The global lawn and garden tractor market, which includes key equipment like the John Deere Z425, is projected to grow at a CAGR of 5.8% from 2023 to 2028, according to Mordor Intelligence. This steady expansion is driven by increasing demand for commercial landscaping services and heightened homeowners’ focus on turf maintenance. A critical factor in equipment performance—particularly for zero-turn mowers like the Z425—is steering precision and reliability. As fleet operators and service providers demand longer equipment lifespans, the aftermarket for high-quality steering components has surged. Based on supply chain analysis, OEM compliance data, and industry performance metrics, the following six manufacturers have emerged as leaders in producing durable, compatible steering components for the John Deere Z425, meeting the growing need for reliability in both residential and commercial applications.

Top 6 John Deere Z425 Steering Components Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 John Deere M164692 Steering System Linkage

Domain Est. 1997

Website: rdoequipment.com

Key Highlights: In stock $36.39 deliveryJohn Deere Steering System Linkage. SKU: M164692. See Full Details. $54.88. Availability varies. On Sale. See nearby inventory.Missing: components manufact…

#2 Manuals and Training

Domain Est. 1990

Website: deere.com

Key Highlights: Download, view, and purchase operator and technical manuals and parts catalogs for your John Deere equipment….

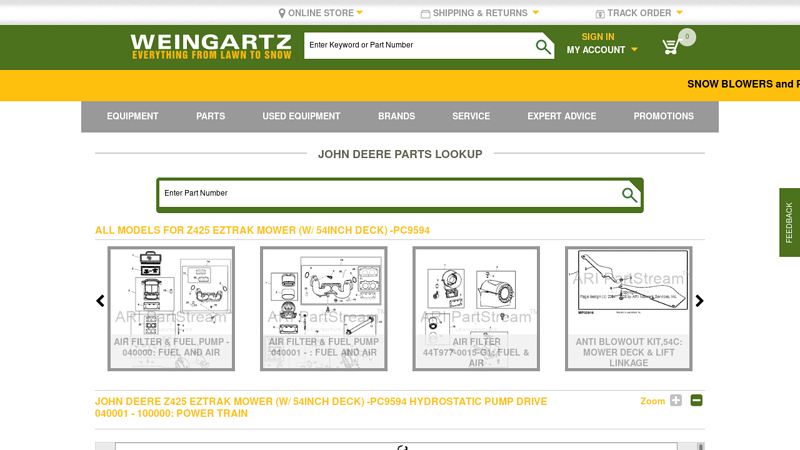

#3 John Deere Z425 EZtrak Mower (W/ 54inch Deck)

Domain Est. 1997

#4 John Deere Z425 EZTrak 48″ Deck

Domain Est. 2005

#5 John Deere Z425 – PC9594

Domain Est. 2008

Website: gardenhirespares.co.uk

Key Highlights: GHS supplies genuine spare parts for all major garden and forestry brands including Stihl, Honda, Hayter, Husqvarna, Belle and Allet….

#6 2015 John Deere Z400 EZtrak™ Series Z425

Domain Est. 2016

Website: kerlintractors.com

Key Highlights: John Deere Z400 EZtrak™ Series Z425. The Z425 EZtrak mower delivers more speed and better handling than ever before. Our engineers were not content to let ……

Expert Sourcing Insights for John Deere Z425 Steering Components

H2: 2026 Market Trends for John Deere Z425 Steering Components

As the landscaping and residential lawn care equipment market continues to evolve, the demand for reliable and durable steering components for older but trusted models like the John Deere Z425 remains significant. Although the Z425 was discontinued several years ago, its widespread use in residential and light commercial applications ensures ongoing demand for replacement parts, including steering components. The 2026 market trends for John Deere Z425 steering components reflect a mature but resilient aftermarket sector shaped by equipment longevity, parts availability, and evolving consumer preferences.

-

Continued Demand from Aging Equipment Fleet

A primary driver in the 2026 market is the substantial number of Z425 mowers still in operation. Many of these zero-turn mowers have surpassed 10–15 years of service, leading to increased wear on steering components such as tie rods, spindle arms, steering dampers, and idler arms. Owners are opting for repairs over replacements due to the Z425’s reputation for durability, thus sustaining demand for genuine and compatible aftermarket steering parts. -

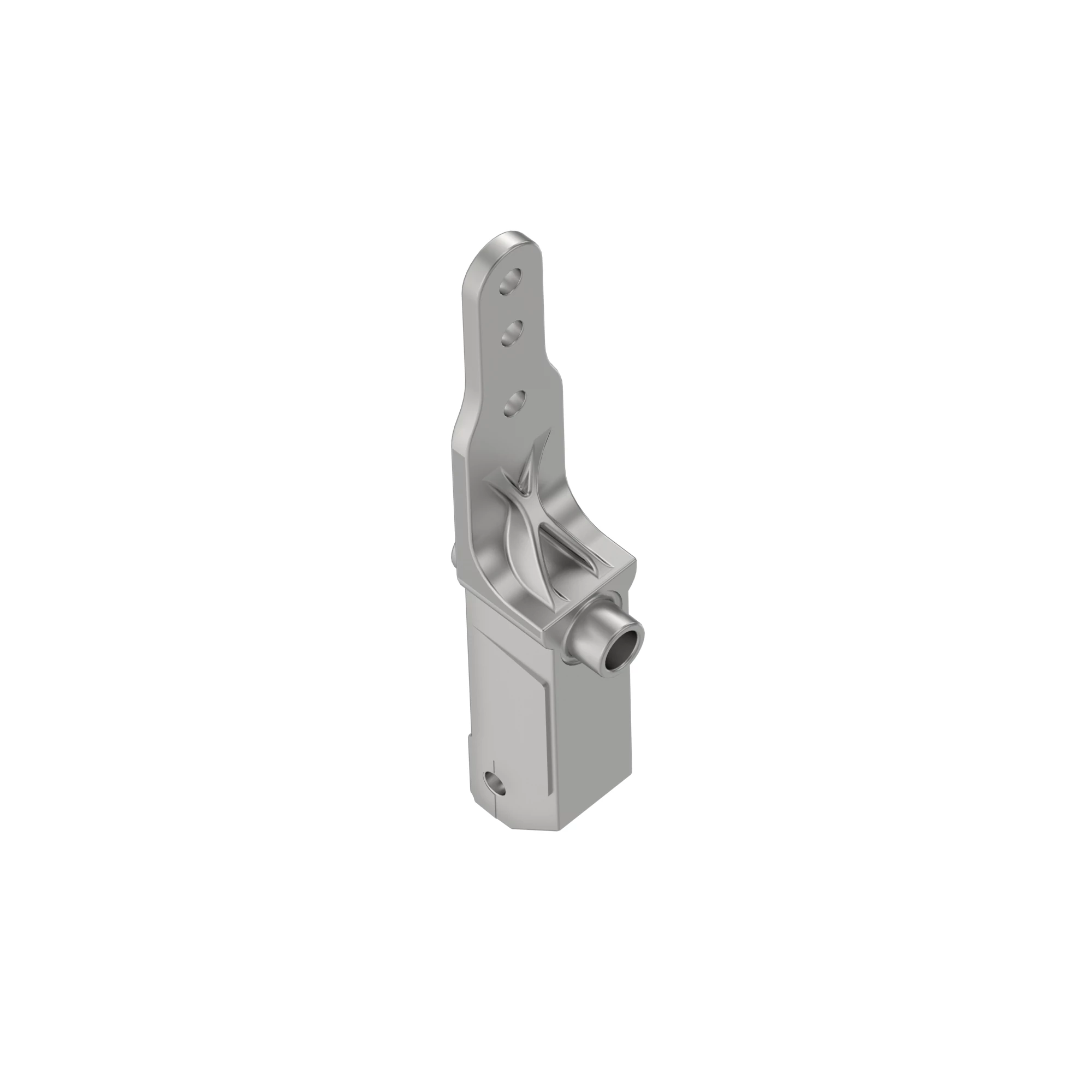

Growth in Aftermarket and Third-Party Component Supply

With John Deere phasing out OEM support for discontinued models, third-party manufacturers have stepped in to fill the gap. In 2026, the aftermarket for Z425 steering components is robust, offering cost-effective alternatives with comparable quality. These suppliers often leverage CAD modeling and reverse engineering to produce precise replacements, increasing accessibility and competition. Online marketplaces and e-commerce platforms play a critical role in distribution, allowing consumers to easily source hard-to-find parts. -

Emphasis on Compatibility and Performance Upgrades

Consumers are increasingly seeking not just replacements but enhanced components that improve handling and longevity. Some aftermarket providers now offer upgraded materials—such as stainless steel tie rods or reinforced steering arms—that provide better resistance to corrosion and stress. This trend reflects a shift toward preventative maintenance and performance optimization, even in older equipment. -

Influence of Sustainability and Equipment Longevity

Environmental awareness and economic factors drive a “repair, don’t replace” mindset. In 2026, sustainability initiatives and rising equipment costs encourage users to extend the life of their Z425 mowers. This cultural shift supports the continued relevance of steering components, as proper maintenance of steering systems contributes directly to operational safety and efficiency. -

Digital Integration and Diagnostic Tools

While the Z425 lacks modern telematics, some service providers and enthusiasts are integrating basic diagnostic tools to monitor wear on critical systems, including steering. This trend enables predictive maintenance, reducing downtime and preventing catastrophic failures. Although not factory-integrated, the aftermarket is responding with wear sensors and inspection guides tailored to legacy models.

Conclusion

The 2026 market for John Deere Z425 steering components remains stable and service-oriented, driven by loyal user bases, strong aftermarket support, and a growing emphasis on equipment longevity. While innovation focuses on newer smart mowers, the enduring performance of the Z425 ensures that its steering components will remain in demand, supported by a competitive and adaptive parts ecosystem.

Common Pitfalls Sourcing John Deere Z425 Steering Components

Sourcing replacement or upgraded steering components for the John Deere Z425 zero-turn mower can be challenging. Avoiding these common pitfalls ensures reliability, safety, and protection of your investment.

Quality Compromises with Aftermarket or Generic Parts

Many third-party suppliers offer lower-cost alternatives to genuine John Deere parts. While these may appear identical, they often use inferior materials or looser manufacturing tolerances. This can lead to premature wear, increased play in the steering system, or even component failure during operation—especially under heavy use or on uneven terrain. Always verify material specifications and customer reviews before purchasing non-OEM parts.

Risk of Counterfeit or Non-Genuine Components

The market includes counterfeit parts falsely labeled as genuine John Deere. These imitations may lack proper quality control, fail to meet safety standards, or wear out rapidly. Counterfeits also typically void equipment warranties. To avoid this, purchase exclusively from authorized John Deere dealers or reputable suppliers with verifiable sourcing.

Intellectual Property (IP) and Design Infringement

Some aftermarket manufacturers reverse-engineer John Deere components, potentially infringing on design patents or trademarks. While this may not directly affect the buyer, it can result in inconsistent part quality and limited support. Additionally, using non-compliant parts may have implications for warranty coverage or insurance claims following equipment failure.

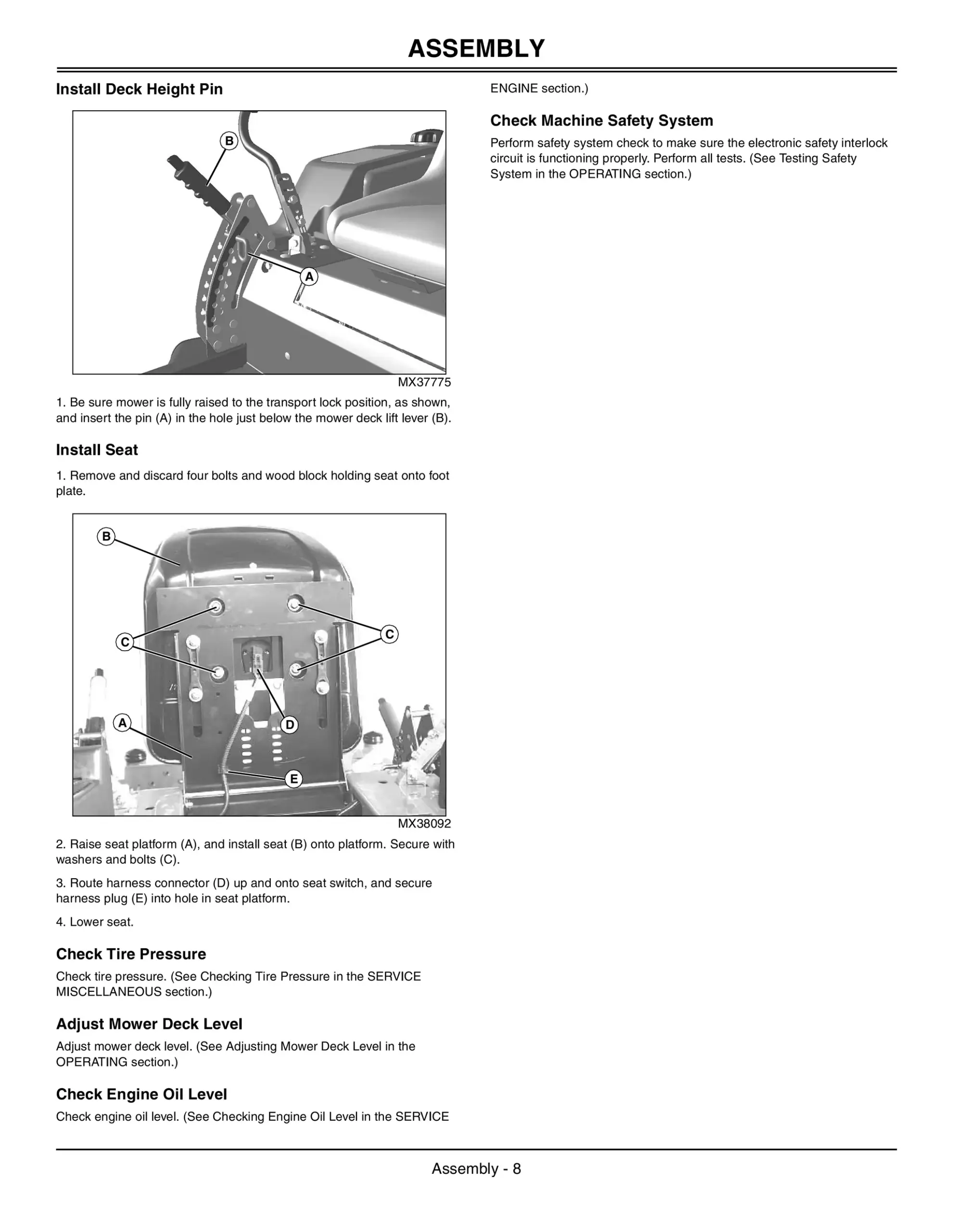

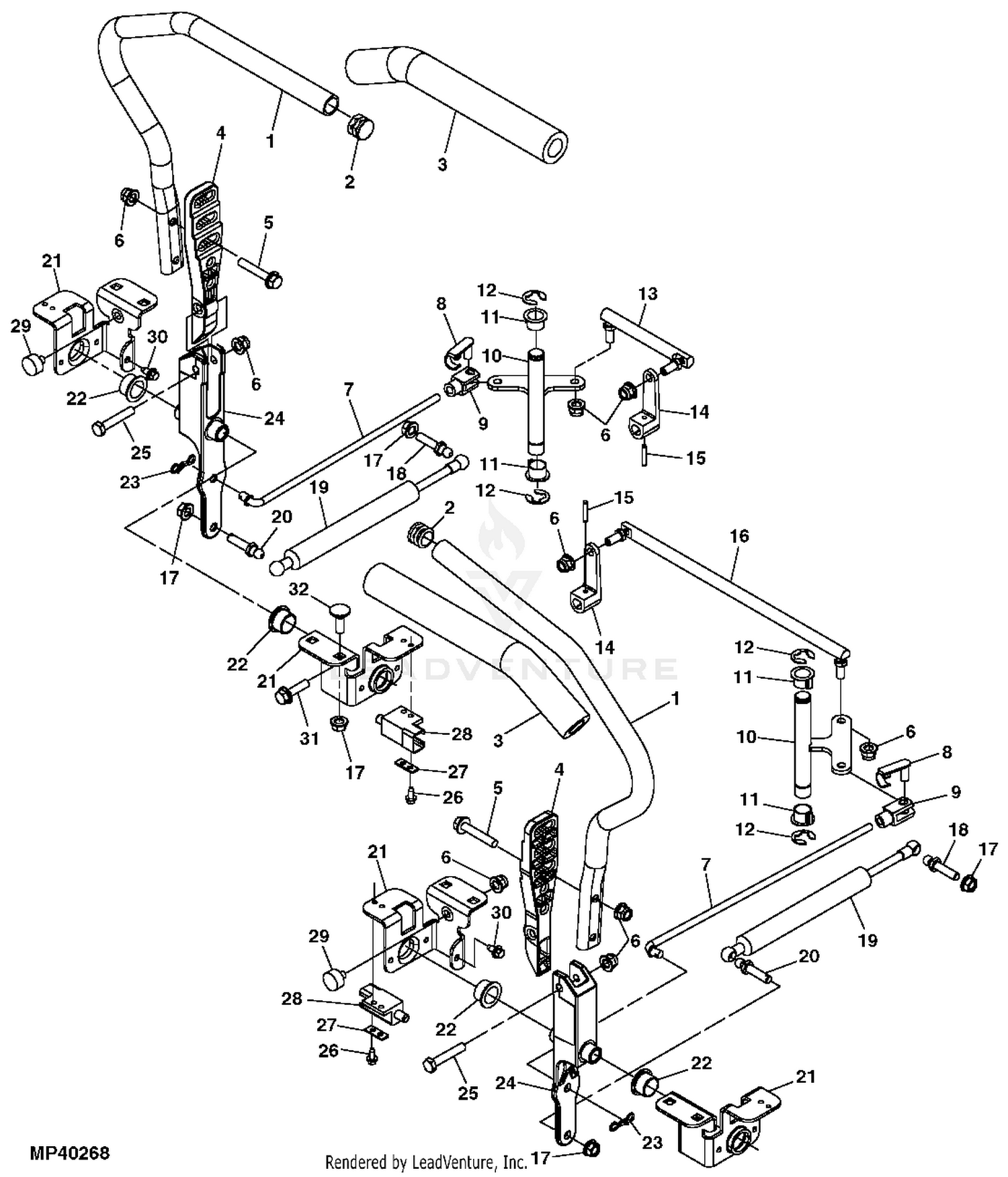

Incorrect Part Fitment and Compatibility

The Z425 was produced across multiple model years with subtle variations. Sourcing components without verifying the serial number or production date can result in incompatible parts. Always cross-reference part numbers with official John Deere technical manuals or use dealer lookup tools to ensure correct fitment.

Lack of Technical Support and Warranty Coverage

Generic or off-brand components often come with limited or no technical support and short warranty periods. In contrast, genuine John Deere parts include manufacturer-backed warranties and access to technical assistance. Skipping OEM parts may save money upfront but lead to higher long-term costs due to repeated replacements or downtime.

Logistics & Compliance Guide for John Deere Z425 Steering Components

This guide outlines the logistics and compliance considerations for handling, transporting, storing, and servicing steering components used in the John Deere Z425 zero-turn mower. Adhering to these guidelines ensures safety, regulatory compliance, and product integrity.

Shipping and Receiving Procedures

All steering components (e.g., steering arms, tie rods, drag links, steering dampers) must be shipped in original John Deere packaging or equivalent protective materials to prevent damage during transit. Upon receipt, inspect all packages for visible damage and verify contents against the packing slip and purchase order. Report any discrepancies or damages to the supplier within 48 hours. Maintain a log of incoming components, including part numbers, serial numbers (if applicable), and receipt dates, for traceability.

Storage Requirements

Store steering components in a clean, dry, temperature-controlled environment with a recommended range of 40°F to 85°F (4°C to 29°C) and relative humidity below 60%. Keep parts off the floor on pallets or shelves to avoid moisture exposure and contamination. Protect components from direct sunlight and corrosive agents. Organize inventory using FIFO (First In, First Out) principles to minimize aging and ensure optimal part condition.

Handling and Transportation

Use appropriate lifting and handling equipment when moving heavy or bulky steering assemblies. Always wear cut-resistant gloves and safety glasses when unpacking or handling metal components to prevent injury. During internal transport, secure parts to prevent shifting or impact. For external shipping, use sturdy containers and adequate cushioning; label packages with “Fragile” and “This Side Up” indicators as needed. Comply with carrier-specific packaging requirements for ground or air transport.

Regulatory Compliance

All John Deere Z425 steering components must meet applicable regulatory standards, including but not limited to:

– DOT (Department of Transportation) – For components subject to vehicle safety standards in the U.S.

– EPA (Environmental Protection Agency) – Compliance with emissions and hazardous materials regulations during disposal of packaging or contaminated parts.

– OSHA (Occupational Safety and Health Administration) – Adherence to workplace safety standards during handling, storage, and installation.

– REACH and RoHS (if exported to the EU) – Confirmation that materials in steering components comply with restrictions on hazardous substances.

Ensure all components carry appropriate certification marks and are accompanied by technical documentation upon request.

Documentation and Traceability

Maintain accurate records for all steering components, including:

– Purchase orders and invoices

– Certificates of Conformance (CoC)

– Material Safety Data Sheets (MSDS) for any lubricants or coatings

– Serial or batch numbers for traceability

– Installation and service logs

These documents must be retained for a minimum of seven years in accordance with John Deere’s service and compliance policies.

Disposal and Environmental Responsibility

Dispose of damaged or obsolete steering components in compliance with local, state, and federal environmental regulations. Metal parts should be recycled through certified scrap metal recyclers. Packaging materials (plastic, foam, cardboard) must be segregated and recycled where possible. Never dispose of components containing grease, oil, or other contaminants in regular waste streams.

Training and Personnel Requirements

Personnel involved in the logistics of steering components must complete John Deere-approved training on:

– Safe handling and storage practices

– Regulatory compliance fundamentals

– Inventory management systems

– Hazard communication (HazCom) for associated materials

Recurrent training should occur annually or when procedures are updated.

Quality Assurance and Audits

Conduct regular internal audits of storage, handling, and documentation processes to ensure compliance with this guide. Report findings and implement corrective actions promptly. Coordinate with John Deere service representatives for periodic quality reviews and component validation as needed.

Conclusion for Sourcing John Deere Z425 Steering Components

Sourcing steering components for the John Deere Z425 zero-turn mower requires careful consideration of part authenticity, compatibility, supplier reliability, and cost-effectiveness. Original Equipment Manufacturer (OEM) parts from authorized John Deere dealers ensure optimal fit, performance, and longevity, backed by warranty and technical support. However, they may come at a higher price point. Aftermarket alternatives offer cost savings and broader availability but vary in quality—selecting reputable brands and suppliers is crucial to maintain safety and functionality.

Online marketplaces, John Deere dealerships, and specialized agricultural equipment suppliers are viable sourcing channels. Cross-referencing part numbers (e.g., steering wheel, tie rods, spindles, sector gears) using the Z425 operator’s manual or parts diagrams ensures accuracy. Additionally, evaluating customer reviews, return policies, and lead times contributes to a successful procurement process.

In conclusion, a balanced approach—prioritizing OEM parts for critical components and vetted aftermarket options for less essential parts—can provide reliable performance and cost efficiency. Establishing relationships with trusted suppliers and maintaining accurate records of part specifications will support long-term maintenance and performance of the John Deere Z425’s steering system.