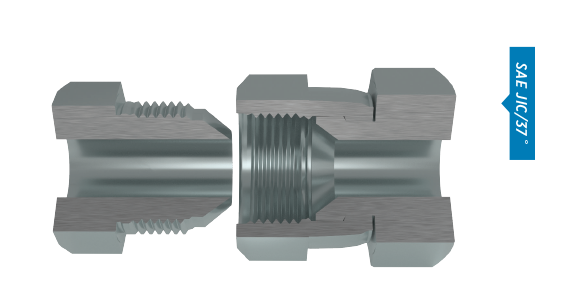

The global demand for hydraulic and pneumatic connection components, including JIC (Joint Industry Council) fittings, continues to rise in tandem with industrial automation, aerospace, and heavy machinery sectors. According to Grand View Research, the global hydraulic and pneumatic equipment market was valued at USD 37.6 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030. This expansion is driven by increasing adoption in manufacturing, construction, and transportation industries where reliability and standardization in fluid power systems are critical. JIC 37° flare fittings, known for their durability and leak-resistant performance under high pressure, are integral components in these systems. As industries prioritize efficiency and compliance with international standards such as SAE J514 and ISO 8434-2, the need for high-quality JIC connection fittings has intensified. In this evolving landscape, a select group of manufacturers has emerged as leaders in precision, innovation, and global reach. Below, we profile the top 10 JIC connection fittings manufacturers shaping the future of fluid power systems.

Top 10 Jic Connection Fittings Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Yuyao Jiayuan Hydraulic Fitting Factory

Domain Est. 2019 | Founded: 1998

Website: jiayuanfitting.com

Key Highlights: Yuyao Jiayuan Hydraulic Fitting Factory, established in 1998, is a professional manufacturer of engineering machinery accessories and hydraulic pipe connections ……

#2 Industrial Fittings, Tube Fittings and Pressure Fittings

Domain Est. 1996

Website: products.swagelok.com

Key Highlights: We offer a complete portfolio of fittings available in a variety of alloy materials for a wide range of industrial applications….

#3 Air

Domain Est. 1997

Website: air-way.com

Key Highlights: We offer a broad range of hydraulic fitting types, including JIC, ORFS, Metric, and many others, designed to meet the rigorous standards of the industry….

#4 Fittings Unlimited

Domain Est. 2011

Website: myfui.com

Key Highlights: Fittings Unlimited Inc. is proud to offer a variety of hydraulics fittings and adapters in various materials as well as standard and international fittings….

#5 JIC Fittings, Manufacturer, Supplier, Distributor, Exporter

Domain Est. 2024

Website: hy-techengineers.com

Key Highlights: We provide JIC Fittings. Our setup is situated in Thane, Pune, Nashik (Maharashtra), Pithampur (Madhya Pradesh), India and Virginia (USA – United States Of ……

#6 Fittings 101: Our JIC Fittings

Domain Est. 1996

Website: brennaninc.com

Key Highlights: JIC (or Joint Industry Council) fittings, defined by SAE J514, are compression fittings machined with a 37 degree flare seating surface and parallel threads….

#7 Aerospace hose, tubing fittings and connectors

Domain Est. 1996

Website: eaton.com

Key Highlights: Eaton hoses and hose fittings provide the ultimate fluid conveyance solutions for a variety of aircraft applications….

#8 Hydraulic High Purity Fittings & Components

Domain Est. 1999

Website: hylokusa.com

Key Highlights: Each of the fitting types provided by Hy-Lok is tailored to the exact requirements of your application. Our large inventory of JIC flare fittings, weld fittings ……

#9 Pegasus Hydraulics

Domain Est. 2004

Website: phydro.com

Key Highlights: JIC fittings are a widely recognised and utilised type of hydraulic connection, known for their robust design and reliable, leak-free performance. Flare & JIC ……

#10 JIC Fittings

Domain Est. 2011

Website: myssp.com

Key Highlights: JIC fittings or SAE 37° flared fittings are available in sizes from 1/8 to 2 in. in both male and female swivel and with a wide range of pipe and weld ……

Expert Sourcing Insights for Jic Connection Fittings

H2: 2026 Market Trends for JIC Connection Fittings

The global market for JIC (Joint Industry Council) connection fittings is poised for steady growth through 2026, driven by increasing demand across key industrial sectors, technological advancements, and a growing emphasis on reliability and standardization in fluid transfer systems. These high-pressure fittings, standardized under SAE J514 and ISO 8434-2, are widely used in hydraulic systems within industries such as aerospace, construction, manufacturing, and oil & gas. The following trends are expected to shape the JIC connection fittings market in 2026:

-

Rising Industrial Automation and Hydraulic System Adoption

As industries continue to automate operations, the need for robust and leak-resistant hydraulic connections grows. JIC fittings, known for their 37° flare design and high-pressure performance, are increasingly integrated into automated machinery, boosting market demand. The push toward smart factories and Industry 4.0 infrastructure will further increase the deployment of hydraulic systems, benefiting JIC fitting manufacturers. -

Expansion in Construction and Off-Highway Equipment

Infrastructure development projects in emerging economies—particularly in Asia-Pacific and Africa—are driving demand for heavy construction and off-highway vehicles. These machines rely heavily on hydraulic systems using JIC fittings for durability and ease of maintenance. The surge in public and private infrastructure investments will sustain strong demand through 2026. -

Growth in Oil & Gas and Energy Sectors

Despite the global shift toward renewables, the oil & gas industry continues to invest in exploration, production, and pipeline maintenance, especially in deepwater and remote areas. JIC fittings are preferred in these harsh environments due to their reliability under high pressure and vibration resistance. Additionally, the growing offshore wind energy sector uses hydraulic systems for turbine maintenance, indirectly supporting demand. -

Emphasis on Leak Prevention and System Efficiency

Environmental regulations and safety standards are becoming stricter worldwide. The inherent design of JIC fittings—offering a metal-to-metal seal—reduces the risk of hydraulic fluid leaks, contributing to safer operations and reduced environmental impact. This factor is increasing their adoption over alternative fitting types like NPT or O-ring face seal (ORFS) in certain applications. -

Material Innovation and Corrosion Resistance

Manufacturers are investing in advanced materials such as stainless steel, brass, and corrosion-resistant alloys to enhance the longevity and performance of JIC fittings in aggressive environments. In 2026, expect greater availability of coated or composite fittings designed for extreme temperatures and corrosive fluids, particularly in chemical processing and marine applications. -

Regional Market Shifts

While North America and Europe remain dominant due to stringent standards and mature industrial bases, the Asia-Pacific region is expected to witness the highest growth rate. Rapid industrialization in countries like India, Vietnam, and Indonesia, coupled with expanding manufacturing capabilities, will drive regional demand. Localized production and supply chain resilience will become key competitive advantages. -

Sustainability and Circular Economy Considerations

The push for sustainable manufacturing is influencing product design and lifecycle management. In 2026, leading JIC fitting producers may adopt greener manufacturing processes, recyclable packaging, and design fittings for reusability and easy disassembly, aligning with circular economy principles. -

Digitalization and Supply Chain Optimization

Digital tools such as AI-driven inventory management, IoT-enabled predictive maintenance, and e-procurement platforms are streamlining the distribution and use of JIC fittings. B2B e-commerce platforms are making it easier for end-users to source standardized fittings, reducing lead times and improving supply chain efficiency.

In conclusion, the JIC connection fittings market in 2026 will be shaped by technological innovation, regulatory demands, and expanding industrial applications. Companies that invest in high-quality, sustainable, and application-specific solutions will be best positioned to capture market share in this evolving landscape.

Common Pitfalls Sourcing JIC Connection Fittings (Quality, IP)

Sourcing JIC (Joint Industry Council) connection fittings—commonly used in high-pressure fluid systems—requires careful consideration to avoid critical issues related to quality and intellectual property (IP). Overlooking these factors can lead to system failures, safety hazards, and legal complications. Below are key pitfalls to watch for:

Poor Material Quality and Non-Compliance

Many suppliers offer JIC fittings made from substandard materials or using incorrect manufacturing processes. Inferior steel alloys or improper heat treatment can compromise strength and corrosion resistance, increasing the risk of leaks or catastrophic failures under pressure. Additionally, fittings may claim to meet SAE J514 or ISO 8434-2 standards but lack proper certification or third-party testing. Always verify material certifications (e.g., mill test reports) and insist on compliance documentation.

Counterfeit or Non-Standard Thread Dimensions

A widespread issue is the proliferation of counterfeit or dimensionally inaccurate fittings. Poorly machined threads or incorrect 37° flare angles prevent proper sealing, leading to leaks and rework. These counterfeits often mimic reputable brands but fail under pressure testing. Conduct dimensional inspections and perform dye penetrant or pressure tests on sample batches before full procurement.

Lack of Traceability and Certification

Reputable suppliers provide full traceability, including heat numbers, batch codes, and test reports. Sourcing from vendors without these records increases the risk of receiving inconsistent or non-compliant products. In regulated industries (e.g., oil & gas, aerospace), this can result in audit failures or project delays. Ensure your supplier adheres to quality management systems like ISO 9001.

Intellectual Property (IP) Infringement

Some manufacturers copy patented designs or use branded logos without authorization, especially in regions with weak IP enforcement. Purchasing such fittings exposes your company to legal risks, including liability for IP violations or being forced to replace entire systems. Always source from authorized distributors or directly from original equipment manufacturers (OEMs) with documented IP rights.

Inadequate Supply Chain Transparency

OEMs may outsource production to third-party factories without proper oversight, resulting in inconsistent quality. Suppliers may also misrepresent their manufacturing capabilities or country of origin. Conduct supplier audits or use third-party inspection services to verify production facilities and processes.

Cost-Driven Sourcing Decisions

Opting for the lowest-cost option often leads to compromised quality. Extremely low prices are a red flag for inferior materials or counterfeit goods. While cost is important, prioritize total cost of ownership—factoring in reliability, maintenance, and downtime—over initial purchase price.

Avoiding these pitfalls requires due diligence, clear specifications, and partnerships with trustworthy suppliers who uphold quality standards and respect intellectual property rights.

Logistics & Compliance Guide for Jic Connection Fittings

This guide outlines the essential logistics and compliance considerations for the handling, transportation, import/export, and usage of JIC (Joint Industry Council) connection fittings. Adhering to these guidelines ensures safe, efficient operations and regulatory compliance across the supply chain.

Overview of JIC Connection Fittings

JIC connection fittings are high-pressure fluid system components commonly used in aerospace, hydraulic, and industrial applications. They feature a 37° flare seating surface and are typically made from materials such as stainless steel, carbon steel, or brass. Due to their use in critical systems, proper handling, documentation, and adherence to standards are vital.

Regulatory Compliance Requirements

JIC fittings must comply with various international and industry-specific standards to ensure performance and safety. Key compliance standards include:

- SAE AS1210: Specifies dimensions and performance requirements for 37° flare fittings.

- ISO 8434-2: International standard for steel tube connections with 37° flare.

- ASME B1.20.1: Governs threaded components to ensure compatibility.

- RoHS and REACH: Applicable if fittings are distributed in the European Union; ensure materials are free from restricted substances.

- NORSOK M-601: Required for use in offshore oil and gas applications (Norway and other regions).

Ensure all fittings are certified and accompanied by Material Test Reports (MTRs) or Certificates of Conformance (CoC).

Packaging and Handling Standards

Proper packaging and handling prevent contamination, corrosion, and mechanical damage:

- Use sealed, moisture-resistant packaging with desiccants for corrosion protection.

- Include protective end caps on all threaded and flared ends.

- Label packages clearly with part numbers, material grade, size, and compliance markings.

- Handle fittings with clean gloves to prevent oil and moisture transfer.

- Store in a dry, temperature-controlled environment away from corrosive agents.

Shipping and Transportation

Follow best practices for domestic and international shipping:

- Use sturdy, crush-resistant outer packaging with internal dividers to prevent movement.

- Clearly mark packages as “Fragile” and “Handle with Care.”

- For international shipments, include a commercial invoice, packing list, and bill of lading.

- Declare accurate Harmonized System (HS) codes (e.g., 7307.29 for steel pipe fittings).

- Comply with IATA/IMDG regulations if transporting by air or sea, especially when shipped with other hazardous materials.

Import/Export Documentation

Ensure full compliance with customs and trade regulations:

- Provide completed customs documentation, including Certificate of Origin if claiming preferential tariffs.

- Declare fittings accurately with correct specifications (material, size, application).

- Be aware of export control regulations (e.g., EAR in the U.S.) if fittings are used in defense or aerospace applications.

- Maintain records for at least five years for audit purposes.

Quality Assurance and Traceability

Implement a traceability system for all JIC fittings:

- Assign unique batch or lot numbers to each production run.

- Maintain records of raw material sources, heat numbers, and inspection reports.

- Conduct incoming inspections for dimensional accuracy, surface finish, and thread integrity.

- Perform pressure testing or non-destructive testing (NDT) as required by the application.

Environmental and Safety Considerations

- Dispose of packaging materials in accordance with local environmental regulations.

- Recycle metal scraps and protect against sharp edges during handling.

- Provide Safety Data Sheets (SDS) if applicable (e.g., for lubricants used in manufacturing).

Supplier and Vendor Compliance

Verify that suppliers adhere to recognized quality management systems:

- Prefer suppliers certified to ISO 9001, AS9100 (aerospace), or ISO 14001.

- Conduct regular audits of supplier facilities and quality processes.

- Require documented compliance with relevant industry standards.

Conclusion

Adhering to this logistics and compliance guide ensures the safe, legal, and efficient movement of JIC connection fittings from manufacturer to end user. Maintaining strict standards in packaging, documentation, and quality control supports reliability in high-pressure applications and minimizes risks across the supply chain.

Conclusion for Sourcing JIC Connection Fittings

Sourcing JIC (Joint Industry Council) connection fittings requires a strategic approach that balances quality, reliability, cost, and compliance with industry standards. These 37-degree flare fittings are widely used in high-pressure hydraulic systems due to their excellent sealing performance and resistance to vibration and pressure cycling. When selecting suppliers, it is essential to prioritize manufacturers and distributors that adhere to international standards such as SAE J514 and ISO 8434-2 to ensure compatibility and system integrity.

Key considerations in the sourcing process include material quality (typically steel, stainless steel, or brass), dimensional accuracy, surface finish, and certification for critical applications. Evaluating supplier reputation, traceability, lead times, and technical support is equally important to maintain supply chain continuity and operational efficiency.

In conclusion, successful sourcing of JIC connection fittings involves a thorough vetting process to ensure product reliability, long-term performance, and compliance with application-specific requirements. By partnering with reputable suppliers and maintaining a clear understanding of technical and regulatory standards, organizations can enhance system safety, reduce maintenance costs, and improve overall operational reliability in hydraulic systems.