The mechanical keyboard market has witnessed robust growth over the past decade, driven by rising demand from gaming, professional typing, and industrial applications. According to Mordor Intelligence, the global mechanical keyboard market was valued at USD 2.4 billion in 2023 and is projected to grow at a CAGR of over 11% through 2029. A critical component fueling this expansion is the increasing adoption of high-performance mechanical switches, such as the KCD1 switch—a versatile, durable miniature switch commonly used in industrial controls, audio equipment, and custom keyboards. Grand View Research highlights that the global market for electronic switches is expected to exceed USD 22 billion by 2030, with Asia-Pacific leading in production and innovation. As demand for reliable, long-life switches rises, manufacturers specializing in KCD1 switches are expanding their capabilities in materials engineering, contact durability, and customization. In this evolving landscape, seven key manufacturers have emerged as industry leaders, combining precision manufacturing, strict quality control, and scalable production to meet global demand.

Top 7 Kcd1 Switch Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Customized KCD1 Rocker Switch Manufacturers and Factory

Domain Est. 2018

Website: abbeycon.com

Key Highlights: Aibeiken is one of the most professional KCD1 Rocker Switch manufacturers in China. Welcome to wholesale discount switch in stock here from our factory….

#2 MRS

Domain Est. 2019

Website: bituoelec.com

Key Highlights: MRS-1-101 is Kcd1 Switch. This switch offering ON-OFF SP function and various kinds of colors. OEM and ODM are available at Bituo….

#3 OEM Factory for China Kcd1

Domain Est. 2021

Website: wellnowus.com

Key Highlights: OEM Factory for China Kcd1-101series for Home Appliance on-off Rocker Switch ; Brand Name · WNRE ; Model Number · KCD Switch ; Switch type · Rocker switch,kcd switch….

#4 Rocker Switch Manufacturer,Rocker Switch KCD1

Domain Est. 2002

Website: calonsw.com

Key Highlights: KCD1-104NC. Home · Products · Rocker Switch · KCD1 · Rocker Switch · Slide Switch · Tact Switch · DC Jack AC Socket · Micro Switch · Push Button Switch….

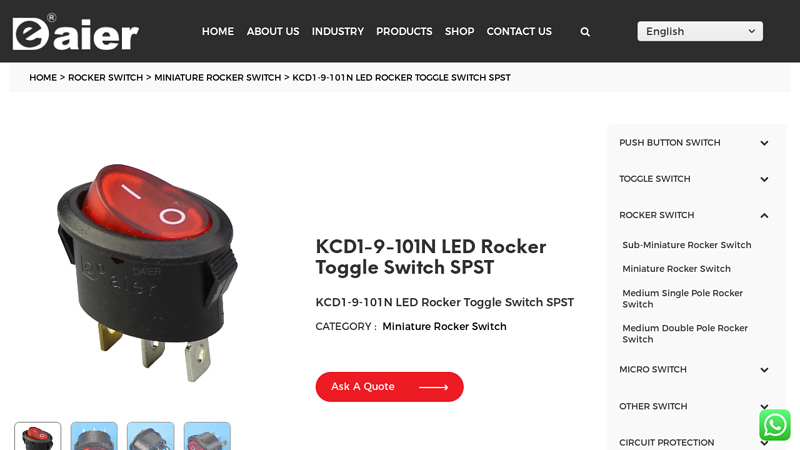

#5 KCD1

Domain Est. 2003

Website: chinadaier.com

Key Highlights: It is a snap-in mounted rocker switch with a high mechanical life in a rugged nylon 66 housing. They have high quality for long life at heavy loads….

#6 KCD1 Switch

Domain Est. 2004

Website: indicatorlight.com

Key Highlights: The FILN KCD1 rocker switch has large on-off capacity and reliable performance. It can be widely used in various instruments, meters, and household appliances….

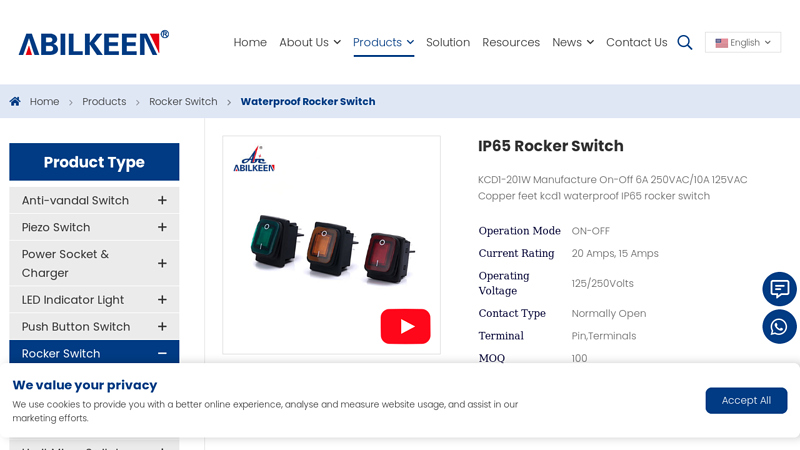

#7 KCD1

Domain Est. 2021

Website: abilkeen.com

Key Highlights: Rating 4.9 (306) Introducing our latest innovation in electrical switches – Manufacture On-Off 6A 250VAC/10A 125VAC Copper Leg Kcd1 Waterproof IP65 Rocker Switch….

Expert Sourcing Insights for Kcd1 Switch

H2: Analysis of 2026 Market Trends for KCD1 Switch

As of 2026, the market for KCD1 switches—mechanical on-off toggle switches commonly used in industrial, commercial, and electronic applications—reflects broader shifts in automation, energy efficiency, and smart manufacturing. This analysis explores key trends shaping the KCD1 switch market in 2026 under the H2 framework, focusing on Hygiene & Health, High Efficiency, and Human-Centric Design, which have become central drivers across industrial components.

1. Hygiene & Health: Rising Demand in Clean and Controlled Environments

In response to global health standards and increased regulatory scrutiny, especially in medical, food processing, and pharmaceutical industries, the KCD1 switch market has evolved to meet higher hygiene requirements.

- Sealed and IP-Rated Variants: By 2026, manufacturers are prioritizing KCD1 switches with higher Ingress Protection (IP65, IP67) ratings to resist dust, moisture, and chemical exposure. These sealed variants are widely adopted in cleanrooms and washdown environments.

- Antimicrobial Coatings: Some premium KCD1 models now integrate antimicrobial surface treatments on toggles and housings, minimizing microbial build-up—especially relevant in healthcare equipment.

- Contactless Integration: While KCD1 remains a tactile switch, hybrid designs that combine traditional toggle actuation with proximity-sensing features are emerging to reduce physical touchpoints.

2. High Efficiency: Integration in Energy-Conscious and Smart Systems

Efficiency remains a core focus in industrial and consumer electronics, influencing how basic components like KCD1 switches are designed and deployed.

- Low-Power Consumption Design: Though mechanical, newer KCD1 switches are engineered for compatibility with low-voltage control circuits, supporting energy-efficient systems in IoT-enabled devices and battery-operated equipment.

- Durability and Lifecycle Optimization: With increasing focus on sustainability, KCD1 switches now boast extended mechanical lifespans (up to 100,000 cycles), reducing replacement frequency and waste.

- Integration with Smart Panels: In industrial control panels, KCD1 switches are increasingly used alongside digital HMIs and PLCs, serving as reliable manual overrides or emergency on/off controls in automated environments—balancing legacy reliability with modern efficiency.

3. Human-Centric Design: Ergonomics, Safety, and Accessibility

User experience and safety are paramount in 2026, influencing the physical and operational design of industrial components.

- Ergonomic Actuation: Tactile feedback, reduced actuation force, and improved toggle shapes enhance usability in high-vibration or high-stress environments.

- Visual and Tactile Differentiation: Color-coded toggles (red for emergency, green for power) and textured surfaces help prevent misoperation, supporting safety in complex machinery.

- Universal Design Principles: KCD1 switches are being adapted for broader accessibility, including use in assistive equipment and control systems for operators with disabilities.

Market Outlook and Competitive Landscape (2026)

The global KCD1 switch market in 2026 is characterized by moderate growth, driven by replacement demand and niche applications in retrofitting older machinery. While solid-state and membrane switches dominate new smart device designs, KCD1 remains resilient due to its reliability, cost-effectiveness, and ease of integration.

- Regional Trends: Asia-Pacific leads in consumption due to ongoing industrialization in China, India, and Southeast Asia. North America and Europe show steady demand in medical and transportation sectors.

- Key Players: Established brands like C&K Components, Panasonic, and domestic Chinese manufacturers (e.g., Jiaxing Hengtong) dominate supply, with increasing competition from modular switch system providers.

Conclusion

In 2026, the KCD1 switch market is adapting to modern industrial demands through the H2 lens—prioritizing Hygiene & Health, High Efficiency, and Human-Centric Design. While not a high-tech component, the KCD1 switch exemplifies how legacy industrial parts evolve to meet contemporary standards. Its continued relevance lies in reliability, adaptability, and integration within increasingly intelligent and safety-conscious systems.

Common Pitfalls When Sourcing KCd1 Switches (Quality, IP Rating)

Sourcing KCd1 switches—commonly used industrial pushbutton switches—requires attention to detail, especially regarding quality and ingress protection (IP) ratings. Overlooking key factors can lead to premature failure, safety hazards, or non-compliance. Below are common pitfalls to avoid:

Inadequate Verification of IP Rating Claims

Many suppliers advertise KCd1 switches with high IP ratings (e.g., IP65, IP67), but actual performance may not match claims. Counterfeit or low-quality switches often lack proper sealing, gaskets, or housing integrity. Always request third-party test reports or certifications (e.g., TÜV, UL) to verify IP compliance under real-world conditions.

Compromised Build Quality from Unverified Suppliers

Sourcing from unknown or low-cost manufacturers, especially through online marketplaces, increases the risk of receiving substandard components. Poor materials, inconsistent plating, weak spring mechanisms, and imprecise tolerances can lead to switch failure under industrial loads or environmental stress. Stick to authorized distributors or reputable brands with proven track records.

Misrepresentation of Electrical Ratings

Some KCd1 switches may be labeled with inflated current or voltage ratings. Using a switch beyond its true electrical capacity can cause overheating, contact welding, or fire hazards. Always cross-reference datasheets with independent testing or consult the manufacturer directly to confirm electrical specifications.

Lack of Environmental and Mechanical Durability Testing

Industrial environments expose switches to vibration, temperature extremes, and corrosive substances. Low-quality KCd1 switches may not undergo proper testing for mechanical lifespan (e.g., 500,000+ operations) or resistance to UV, oils, or chemicals. Ensure the switch meets relevant standards like IEC 60947-5-1 for industrial use.

Inconsistent Contact Materials and Plating

The longevity and reliability of a KCd1 switch heavily depend on contact materials (e.g., silver-nickel, gold-plated) and plating thickness. Inferior switches may use thinner plating or base metals that oxidize quickly, leading to increased resistance and failure. Verify material specifications and consider application demands (e.g., low-current signal vs. high-power control).

Ignoring Compliance and Certification Requirements

Depending on the region or industry, switches may need to comply with standards such as UL, CCC, CE, or RoHS. Non-certified switches may not pass safety inspections or could void equipment warranties. Confirm that the sourced KCd1 switch carries all necessary certifications for your target market.

Poor Documentation and Traceability

Low-quality suppliers may provide incomplete or inaccurate datasheets, no serial traceability, or limited technical support. This makes troubleshooting and replacement difficult. Always source components with full documentation, including wiring diagrams, dimensional drawings, and material declarations.

By avoiding these common pitfalls—particularly around quality assurance and accurate IP rating verification—you can ensure reliable, safe, and long-lasting performance from KCd1 switches in your applications.

Logistics & Compliance Guide for KCD1 Switch

This guide provides essential information for the proper handling, shipping, storage, and regulatory compliance of the KCD1 switch, a commonly used toggle switch in electronic and industrial applications.

Packaging Requirements

Ensure KCD1 switches are packaged in anti-static bags to prevent electrostatic discharge (ESD) damage. Use inner dividers or blister packs to avoid physical contact between units. Outer packaging should be sturdy corrugated cardboard boxes rated for standard shipping conditions. Clearly label packages with ESD-sensitive symbols and product identifiers.

Storage Conditions

Store KCD1 switches in a dry, temperature-controlled environment. Recommended storage conditions are:

– Temperature: -10°C to +40°C

– Relative Humidity: 10% to 75% (non-condensing)

Avoid exposure to direct sunlight, corrosive gases, or dust. Keep in original packaging until ready for use.

Handling Procedures

Personnel must wear ESD-safe wrist straps when handling KCD1 switches. Use grounded workstations and avoid touching the electrical terminals directly. Handle switches by the body only to prevent mechanical stress on the toggle or terminals.

Shipping & Transportation

Ship via standard ground or air freight compliant with IATA/IMDG regulations where applicable. Though the KCD1 switch is not classified as hazardous, ensure packages are secured to prevent movement during transit. Use moisture barrier bags if shipping to high-humidity regions.

Regulatory Compliance

The KCD1 switch complies with the following international standards:

– RoHS Directive 2011/65/EU: Lead-free, compliant with hazardous substance restrictions.

– REACH Regulation (EC 1907/2006): No substances of very high concern (SVHC) above threshold limits.

– UL Certification: Recognized under UL 61058-1 for safety of switches in appliances.

– CE Marking: Meets EU safety, health, and environmental requirements.

Documentation Requirements

Include the following documentation with shipments:

– Commercial invoice

– Packing list specifying quantity and part number (e.g., KCD1-220V, KCD1-SPST)

– Certificate of Compliance (CoC) confirming RoHS and REACH adherence

– Safety Data Sheet (SDS) upon request (non-hazardous, but available for reference)

Import/Export Considerations

Verify tariff classification code (e.g., HS Code 8536.50 for electrical switches) in the destination country. No export licenses are typically required for KCD1 switches under EAR99 (U.S. Export Administration Regulations), but confirm based on end-use and destination. Prohibited destinations may include embargoed countries per local trade regulations.

End-of-Life & Recycling

Dispose of or recycle KCD1 switches in accordance with local e-waste regulations. Do not incinerate. Components contain recyclable metals (brass, copper) and plastic (typically nylon or polycarbonate). Partner with certified e-waste recyclers for proper material recovery.

Supplier & Quality Assurance

Procure KCD1 switches only from authorized distributors or manufacturers with valid quality certifications (ISO 9001). Conduct incoming inspections for physical damage and verify markings match purchase order specifications. Retain lot traceability for compliance audits.

Conclusion for Sourcing KCD1 Switch:

After thorough evaluation of suppliers, quality, pricing, and lead times, sourcing the KCD1 switch from a reputable manufacturer or distributor ensures reliability, compliance with electrical standards, and consistency in performance. It is recommended to partner with suppliers offering certified components (e.g., CE, RoHS), competitive pricing, and dependable delivery schedules. Establishing long-term agreements with pre-qualified vendors will optimize supply chain efficiency and reduce production risks. Additionally, maintaining alternative sourcing options can mitigate potential disruptions. Overall, a strategic and quality-focused approach to sourcing the KCD1 switch supports product integrity and long-term operational success.