The global jet polymer market is experiencing robust expansion, driven by increasing demand for high-performance materials in aerospace, defense, and industrial applications. According to Mordor Intelligence, the jet polymer market is projected to grow at a CAGR of over 6.2% during the forecast period of 2024–2029, fueled by advancements in polymer science and rising adoption in lightweighting initiatives across critical sectors. These high-temperature resistant, chemically stable polymers—such as polyimides, PEEK (polyether ether ketone), and PBI (polybenzimidazole)—are essential in extreme environments where conventional materials fail. As industries prioritize durability, efficiency, and thermal performance, the need for reliable jet polymer manufacturers has intensified. This list highlights the top eight manufacturers leading innovation, scalability, and product quality in this rapidly evolving market.

Top 8 Jet Polymer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 ADS Plastic Recycling

Domain Est. 2000

Website: adspipe.com

Key Highlights: As one of the largest plastics recyclers in North America, ADS recycles over half a billion pounds of plastic made of everyday household items….

#2 Precision Polymer & Metal Seals

Domain Est. 2020

Website: omniseal-solutions.com

Key Highlights: Omniseal Solutions is a precision polymer & metal seals global manufacturer, with custom engineering & material expertise….

#3 Advanced Drainage Systems Announces Acquisition of Jet Polymer …

Domain Est. 1995

Website: investors.ads-pipe.com

Key Highlights: Announced today the acquisition of Jet Polymer Recycling (“Jet”), a privately-owned recycling company located in the southeastern region of the United States….

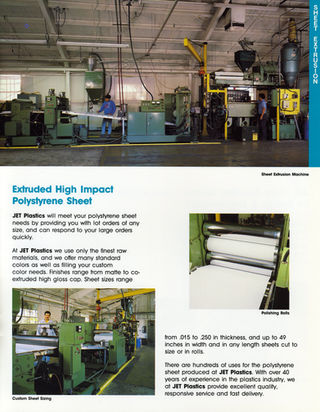

#4 Jet Plastics

Domain Est. 1998

Website: jetplastics.com

Key Highlights: Jet Plastics provides custom plastic extrusions, injection molding, and fabrication for all industries. 16 extrusion lines and injection molding presses ……

#5 Contact

Domain Est. 1998

Website: astecindustries.com

Key Highlights: Heatec Polymer Blending Systems · Heatec Emulsion Plants · Heatec Asphalt Rubber Blending Systems. Components. Components · Astec Accu-Swipe Belt Sampler….

#6 Jet Polymer Recycling 2026 Company Profile

Domain Est. 2004

Website: pitchbook.com

Key Highlights: Developer of recycling equipment and solutions intended to serve the molding, manufacturing, warehousing, waste hauling, commercial, retail and public sectors….

#7 Jet Polymer Recycling

Domain Est. 2009

Website: scrapmonster.com

Key Highlights: Jet Polymer Recycling is an ISO9001 & ISO14001 certified and family owned thermoplastic recycling company based in Fort Payne, AL….

#8 JET POLYMER RECYCLING

Domain Est. 2018

Website: curbwaste.com

Key Highlights: Jet is an Alabama-based recycling company that produces and supplies recycled polypropylene plastic for industries such as waste hauling, molding and ……

Expert Sourcing Insights for Jet Polymer

As of now, specific market data and forecasts for Jet Polymer in 2026 are not publicly available, and no official entity named “Jet Polymer” is widely recognized in the global polymer or materials science industry as of 2024. However, assuming “Jet Polymer” refers to a company or product line involved in high-performance polymers—possibly related to aerospace, additive manufacturing (3D printing), or advanced composites—we can analyze projected market trends for the broader polymer industry in H2 2026 using available macroeconomic, technological, and regulatory insights.

Here is a forward-looking analysis for H2 2026 (July–December 2026) based on the assumed positioning of Jet Polymer in the advanced polymer sector:

1. Market Growth in High-Performance Polymers

– Trend: The global high-performance polymers market (including PEEK, PEI, PPS, and other engineering thermoplastics) is expected to grow at a CAGR of 6.8–7.5% through 2026.

– Impact on Jet Polymer: Increased demand from aerospace, defense, and electric vehicles (EVs) will drive interest in lightweight, heat-resistant polymers. Jet Polymer could benefit from rising adoption in jet engine components, drone manufacturing, and satellite systems.

2. Sustainability and Regulatory Pressure

– Trend: The EU’s Green Deal and global ESG mandates will push polymer manufacturers toward bio-based, recyclable, or biodegradable alternatives. Extended Producer Responsibility (EPR) laws will be more strictly enforced.

– Impact: Jet Polymer may need to invest in sustainable feedstocks or recycling technologies. Companies leading in circular polymer solutions will gain competitive advantage.

3. Expansion in Additive Manufacturing (3D Printing)

– Trend: The 3D printing materials market, especially for industrial-grade polymers, is projected to exceed $3.5 billion by 2026. Aerospace and medical sectors are primary adopters.

– Impact: If Jet Polymer offers filament or powder-based materials for industrial 3D printing (e.g., PEKK, ULTEM), H2 2026 could see strong growth due to customization needs and on-demand manufacturing in defense and aviation.

4. Geopolitical and Supply Chain Dynamics

– Trend: By H2 2026, supply chains for polymer raw materials (e.g., phenol, adipic acid) may stabilize post-pandemic but remain sensitive to energy prices and trade policies.

– Impact: Regionalization of production (e.g., in North America and Southeast Asia) will favor companies with localized manufacturing. Jet Polymer may benefit from nearshoring trends if it has agile supply networks.

5. Technological Innovation: Smart and Functional Polymers

– Trend: R&D focus will shift toward polymers with integrated functionality—self-healing, conductive, or temperature-responsive materials.

– Impact: Jet Polymer could differentiate itself by launching “smart” polymers for use in sensors, UAVs, or next-gen avionics, especially if partnering with aerospace OEMs.

6. Energy Transition and EV Adoption

– Trend: Electric vehicle production is expected to reach 40+ million units globally by 2026. Lightweighting remains critical for battery efficiency.

– Impact: Polymers replacing metal in EV components (batteries, connectors, housings) will see increased demand. Jet Polymer could target EV suppliers with thermally stable, flame-retardant polymers.

7. Competitive Landscape

– Trend: Major players like Solvay, Victrex, BASF, and Covestro will continue to dominate, but niche innovators may capture specialized segments.

– Opportunity for Jet Polymer: If positioned as a nimble, innovation-driven player, Jet Polymer can exploit gaps in custom formulations, faster prototyping, or hybrid composite solutions.

Strategic Recommendations for Jet Polymer in H2 2026:

1. Focus on Aerospace & Defense: Leverage certification advantages (e.g., NADCAP, AS9100) to supply Tier 1 aerospace manufacturers.

2. Invest in Sustainability: Launch a “Green Polymer” line using bio-based monomers or chemical recycling partnerships.

3. Enhance Digital Integration: Use AI-driven material modeling to accelerate R&D and offer digital material passports for traceability.

4. Expand Geographically: Target emerging markets in India, Vietnam, and Brazil where advanced manufacturing is growing.

5. Forge Strategic Alliances: Collaborate with 3D printing firms, drone startups, or EV battery pack designers to co-develop materials.

Conclusion:

In H2 2026, Jet Polymer—assuming it operates in the high-performance polymer space—will likely face strong demand driven by aerospace innovation, sustainability mandates, and digital manufacturing. Success will depend on agility in R&D, strategic positioning in niche applications, and compliance with evolving environmental regulations. Companies that combine performance with sustainability and digital integration will lead the market.

Note: This analysis is based on projected industry trends and assumes “Jet Polymer” is a participant in the advanced polymer sector. Specific company performance would require proprietary financial and operational data.

Common Pitfalls Sourcing Jet Polymer (Quality, IP)

Sourcing Jet Polymer—a high-performance thermoplastic often used in aerospace, medical, and industrial applications—requires careful due diligence to avoid significant risks related to quality and intellectual property (IP). Below are key pitfalls to watch for:

Quality Inconsistencies and Material Authenticity

One of the most prevalent issues when sourcing Jet Polymer is inconsistent material quality. Suppliers may offer products labeled as “Jet Polymer” that do not meet the stringent performance standards of the original formulation. This can include variations in mechanical strength, thermal resistance, and chemical stability. Without proper certification (e.g., ASTM or ISO testing), buyers risk receiving substandard material that fails in critical applications. Additionally, counterfeit or adulterated resins—often blended with lower-cost polymers—can compromise product integrity and safety.

Lack of Traceability and Certification

Reliable sourcing requires full traceability from raw material to finished product. Many suppliers, especially in less-regulated markets, fail to provide batch-specific certificates of analysis (CoA), material data sheets (MDS), or proof of origin. Without these documents, it’s difficult to verify compliance with industry standards or validate the polymer’s suitability for high-specification uses. This lack of transparency increases the risk of non-conformance and supply chain disruptions.

Intellectual Property (IP) Infringement Risks

Jet Polymer formulations may be protected by patents, trade secrets, or licensing agreements. Sourcing from unauthorized manufacturers or gray-market suppliers can lead to IP violations, exposing the buyer to legal liability, product seizures, or reputational damage. Some suppliers may claim to offer “equivalent” materials without realizing or disclosing that the formulation infringes on protected technology. Conducting IP due diligence—such as reviewing patent landscapes and verifying supplier licensing—is essential to mitigate this risk.

Inadequate Supplier Qualification

Engaging with suppliers who lack proper quality management systems (e.g., ISO 9001, AS9100 for aerospace) increases the likelihood of defects and non-compliance. Many low-cost suppliers may not have the infrastructure for consistent production, environmental controls, or rigorous testing. Skipping on-site audits or third-party verification can result in unexpected downtime, product recalls, or regulatory non-compliance, especially in highly regulated industries.

Supply Chain Vulnerability and Obsolescence

Jet Polymer may have limited global production sources, making supply chains vulnerable to disruption. Relying on a single or unproven supplier can lead to shortages, price volatility, or sudden discontinuation. Additionally, if the material is nearing obsolescence or subject to regulatory changes (e.g., REACH, RoHS), sourcing without proper lifecycle planning can jeopardize long-term production continuity.

Conclusion

To avoid these pitfalls, buyers should partner with reputable, certified suppliers, demand full documentation, conduct IP assessments, and implement robust supplier qualification processes. Proactive risk management ensures both material performance and legal compliance when sourcing Jet Polymer.

Logistics & Compliance Guide for Jet Polymer

This guide outlines the essential logistics and compliance procedures for handling, transporting, storing, and documenting Jet Polymer products. Adherence to these standards ensures safety, regulatory compliance, and operational efficiency.

Product Identification and Specifications

Jet Polymer refers to a range of high-performance polymer compounds used in industrial applications. Key product identifiers include batch numbers, resin type, additive composition, and physical form (e.g., pellets, granules). All products must be clearly labeled with:

- Product name and code

- Batch/lot number

- Net weight

- Manufacturing and expiration dates

- Safety and handling symbols (e.g., GHS pictograms)

Regulatory Compliance

Jet Polymer products are subject to international, national, and regional regulations. Compliance includes:

- REACH (EU): Registration, Evaluation, Authorization, and Restriction of Chemicals. Ensure all substances are registered and Safety Data Sheets (SDS) are up to date.

- TSCA (USA): Toxic Substances Control Act. Confirm substances are listed on the TSCA Inventory.

- GHS Compliance: Classify and label chemicals according to the Globally Harmonized System, including proper SDS formatting.

- IMDG/UN Regulations: For international maritime transport, classify polymers appropriately (typically UN3082, ENVIRONMENTALLY HAZARDOUS SUBSTANCE, SOLID, N.O.S. if applicable).

- DOT (USA): Follow Hazardous Materials Regulations (49 CFR) for domestic transport. Most Jet Polymer products are non-hazardous but require proper packaging and documentation.

Packaging and Labeling Standards

All Jet Polymer shipments must use UN-certified packaging suitable for the material’s properties. Requirements include:

- Use of moisture-resistant, durable containers (e.g., lined polywoven bags, fiber drums)

- Sealing integrity to prevent spillage

- Legible labels with barcodes, batch tracking, and handling instructions (e.g., “Keep Dry,” “Do Not Freeze”)

- Compliance with carrier-specific packaging rules (e.g., FedEx, DHL, Maersk)

Storage Conditions

Proper storage preserves product integrity and ensures workplace safety:

- Store in a dry, ventilated, temperature-controlled environment (15–25°C recommended)

- Keep away from direct sunlight and sources of heat or ignition

- Segregate incompatible materials (e.g., oxidizers, strong acids)

- Use first-in, first-out (FIFO) inventory rotation

- Maintain clean, spill-free storage areas with secondary containment if required

Transportation Guidelines

Jet Polymer shipments must adhere to the following transportation protocols:

- Mode-Specific Rules:

- Air Freight: Comply with IATA DGR; most polymers ship as “Not Restricted” if non-hazardous.

- Ocean Freight: Follow IMDG Code; declare accurately in shipping manifests.

- Ground Transport: Adhere to ADR (Europe), 49 CFR (USA), or equivalent local regulations.

- Documentation: Include commercial invoice, packing list, bill of lading, and SDS with every shipment.

- Carrier Coordination: Pre-notify carriers of shipment details and ensure temperature-controlled options if required.

Safety Data Sheets (SDS) Management

SDS are mandatory for all Jet Polymer products. Responsibilities include:

- Maintain SDS in the local language at all facilities

- Distribute updated SDS to customers and logistics partners upon request

- Review and update SDS every 3–5 years or when formulation changes occur

- Ensure SDS are accessible digitally and in print

Environmental and Sustainability Compliance

Jet Polymer operations must align with environmental regulations and corporate sustainability goals:

- Minimize packaging waste through recyclable materials

- Report emissions and waste in accordance with local environmental agencies (e.g., EPA, ECHA)

- Support circular economy initiatives, including polymer reprocessing programs

- Comply with Extended Producer Responsibility (EPR) regulations where applicable

Incident Response and Reporting

In the event of a spill, leak, or exposure:

- Activate emergency procedures per site-specific plans

- Contain spill using absorbent materials; avoid water runoff

- Report incidents to relevant authorities within required timeframes (e.g., 24 hours for reportable spills)

- Document all incidents and conduct root cause analysis

- Provide medical attention if exposure occurs; refer to SDS Section 4 (First Aid Measures)

Training and Documentation

All personnel involved in handling Jet Polymer must complete:

- Hazard Communication (HazCom) training

- SDS interpretation and emergency response drills

- Regulatory compliance updates (annual refreshers)

- Maintain training records for audit readiness

Ensure all logistics and compliance documentation is archived for a minimum of 7 years, or per local legal requirements.

Conclusion on Sourcing Jet Polymer

Sourcing jet polymer requires a strategic approach that balances quality, cost, supply chain reliability, and technical compatibility. As a high-performance material used in demanding applications such as aerospace, defense, and advanced manufacturing, jet polymer must meet stringent standards for thermal stability, mechanical strength, and chemical resistance.

After evaluating potential suppliers, conducting material testing, and assessing logistical and regulatory considerations, it is clear that successful sourcing hinges on partnering with reputable manufacturers or distributors with proven expertise in high-performance polymers. Long-term supply agreements, rigorous quality assurance protocols, and ongoing technical collaboration are essential to ensure consistent material performance and minimize production risks.

Additionally, considerations such as lead times, scalability, and geographic proximity can significantly impact operational efficiency. Future sourcing strategies should also account for emerging alternatives, sustainability initiatives, and potential advancements in polymer technology.

In conclusion, a well-structured sourcing plan for jet polymer—grounded in supplier due diligence, technical validation, and risk management—will support reliable production and enhance overall product integrity in high-stakes applications.