The global wire cloth market is experiencing steady expansion, driven by rising demand across industries such as mining, construction, filtration, and chemical processing. According to Grand View Research, the global wire mesh market was valued at USD 10.9 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by increasing industrialization, stringent regulatory standards for filtration and separation processes, and advancements in material engineering that enhance durability and performance. Within this competitive landscape, Johnson & Johnson, LTV Steel (historically referenced as “J&L Steel”)—though not active today in the wire cloth segment—have been confused in name, but the current leaders in precision wire cloth manufacturing have emerged through technological innovation and consistent quality. As demand surges, especially in Asia Pacific and North America, identifying the top-performing manufacturers becomes critical for procurement managers and engineers seeking reliable supply chains. Based on production capacity, global reach, quality certifications, and customer reviews, the following three manufacturers stand out in delivering high-performance wire cloth solutions aligned with evolving industry standards.

Top 3 J&L Wire Cloth Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 J&L Wire Cloth LLC

Domain Est. 2001

Website: wire-cloth.net

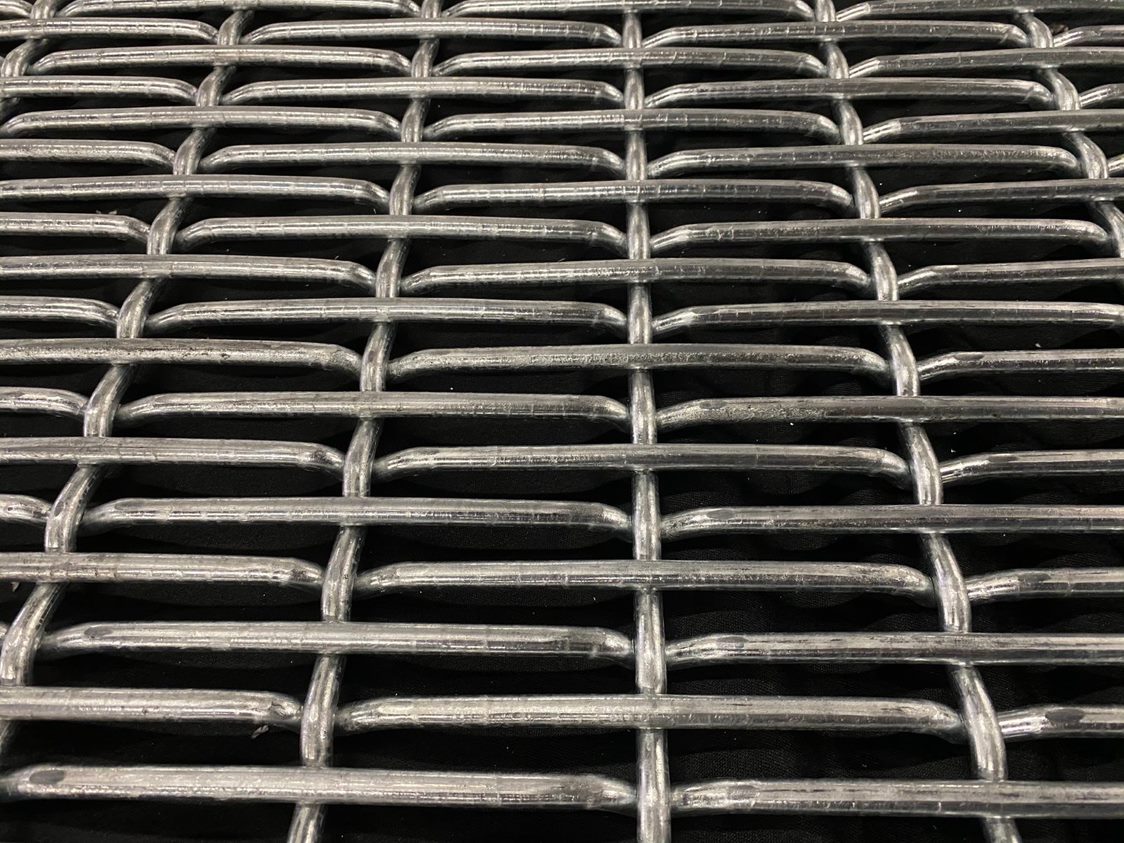

Key Highlights: J&L Wire Cloth LLC is a leading manufacturer of galvanized and bright basic wire, serving a diverse range of industrial applications….

#2 J&L Wire Cloth

Domain Est. 1998

Website: jlwire.com

Key Highlights: J&L Wire of St. Paul, MN and Walterboro, SC, is the leading manufacturer of galvanized and bright basic wire, galvanized wire decking and shelving….

#3 J&L Wire Products & Expert Installation

Domain Est. 2023

Website: jnj-companies.com

Key Highlights: J&L provides our customers with high-quality galvanized and bright basic wire for decking, shelving, and racks used in warehouse storage, material handling, and …Missing: cloth …

Expert Sourcing Insights for J&L Wire Cloth

H2 2026 Market Trends Analysis for J&L Wire Cloth

Based on current trajectories, macroeconomic indicators, and industry dynamics, the second half of 2026 presents a complex but largely favorable landscape for J&L Wire Cloth. Success will hinge on strategic adaptation to key trends.

1. Sustained Industrial & Infrastructure Demand:

* Positive Driver: Major global infrastructure initiatives (e.g., U.S. IIJA/IRA, EU Green Deal, Asian high-speed rail/urbanization) will reach peak construction and materials procurement phases in H2 2026. This fuels demand for robust wire cloth in filtration (water treatment, construction aggregates), screening (mining, quarrying), and protective applications (safety barriers, fencing).

* J&L Implication: High-volume contracts for standard and specialized meshes (e.g., wedge wire for dewatering, perforated for facades) are expected. Focus on reliability and large-scale production capacity will be critical. Supply chain resilience becomes paramount to meet delivery schedules.

2. Accelerated Industrial Automation & Advanced Filtration:

* Positive Driver: Industries (pharma, food & beverage, chemicals, EV battery manufacturing) continue automating and demanding higher precision, efficiency, and hygiene. This drives demand for advanced wire cloth solutions: finer micron-rated filter media, specialized alloys (Hastelloy, titanium) for corrosive environments, and custom-engineered sintered mesh or multi-layer laminates.

* J&L Implication: A significant shift towards higher-value, engineered products. R&D investment in niche alloys, precision weaving technologies (e.g., photolithography for ultra-fine screens), and value-added services (custom cutting, frame assembly) will differentiate J&L from commodity suppliers. Technical sales expertise will be crucial.

3. Energy Transition & Electrification Boom:

* Major Positive Driver: The EV battery supply chain and renewable energy sectors are key growth engines.

* EVs: Demand for wire cloth in battery electrode manufacturing (current collectors, processing screens) and thermal management systems will surge.

* Renewables: Filtration in geothermal plants, screens for biomass processing, and protective mesh for solar farms and offshore wind installations.

* J&L Implication: Requires significant investment in specialized materials (e.g., nickel alloys for battery processing) and potentially new production lines or partnerships. Proactive engagement with emerging players in the battery and renewable sectors is essential for market share.

4. Persistent Inflationary & Supply Chain Pressures:

* Significant Challenge: While inflation may moderate slightly from 2025 peaks, base metal prices (stainless steel, nickel, copper) and energy costs are expected to remain structurally higher than pre-2021 levels. Geopolitical risks (e.g., Red Sea, Taiwan Strait) continue to threaten supply chains.

* J&L Implication: Margin pressure will persist. Success depends on:

* Strategic Sourcing: Diversifying raw material suppliers, potentially nearshoring/reshoring key inputs.

* Pricing Power: Leveraging technical expertise and customization to justify premium pricing, especially on engineered products.

* Operational Efficiency: Continuous improvement in manufacturing (automation, yield optimization) to offset cost increases.

* Long-Term Contracts: Securing stable supply and pricing through longer-term agreements where possible.

5. Intensifying Competition & Market Consolidation:

* Mixed Driver: Global competition remains fierce, with low-cost producers and established players vying for market share. However, consolidation within the industrial filtration and specialty materials sectors is likely, creating both threats (larger competitors) and opportunities (acquisition targets for J&L to expand capabilities).

* J&L Implication: Differentiation through superior quality, technical service, and innovation is non-negotiable. Exploring strategic partnerships or M&A to access new technologies (e.g., advanced coating) or geographic markets could be vital for growth.

6. Sustainability & Circular Economy Focus:

* Growing Imperative: Customer demand for sustainable practices and recyclable materials will intensify. Regulations (e.g., extended producer responsibility) may increase.

* J&L Implication: Opportunity to highlight inherent sustainability of metal wire cloth (durability, recyclability >95%). Investment in:

* Recycling Programs: Offering take-back programs for end-of-life screens.

* Process Efficiency: Reducing energy consumption and waste in manufacturing.

* Transparency: Providing Environmental Product Declarations (EPDs) for key products.

H2 2026 Strategic Outlook for J&L:

The second half of 2026 offers strong demand tailwinds, particularly in infrastructure, energy transition, and advanced manufacturing. J&L’s position is largely positive but requires proactive management of significant challenges.

- Winners: Companies that successfully pivot towards high-value, engineered solutions for emerging sectors (EVs, renewables, automation) while maintaining operational excellence and supply chain resilience.

- Risks: Companies overly reliant on commodity products face margin erosion from competition and inflation. Failure to innovate or adapt to sustainability demands will hinder growth.

Recommendations for J&L:

1. Double Down on Engineering & Innovation: Prioritize R&D for EV battery, renewable energy, and advanced filtration applications.

2. Optimize Supply Chain: Secure critical raw materials, diversify suppliers, and enhance logistics agility.

3. Leverage Sustainability: Formalize recycling initiatives and communicate environmental benefits.

4. Target High-Growth Sectors: Allocate sales and marketing resources aggressively to EV, renewable energy, and automation markets.

5. Evaluate Strategic Options: Assess potential partnerships or M&A to accelerate growth in key technology areas.

By focusing on value-added solutions, managing costs proactively, and aligning with powerful macro trends, J&L Wire Cloth is well-positioned to capitalize on the opportunities presented in H2 2026.

Common Pitfalls Sourcing J&L Wire Cloth (Quality, IP)

Sourcing wire cloth from J&L or similar suppliers can present several risks, particularly concerning product quality and intellectual property (IP) protection. Being aware of these pitfalls helps mitigate potential issues and ensures reliable, compliant procurement.

Quality Inconsistencies

One of the primary concerns when sourcing J&L wire cloth is inconsistent product quality. Despite J&L’s reputation for manufacturing precision wire mesh, variations can occur due to differences in raw material sourcing, production batches, or supplier subcontracting. Buyers may receive wire cloth with incorrect mesh counts, wire diameters, or surface finishes that deviate from specifications. These inconsistencies can compromise performance in critical applications such as filtration, screening, or safety enclosures. To avoid this, it is essential to request material certifications (e.g., mill test reports), conduct incoming quality inspections, and establish clear quality agreements with the supplier.

Intellectual Property Risks

Another significant pitfall involves intellectual property concerns, especially when J&L or third-party suppliers replicate patented mesh designs or proprietary patterns. Unauthorized production or distribution of IP-protected wire cloth configurations can expose buyers to legal liability, particularly if the end product is used in regulated or competitive industries. Additionally, counterfeit or reverse-engineered products may enter the supply chain under the J&L name, further complicating IP compliance. To mitigate these risks, purchasers should verify the supplier’s authorization to produce or distribute J&L products, review licensing agreements where applicable, and conduct due diligence on the supply chain’s transparency.

Logistics & Compliance Guide for J&L Wire Cloth

This guide outlines the essential logistics and compliance procedures for the handling, transportation, and regulatory adherence related to J&L Wire Cloth products. Adherence ensures timely delivery, safety, and full compliance with domestic and international standards.

Order Processing & Documentation

All orders must be confirmed with a valid purchase order (PO) referencing the correct product specifications, quantity, and delivery requirements. Required documentation includes a commercial invoice, packing list, bill of lading (or air waybill), and any applicable certificates of origin or compliance. Ensure all documents reflect accurate Harmonized System (HS) codes for wire cloth products to support customs clearance.

Packaging & Handling Standards

J&L Wire Cloth must be packaged to prevent deformation, corrosion, and transit damage. Rolls should be secured on robust cores and wrapped in moisture-resistant material, with protective corner boards and stretch-wrapped onto pallets. Sheets must be separated with protective interleafing and banded securely. Label each unit with product ID, batch number, weight, and handling instructions (e.g., “Fragile,” “This Side Up”).

Transportation Requirements

Use carriers experienced in handling industrial metal products. For domestic shipments within the U.S., comply with Department of Transportation (DOT) regulations for load securement (49 CFR). For international shipments, adhere to International Maritime Organization (IMO) and International Air Transport Association (IATA) standards as applicable. Ensure proper stowage to avoid shifting or moisture exposure during transit.

Import/Export Compliance

Verify export eligibility under the Export Administration Regulations (EAR) administered by the U.S. Department of Commerce. Most wire cloth products fall under EAR99, but confirm classification prior to shipment. For exports to sanctioned countries or restricted parties, conduct screening via the Automated Export System (AES) and obtain necessary licenses if required. Maintain records for a minimum of five years.

Customs Clearance

Provide complete and accurate data to customs brokers for swift clearance. Include material composition (e.g., stainless steel grade), country of origin, and declared value. Be prepared to supply a Certificate of Conformity if requested by destination country authorities. Monitor changes in tariffs or trade agreements affecting wire cloth imports.

Regulatory Compliance

Ensure all products meet relevant industry standards such as ASTM E2016 for woven wire cloth. Comply with OSHA guidelines for workplace handling and storage. For shipments to the European Union, verify adherence to REACH and RoHS directives regarding restricted substances. Maintain up-to-date Material Safety Data Sheets (MSDS/SDS) for all product lines.

Quality & Traceability

Implement a traceability system linking each batch to production records, inspection results, and shipping data. Conduct routine internal audits to verify compliance with logistics and regulatory requirements. Report and investigate any non-conformances promptly to prevent recurrence.

Sustainability & Environmental Responsibility

Minimize packaging waste through reusable or recyclable materials. Partner with carriers that report on carbon emissions and support J&L’s environmental stewardship goals. Comply with all applicable environmental regulations related to metal processing and shipping, including proper disposal of packaging materials.

Conclusion for Sourcing J&L Wire Cloth:

Sourcing wire cloth from J&L can be a strategic decision for businesses requiring high-quality, durable, and precision-engineered mesh products. J&L’s long-standing reputation in the industry, commitment to quality control, and ability to customize wire cloth solutions make them a reliable supplier for a wide range of industrial applications—from filtration and screening to architectural and safety uses. While factors such as lead times, pricing, and minimum order quantities should be evaluated to ensure alignment with project requirements, the overall value, technical expertise, and consistency offered by J&L justify their consideration as a primary or complementary supplier. Establishing a strong partnership with J&L can contribute to improved product performance, operational efficiency, and long-term cost savings across various manufacturing and engineering processes.