The global condiments and sauces market, driven by shifting consumer preferences toward convenient and flavor-enhanced food options, is experiencing steady growth—with ketchup remaining one of the most dominant segments. According to Mordor Intelligence, the global ketchup market was valued at approximately USD 19.5 billion in 2023 and is projected to grow at a CAGR of 4.3% from 2024 to 2029. A key enabler of this growth is the rising demand for premium packaging solutions, particularly glass bottles, which are favored for their aesthetic appeal, recyclability, and ability to preserve product quality. As consumer awareness of sustainability intensifies, glass packaging has seen a resurgence, especially in premium and organic ketchup segments. Grand View Research noted that the global glass packaging market reached USD 70.4 billion in 2022 and is expected to expand at a CAGR of 4.5% through 2030, supported by food and beverage industry demand. Against this backdrop, specialized glass bottle manufacturers play a pivotal role in meeting the needs of ketchup brands aiming to differentiate on shelf and align with eco-conscious values. The following list highlights the top five ketchup glass bottle manufacturers leading innovation, volume, and sustainability in this evolving landscape.

Top 5 Ketchup Glass Bottle Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Tomato Ketchup Glass Bottle

Domain Est. 1997

Website: heinz.com

Key Highlights: 3–12 day deliverySince 1876, Heinz Tomato Ketchup has been synonymous with adding flavour to your favourite foods. Heinz Tomato Ketchup is made with fresh red ripe tomatoes, ……

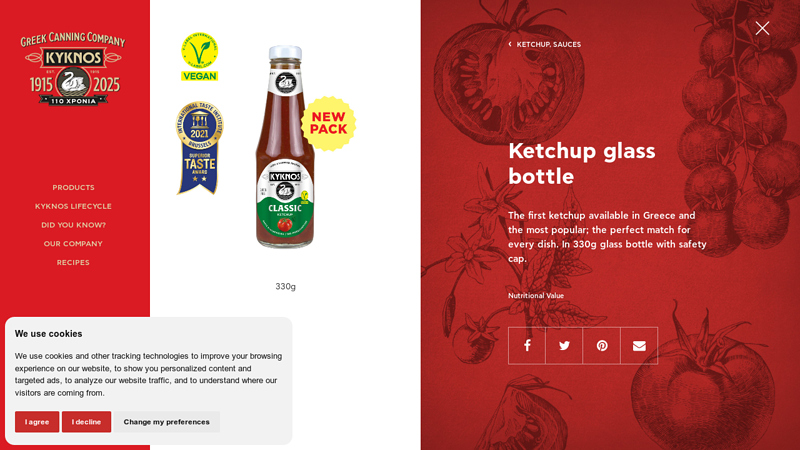

#2 Ketchup Glass Bottle

Domain Est. 2015

Website: kyknoscanning.com

Key Highlights: Ketchup glass bottle. The first ketchup available in Greece and the most popular; the perfect match for every dish. In 330g glass bottle with safety cap….

#3 Your Favorite Food Brands

Domain Est. 2015

Website: kraftheinz.com

Key Highlights: Heinz Breakfast Ketchup bottle on a red background. Ketchup is for Breakfast … Close-up of a clear glass holding colorful layered Jell-O topped with a….

#4 to the ketchup bottle of tomorrow

Domain Est. 2019

Website: pulpex.com

Key Highlights: Heinz, maker of the world’s favourite ketchup and beloved condiments, is teaming up with Pulpex to develop a paper-based, renewable and recyclable bottle….

#5 Heinz Tomato Ketchup, 24/14 oz Case (Bottle), 21 LB

Domain Est. 2020

Website: kraftheinzawayfromhome.com

Key Highlights: Heinz Ketchup 14 oz. classic glass bottles with removable caps (24 per case) are ideal for table top placement in sit-down restaurants….

Expert Sourcing Insights for Ketchup Glass Bottle

H2: 2026 Market Trends for Ketchup Glass Bottles

The global ketchup market is undergoing a transformation driven by evolving consumer preferences, sustainability demands, and packaging innovations. Within this context, glass bottles—once the dominant packaging format—are regaining traction due to shifting trends focused on premiumization, environmental responsibility, and product integrity. Here are the key market trends expected to shape the ketchup glass bottle segment in 2026:

-

Sustainability and Eco-Conscious Packaging

In 2026, sustainability will remain a primary driver in the condiments market. Consumers are increasingly favoring recyclable, reusable, and low-impact packaging. Glass bottles, being 100% recyclable and inert (non-leaching), align with eco-conscious values. Brands are leveraging glass as a “green” differentiator, particularly in premium and organic ketchup lines, to appeal to environmentally aware demographics. -

Premiumization and Brand Positioning

Glass bottles are associated with higher quality and artisanal appeal. In 2026, niche and craft ketchup brands are expected to use glass packaging to position their products as gourmet or specialty items. This trend is amplified by rising demand for natural ingredients, small-batch production, and transparent labeling—all of which complement the premium image of glass. -

Consumer Demand for Product Freshness and Shelf Life

Glass offers superior barrier properties compared to plastic, preserving flavor, color, and nutritional content over time. As consumers become more ingredient-aware, the ability of glass to maintain ketchup quality without chemical interaction will be a competitive advantage, especially for clean-label and organic variants. -

Regulatory Pressures on Single-Use Plastics

Global regulations targeting single-use plastics are influencing packaging decisions. By 2026, stricter environmental policies in regions like the EU, Canada, and parts of Asia-Pacific are expected to accelerate the shift from PET and HDPE bottles to glass alternatives. This regulatory tailwind supports the resurgence of glass in the ketchup segment. -

Innovation in Lightweight and Shatter-Resistant Glass

Advancements in glass manufacturing—such as lightweighting and improved durability—will address traditional drawbacks like weight and breakability. In 2026, these innovations will reduce transportation costs and safety concerns, making glass bottles more viable for broader distribution, including e-commerce channels. -

Growth in Foodservice and Retail Premium Segments

Upscale restaurants, gourmet delis, and premium retail outlets are increasingly adopting glass-bottled ketchup to enhance brand image and dining experience. This trend is expected to expand in 2026, supported by consumer willingness to pay a premium for aesthetically pleasing and sustainable packaging. -

Regional Market Variations

While North America and Europe lead in glass bottle adoption due to strong environmental regulations and consumer awareness, emerging markets in Latin America and Asia-Pacific are beginning to follow suit. By 2026, localized production and refill station models could emerge in urban centers, further boosting glass bottle usage.

In conclusion, the 2026 market for ketchup glass bottles is poised for growth, driven by sustainability, premiumization, and technological advancements. While challenges such as cost and logistics persist, strategic brand positioning and regulatory support will likely solidify glass as a preferred packaging format in the higher-end ketchup segment.

Common Pitfalls When Sourcing Ketchup in Glass Bottles (Quality and Intellectual Property)

Sourcing ketchup in glass bottles involves navigating both product quality and legal considerations. Overlooking these factors can lead to customer dissatisfaction, supply chain disruptions, or legal disputes. Below are key pitfalls to avoid:

Quality-Related Pitfalls

Inconsistent Product Formulation

Sourcing ketchup from multiple or unreliable suppliers may result in variations in taste, color, viscosity, or ingredient composition. This inconsistency can damage brand reputation, especially if the product is rebranded. Always require suppliers to adhere to a strict formulation specification and conduct regular batch testing.

Poor Glass Bottle Integrity

Low-quality glass bottles may have defects such as micro-cracks, uneven thickness, or weak seals, increasing the risk of breakage during transport or shelf life. Ensure suppliers follow international standards (e.g., ISO 9001) and conduct drop tests or pressure tests on packaging.

Inadequate Sterilization and Filling Processes

Contamination risks rise if the filling line is not properly sanitized. This can lead to mold growth or shortened shelf life. Audit suppliers for Good Manufacturing Practices (GMP) compliance and review their HACCP plans to confirm hygiene standards.

Label Adhesion and Durability Issues

Glass bottles exposed to moisture (e.g., refrigeration or condensation) may suffer from peeling or smudging labels. Confirm that labels are water-resistant and properly applied using durable adhesives suitable for cold and humid environments.

Insufficient Shelf Life Testing

Ketchup must maintain quality throughout its labeled shelf life. Some suppliers may overstate stability without proper accelerated aging tests. Request third-party shelf life validation reports and monitor pH and preservative levels (e.g., sodium benzoate).

Intellectual Property (IP)-Related Pitfalls

Unauthorized Use of Branding or Recipes

Sourcing generic ketchup and applying a branded label without proper rights can infringe on trademarks or trade dress. Ensure your branding, logo, and packaging design are legally protected and not mimicking established brands (e.g., Heinz).

Recipe Copying and Reverse Engineering

If you supply a custom ketchup formula to a manufacturer, there’s a risk they may replicate or sell it to competitors. Protect your recipe by using Non-Disclosure Agreements (NDAs) and work with trusted co-packers under formal IP assignment clauses.

Lack of Trademark Clearance

Launching a ketchup product with a name or logo that conflicts with existing trademarks can lead to cease-and-desist letters or litigation. Conduct comprehensive trademark searches in all target markets before finalizing branding.

Patented Packaging Designs

Some glass bottle shapes or dispensing mechanisms (e.g., inverted bottles) may be patented. Using such designs without authorization exposes you to IP infringement claims. Verify freedom-to-operate regarding bottle design and cap mechanisms.

Weak Supplier Agreements on IP Ownership

Standard manufacturing contracts may not explicitly assign IP rights to the buyer. Ensure your agreement states that all custom formulations, packaging designs, and tooling developed for your product are your sole property.

By proactively addressing these quality and IP pitfalls, businesses can protect their brand, ensure customer satisfaction, and minimize legal and operational risks when sourcing ketchup in glass bottles.

Logistics & Compliance Guide for Ketchup Glass Bottles

Product Overview and Packaging Specifications

Ketchup packaged in glass bottles requires careful consideration of packaging integrity, weight, and material compatibility. Standard packaging includes food-grade glass bottles with tamper-evident lids, often grouped in cardboard trays or shrink-wrapped multipacks. Outer shipping containers are typically corrugated cardboard cases designed to withstand stacking and transport stress. Ensure bottles are adequately cushioned with dividers or padding to prevent breakage during transit.

Transportation and Handling Requirements

Due to the fragility and weight of glass, ketchup bottles must be handled with care during all logistics stages. Use palletized loads secured with stretch wrap or strapping to prevent shifting. Avoid dropping or stacking excessive weight. Transport vehicles should be clean, dry, and temperature-controlled, especially in extreme climates, to prevent thermal shock to glass. Forklifts and material handling equipment must operate smoothly to reduce impact risks.

Storage Conditions and Shelf Life Management

Store ketchup glass bottles in a cool, dry, and well-ventilated warehouse, away from direct sunlight and heat sources. Ideal storage temperature ranges from 10°C to 25°C (50°F to 77°F). Maintain proper stock rotation using the FIFO (First In, First Out) method to ensure product freshness. Monitor expiration dates and conduct regular inventory checks to prevent spoilage or compliance issues.

Regulatory Compliance and Labeling

Ketchup must comply with food safety regulations in the destination market. In the U.S., adhere to FDA food labeling requirements under 21 CFR Part 101, including accurate ingredient listing, nutritional facts, allergen declarations (e.g., gluten or vinegar sources), net quantity, and manufacturer information. In the EU, follow EU Regulation (EU) No 1169/2011 for food information to consumers. Labels must be legible, permanent, and affixed securely to the glass bottle.

Food Safety and HACCP Considerations

Implement a Hazard Analysis and Critical Control Points (HACCP) plan to identify and mitigate risks during filling, capping, and packaging. Ensure bottling facilities maintain GMP (Good Manufacturing Practices) and are regularly audited. Glass integrity must be inspected before filling to prevent contamination. Post-filling, verify seal integrity and conduct microbiological testing as part of quality control.

Import/Export Documentation and Customs Clearance

For international shipments, prepare complete documentation including commercial invoice, packing list, bill of lading/air waybill, and certificate of origin. Depending on the destination, a phytosanitary certificate or food safety certificate may be required. Classify ketchup under the correct HS Code—typically 2103.30 for tomato-based sauces. Confirm tariff rates and import restrictions with local customs authorities.

Environmental and Sustainability Compliance

Glass packaging is recyclable, but producers and distributors must comply with local Extended Producer Responsibility (EPR) regulations where applicable. In regions such as the EU, adhere to the Packaging and Packaging Waste Directive (94/62/EC) regarding recyclability, labeling, and recovery targets. Consider lightweight glass designs and recycled content to reduce environmental impact and transportation costs.

Incident Response and Recall Preparedness

Establish a traceability system using batch/lot numbers on each bottle to enable rapid recall if contamination or labeling errors occur. Maintain a recall plan aligned with FDA or EU Rapid Alert System for Food and Feed (RASFF) requirements. Train logistics and warehouse staff on quarantine procedures and communication protocols in case of product issues.

Conclusion for Sourcing Ketchup in Glass Bottles:

Sourcing ketchup in glass bottles presents a compelling option for businesses aiming to emphasize quality, sustainability, and brand premiumness. Glass packaging enhances product preservation, maintains flavor integrity, and offers a visually appealing presentation that resonates well with eco-conscious and premium market segments. Although glass bottles typically involve higher initial costs and transportation challenges due to weight and fragility, their recyclability and consumer perception of cleanliness and authenticity often justify the investment.

Strategic sourcing requires selecting reliable suppliers with strong quality control, compliance with food safety standards, and sustainable manufacturing practices. Establishing long-term partnerships can help mitigate cost and supply chain risks. Additionally, aligning the packaging choice with brand values—such as environmental responsibility and product excellence—can strengthen customer loyalty and market differentiation.

In conclusion, sourcing ketchup in glass bottles is a viable and increasingly favorable option, especially for niche, premium, or environmentally focused brands. With careful supplier evaluation and supply chain planning, glass bottled ketchup can deliver both operational success and enhanced brand value.