The global key cutting machine market is experiencing steady growth, driven by rising demand across automotive, residential, and commercial sectors. According to Grand View Research, the global locksmith and key duplication market was valued at USD 10.2 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This expansion is fueled by increasing vehicle production, advancements in key technology—particularly transponder and high-security keys—and the growing need for precision and efficiency in key duplication services. Mordor Intelligence corroborates this trend, highlighting robust demand in after-sales automotive services and heightened security requirements in emerging economies. As the market evolves, manufacturers are investing in automation, software integration, and AI-enhanced diagnostics to improve accuracy and reduce service time. In this competitive landscape, the top 10 key cutting machine manufacturers are distinguished by innovation, global reach, and a strong focus on R&D, positioning them at the forefront of industry transformation.

Top 10 Key Cutting Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Key Machines

Domain Est. 1996

Website: mbausa.com

Key Highlights: 2-day deliveryThe Mini Speedex® has 4-way jaws which allows it to cut a wide variety of keys. This lightweight duplicator is able to cut regular or large- ……

#2 Key Cutting Machines

Domain Est. 1997

Website: mul-t-lock.com

Key Highlights: Mul-T-Lock is a developer and manufacturer of machines for the advanced locking industry. From the simplest hand-loading cutting machines through to state-of- ……

#3 Keyline

Domain Est. 1999

Website: keyline.it

Key Highlights: Keyline is an Italian company that specialised in the production of door and car keys, key cutting machines. And transponder technology….

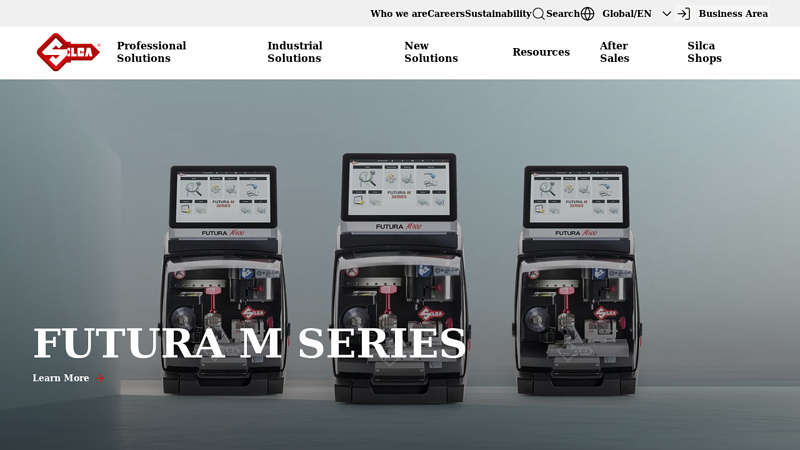

#4 Specialist in keys, key cutting machines, key duplication

Domain Est. 2002

Website: silca.biz

Key Highlights: Design and production of keys, key cutting machines, integrated duplicating systems, and industrial machines for key production and duplicating….

#5 Ilco Key System

Domain Est. 2002

Website: ilco.us

Key Highlights: Kaba Ilco Corp is the world’s premier manufacturer of the most extensive line of quality key blanks available and key machines….

#6 Lock Labs, Inc.

Domain Est. 2017

Website: lock-labs.com

Key Highlights: Introducing the revolutionary Anycut key cutting machine–quality, reliability, and finally, USA-based customer support, all for an incredibly low price! Brought ……

#7

Domain Est. 2004

Website: hudsonlock.com

Key Highlights: Proudly manufacturing key-cutting machines, USA key blanks, locks, locksmith tools, security supplies and various key storage systems….

#8 Laser Key Prodcuts

Domain Est. 2008

Website: laserkeyproducts.com

Key Highlights: Laser Key Products specializes in manufacturing key machines and locksmith tools. Our latest innovation is the 3D Pro Xtreme, a fully automatic high security ……

#9 Top Brands of Automotive Key Cutting Machines

Domain Est. 2011

Website: keylessentryremotefob.com

Key Highlights: Free delivery over $75 · Free 60-day returns…

#10 Futura Auto Key Machine

Domain Est. 2024

Website: toyotatoolsandequipment.com

Key Highlights: An economically-priced key cutting machine that will cut both the edge cut and laser cut keys. The machine’s single-cutting station is specifically designed ……

Expert Sourcing Insights for Key Cutting Machine

H2: Market Trends in Key Cutting Machines for 2026

The key cutting machine market is undergoing significant transformation as it enters 2026, driven by technological advancements, increased demand for security solutions, and evolving consumer needs. Several key trends are shaping the industry landscape this year:

1. Rise of Smart and Digital Key Cutting Technologies

The integration of smart technology into key cutting machines is a dominant trend in 2026. Manufacturers are increasingly incorporating IoT (Internet of Things) connectivity, cloud-based software, and mobile app integration, enabling remote diagnostics, real-time inventory tracking, and automated key duplication processes. These digital enhancements improve efficiency for locksmiths and automotive service providers, reducing human error and increasing precision.

2. Growth in Automotive and Keyless Entry Systems

With the automotive industry shifting toward keyless entry and smart key fobs, key cutting machines are adapting to support transponder programming and RFID chip duplication. In 2026, demand is rising for multi-functional machines capable of both mechanical key cutting and electronic key programming. This convergence is particularly strong in markets with high vehicle ownership and aging fleets requiring key replacements.

3. Expansion of Retail and DIY Key Cutting Kiosks

Self-service key cutting kiosks in retail outlets such as hardware stores, supermarkets, and pharmacies are gaining popularity. These automated kiosks, often branded by major lock and hardware companies, offer convenience and lower costs for consumers. In 2026, advancements in user interface design and AI-powered pattern recognition are making these kiosks more accurate and user-friendly, driving adoption across North America, Europe, and parts of Asia.

4. Focus on Portability and Compact Designs

There is growing demand for portable and handheld key cutting machines, especially among mobile locksmiths and emergency service providers. In 2026, manufacturers are releasing compact, battery-powered models with high precision and rugged build quality. These devices allow on-site key duplication without the need for a fixed workshop, enhancing service speed and customer satisfaction.

5. Emphasis on Cybersecurity and Data Protection

As key cutting machines become more connected, concerns over cybersecurity are rising. In 2026, leading vendors are implementing enhanced encryption, secure boot processes, and firmware authentication to prevent unauthorized access and cloning of high-security keys. This is particularly critical for government, military, and commercial applications where key duplication must be tightly controlled.

6. Sustainability and Eco-Friendly Manufacturing

Environmental considerations are influencing product design and manufacturing processes. Companies are adopting energy-efficient components, recyclable materials, and modular designs that allow for easy repair and part replacement. This shift aligns with broader industrial trends toward sustainability and meets increasing regulatory and consumer demands.

7. Regional Market Diversification

While North America and Europe remain strong markets due to advanced security infrastructure and high vehicle density, emerging economies in Asia-Pacific, Latin America, and Africa are witnessing rapid growth. In 2026, localized production and distribution strategies are helping global brands capture market share in these regions, often through partnerships with regional locksmith associations and distributors.

In conclusion, the key cutting machine market in 2026 is defined by digitalization, automation, and adaptability. As security needs grow and technology evolves, manufacturers and service providers who embrace innovation and prioritize user-centric design are best positioned to succeed in this dynamic environment.

Common Pitfalls When Sourcing Key Cutting Machines (Quality, IP)

Sourcing key cutting machines—especially from international suppliers—can present several risks related to quality control and intellectual property (IP) protection. Being aware of these pitfalls is essential to avoid costly mistakes, legal issues, and damaged reputation.

Poor Manufacturing Quality and Inconsistent Performance

One of the most frequent issues when sourcing key cutting machines is receiving units that fail to meet expected performance standards. Machines may have misaligned components, inferior motors, or substandard cutting blades, leading to inaccurate cuts and frequent breakdowns. Inconsistent quality between production batches is common with suppliers who lack robust quality assurance processes, resulting in unreliable output and customer dissatisfaction.

Use of Counterfeit or Infringing Components

Some suppliers may incorporate counterfeit or IP-infringing parts—such as cloned control boards, pirated software, or imitation brand-name cutters—into their machines. These components not only compromise machine reliability but also expose the buyer to legal liability. If the sourced machine uses patented technology or copyrighted software without authorization, your business could face cease-and-desist letters, customs seizures, or lawsuits, particularly in markets with strong IP enforcement.

Lack of Genuine Software and Firmware Licensing

Many modern key cutting machines rely on proprietary software for key code databases, transponder programming, and machine calibration. Unscrupulous suppliers may provide machines with pirated, cracked, or unauthorized software versions. This poses a significant risk: the software may stop working after an update, contain malware, or violate licensing agreements, making your business complicit in software piracy.

Inadequate Documentation and Technical Support

Low-cost suppliers often fail to provide comprehensive technical documentation, user manuals, or firmware update procedures. This becomes a major issue when troubleshooting, training staff, or maintaining machines over time. The absence of reliable customer support—especially across time zones or language barriers—can lead to extended downtime and increased operational costs.

IP Ownership and Design Copying Risks

When working with OEM/ODM suppliers, there is a risk that your custom design or specifications could be replicated and sold to competitors. Without a solid legal agreement that clearly assigns IP ownership and includes non-disclosure and non-compete clauses, your investment in product development may inadvertently benefit other buyers. Additionally, the machine design itself might be a copy of a branded product, exposing you to infringement claims.

Regulatory and Certification Non-Compliance

Key cutting machines, especially those with electronic or laser components, may be subject to regional safety, electromagnetic compatibility (EMC), or import regulations (e.g., CE, FCC, RoHS). Sourcing machines that lack proper certification can result in shipment rejections, fines, or product recalls. Poor-quality machines are more likely to fail compliance testing, especially if built with untested or non-standard components.

Hidden Costs from Maintenance and Downtime

Low initial purchase prices can be misleading. Machines of poor quality often require frequent repairs, replacement parts, and recalibration. The total cost of ownership rises significantly when factoring in technician labor, machine downtime, and customer service disruptions. Additionally, spare parts may be unavailable or incompatible, further hampering operations.

Mitigation Strategies

To avoid these pitfalls:

– Conduct thorough due diligence on suppliers, including factory audits and sample testing.

– Require proof of IP rights for software and components.

– Use legally binding contracts that define quality standards, IP ownership, and warranty terms.

– Insist on authentic software licenses and firmware update access.

– Verify regulatory certifications relevant to your market.

– Consider partnering with reputable distributors or authorized resellers instead of sourcing directly from unknown manufacturers.

By proactively addressing these common challenges, businesses can source reliable, compliant, and legally sound key cutting machines that support long-term operational success.

Logistics & Compliance Guide for Key Cutting Machines

Overview

This guide outlines the essential logistics and compliance considerations for the import, export, distribution, and operation of key cutting machines. These devices, while common in locksmithing and retail, are subject to specific regulations due to their potential security implications.

Regulatory Classification

Key cutting machines are typically classified under the Harmonized System (HS) code 8461.40 (Machines for working metal by removing material, not elsewhere specified). Accurate classification is critical for customs clearance and tariff determination. Always verify the applicable HS code with local customs authorities, as classifications may vary by country.

Import/Export Licensing Requirements

Some countries require import or export licenses for key cutting machines, particularly for high-precision or automated models. Check with the destination country’s trade authority (e.g., U.S. Department of Commerce, EU Commission) to determine if licensing is required. Dual-use regulations may apply if the machine can produce restricted or high-security keys.

End-Use and End-User Compliance

Due to the potential for misuse in unauthorized key duplication, many jurisdictions require end-user declarations or proof of legitimate business purpose (e.g., licensed locksmith, authorized retail outlet). Exporters may be required to verify that recipients are not on any sanctions lists (e.g., OFAC, EU Consolidated List).

Packaging and Shipping Standards

Ensure machines are securely packaged to prevent damage during transit. Use shock-absorbing materials and secure internal components. Label packages with standard handling symbols (fragile, this way up). Include documentation such as packing lists, commercial invoices, and safety data sheets (if applicable) in a waterproof envelope.

Transportation Modes and Considerations

Key cutting machines can generally be shipped via air, sea, or ground freight. Air freight offers speed but may have stricter size and weight limits. Sea freight is cost-effective for large shipments but requires longer lead times. Always declare the nature of the equipment and comply with carrier-specific hazardous material policies (no hazardous components typically, but verify).

Customs Documentation

Prepare and submit all required customs documentation, including:

– Commercial invoice (with full product description, value, and HS code)

– Bill of lading or air waybill

– Certificate of origin (if claiming preferential tariff treatment)

– Import/export licenses (if applicable)

Ensure all documents are accurate and consistent to avoid delays or penalties.

Country-Specific Regulations

Compliance requirements vary by country:

– United States: No federal restrictions on ownership, but state-level regulations may apply. Export controls under EAR may apply to advanced models.

– European Union: Subject to standard CE marking requirements for machinery safety (Machinery Directive 2006/42/EC). Member states may impose additional restrictions on sales to private individuals.

– Australia: Requires conformity with AS/NZS standards; importers must ensure compliance with electrical safety regulations.

– Canada: Must meet CSA safety standards; no specific licensing but end-user verification is recommended.

Data Protection and Security Features

Some modern key cutting machines store digital key profiles or usage logs. Ensure compliance with data protection laws (e.g., GDPR, CCPA) if personal or sensitive data is processed or stored. Implement password protection and encryption where available.

Disposal and Environmental Compliance

Dispose of obsolete machines in accordance with local e-waste regulations (e.g., WEEE Directive in the EU). Do not landfill electronic components. Recycle motors, circuit boards, and metal parts through certified e-waste handlers.

Compliance Best Practices

- Maintain records of all transactions for at least five years.

- Conduct due diligence on buyers, especially for international shipments.

- Train staff on export control laws and anti-diversion policies.

- Regularly review changes in trade regulations affecting security-related equipment.

Conclusion

Proper logistics planning and strict adherence to compliance requirements are essential when handling key cutting machines. By following this guide, businesses can minimize legal risks, ensure smooth cross-border operations, and contribute to responsible use of key duplication technology.

Conclusion for Sourcing a Key Cutting Machine:

After a thorough evaluation of technical specifications, cost considerations, supplier reliability, and long-term operational needs, sourcing a key cutting machine is a strategic investment that enhances service delivery, efficiency, and customer satisfaction. The chosen machine meets the required precision, durability, and versatility standards while aligning with budgetary constraints and scalability goals. By partnering with a reputable supplier offering comprehensive after-sales support, training, and warranty coverage, the organization ensures minimal downtime and sustained performance. Ultimately, the selected key cutting machine supports both current operational demands and future growth, positioning the business to deliver high-quality key duplication services reliably and efficiently.