The global keychain components market is experiencing steady growth, driven by rising demand across automotive, consumer electronics, and industrial sectors. According to Mordor Intelligence, the global key fob market—closely tied to keychain component manufacturing—is projected to grow at a CAGR of over 4.5% from 2024 to 2029, fueled by increasing vehicle production and the adoption of smart access systems. Additionally, Grand View Research reports that the broader automotive keyless entry system market, which relies heavily on precision-engineered keychain components, was valued at USD 3.7 billion in 2023 and is expected to expand significantly due to advancements in remote keyless technology and heightened consumer preference for convenience and security. As demand for durable, high-performance, and aesthetically refined keychain components rises, a select group of manufacturers has emerged as leaders in innovation, scalability, and material expertise—setting the standard in a competitive and evolving supply landscape.

Top 8 Key Chain Components Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Leather Keychains

Domain Est. 2003

Website: shishifeihong.com

Key Highlights: A professional custom leather keychain maker, provides bulk and wholesale leather keychain services. The majority of our leather keychains are made of premium ……

#2 High Quality Zamac Alloy Keychain Souvenirs Manufacturer

Domain Est. 1999

Website: chungjen.com

Key Highlights: We are a leading manufacturer specializing in the production of zinc alloy keychains, focusing on high-quality zinc alloy die-casting technology….

#3 Wholesale Parts for Making Keychains

Domain Est. 2000

#4 Custom Metal, PVC, Leather & More Keychains

Domain Est. 2002

Website: montereycompany.com

Key Highlights: Premium custom keychains – metal, PVC, leather, bottle openers, 3D, and more. Free proofs and quick delivery. Start your quote today….

#5 Key Chains

Domain Est. 2004

Website: americanbuttonmachines.com

Key Highlights: 4-day deliveryAmerican Button Machines has all of the supplies that you need to begin producing your own keychains easily and affordable….

#6 Keychains

Domain Est. 2008

Website: usalanyards.com

Key Highlights: Free deliveryGreat source of wholesale key chain supplies with a large selection to choose from with low bulk-order prices in stock – ship immediately!…

#7 Maglockz Keychain

Domain Est. 2013

#8 Keychain

Domain Est. 2013

Website: chibuttons.com

Key Highlights: Special Price USD$22.49 Regular Price USD$24.99. Sale. Keychain Parts – 32mm Round Versa-back Keychain (100 sets). Add to Cart….

Expert Sourcing Insights for Key Chain Components

H2: 2026 Market Trends for Key Chain Components

The global market for key chain components is poised for notable transformation by 2026, driven by technological advancements, shifting consumer preferences, sustainability demands, and evolving manufacturing techniques. As part of the broader consumer accessories and hardware industry, key chain components—ranging from rings and clips to decorative elements and smart modules—are adapting to new market dynamics. Below is an analysis of the key trends expected to shape the industry in 2026.

1. Increased Demand for Smart Key Chain Components

By 2026, smart key chains integrating Bluetooth tracking, GPS, and NFC technology are projected to dominate the higher end of the market. With rising concerns over lost items and digital security, consumers are increasingly adopting key finders and connected tags. Major tech companies and startups alike are incorporating miniaturized circuitry into durable, compact key chain components, fueling innovation and market growth. This segment is expected to see double-digit annual growth, especially in North America and Western Europe.

-

Customization and Personalization

Consumers are demanding personalized accessories, and key chain components are no exception. Advances in laser engraving, 3D printing, and on-demand manufacturing are enabling mass customization at scale. In 2026, OEMs and retailers will likely offer modular key chain systems that allow users to interchange components—such as engraved tags, rotating charms, or brand-emblem clips—based on style or function. This trend is particularly strong among younger demographics who value individuality and self-expression. -

Sustainable and Eco-Friendly Materials

Environmental consciousness is reshaping material choices in the key chain component market. By 2026, there will be a significant shift toward recyclable metals (e.g., recycled stainless steel, aluminum), bio-based plastics, and biodegradable composites. Regulatory pressures in the EU and increasing ESG (Environmental, Social, and Governance) standards are compelling manufacturers to reduce carbon footprints and adopt circular economy practices. Brands that emphasize sustainability in their supply chains will gain a competitive edge. -

Growth in Automotive and Industrial Applications

Beyond personal use, key chain components are increasingly integrated into automotive key fobs, industrial equipment tags, and access control systems. With the rise of connected vehicles and smart buildings, robust, high-precision components—such as reinforced split rings and security lanyard attachments—are in growing demand. The industrial and automotive sectors will contribute significantly to market expansion, particularly in emerging economies investing in smart infrastructure. -

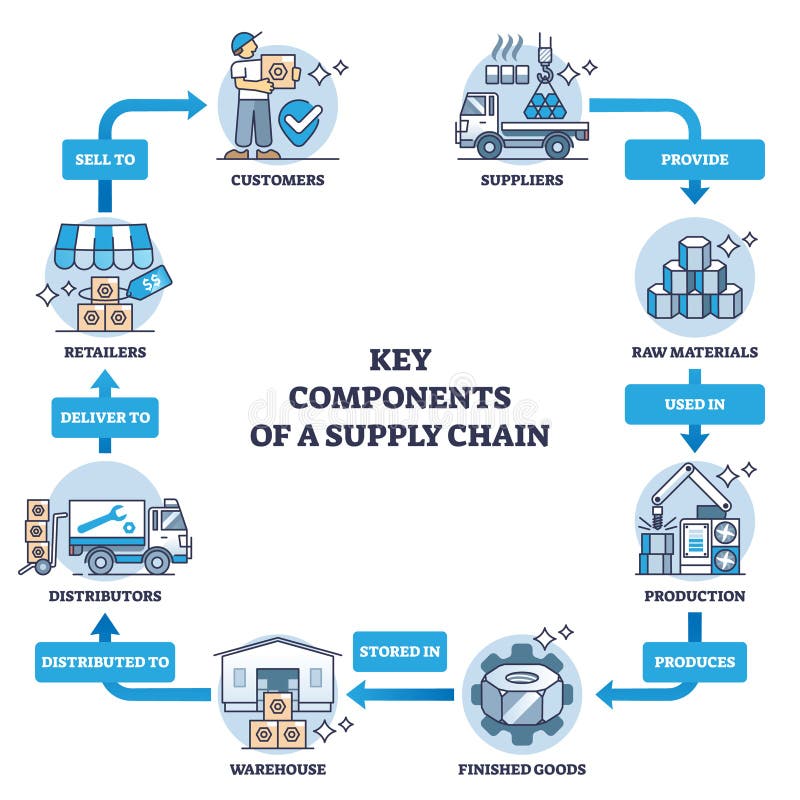

Supply Chain Resilience and Regional Manufacturing

The disruptions experienced in global supply chains during the early 2020s have prompted a move toward regionalization. By 2026, manufacturers of key chain components are expected to diversify sourcing and increase local production, especially in Southeast Asia, Eastern Europe, and North America. This shift enhances responsiveness to market demands and reduces dependency on single-source suppliers, particularly for raw materials like zinc alloys and rare-earth magnets. -

Design Innovation and Aesthetic Integration

Functionality is being seamlessly blended with design. Key chain components in 2026 will feature minimalist aesthetics, ergonomic shapes, and premium finishes such as matte coatings, anodized colors, and anti-corrosion treatments. Collaborations between accessory brands and designers will drive limited-edition releases, boosting desirability and brand loyalty.

Conclusion

The key chain components market in 2026 will be defined by smart integration, personalization, sustainability, and resilience. As consumer expectations evolve and technology advances, manufacturers who innovate across materials, design, and functionality will lead the market. The convergence of utility and style, along with digital connectivity, ensures that even the smallest hardware components remain relevant in an increasingly connected world.

Common Pitfalls Sourcing Key Chain Components (Quality, IP)

Sourcing key chain components—whether for promotional items, fashion accessories, or branded merchandise—can present several challenges. Two of the most critical areas where businesses often encounter issues are quality control and intellectual property (IP) risks. Understanding and mitigating these pitfalls is essential to maintaining brand reputation, avoiding legal disputes, and ensuring customer satisfaction.

Quality Control Issues

One of the most frequent challenges in sourcing key chain components is ensuring consistent product quality. Many suppliers, especially in low-cost manufacturing regions, may deliver substandard materials or inconsistent finishes.

- Inconsistent Material Quality: Components such as metal alloys, plastics, or leather may not meet durability or safety standards. For example, zinc alloy key rings may corrode or break prematurely if low-grade materials are used.

- Poor Craftsmanship: Misaligned engravings, rough edges, weak attachments (e.g., split rings or connectors), or uneven coloring can result from inadequate production processes or lack of quality oversight.

- Lack of Standardization: Without clear specifications and rigorous inspections, batch-to-batch variations can occur, leading to mismatched products or customer complaints.

- Insufficient Testing: Suppliers may skip durability tests (e.g., salt spray for corrosion resistance, load testing for split rings), resulting in components that fail under normal use.

Mitigation: Establish detailed quality specifications, conduct pre-production samples, perform third-party inspections (e.g., AQL checks), and maintain ongoing communication with suppliers.

Intellectual Property (IP) Risks

Sourcing key chain components also carries significant IP risks, particularly when designs, logos, or patented mechanisms are involved.

- Unauthorized Use of Trademarks or Logos: Using branded emblems (e.g., sports team logos, corporate trademarks) without proper licensing exposes buyers to legal liability and potential seizure of goods by customs.

- Design Infringement: Copying the aesthetic design of existing key chains—especially those protected by design patents or trade dress—can lead to infringement claims.

- Counterfeit Components: Some suppliers may offer “compatible” or imitation versions of patented hardware (e.g., specific buckle or locking mechanisms), unknowingly or deliberately violating IP rights.

- Supplier Misrepresentation: A supplier may claim they have IP rights to a design they do not own, leaving the buyer liable for damages if the original rights holder takes legal action.

Mitigation: Conduct IP due diligence before production, obtain written proof of licensing for branded elements, use original designs or properly licensed artwork, and include IP indemnification clauses in supplier contracts.

By proactively addressing these quality and IP pitfalls, businesses can reduce risk, ensure compliance, and deliver reliable, legally sound key chain products to their customers.

Logistics & Compliance Guide for Key Chain Components

This guide outlines essential logistics and compliance considerations for the manufacturing, transportation, and distribution of key chain components. Adherence to these standards ensures product safety, legal conformity, and efficient supply chain operations.

Product Classification and HS Codes

Accurately classify key chain components using the Harmonized System (HS) to determine import/export requirements, duties, and restrictions. Common classifications include:

- Base Metals (e.g., zinc alloy, stainless steel): HS Code 7326 – Other articles of iron or steel

- Plastic Components: HS Code 3926 – Other articles of plastics

- Leather or Textile Attachments: HS Code 4202 – Articles of apparel, bags, or similar containers

- Electronics (e.g., LED key fobs): HS Code 8543 – Electrical machines and apparatus

Verify codes with local customs authorities, as classifications may vary by region and component composition.

Material Compliance and Safety Standards

Ensure all materials used in key chain components meet relevant safety and environmental regulations:

- REACH (EU): Comply with Registration, Evaluation, Authorisation and Restriction of Chemicals. Restrict substances such as lead, cadmium, and phthalates, particularly in metal plating and plastic materials.

- RoHS (EU): If components include electronic features (e.g., USB drives, lights), limit hazardous substances like lead, mercury, and hexavalent chromium.

- CPSIA (USA): Prohibit lead content exceeding 100 ppm in accessible component parts and ensure compliance with phthalate limits if marketed to children.

- Proposition 65 (California, USA): Provide clear warnings if products contain chemicals known to cause cancer or reproductive harm (e.g., certain metal alloys).

Maintain documentation such as Certificates of Compliance (CoC) and material test reports from suppliers.

Packaging and Labeling Requirements

Adopt sustainable and compliant packaging practices:

- Use recyclable or biodegradable materials where possible to meet environmental regulations (e.g., EU Packaging Waste Directive).

- Include required labeling: product identification, country of origin, material composition, and safety warnings (if applicable).

- For export, ensure multilingual labeling if required by destination country.

- Clearly mark fragile or high-value components to prevent damage during transit.

Import/Export Documentation

Prepare accurate documentation to facilitate customs clearance:

- Commercial Invoice

- Packing List

- Bill of Lading or Air Waybill

- Certificate of Origin (preferential or non-preferential, depending on trade agreements)

- Test Reports or Compliance Certificates (REACH, RoHS, CPSIA, etc.)

- Import Licenses (if required by destination country)

Ensure all documents reflect consistent product descriptions and HS codes.

Transportation and Handling

Optimize logistics for safe and efficient delivery:

- Use secure packaging to prevent damage during handling and shipping.

- Label shipments with proper handling instructions (e.g., “Fragile,” “Do Not Stack”).

- Choose carriers experienced in handling small hardware components to minimize loss or mix-ups.

- Consider insurance for high-value or large-volume shipments.

For international air freight, comply with IATA regulations—especially if batteries (e.g., in LED key fobs) are included.

Customs Clearance and Duties

- Pre-clear shipments by submitting documentation electronically where possible.

- Calculate landed costs including duties, taxes, and handling fees.

- Work with licensed customs brokers in destination countries to ensure compliance with local regulations.

- Monitor changes in trade agreements or tariffs that may affect component imports.

Quality Control and Traceability

- Implement quality checks at production and pre-shipment stages to ensure consistency and compliance.

- Maintain lot traceability for raw materials and finished components to support recalls or audits.

- Use unique batch or serial numbers where feasible.

Environmental and Ethical Sourcing

- Source materials from suppliers adhering to ethical labor practices (e.g., aligned with SMETA or SA8000 standards).

- Prefer vendors with environmental management systems (e.g., ISO 14001).

- Minimize waste through lean manufacturing and recycling programs.

By following this guide, businesses can ensure that key chain components are produced, transported, and sold in full compliance with global logistics and regulatory requirements. Regular audits and updates to compliance protocols are recommended to adapt to changing regulations.

Conclusion for Sourcing Key Chain Components:

Sourcing key chain components requires a strategic approach that balances quality, cost, lead time, and supplier reliability. After evaluating various materials—such as metal, plastic, silicone, and wood—and assessing manufacturing methods like die-casting, stamping, injection molding, and laser engraving, it is clear that the optimal sourcing decision depends on the intended application, design complexity, and volume requirements.

Establishing relationships with reputable suppliers, preferably those compliant with industry standards and offering proven quality control, ensures consistent product quality and on-time delivery. Additionally, considering sustainability, customization capabilities, and minimum order quantities plays a crucial role in long-term success.

In conclusion, effective sourcing of key chain components involves thorough market research, clear specification definition, and ongoing supplier evaluation. By prioritizing these factors, businesses can achieve cost-efficiency, maintain brand integrity, and meet customer expectations in a competitive market.