-specific import regulations, including energy efficiency certifications (e.g., ERP Directive in EU).

Regulatory and Safety Compliance

Key Radiator products must comply with relevant regional regulations:

– European Union: CE marking per the Construction Products Regulation (CPR) and Energy-related Products (ErP) Directive 2009/125/EC.

– United Kingdom: UKCA marking with conformity to BS EN 442 standards.

– North America: Compliance with ASHRAE standards and local building codes; UL or CSA certification if required.

– Other Regions: Confirm local certification requirements (e.g., GOST in Russia, CCC in China).

Maintain up-to-date technical files, Declaration of Performance (DoP), and test reports for all models.

Environmental and Sustainability Practices

Adhere to WEEE (Waste Electrical and Electronic Equipment) and RoHS (Restriction of Hazardous Substances) directives where applicable. Use packaging materials with high recycled content and minimize plastic use. Provide end-of-life disposal guidance to customers. Track and report carbon emissions associated with logistics operations annually.

Quality Assurance and Traceability

Implement a batch traceability system enabling full product recall if necessary. Record all logistics events (packing, shipping, delivery) in the ERP system. Conduct regular internal audits of logistics and compliance procedures. Train warehouse and logistics staff annually on handling, safety, and regulatory updates.

Emergency Procedures

In the event of damaged shipments, document the issue with photos and notify the carrier and supplier immediately. For product defects discovered post-shipment, initiate the non-conformance reporting process and follow the recall protocol outlined in the Quality Management System. Maintain a 24/7 incident response contact for critical logistics disruptions.

By following this guide, all parties involved in the distribution of Key Radiator products ensure operational excellence, regulatory adherence, and customer satisfaction.

Conclusion for Sourcing Key Radiator:

After a thorough evaluation of potential suppliers, technical specifications, cost implications, and lead times, sourcing the key radiator from a reliable and experienced manufacturer is critical to ensuring optimal performance, durability, and compatibility within the overall thermal management system. A strategic sourcing approach that balances cost-efficiency with quality, supported by strong supplier relationships and rigorous quality assurance processes, will mitigate risks and support long-term reliability. Ultimately, selecting a supplier that demonstrates technical expertise, consistent manufacturing standards, and timely delivery capabilities will ensure the successful integration of the radiator into the final application, contributing to enhanced system efficiency and customer satisfaction.