The global woodworking machinery market is experiencing steady growth, driven by rising demand in construction, furniture manufacturing, and DIY woodworking projects. According to Grand View Research, the market was valued at USD 4.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This growth is fueled by technological advancements in precision tools, increasing adoption of modular woodworking solutions, and the expansion of the residential and commercial construction sectors, particularly in Asia-Pacific and North America. As woodworkers seek greater accuracy, repeatability, and efficiency, the demand for high-quality jigs—essential guides that enhance tool performance and safety—has surged. In response, manufacturers are innovating with ergonomic designs, durable materials, and modular systems to meet both professional and hobbyist needs. Below, we examine the top 8 jig manufacturers shaping this evolving landscape, evaluated on product range, customer reviews, industry reputation, and technological innovation.

Top 8 Jig For Woodworking Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Dovetail Jig

Domain Est. 2007

Website: tool-r-us.com

Key Highlights: 15-Inch Dovetail Jig System With Templates, Bits, Hardware (KDS13) Fast Joint Templates Wood Fast Joint Precision Joinery System Templates…

#2 Wood Working Tools

Domain Est. 1998

Website: jessem.com

Key Highlights: Free Shipping & Tariff Free · Box Joint Jig for Router Tables · Stainless Steel Precision Squares · Clear-Cut STS Stock Guides · Sword T-Squares · Quick Angle Square….

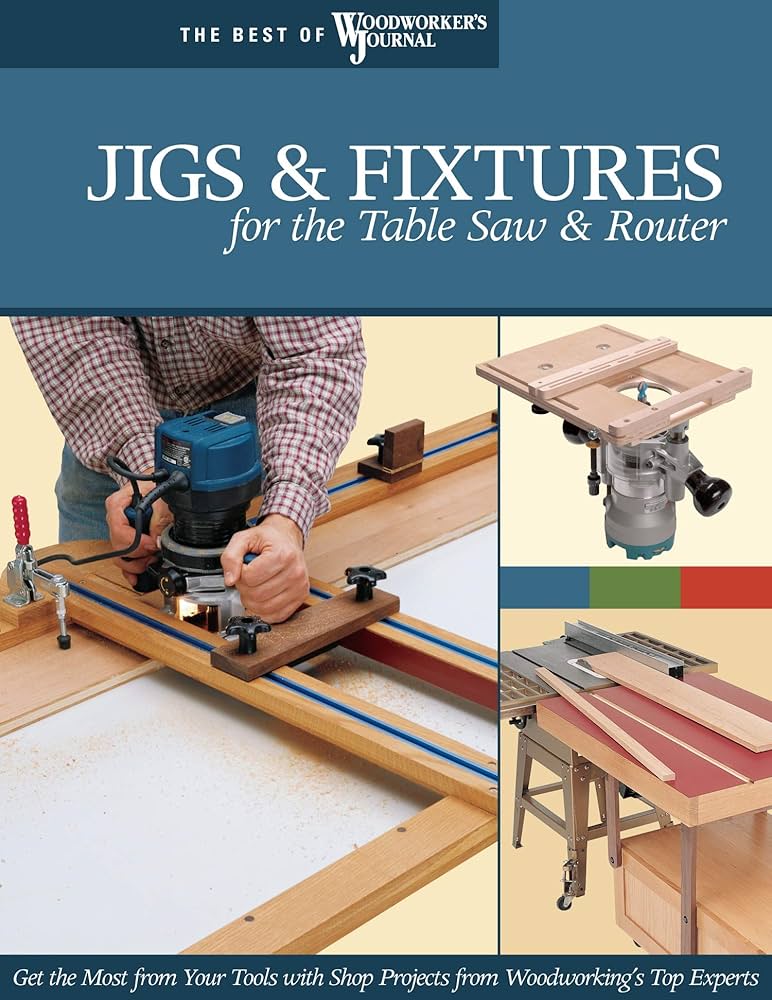

#3 Woodworking Jig and Fixtures

Domain Est. 1998

Website: woodpeck.com

Key Highlights: Find all the hardware, knobs, and tracks you need to build your own woodworking jigs. Various track styles, knobs, and more….

#4 to Kreg Tool

Domain Est. 1999

Website: kregtool.com

Key Highlights: From easy storage upgrades to advanced woodworking projects, this jig helps every build come together with confidence. … Kreg 12 Dowel Jig Upgrade Kit. Buy Now….

#5 All Products

Domain Est. 2002

Website: microjig.com

Key Highlights: Full catalog of all MICROJIG products, accessories, and replacement parts….

#6 INCRA I

Domain Est. 2007

Website: incrementaltools.com

Key Highlights: In stockThis is the most advanced box joint jig ever produced! Works at both table saws and router tables, features micro-adjustable joint tightness, and allows pin ……

#7 Leigh Super Jigs 12 18 And 24 Inch Dovetail Jigs

Domain Est. 2013

Website: leightools.com

Key Highlights: The Leigh Super Jig is an incredibly versatile tool for precise joinery. Learn how to get optimal results with the step by step instructions in the included ……

#8 Woodworking jig

Domain Est. 2014

Website: powertecproducts.com

Key Highlights: Rating 4.4 (89) · Free delivery over $39…

Expert Sourcing Insights for Jig For Woodworking

2026 Market Trends for Jigs in Woodworking

Rising Demand for Precision and Repeatability

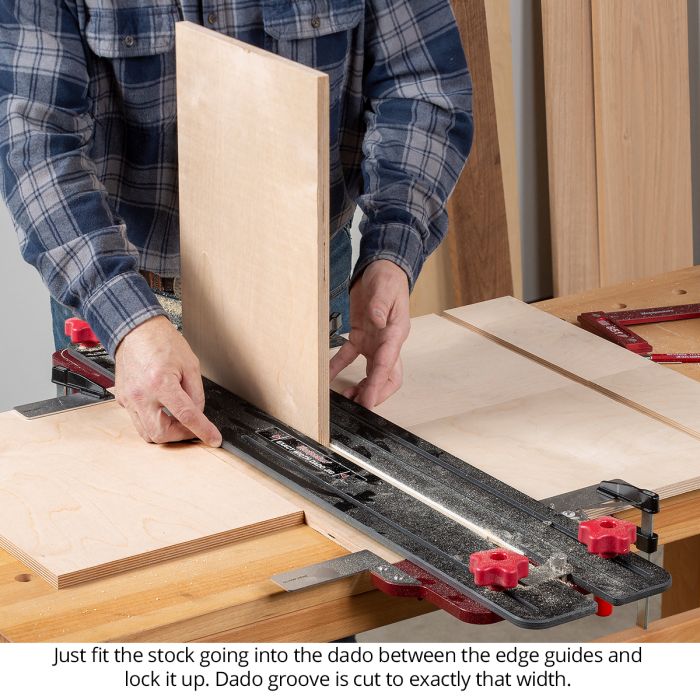

By 2026, the woodworking industry will increasingly prioritize precision and consistency, especially among hobbyists and small-scale producers. Jigs offer measurable accuracy in repetitive tasks like joinery, drilling, and cutting. With the growing popularity of custom furniture and cabinetry, users demand tools that ensure flawless results across multiple project components. As a result, jigs designed for dovetails, mortise-and-tenon joints, and pocket-hole systems will see expanded adoption.

Growth in DIY and Home Workshop Segments

The DIY movement continues to gain momentum, fueled by online tutorials, social media, and e-commerce access to tools. More consumers are setting up home workshops, driving demand for affordable, easy-to-use jigs. In 2026, manufacturers will likely focus on user-friendly, modular jig systems that require minimal setup and are compatible with common power tools like routers and table saws. Kits targeting beginners will emphasize safety, clear instructions, and adaptability across various wood types.

Integration with Smart Tools and Digital Design

Advancements in digital fabrication, such as CAD software and CNC compatibility, will influence jig design. By 2026, expect to see “smart” jigs that integrate with digital workflows—allowing users to transfer measurements from design software directly to physical guides. Jigs with adjustable, programmable components or those compatible with laser guides and smartphone apps will gain traction, particularly among tech-savvy woodworkers and makerspaces.

Sustainability and Material Innovation

Eco-consciousness is reshaping product development across industries, including woodworking. In 2026, jig manufacturers may shift toward sustainable materials like recycled plastics, bamboo composites, or biodegradable polymers. Additionally, durable, long-lasting jig designs will be favored to reduce waste. Modular jigs that can be reconfigured for multiple uses will appeal to environmentally aware consumers seeking efficiency and minimal consumption.

Expansion of Online Marketplaces and Subscription Models

E-commerce platforms like Amazon, Etsy, and specialized woodworking retailers will continue to dominate jig distribution. By 2026, niche online brands offering customizable or 3D-printed jigs will emerge, catering to specific project needs. Subscription services for jig templates, downloadable plans, or monthly jig kits could also gain popularity, providing ongoing value and community engagement.

Conclusion

The 2026 market for woodworking jigs will be shaped by precision demands, DIY culture, technological integration, sustainability, and digital commerce. Manufacturers and retailers who innovate in usability, adaptability, and eco-conscious design will be best positioned to capture growth in this evolving segment.

Common Pitfalls When Sourcing Jigs for Woodworking: Quality and Intellectual Property

Sourcing jigs for woodworking—whether purchasing pre-made tools or commissioning custom designs—can streamline your workflow, but it comes with potential pitfalls, especially regarding quality and intellectual property (IP). Being aware of these issues helps ensure you get reliable tools without legal or performance complications.

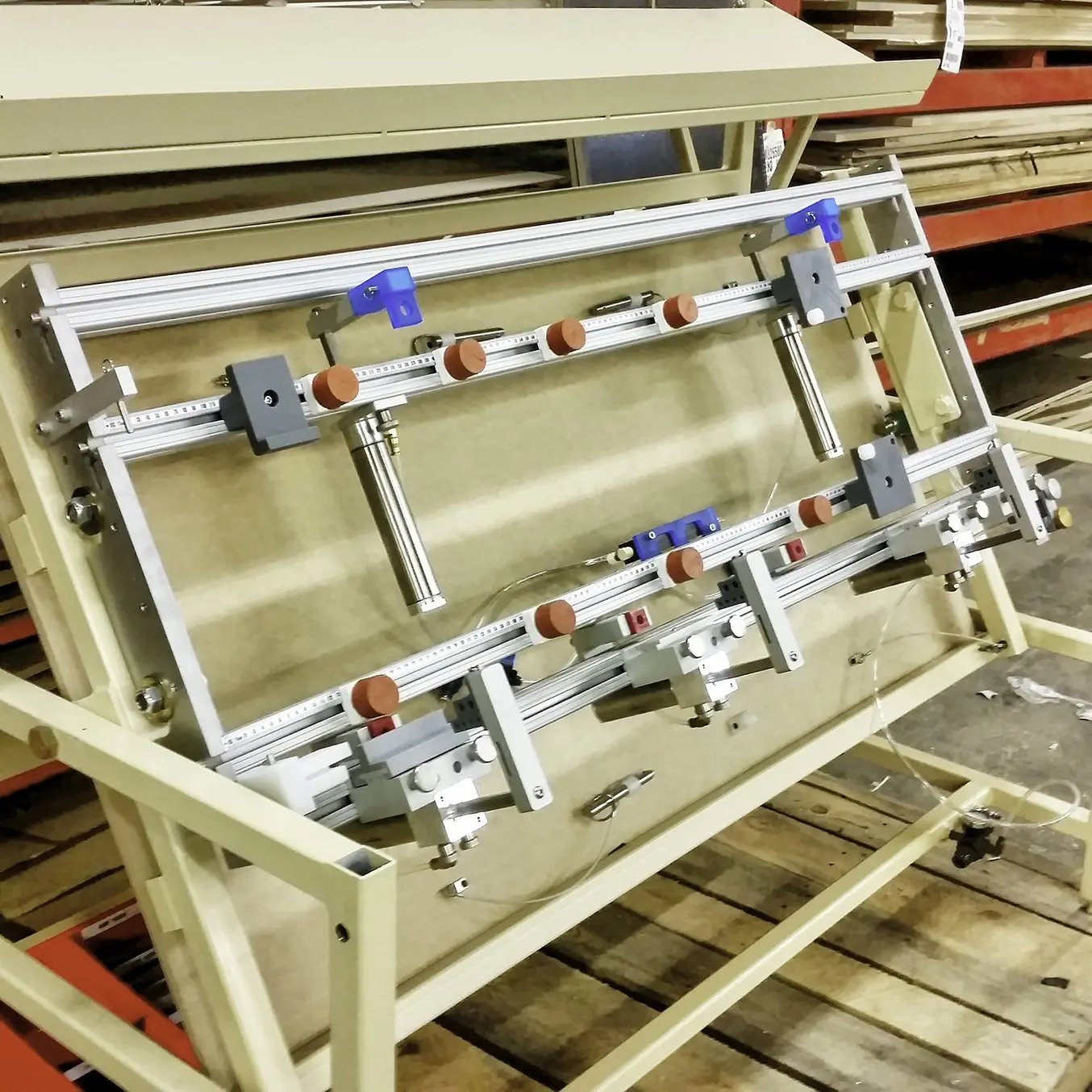

Poor Build Quality and Material Selection

One of the most frequent issues when sourcing woodworking jigs is encountering subpar craftsmanship. Low-cost jigs, especially those from overseas suppliers or generic online marketplaces, often use inferior materials like flimsy plywood, soft plastics, or poorly machined metals. These materials wear down quickly under repeated use, leading to inaccuracy, misalignment, or complete failure. Look for jigs constructed from stable hardwoods, high-grade aluminum, or steel with proper tolerances. Always check for smooth finishes, precise fit, and robust fastening mechanisms to avoid compromising your project quality.

Inaccurate or Poorly Designed Functionality

A jig is only as good as its design. Many sourced jigs—particularly mass-produced or copycat versions—suffer from flawed geometries or miscalibrated measurements. These design flaws can lead to inconsistent cuts, misaligned joints, or safety hazards. Before purchasing, review user feedback, watch demonstration videos, or request prototypes (if custom). Verify that the jig aligns with your specific tools and intended applications, such as dovetail joinery, pocket holes, or router guidance.

Lack of Durability and Long-Term Reliability

Even jigs that perform well initially may degrade over time if not made with longevity in mind. Components like clamps, guide bushings, or alignment pins can loosen or break after extended use. Sourcing from reputable manufacturers with a track record of durable products—or investing in modular jigs with replaceable parts—can mitigate this risk. Avoid disposable or “one-off” jigs unless they’re for a very short-term project.

Intellectual Property Infringement Risks

Many popular jig designs are protected by patents, trademarks, or copyrights. When sourcing jigs—especially from third-party vendors or online marketplaces—there’s a risk of purchasing counterfeit or illegally copied designs. Using such products can expose you to legal liability, particularly if you’re using the jig commercially. Always buy from authorized dealers or directly from the original designer. If commissioning a custom jig, ensure the design doesn’t replicate patented features without permission.

Unclear or Missing Licensing for Commercial Use

Even if a jig design is not patented, some creators license their designs with specific usage terms. For example, a jig plan downloaded from a woodworking website might be for personal use only. Using it to produce products for sale could violate the license agreement. Always review the terms of use before sourcing plans or kits, and clarify licensing when working with freelance designers or fabricators.

Limited Support and Documentation

Lower-quality or infringing jigs often come with poor or nonexistent instructions, troubleshooting guides, or customer support. This lack of documentation makes setup difficult and increases the chance of misuse or damage. Reputable suppliers typically provide clear assembly instructions, usage videos, and access to technical support. Prioritize vendors that offer comprehensive documentation and responsive service.

Hidden Costs from Rework or Tool Damage

A poorly made or misdesigned jig may seem like a bargain upfront, but it can lead to wasted materials, ruined workpieces, or even damage to expensive tools like routers or saw blades. The long-term cost of rework, downtime, and replacements often exceeds the savings from a cheap jig. Invest in quality to protect your tools and maintain precision.

By carefully evaluating both the physical quality and legal integrity of sourced jigs, woodworkers can avoid these common pitfalls and ensure their jigs enhance, rather than hinder, their craft.

Logistics & Compliance Guide for Jigs for Woodworking

Overview

Jigs for woodworking are precision tools designed to guide other tools or workpieces during manufacturing processes. While they are not typically classified as finished goods, they may be subject to various logistics and compliance requirements when manufactured, transported, or sold internationally. This guide outlines key considerations for managing the logistics and regulatory compliance of woodworking jigs.

Classification & Tariff Codes

Woodworking jigs are usually categorized under industrial tooling or fixtures. Accurate classification is essential for customs clearance and duty assessment.

– HS Code (Harmonized System): Typically falls within Chapter 82 (Tools, cutlery, and general hardware).

– Example: 8205.40 – “Hand tools (including glass cutters) not elsewhere specified, of base metal” (may apply to manually operated jigs).

– Alternatively, 8466.30 – “Parts and accessories suitable for use solely or principally with machine tools… for working wood” may be applicable for jigs used with power tools.

– Always verify the correct HS code with local customs authorities or a customs broker, as classification can vary based on design, function, and materials.

Material Compliance

The materials used in jig construction may be subject to environmental and safety regulations.

– Metals: Ensure compliance with RoHS (Restriction of Hazardous Substances) if exporting to the EU. Avoid lead, cadmium, and other restricted substances.

– Plastics: Comply with REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) in the EU. Avoid substances of very high concern (SVHCs).

– Wood Components: If the jig includes wood, verify compliance with CITES (Convention on International Trade in Endangered Species) and Lacey Act (USA), ensuring wood sourcing is legal and sustainable.

Packaging & Labeling Requirements

Proper packaging and labeling are crucial for safe shipping and customs compliance.

– Use durable packaging to prevent damage during transit, especially for precision-machined jigs.

– Label packages with:

– Product name (“Woodworking Jig”)

– Part/model number

– Country of origin

– Weight and dimensions

– Handling symbols (e.g., “Fragile”, “This Side Up”)

– Include a detailed packing list and commercial invoice with each shipment.

Export Documentation

Ensure all required documentation is prepared accurately:

– Commercial Invoice: Must include description, quantity, value, HS code, and Incoterms (e.g., FOB, EXW).

– Packing List: Itemizes contents of each package.

– Bill of Lading (for sea freight) or Air Waybill (for air freight): Issued by the carrier.

– Certificate of Origin: May be required to claim tariff preferences under trade agreements.

– Export License: Generally not required for woodworking jigs, but verify with export control authorities (e.g., BIS in the U.S.) if the jig incorporates advanced technology.

Shipping & Transportation

Choose the appropriate shipping method based on urgency, cost, and destination.

– Air Freight: Faster but more expensive; suitable for high-value or time-sensitive jigs.

– Ocean Freight: Cost-effective for large or heavy shipments; use FCL (Full Container Load) or LCL (Less than Container Load).

– Inland Transport: Coordinate with reliable carriers for pickup and final delivery.

– Consider insuring shipments against loss or damage.

Import Regulations by Region

Be aware of regional import requirements:

– United States: Comply with CBP (Customs and Border Protection) regulations; ensure accurate entry filings.

– European Union: Verify conformity with CE marking requirements if the jig is part of a machine system (under Machinery Directive 2006/42/EC). While standalone jigs may not require CE marking, integration into machinery may trigger compliance.

– Canada: Follow CBSA (Canada Border Services Agency) rules; use accurate B3 forms for customs clearance.

– Australia/NZ: Comply with biosecurity standards if packaging includes wood (ISPM 15 compliant pallets required).

Safety & Technical Standards

Although jigs themselves are not always regulated, they may be subject to workplace safety standards:

– Follow ANSI B11 series (U.S.) or ISO 19353 (Safety of Machine Tools) guidelines if the jig is used in industrial settings.

– Provide user instructions highlighting safe handling and operational practices.

– Avoid sharp edges or pinch points in design to minimize injury risk.

Recordkeeping & Audit Readiness

Maintain accurate records for at least five years:

– Product specifications and material certifications

– Export documentation (invoices, packing lists, shipping records)

– Compliance documentation (RoHS, REACH declarations)

– Customer communications and warranty claims

Conclusion

Successfully managing the logistics and compliance of woodworking jigs requires attention to classification, materials, documentation, and regional regulations. By adhering to international standards and maintaining thorough records, manufacturers and exporters can ensure smooth customs clearance, avoid penalties, and support safe, sustainable operations. Always consult legal and logistics professionals when entering new markets.

In conclusion, sourcing a jig for woodworking is a crucial step in enhancing precision, efficiency, and repeatability in your projects. A well-designed, properly sourced jig not only improves the quality of your work but also increases safety by providing better control over tools and materials. When selecting a jig, consider factors such as compatibility with your tools and project requirements, build quality, adjustability, and ease of use. Whether purchasing from reputable manufacturers or building your own based on proven designs, investing time in sourcing the right jig pays off through consistent, professional results. Ultimately, the right jig becomes an invaluable asset in any woodworker’s toolkit, supporting both craftsmanship and productivity.