The global jewelry laser welding machine market is experiencing robust growth, driven by increasing demand for precision craftsmanship and the rising adoption of automation in fine jewelry manufacturing. According to a report by Grand View Research, the global laser welding market size was valued at USD 1.32 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 7.8% from 2023 to 2030, with the jewelry segment contributing significantly to this expansion. Similarly, Mordor Intelligence projects the laser systems market to grow at a CAGR of over 6.5% during the forecast period of 2023–2028, citing increased applications in micro-welding and repair operations within the luxury and customized jewelry sectors. As manufacturers seek greater accuracy, minimal material distortion, and improved production efficiency, laser welding technology has become indispensable. This growing demand has led to the emergence of advanced machinery from leading global suppliers specializing in jewelry applications. Here are the top 9 manufacturers shaping the future of precision welding in the jewelry industry.

Top 9 Jewelry Laser Welding Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laser Machine – Laser Equipment Manufacturer

Website: dplaser.com

Key Highlights: DPLASER is a leading manufacturer & factory of industrial laser welding, laser cutting, laser marking and laser cleaning machines….

#2 Laser Technology & Laser Machines from ALPHA LASER

Website: alphalaser.eu

Key Highlights: As a leading manufacturer of mobile, flexible, and high-performance laser systems for laser welding, laser hardening, powder deposit welding and additive metal ……

#3 LaserStar Technologies

Website: laserstar.net

Key Highlights: LaserStar Technologies designs and manufactures high-performance laser welding, marking, and cutting systems for industrial, jewelry, ……

#4 Professional Laser Cutting Machine Welding Machine Manufacturer

Website: goldmarklaser.com

Key Highlights: We specialized in design, manufacture fiber laser cutting machine, laser welding machine, laser cleaning machine. Spanning over 20,000 square meters, our modern ……

#5 Mavenlaser is focus on laser application solution company

Website: mavenlazer.com

Key Highlights: Maven Laser Automation Company is a creative manufacturer of laser machines, focusing on jewelry laser marking and cutting machine, jewelry laser welding ……

#6 Orotig: Laser Machinery

Website: orotig.com

Key Highlights: We specialise in engineering and manufacturing laser solutions for welding, engraving, casting and cutting precious and non-precious metals….

#7 Laser Welding Machine

Website: baikeopto.com

Key Highlights: Model:60W YAG laser jewelry welding machine BK-JW60E Pro Voltage:110V/220V Laser Type:1064nm YAG Laser Small size Low weight Easy to operate St……

#8 Machinery and laser systems

Website: sisma.com

Key Highlights: More than 130 machine models for the automatic production of gold chains. Laser systems for brandingmarking, welding, cutting and engraving….

#9 Jewelry Laser Welding Machine

Website: triumphlaser.com

Key Highlights: The jewelry laser welding machine is specifically for jewelry laser welding of a product, mainly used in gold and silver ornaments of the hole and spot welding ……

Expert Sourcing Insights for Jewelry Laser Welding Machine

H2: 2026 Market Trends for Jewelry Laser Welding Machines

The global market for jewelry laser welding machines is poised for significant transformation by 2026, driven by advancements in laser technology, rising demand for precision in jewelry manufacturing, and the growing adoption of automation in small and medium enterprises (SMEs). This analysis explores the key trends expected to shape the industry landscape in 2026 under the H2 framework, focusing on technological innovation, market demand, regional dynamics, and competitive developments.

1. Technological Advancements and Automation Integration

By 2026, jewelry laser welding machines are expected to incorporate smarter, more intuitive features powered by artificial intelligence (AI) and machine learning. Enhanced precision through real-time monitoring systems, adaptive feedback loops, and automated path programming will become standard, reducing operator dependency and minimizing human error. Fiber laser technology, known for its superior beam quality and energy efficiency, will dominate the market, replacing older CO2 and YAG systems. Integration with CAD/CAM software and 3D printing workflows will streamline end-to-end jewelry production, enabling seamless transitions from design to fabrication.

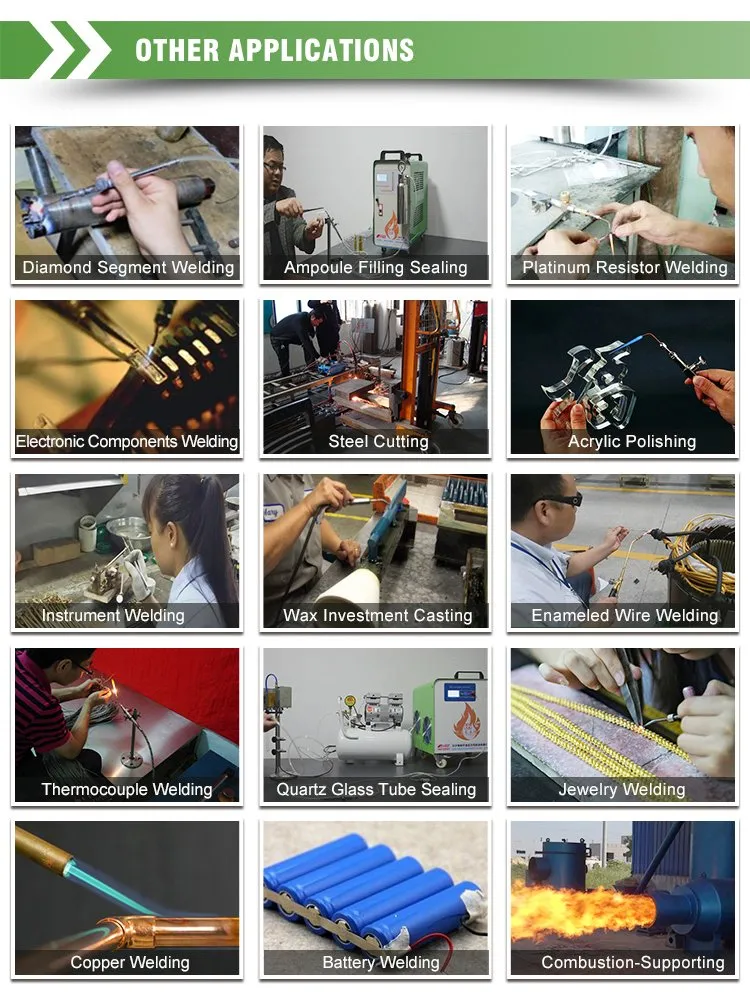

2. Rising Demand for Customization and High-Precision Work

Consumer preference for personalized and intricately designed jewelry is driving demand for high-precision welding solutions. Laser welding allows jewelers to work with delicate materials and complex geometries without damaging surrounding areas. In 2026, the ability to perform micro-welding on small components—such as prongs, clasps, and filigree—will be a key differentiator for laser machine manufacturers. This trend will be particularly strong in luxury and bespoke jewelry segments, where craftsmanship and detail are paramount.

3. Growth in Emerging Markets

Asia-Pacific, especially countries like India, China, and Thailand, will emerge as high-growth regions for jewelry laser welding machines. These nations have long-standing jewelry manufacturing hubs transitioning from traditional techniques to modern laser-based methods to improve efficiency and meet export quality standards. Government initiatives promoting smart manufacturing and digital transformation in sectors like gemstone and jewelry will further accelerate adoption.

4. Sustainability and Energy Efficiency

Environmental considerations are influencing equipment choices in the jewelry industry. By 2026, manufacturers will prioritize energy-efficient laser systems with lower heat output and reduced material waste. Laser welding produces minimal distortion and requires less post-processing, aligning with sustainable manufacturing goals. Equipment suppliers will increasingly market their machines based on eco-friendly performance metrics and compliance with international environmental standards.

5. Competitive Landscape and Market Consolidation

The jewelry laser welding machine market will witness increased competition, with established players such as Rofin-Sinar (now part of Coherent), IPG Photonics, and Han’s Laser expanding their niche offerings. At the same time, smaller regional manufacturers will innovate with cost-effective, entry-level models tailored to artisanal jewelers and startups. Strategic mergers, partnerships, and technology licensing are expected to consolidate the market, especially as demand grows in developing economies.

6. Training and After-Sales Support as Key Differentiators

As laser technology becomes more sophisticated, the availability of training programs, technical support, and remote diagnostics will become critical for customer acquisition and retention. Leading vendors will invest in comprehensive service ecosystems, including online tutorials, certification courses, and cloud-based maintenance platforms, to support a global user base with varying levels of technical expertise.

In conclusion, the 2026 market for jewelry laser welding machines will be defined by innovation, precision, and accessibility. As the jewelry industry embraces digital transformation, laser welding technology will play a central role in enabling faster, cleaner, and more customizable production—positioning it as an indispensable tool for modern jewelers worldwide.

H2: Common Pitfalls When Sourcing Jewelry Laser Welding Machines (Quality and Intellectual Property)

Sourcing a jewelry laser welding machine involves several critical considerations, especially regarding quality assurance and intellectual property (IP) protection. Buyers—particularly small to mid-sized jewelry manufacturers or workshops—often encounter pitfalls that can impact performance, safety, and legal compliance. Below are common issues to watch for:

1. Compromised Machine Quality Due to Low-Cost Suppliers

Many suppliers, especially from regions with less stringent manufacturing standards, offer attractive prices but deliver subpar machines. These may use inferior optics, unstable laser sources, or poorly calibrated components, leading to inconsistent welds, frequent breakdowns, and higher long-term costs. Always verify build quality, component origins (e.g., laser diode manufacturer), and real-world performance through third-party testing or user reviews.

2. Inadequate After-Sales Support and Service

A major pitfall is selecting a supplier without reliable technical support or local service networks. Laser welding machines require regular maintenance, software updates, and troubleshooting. If the supplier is unresponsive or lacks service centers, downtime can severely disrupt production. Ensure service agreements, spare parts availability, and remote support are clearly defined before purchase.

3. Misrepresentation of Technical Specifications

Some vendors exaggerate key specs like laser power (e.g., stating peak instead of continuous output), beam quality (M² factor), or pulse control accuracy. This misleads buyers into believing they’re getting high-precision equipment. Request independent test reports or demo units to validate performance claims under actual working conditions.

4. Lack of IP Compliance and Risk of Infringement

Purchasing machines that incorporate patented technologies (e.g., specific beam delivery systems, software algorithms, or ergonomic designs) without proper licensing can expose buyers to legal liability. Some low-cost manufacturers reverse-engineer or copy protected designs, especially in regions with weak IP enforcement. Always ensure the supplier can provide documentation proving their technology is legally developed or licensed.

5. Hidden Software Limitations and Licensing Issues

Many modern laser welders rely on proprietary software for control, calibration, and diagnostics. Some suppliers lock features behind paid upgrades or fail to provide full software access. Others may use unlicensed software components, creating compliance risks. Confirm software functionality, update policies, and ownership rights in writing.

6. Absence of Safety and Regulatory Certifications

Laser equipment must comply with international safety standards (e.g., IEC 60825 for laser safety, CE, FDA, or RoHS). Machines lacking proper certification may pose health risks or be barred from import in certain countries. Verify all applicable certifications and ensure the machine includes required safety features like interlocks and protective enclosures.

7. Insufficient Training and Documentation

Even high-quality machines underperform if operators aren’t properly trained. Some suppliers provide minimal or poorly translated manuals and no hands-on training. This leads to misuse, accidents, or suboptimal results. Insist on comprehensive training programs and multilingual documentation before finalizing the purchase.

By carefully evaluating suppliers for technical reliability, IP integrity, and post-purchase support, jewelry manufacturers can avoid costly mistakes and ensure a successful investment in laser welding technology.

Logistics & Compliance Guide for Jewelry Laser Welding Machine

General Overview

Transporting and deploying a jewelry laser welding machine requires careful attention to international logistics, customs regulations, and compliance with technical and safety standards. This guide outlines key considerations for seamless delivery and lawful operation.

Packaging & Handling Requirements

Ensure the machine is packed in a custom wooden crate with anti-vibration padding and moisture barriers. Include shock and tilt indicators to monitor handling during transit. All accessories, lenses, and power components should be separately secured and labeled. Properly ground the machine to prevent electrostatic damage.

International Shipping & Documentation

Use air freight for speed or sea freight for cost-efficiency, depending on urgency. Required documents include:

– Commercial Invoice (with full technical specifications and declared value)

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin

– Technical Manual (in English)

– Warranty Certificate

Ensure Harmonized System (HS) code 8515.21.00 (Laser Welding Machines) is correctly applied for customs classification.

Import Regulations & Duties

Research tariffs and import restrictions in the destination country. Some regions may require prior approval from industrial or telecommunications authorities due to laser classification. VAT, customs duties, and possible anti-dumping taxes may apply. Engage a local customs broker for accurate assessment.

Laser Safety & Regulatory Compliance

The machine must comply with laser safety standards:

– IEC 60825-1: Safety of laser products (Class 4 laser – requires interlocks, warning labels, key switch)

– FDA 21 CFR Part 1040.10 (for U.S. market): Requires laser product reporting and compliance certification

– CE Marking (for EU): Includes compliance with Machinery Directive 2006/42/EC and EMC Directive 2014/30/EU

Provide a Declaration of Conformity and user safety instructions in the local language.

Electrical & Environmental Standards

Verify voltage compatibility (typically 110V or 220V, 50/60Hz). Include appropriate plug adapters or recommend voltage converters. Confirm compliance with RoHS (EU) and REACH regulations for material restrictions. Ensure electromagnetic compatibility (EMC) per local standards.

Installation & Operational Compliance

Installation must be performed by certified technicians. The workplace must have:

– Adequate ventilation or fume extraction

– Laser-safe eyewear for operators (wavelength-specific)

– Controlled access to the laser operation zone

– Emergency stop mechanisms

Maintain logs for laser usage, maintenance, and safety inspections.

After-Sales Service & Warranty Logistics

Confirm warranty terms, including coverage for parts, labor, and on-site support. Provide contact details for technical support and spare parts ordering. Ship replacement components with proper documentation to avoid customs delays.

Key Tips for Smooth Deployment

- Pre-verify import requirements with local authorities

- Retain all compliance certificates for customs and audits

- Train staff on safety protocols before operation

- Register the laser device if required by local regulations

Adhering to this guide ensures timely delivery, regulatory compliance, and safe, efficient use of your jewelry laser welding machine.

Conclusion for Sourcing a Jewelry Laser Welding Machine

Sourcing a jewelry laser welding machine is a strategic investment that can significantly enhance precision, efficiency, and quality in jewelry manufacturing and repair. After evaluating key factors such as power output, pulse control, beam quality, ease of use, after-sales support, and budget, it becomes clear that selecting the right machine requires a balance between technical capabilities and long-term value.

Laser welding offers distinct advantages over traditional methods—minimized heat distortion, excellent control for delicate designs, and strong, clean welds—making it ideal for intricate jewelry work. When sourcing, prioritize reputable suppliers with proven experience in the jewelry industry, comprehensive training, and reliable technical support.

Additionally, consider future scalability and integration with other digital tools like CAD/CAM systems. Whether purchasing new or opting for a certified pre-owned unit, ensure proper verification of specifications and performance.

In conclusion, investing in the right jewelry laser welding machine not only improves craftsmanship and productivity but also positions a business to meet evolving customer demands and maintain a competitive edge in a precision-driven market. A well-informed sourcing decision today lays the foundation for long-term success in modern jewelry production.