The global industrial sewing machine market is experiencing steady growth, driven by rising demand from the apparel, automotive, and technical textiles sectors. According to a report by Mordor Intelligence, the market was valued at USD 3.8 billion in 2023 and is projected to grow at a CAGR of 4.2% from 2024 to 2029. This expansion is fueled by increased automation in garment manufacturing, the need for high-speed and precision stitching, and growing investments in smart factory technologies. Among the specialized machines gaining traction, walking foot industrial sewing machines—particularly those under the Juki brand—are in high demand due to their superior material handling, consistent stitch quality, and durability in heavy-duty applications. Originally developed to manage thick or layered fabrics without slippage, Juki’s walking foot technology has become a benchmark in industrial sewing performance. As demand rises, several manufacturers have emerged as leaders in producing and innovating Juki-compatible or Juki-branded walking foot machines. Based on market presence, production volume, technological advancements, and distribution reach, the following six manufacturers stand out in the competitive landscape.

Top 6 Juki Walking Foot Industrial Sewing Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Juki America

Domain Est. 2010

Website: jukihome.com

Key Highlights: Juki America. Our Latest Sewing, Serging, and Quilting Machines. JUKI Quilting Machines. built with industrial sewing machine technology. Learn More. Mechanical….

#2 Industrial and Commercial Sewing Machines

Domain Est. 1995

Website: juki.com

Key Highlights: Explore JUKI’s industrial and commercial machines for apparel, non-apparel, automated, and digital sewing solutions. Innovation and precision for every …Missing: walking foot…

#3 Juki UK Sewing Machines

Domain Est. 2007

Website: jukiuk.com

Key Highlights: See the Juki sewing machines, overlockers, coverstitch machines and semi-industrial machines used on Dress the Nation series 1 and 2….

#4 Industrial Juki Sewing Machines

Domain Est. 2018

#5 Jacksew

Domain Est. 2021

Website: jacksew.com

Key Highlights: Free delivery 30-day returnsJUKI LU-2828V-7 Fully Automatic Single Needle Compound Walking Foot 2.7 X-Large Hook Industrial Sewing Machine with Table and Motor · Speedway SW82440 S…

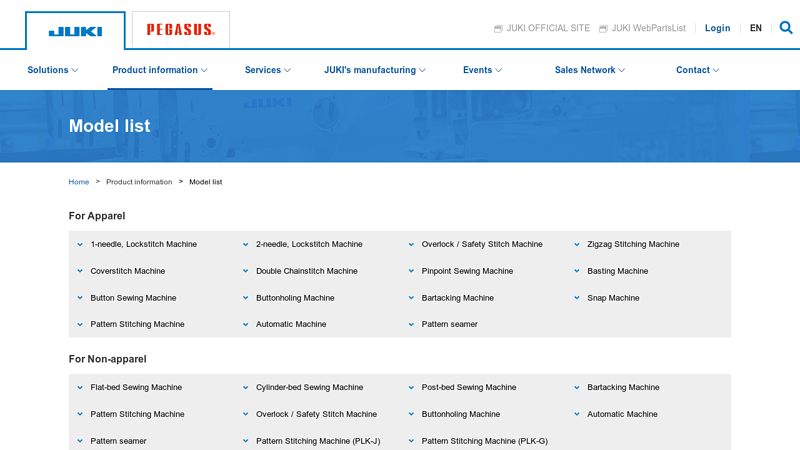

#6 Model list

Website: juki.co.jp

Key Highlights: This list shows product models of industrial sewing machines from JUKI….

Expert Sourcing Insights for Juki Walking Foot Industrial Sewing Machine

H2: 2026 Market Trends for Juki Walking Foot Industrial Sewing Machines

The global market for industrial sewing machines, particularly specialized models like the Juki walking foot industrial sewing machine, is expected to experience significant shifts by 2026, driven by technological advancements, evolving manufacturing demands, and regional industrial growth. Juki, a well-established name in the textile machinery industry, is poised to benefit from several key trends shaping the sector.

1. Rising Demand in Apparel and Technical Textiles

The apparel manufacturing sector remains a primary driver for industrial sewing equipment. By 2026, increasing global apparel production—especially in emerging economies such as Bangladesh, Vietnam, and India—is expected to boost demand for high-efficiency, durable sewing machines. Juki walking foot machines, known for their ability to handle thick, layered, or slippery fabrics with precision, are increasingly favored in outerwear, denim, and bag manufacturing. Additionally, growth in technical textiles (e.g., automotive upholstery, protective gear, and geotextiles) will further expand the use cases for walking foot technology.

2. Automation and Smart Manufacturing Integration

Industry 4.0 trends are transforming textile production. By 2026, manufacturers will increasingly adopt smart sewing systems with IoT connectivity, real-time diagnostics, and automated feeding mechanisms. Juki has been investing in servo motor technology and programmable stitching options, and future models are likely to offer enhanced integration with factory-wide production management systems. This shift supports lean manufacturing, reduces downtime, and improves consistency—key selling points for large-scale producers.

3. Focus on Energy Efficiency and Sustainability

With growing regulatory and consumer pressure for sustainable manufacturing, energy-efficient machines are gaining prominence. Juki’s servo-driven walking foot models, which consume less power compared to clutch motors, align well with this trend. By 2026, demand is expected to rise for sewing machines that reduce energy consumption, noise levels, and waste—factors that also contribute to lower operational costs and better working environments.

4. Regional Market Shifts and Supply Chain Reconfiguration

Due to geopolitical factors and post-pandemic supply chain recalibration, nearshoring and friend-shoring are influencing production locations. North America and Europe are seeing a modest resurgence in localized garment manufacturing, particularly for fast fashion and custom orders. This trend increases demand for reliable, high-performance machines like Juki’s walking foot models in smaller, agile factories. Meanwhile, Southeast Asia will remain a dominant market, supported by government incentives and expanding industrial zones.

5. Competitive Landscape and After-Sales Services

While Juki faces competition from brands like Brother, Jack, and ZOJE, its reputation for durability and precision gives it a strong foothold. By 2026, the competitive edge will increasingly depend on after-sales service, training, and parts availability. Juki’s global service network and partnerships with local distributors will be crucial in maintaining market share, especially in regions with limited technical support infrastructure.

Conclusion

By 2026, the market for Juki walking foot industrial sewing machines will be shaped by automation, sustainability, and shifting manufacturing geographies. Juki is well-positioned to capitalize on these trends through continued innovation, energy-efficient designs, and strong support networks. As industries demand greater precision and efficiency in heavy-duty sewing applications, Juki’s walking foot models are expected to remain a preferred choice across apparel, footwear, and technical textile sectors.

Common Pitfalls When Sourcing a Juki Walking Foot Industrial Sewing Machine (Quality & IP)

Sourcing industrial sewing machines, especially high-performance models like the Juki walking foot machine, requires careful attention to avoid quality compromises and intellectual property (IP) issues. Here are the most common pitfalls to watch for:

Purchasing Counterfeit or Clone Machines

One of the biggest risks is inadvertently buying a counterfeit or unauthorized clone of a genuine Juki machine. These machines often mimic the branding and appearance of authentic Juki models but use inferior materials, substandard components, and lack proper engineering. They typically underperform, require frequent repairs, and can damage materials due to inconsistent stitch quality. Always verify authenticity through authorized distributors and check for official serial numbers and documentation.

Dealing with Unauthorized Resellers or Grey Market Imports

Purchasing from unauthorized resellers or grey market sources may offer lower prices but comes with significant risks. These machines may not meet regional safety or electrical standards, lack proper warranty coverage, and could be used, refurbished, or reconditioned units misrepresented as new. Additionally, support and spare parts availability can be severely limited or nonexistent.

Overlooking Machine Specifications and Application Fit

Not all walking foot machines are the same. Juki offers various models tailored for specific applications (e.g., heavy leather, upholstery, synthetic fabrics). Sourcing the wrong model can lead to poor performance, premature wear, and production delays. Ensure the machine’s feed mechanism, motor power, stitch type, and throat space match your exact production needs.

Ignoring Intellectual Property (IP) and Brand Licensing

Counterfeit machines often violate Juki’s intellectual property rights, including trademarks, design patents, and technical innovations. Supporting such products not only risks legal exposure but also undermines innovation and quality standards. Always confirm that the supplier respects IP laws and provides genuine, licensed equipment.

Compromising on Build Quality and Component Sourcing

Genuine Juki machines are manufactured with precision engineering and high-grade components. Clones often use cheaper alternatives—such as lower-quality gears, motors, and castings—which lead to increased downtime, higher maintenance costs, and reduced lifespan. Inspect build quality carefully and ask about component origins when possible.

Lack of After-Sales Support and Spare Parts Availability

Even if the initial machine appears authentic, sourcing from unreliable channels can result in poor access to technical support, training, and genuine spare parts. Downtime in industrial settings is costly, so ensure your supplier offers reliable maintenance services and a consistent supply of OEM parts.

Falling for Misleading Marketing or Fake Certifications

Some sellers use fake certifications, forged documentation, or misleading product descriptions to appear legitimate. Verify certifications (such as CE, UL, or ISO) independently and cross-check model numbers with Juki’s official product lineup to avoid being misled.

By avoiding these common pitfalls, you can ensure you invest in a genuine, high-quality Juki walking foot machine that delivers reliability, performance, and long-term value. Always source through authorized channels and conduct due diligence on suppliers to protect your business and uphold ethical manufacturing standards.

Logistics & Compliance Guide for Juki Walking Foot Industrial Sewing Machine

Product Overview

The Juki Walking Foot Industrial Sewing Machine is a heavy-duty sewing solution designed for high-volume production environments. It is commonly used in the manufacturing of thick or layered materials such as leather, canvas, upholstery, and automotive textiles. The integrated walking foot mechanism ensures consistent feed and stitch quality, reducing fabric shifting during operation.

Shipping & Handling

Packaging

- The machine is shipped in a reinforced wooden crate or heavy-duty cardboard packaging with internal foam or plastic supports to prevent movement.

- All accessories (foot pedal, power cord, oil, needles, wrenches) are packaged in a separate compartment or box within the main crate.

- Ensure packaging remains intact until the machine is ready for installation.

Transport Considerations

- Use a pallet jack or forklift for unloading; the machine typically weighs between 35–50 kg (77–110 lbs) depending on the model.

- Avoid tilting the machine more than 10 degrees during transport to prevent oil leakage from the lubrication system.

- Store in a dry, temperature-controlled environment during transit to prevent condensation and moisture damage.

Delivery Verification

- Inspect packaging for visible damage before signing the delivery receipt.

- Verify the model number, serial number, and included accessories against the packing slip.

- Report any discrepancies or damage to the carrier and supplier immediately.

Import & Export Compliance

Harmonized System (HS) Code

- Typical HS Code: 8452.21.00 (Sewing machines, other than household; industrial)

- Confirm applicable code with local customs authority, as classifications may vary by country.

Documentation Requirements

- Commercial Invoice: Must include product description, value, weight, country of origin (Japan or Vietnam, depending on model), and buyer/seller details.

- Packing List: Itemized list of contents, packaging type, dimensions, and gross/net weights.

- Bill of Lading/Air Waybill: Required for freight tracking and customs clearance.

- Certificate of Origin: May be required for tariff determination; provided by Juki or authorized distributor.

Import Duties & Taxes

- Import duties vary by destination country. Consult local customs for current rates.

- Value Added Tax (VAT) or Goods and Services Tax (GST) typically applies to the total landed cost (product + shipping + insurance + duties).

- Some countries may require an import license for industrial machinery.

Safety & Regulatory Compliance

Electrical Compliance

- The machine must comply with electrical standards in the destination country:

- North America: UL/CSA certification (model-specific)

- Europe: CE marking per Machinery Directive 2006/42/EC and Low Voltage Directive 2014/35/EU

- Australia/New Zealand: RCM mark per AS/NZS 60204.1

- Voltage and frequency must match local supply (e.g., 110V/60Hz, 220V/50Hz). Use of voltage converters may be necessary.

Machine Safety Standards

- Complies with ISO 13849-1 (Safety of machinery — Safety-related parts of control systems)

- Equipped with emergency stop button, safety shield over drive belt, and foot pedal guard

- Users must follow Juki’s safety instructions and conduct routine maintenance

Installation & Operational Compliance

Setup Environment

- Install on a stable, level table or industrial stand.

- Provide adequate ventilation; avoid dusty or humid environments.

- Ensure proper grounding of electrical supply to prevent shock hazards.

Operator Training

- Only trained personnel should operate the machine.

- Training must include threading, tension adjustment, maintenance, and emergency shutdown procedures.

- Use appropriate personal protective equipment (PPE), including safety glasses and cut-resistant gloves when handling needles.

Maintenance & Documentation

- Follow Juki’s recommended maintenance schedule (daily oiling, monthly cleaning, annual inspection).

- Keep a maintenance log for audit and compliance purposes.

- Use only genuine Juki replacement parts and lubricants.

Disposal & Environmental Compliance

End-of-Life Disposal

- Recycle metal components through certified e-waste or industrial recycling programs.

- Dispose of electrical cables and motors in accordance with local environmental regulations (e.g., WEEE Directive in the EU).

- Do not incinerate plastic or electronic parts.

Lubricant Management

- Use biodegradable sewing machine oil where possible.

- Collect and dispose of waste oil through licensed hazardous waste handlers.

Contact Information & Support

- For compliance documentation or technical support, contact:

- Juki Corporation Global Support: [email protected]

- Regional Distributor (varies by country)

- Keep warranty and compliance certificates on file for audit purposes.

Note: Regulations vary by jurisdiction. Always verify requirements with local authorities before importing, installing, or operating the machine.

Conclusion:

After thorough research and evaluation, sourcing a Juki walking foot industrial sewing machine proves to be a highly beneficial investment for businesses requiring durable, high-performance sewing solutions, especially for heavy-duty, thick, or layered materials such as leather, denim, and upholstery. The Juki brand is renowned for its reliability, precision engineering, and consistent stitch quality, making it a preferred choice among professionals in the garment, footwear, and automotive industries.

The walking foot mechanism in Juki’s industrial models ensures smooth feeding of multiple fabric layers without slipping, significantly reducing operator fatigue and enhancing productivity. Whether purchasing new or sourcing refurbished units, Juki machines offer long-term value through minimal maintenance requirements and extended service life.

When sourcing, it’s essential to consider reputable suppliers, warranty options, availability of spare parts, and after-sales support to maximize operational efficiency. Additionally, proper training for operators will ensure optimal performance and machine longevity.

In summary, investing in a Juki walking foot industrial sewing machine supports improved production quality, efficiency, and durability—making it a strategic choice for industrial sewing applications.