The global demand for precision and traceability in the jewellery industry has driven significant adoption of laser marking technology, with the laser marking machines market projected to grow at a CAGR of 7.8% from 2024 to 2030, according to Grand View Research. As consumers increasingly prioritize authenticity and craftsmanship, jewellers are turning to advanced marking solutions that ensure permanent, high-contrast identification without compromising delicate designs. This shift is further accelerated by rising regulatory requirements for hallmarking and supply chain transparency across major markets like India, the Middle East, and Europe. With an estimated 40% of mid-to-large scale jewellery manufacturers expected to integrate laser-based identification systems by 2026 (Mordor Intelligence, 2023), the competitive landscape has seen a surge in specialized manufacturers offering fibre, UV, and green laser technologies tailored to precious metals and gemstone settings. This growing demand underscores the importance of selecting reliable and technologically advanced partners—making the evaluation of the top eight jewellery laser marking machine manufacturers a critical step for industry stakeholders aiming to enhance traceability, meet compliance standards, and deliver branded excellence.

Top 8 Jewellery Laser Marking Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 International Laser Marking Machine Manufacturer & Supplier …

Website: hunstlaser.com

Key Highlights: Hunst Laser is a laser marking machine manufacturer which represents high quality laser technology and its application expertise….

#2 Dolphin Laser Machine Pvt. Ltd.

Website: dolphinlasermachine.com

Key Highlights: Dolphin Laser Machine Pvt. Ltd., based in Ahmedabad, is a leading manufacturer and exporter of industrial laser machines, including marking, cutting, engraving ……

#3 Laser Marking for All Industries

Website: lasermarktech.com

Key Highlights: Discover innovative laser marking solutions tailored for various industries. Explore our cutting-edge technology as leaders in laser marking and engraving….

#4 Orotig: Laser Machinery

Website: orotig.com

Key Highlights: We specialise in engineering and manufacturing laser solutions for welding, engraving, casting and cutting precious and non-precious metals in the jewellery, ……

#5 Laser Equipment Supplier

Website: radianlaser.com

Key Highlights: Radian Laser Systems is a laser equipment supplier specializing in high-speed, customizable laser machinery, including fiber, CO2, and galvo lasers….

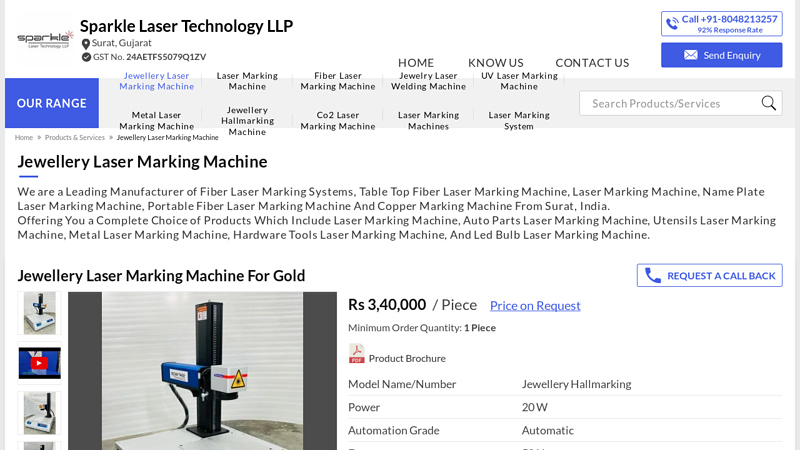

#6 Jewellery Laser Marking Machine For Gold

Website: sparklelasermachine.com

Key Highlights: Fiber Laser Hallmarking Machine · Marking Speed: 8000 mm/s · Usage/Application: Jewellery Gold, Silver, Platinum · Marking Speed Capacity: 7000 mm/s · Country of ……

#7 Machinery and laser systems

Website: sisma.com

Key Highlights: More than 130 machine models for the automatic production of gold chains · Laser systems for marking, welding, cutting and engraving. · Laser systems for welding….

#8 Laser Cutting, Engraving & Marking Machines

Website: thunderlaser.com

Key Highlights: Thunder Laser offers high-quality, reliable laser machines to meet the needs of a variety of industries. ThunderLaser has become a well-recognized icon in ……

Expert Sourcing Insights for Jewellery Laser Marking Machine

H2: 2026 Market Trends for Jewellery Laser Marking Machines

The global market for jewellery laser marking machines is poised for significant transformation by 2026, driven by technological advancements, rising consumer demand for personalized jewellery, and the increasing need for traceability and anti-counterfeiting measures in the luxury goods sector. Key trends shaping the industry include:

1. Rising Demand for Personalization and Customization

Consumers are increasingly seeking unique, bespoke jewellery pieces, fueling demand for precision marking technologies. Laser marking machines enable intricate engravings, serial numbers, logos, and QR codes on delicate materials such as gold, silver, platinum, and gemstones. By 2026, manufacturers are expected to integrate more user-friendly software and AI-driven design interfaces to streamline custom orders, enhancing customer engagement and brand loyalty.

2. Advancements in Laser Technology

By 2026, fibre and UV laser systems are projected to dominate the jewellery marking segment due to their high precision, minimal thermal impact, and ability to mark on reflective surfaces without damage. Innovations such as ultra-short pulse (picosecond and femtosecond) lasers will enable finer detailing and high-contrast marks, meeting the aesthetic standards of luxury jewellery brands.

3. Integration with Smart Manufacturing and Industry 4.0

Jewellery manufacturers are adopting digital factory solutions, integrating laser marking systems with ERP and MES platforms. This connectivity allows real-time tracking, automated batch processing, and seamless traceability from production to retail. By 2026, IoT-enabled laser marking machines with remote monitoring and predictive maintenance capabilities will become standard in high-volume production environments.

4. Emphasis on Traceability and Compliance

Regulatory requirements and ethical sourcing standards are pushing brands to adopt permanent, tamper-proof marking for authenticity and provenance verification. Laser marking supports compliance with international standards such as the Kimberley Process and EU Conflict Minerals Regulation. By 2026, the integration of laser-marked QR codes or Data Matrix codes linked to blockchain-based certification systems is expected to gain widespread adoption.

5. Expansion in Emerging Markets

Asia-Pacific, particularly India, China, and Southeast Asia, will remain key growth regions due to rising disposable incomes, a growing middle class, and expanding jewellery manufacturing hubs. Local manufacturers are investing in cost-effective, high-efficiency laser marking solutions, driving demand for compact and semi-automated systems tailored to small and medium enterprises (SMEs).

6. Sustainability and Eco-Friendly Production

As sustainability becomes a priority, laser marking offers a chemical-free, non-contact alternative to traditional engraving and acid etching. By 2026, eco-conscious brands will increasingly favor laser systems that reduce material waste and energy consumption, aligning with green manufacturing initiatives.

7. Competitive Landscape and Market Consolidation

The market will witness increased competition among key players such as Trumpf, Han’s Laser, Gravograph, Trotec, and Epilog Laser, leading to product differentiation through software integration, service support, and modular designs. Strategic partnerships with jewellery design platforms and retail chains are expected to emerge, offering turnkey marking solutions.

In conclusion, the jewellery laser marking machine market in 2026 will be shaped by digital transformation, customization demands, and regulatory pressures. Companies that invest in precision technology, smart integration, and sustainable practices will lead the next phase of growth in this dynamic sector.

Common Pitfalls When Sourcing a Jewellery Laser Marking Machine: Quality and Intellectual Property Risks

Logistics & Compliance Guide for Jewellery Laser Marking Machine

Overview

This guide provides essential information for the safe, efficient, and compliant international shipment and operation of jewellery laser marking machines. It covers packaging, shipping, import/export regulations, safety standards, and end-user compliance considerations.

Packaging & Handling

Ensure the laser marking machine is securely packaged to prevent damage during transit. Use original manufacturer packaging whenever possible, including foam inserts and protective wraps. All components (laser head, control unit, power supply, cables) should be individually wrapped and immobilized within a sturdy, shock-resistant export crate. Clearly label the crate as “Fragile,” “This Side Up,” and “Do Not Stack.” Include desiccant packs to control moisture, especially for long sea freight routes.

Shipping & Transportation

Use reputable freight forwarders experienced in handling precision machinery. Choose appropriate transport modes (air, sea, or land) based on urgency, cost, and destination. For air freight, ensure compliance with IATA Dangerous Goods Regulations if batteries (e.g., backup or embedded) are present. For sea freight, secure the machine against vibration and environmental exposure. Provide detailed shipping documents, including commercial invoice, packing list, bill of lading/air waybill, and insurance certificate.

Export Compliance

Verify that the laser marking machine complies with export control regulations in the country of origin. In the United States, check if the machine falls under the Export Administration Regulations (EAR) and determine the correct Export Control Classification Number (ECCN). Most industrial laser systems are classified under ECCN 2B001 or 2B201, requiring a license for certain destinations. Similar controls exist under the EU Dual-Use Regulation and other national frameworks. Obtain necessary export licenses before shipment.

Import Regulations

Research import requirements in the destination country, including customs duties, import taxes, and product-specific regulations. Provide accurate Harmonized System (HS) codes—typically under 8456.20 (laser machining tools) or 8515.21 (laser-based processing machines). Some countries require pre-shipment inspections, import permits, or conformity assessments. Ensure all documentation is translated if required by local customs authorities.

Laser Safety Certification

Confirm that the machine complies with international laser safety standards. Key certifications include:

– IEC 60825-1: Safety of laser products – Equipment classification and requirements

– FDA 21 CFR Part 1040.10 (USA): Performance standard for laser products

– CE Marking (Europe): Includes compliance with the Machinery Directive (2006/42/EC) and Laser Product Safety standards

Provide the end-user with the laser classification (typically Class 1 or Class 4, depending on enclosure), technical specifications, and safety interlocks documentation.

Electrical & EMC Compliance

Ensure the machine meets the electrical safety and electromagnetic compatibility (EMC) standards of the destination market. Required certifications may include:

– CE (Europe): Low Voltage Directive (LVD) and EMC Directive

– UKCA (United Kingdom): Equivalent to CE marking

– UL/CSA (North America): UL 61010-1 for electrical safety

Verify voltage compatibility (e.g., 110V vs. 220–240V) and provide appropriate power cords or transformers.

End-User Compliance Responsibilities

Inform buyers of their obligations under local regulations. In many countries, Class 3B or Class 4 lasers (even if enclosed) require registration with national radiation protection or occupational safety authorities. Users may need to appoint a Laser Safety Officer (LSO), conduct risk assessments, and implement safety protocols such as controlled access, warning signs, and protective eyewear. Provide multilingual user manuals and safety instructions.

Environmental & RoHS Compliance

Ensure the machine complies with environmental directives such as the EU’s Restriction of Hazardous Substances (RoHS) Directive 2011/65/EU, which restricts lead, mercury, cadmium, and other substances. Provide a RoHS compliance declaration. Also, consider WEEE (Waste Electrical and Electronic Equipment) requirements for end-of-life disposal guidance.

After-Sales & Service Support

Include information on warranty, technical support, and service availability. For international customers, clarify whether support is provided locally or remotely. Ensure spare parts logistics are established and repair turnaround times are communicated.

Summary

Successful logistics and compliance for jewellery laser marking machines require careful attention to packaging, documentation, and regulatory standards across jurisdictions. Proactive planning ensures timely delivery, avoids customs delays, and enables safe, legal operation by the end-user. Always consult with legal and logistics experts familiar with your target markets.

Conclusion: Sourcing a Jewellery Laser Marking Machine

Sourcing a laser marking machine for the jewellery industry is a strategic investment that enhances product value, traceability, and brand integrity. After evaluating technical specifications, material compatibility, precision requirements, and budget considerations, it is clear that fiber laser marking machines are the most suitable choice for marking precious metals such as gold, silver, and platinum. Their ability to produce high-contrast, permanent, and intricate markings—including serial numbers, logos, hallmarks, and QR codes—ensures compliance with industry standards and strengthens customer trust.

Key factors in the sourcing decision include the machine’s marking speed, software ease of use, integration capabilities with existing production systems, after-sales support, and warranty. Opting for a reputable supplier with proven experience in the jewellery sector ensures reliability, minimal downtime, and access to technical expertise.

In conclusion, investing in a high-quality, precision-engineered laser marking machine not only improves operational efficiency but also supports branding, anti-counterfeiting efforts, and customer satisfaction. As demand for personalized and authenticated jewellery grows, adopting laser marking technology positions businesses competitively in a modern, quality-driven market.