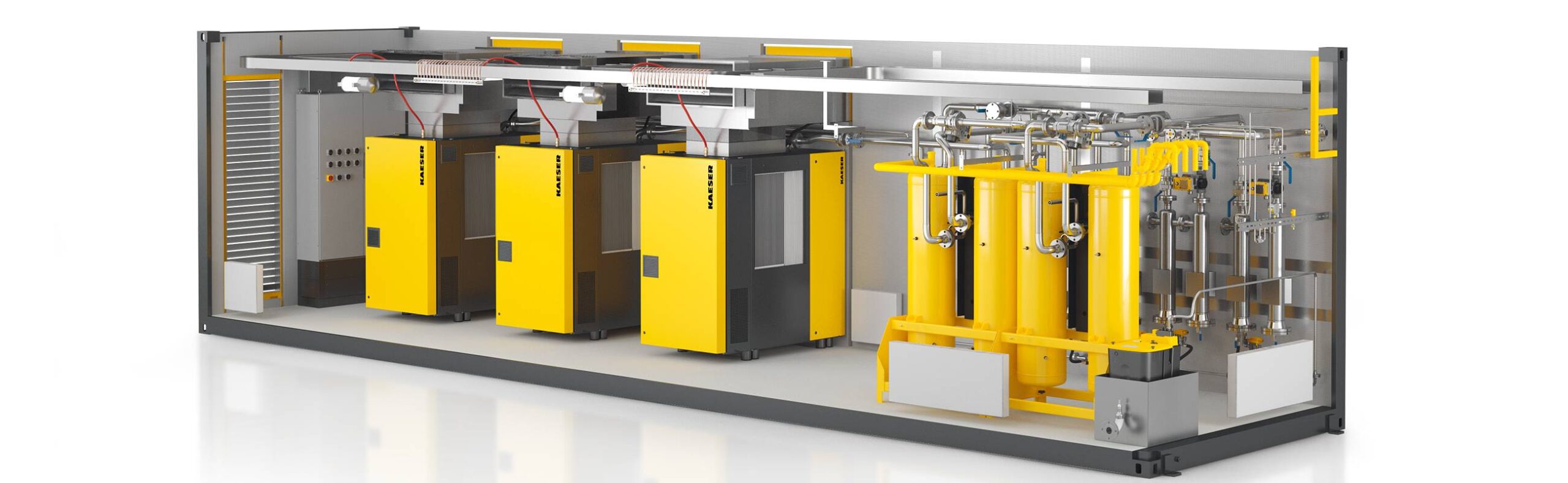

The global air compressor market, valued at USD 28.5 billion in 2022, is projected to grow at a CAGR of 4.1% through 2030, driven by rising industrial automation, manufacturing expansion, and demand for energy-efficient compressed air systems (Grand View Research, 2023). Within this evolving landscape, Kaeser Kompressoren SE—ranked among the top-tier compressor OEMs—relies on a robust network of precision component suppliers to maintain its reputation for reliability and performance. As industries from automotive to pharmaceuticals increasingly depend on continuous compressed air supply, the demand for high-quality, OEM-aligned parts such as airends, control systems, and filtration units has intensified. This growing need has elevated the strategic importance of specialized manufacturers capable of meeting Kaeser’s stringent engineering and quality standards. Based on supply chain analysis, production capacity, and alignment with Kaeser’s global service infrastructure, the following three manufacturers stand out as leading suppliers of critical compressor components.

Top 3 Kaeser Compressor Parts Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 KAESER KOMPRESSOREN

Domain Est. 1996

Website: kaeser.com

Key Highlights: KAESER is one of the world’s leading manufacturers and providers of compressed air systems. With the motto: “More compressed air for less energy”, ……

#2 Genuine OEM Replacement Kaeser Air Compressor Parts

Domain Est. 2009

Website: oemaircompressor.com

Key Highlights: Genuine OEM Replacement Kaeser Air Compressor Parts including oils, filters, separators, pumps, elements, repair kits, and maintenance kits….

#3 Kaeser Compressors Customer Service

Domain Est. 1996

Website: us.kaeser.com

Key Highlights: Maintenance and repair parts: Click here for details on how to get genuine Kaeser parts. Manuals: Looking for manual for your Kaeser product? Request a PDF ……

Expert Sourcing Insights for Kaeser Compressor Parts

H2: 2026 Market Trends for Kaeser Compressor Parts

The global market for industrial air compressor components is poised for significant transformation by 2026, driven by technological advancements, sustainability mandates, and evolving industrial automation. For a leading manufacturer like Kaeser Kompressoren SE, known for its high-quality compressor systems and parts, these shifts present both opportunities and strategic imperatives. Below is an analysis of key market trends expected to shape demand and competition for Kaeser compressor parts in 2026.

-

Increasing Demand for Energy-Efficient Components

Energy efficiency remains a dominant driver in the industrial compressor market. With rising energy costs and stricter regulatory standards—such as the EU’s Ecodesign Directive and U.S. DOE efficiency regulations—end users are prioritizing compressor systems with lower total cost of ownership (TCO). Kaeser’s reputation for energy-optimized rotary screw compressors and intelligent control systems positions its aftermarket parts (e.g., airend rebuild kits, VSD drives, and cooling units) for strong demand. Replacement parts that enhance efficiency, such as low-friction rotors and high-performance air/oil separators, will see growing adoption. -

Growth in Predictive Maintenance and IoT Integration

By 2026, predictive maintenance is expected to be standard in industrial settings. Kaeser’s SIGMA CONTROL SMART and SIGMA AIR MANAGER systems already support IoT connectivity, enabling real-time monitoring of compressor health. This trend increases demand for smart-ready replacement parts equipped with sensors or compatible with digital diagnostics. Parts like motor bearings, oil filters, and intake valves will increasingly be sold as part of integrated predictive maintenance kits, where data-driven insights trigger part replacements before failure occurs. -

Expansion of Aftermarket and Remanufactured Parts

As industries seek cost-effective maintenance solutions, the aftermarket for compressor parts is expanding rapidly. Kaeser’s Certified Remanufactured Parts program, which offers factory-rebuilt airends, motors, and controls with full warranty, aligns well with this trend. In 2026, circular economy principles and corporate sustainability goals will further boost demand for remanufactured and refurbished components. Kaeser’s emphasis on quality control and traceability gives it a competitive edge in this segment. -

Regional Industrial Growth in Asia-Pacific and Emerging Markets

Industrialization in countries like India, Vietnam, and Indonesia is driving air compressor demand. These markets require durable, serviceable compressor parts due to harsh operating conditions and intermittent maintenance. Kaeser’s global service network and localized distribution of critical spare parts (e.g., inlet valves, couplings, and cooling fans) will be essential to capturing market share. Additionally, investments in local service centers will support faster turnaround for part repairs and replacements. -

Supply Chain Resilience and Localization

Post-pandemic supply chain disruptions have prompted manufacturers to reevaluate sourcing strategies. By 2026, Kaeser is expected to strengthen regional supply chains and increase inventory of high-turnover parts in strategic hubs. 3D printing and on-demand manufacturing may also play a role in producing low-volume, complex parts (e.g., custom manifolds or brackets), reducing lead times and improving customer satisfaction. -

Electrification and Shift Toward Oil-Free Technologies

Growing demand in food & beverage, pharmaceuticals, and electronics industries is accelerating the shift toward oil-free compressors. This trend increases demand for specialized parts such as PTFE-coated rotors, advanced air-end seals, and corrosion-resistant filtration systems. Kaeser’s expertise in oil-free screw and scroll compressors positions its parts division to benefit from this high-growth niche. -

Regulatory and Environmental Compliance

Environmental regulations targeting greenhouse gas emissions and refrigerant use (e.g., F-gas regulations) will influence compressor design and component materials. Kaeser parts made with recyclable materials or lower environmental impact—such as biodegradable gaskets or low-emission coatings—will gain preference. Compliance-ready parts will be a differentiator in regulated industries.

Conclusion

By 2026, the market for Kaeser compressor parts will be shaped by digitalization, sustainability, and regional industrial growth. Success will depend on Kaeser’s ability to leverage its brand reputation for reliability, expand its digital service ecosystem, and offer a comprehensive portfolio of efficient, smart, and sustainable replacement components. Strategic investments in remanufacturing, predictive maintenance integration, and supply chain localization will be critical to maintaining market leadership.

Common Pitfalls Sourcing Kaeser Compressor Parts (Quality, IP)

Sourcing genuine Kaeser compressor parts is critical to ensuring the reliability, efficiency, and longevity of your compressed air systems. However, many businesses encounter significant challenges related to part quality and intellectual property (IP) when procuring these components. Below are the most common pitfalls:

1. Risk of Counterfeit or Substandard Parts

One of the biggest risks when sourcing Kaeser parts is inadvertently purchasing counterfeit or low-quality aftermarket alternatives. These parts may mimic the appearance of genuine components but often fail to meet Kaeser’s engineering standards. Consequences include:

- Reduced compressor performance and efficiency

- Increased downtime due to premature failure

- Voided warranties when non-genuine parts are used

- Safety hazards in high-pressure environments

Always verify the supplier’s authorization and request documentation proving part authenticity.

2. Lack of OEM Certification and Traceability

Genuine Kaeser parts are manufactured under strict ISO-certified processes with full traceability. Unauthorized suppliers may not provide batch numbers, certificates of conformance, or manufacturing data. Without this, businesses face:

- Inability to audit part origins during compliance checks

- Challenges in diagnosing failures or managing recalls

- Exposure to regulatory non-compliance in regulated industries (e.g., food & beverage, pharmaceuticals)

Ensure parts are sourced from Kaeser-authorized distributors or directly through Kaeser’s global network.

3. Intellectual Property (IP) Infringement

Manufacturing or distributing parts that replicate patented Kaeser designs may infringe on intellectual property rights. Using such parts exposes end-users and resellers to legal risks, including:

- Lawsuits for IP violation

- Seizure of infringing inventory

- Damage to brand reputation and business relationships

Even if a part appears functionally equivalent, design patents, trademarks, and technical specifications are legally protected.

4. Incompatibility and System Integration Issues

Aftermarket or reverse-engineered parts may not align precisely with Kaeser’s system specifications. This can lead to:

- Improper fit or alignment causing mechanical stress

- Inaccurate pressure or temperature control

- Communication failures in smart monitoring systems (e.g., Sigma Control)

Only genuine parts are guaranteed to integrate seamlessly with Kaeser’s digital and mechanical ecosystems.

5. Voided Warranty and Lost Support

Kaeser typically voids equipment warranties if non-genuine parts cause damage. Additionally, technical support may be refused during troubleshooting if unauthorized components are detected. This results in:

- Higher long-term maintenance costs

- Extended downtime

- Reduced return on investment

Always consult Kaeser or an authorized service partner before replacing critical components.

Conclusion

To avoid quality compromises and IP-related legal exposure, prioritize sourcing Kaeser compressor parts from official channels. Investing in genuine components ensures operational reliability, compliance, and protection against hidden risks.

Logistics & Compliance Guide for Kaeser Compressor Parts

This guide outlines the essential logistics and compliance procedures for handling Kaeser compressor parts to ensure efficient operations, regulatory adherence, and customer satisfaction.

Order Processing and Documentation

Ensure all purchase orders are verified for part numbers, quantities, and delivery requirements. Use Kaeser-approved systems to process orders promptly. Maintain accurate records including order confirmations, packing slips, and invoices. All documentation must comply with local and international trade standards, including correct HS codes and origin declarations.

Packaging and Labeling Standards

Kaeser parts must be packaged according to company specifications to prevent damage during transit. Use anti-static and moisture-resistant materials where applicable. Each package must include a clear label with part number, serial number (if applicable), batch/lot number, quantity, destination, and handling instructions (e.g., “Fragile,” “This Side Up”). Labels must be durable and machine-readable when required.

Shipping and Transportation

Select carriers certified for precision industrial components. Prioritize temperature-controlled and shock-monitored options for sensitive parts. For international shipments, coordinate with freight forwarders experienced in industrial equipment logistics. All shipments must include proper airway bills, bills of lading, or e-CMRs, as appropriate. Ensure real-time tracking is available and shared with the recipient.

Import/Export Compliance

Adhere strictly to export control regulations, including EAR (Export Administration Regulations) and ITAR (if applicable). Verify end-user information and obtain necessary export licenses for restricted destinations. Complete accurate commercial invoices, packing lists, and certificates of origin. Ensure compliance with customs requirements in both origin and destination countries to prevent delays.

Storage and Inventory Management

Store parts in secure, climate-controlled environments with appropriate racking and inventory zoning. Follow FIFO (First In, First Out) or FEFO (First Expired, First Out) principles where applicable. Conduct regular cycle counts and audits to maintain inventory accuracy. Use Kaeser’s inventory management system to track stock levels, shelf life, and reordering points.

Regulatory and Environmental Compliance

Dispose of packaging and obsolete parts in accordance with local environmental regulations. Recycle materials such as cardboard, plastic, and metal whenever possible. Maintain records of waste disposal and recycling activities. Ensure all operations comply with REACH, RoHS, and other applicable environmental directives.

Quality Assurance and Traceability

Maintain full traceability of parts from supplier to end customer. Retain batch records, inspection reports, and certificates of conformance for a minimum of seven years. Report any non-conforming materials immediately through Kaeser’s quality management system. Conduct regular internal audits to verify compliance with ISO 9001 and ISO 14001 standards.

Emergency and Contingency Procedures

Establish protocols for handling logistics disruptions, including natural disasters, customs delays, or carrier failures. Maintain a list of alternate suppliers and shipping routes. Communicate proactively with customers during delays and provide revised delivery timelines. Keep backup inventory of critical spare parts to ensure service continuity.

Conclusion for Sourcing Kaeser Compressor Parts:

Sourcing genuine Kaeser compressor parts is essential for maintaining the performance, reliability, and longevity of your compressed air systems. Due to Kaeser’s reputation for engineering excellence and high-quality manufacturing, using authentic components ensures optimal efficiency, reduces downtime, and helps maintain compliance with warranty requirements. While alternative or aftermarket parts may appear cost-effective initially, they often compromise system integrity and can lead to increased maintenance costs and operational failures over time.

Establishing relationships with authorized Kaeser distributors or directly sourcing from Kaeser’s global service network ensures access to OEM parts, technical support, and up-to-date product information. Additionally, leveraging Kaeser’s digital tools and part identification systems streamlines the procurement process and minimizes the risk of ordering incorrect components.

In conclusion, a strategic and proactive approach to sourcing genuine Kaeser compressor parts not only supports continuous operational efficiency but also contributes to long-term cost savings and system reliability. Prioritizing authenticity and expert support is a wise investment in the sustained performance of your compressed air infrastructure.