The global jet propulsion system market, a key enabler for high-performance watercraft such as jet boats, is experiencing steady growth driven by rising demand in recreational marine applications and advancements in propulsion efficiency. According to a report by Grand View Research, the global marine propulsion market size was valued at USD 22.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030. This growth is fueled by increasing investments in lightweight, high-efficiency propulsion systems—particularly jet pumps—which offer superior maneuverability and shallow-water operation compared to traditional propeller-driven units. As demand for personal watercraft and utility jet boats continues to rise across North America, Europe, and the Asia Pacific, the need for reliable and high-performance jet pumps has placed manufacturers at the forefront of marine innovation. In this competitive landscape, a select group of companies are leading through advanced engineering, scalable production, and a strong focus on durability and efficiency. Here, we present the top 10 jet boat jet pump manufacturers shaping the industry with proven performance, innovation, and global reach.

Top 10 Jet Boat Jet Pumps Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 All our parts online!

Domain Est. 2010

Website: jetthruster.com

Key Highlights: The Official Jet Thruster Manufacturer Website Copyright 2010-2024. Disclaimer: CE All our products are manufactured according to CE regulations. Towards all ……

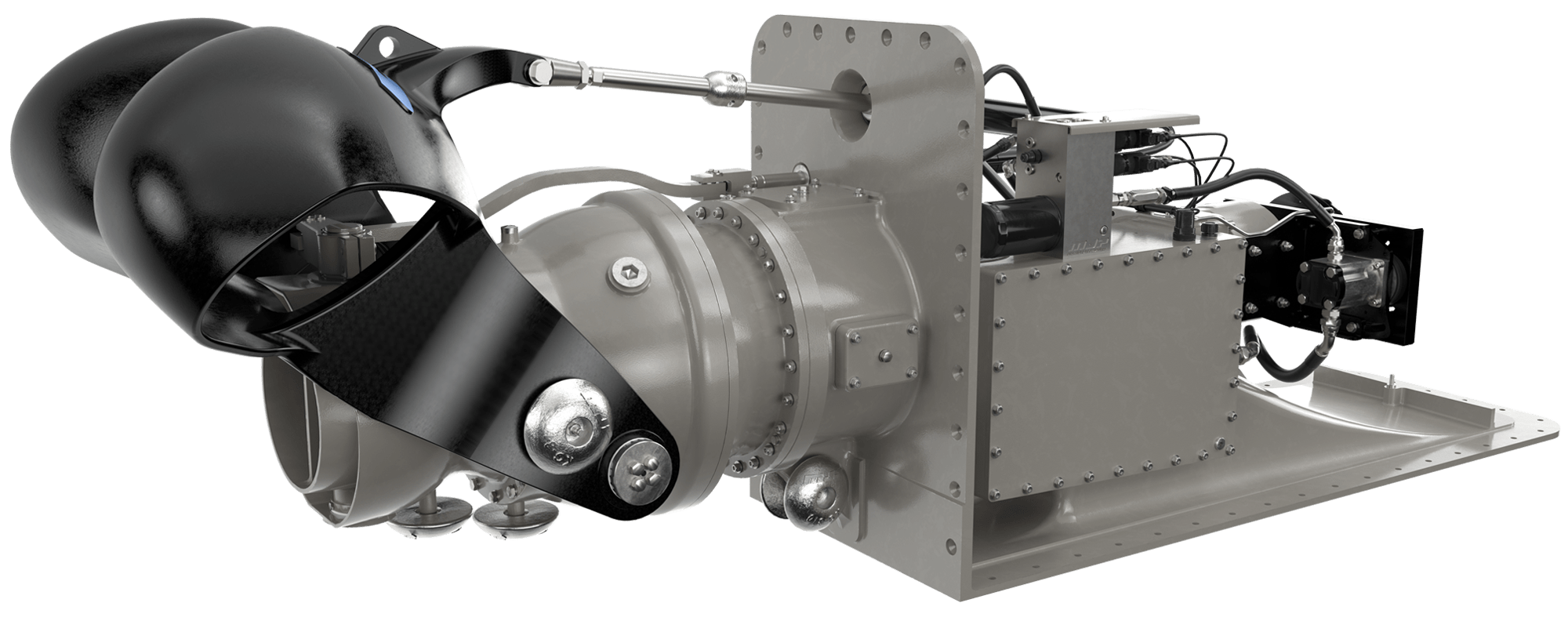

#2 Marine Jet Power

Domain Est. 2012

Website: marinejetpower.com

Key Highlights: PROVEN PUMP DESIGN MJP’s proprietary pump design features a stainless steel impeller and proven mixed-flow technology for maximum efficiency and high speeds….

#3 Jet Pump

Domain Est. 1996

Website: solas.com

Key Highlights: A new product line of jet pump series, for the personal watercraft market. This new line of products is based on modern hydrodynamics design and intensive ……

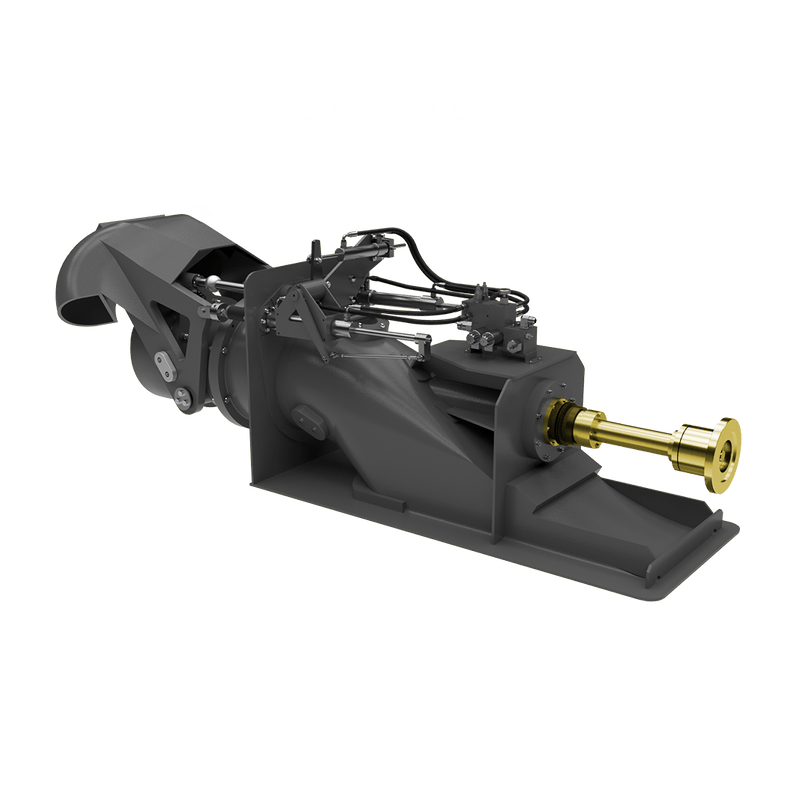

#4 HamiltonJet

Domain Est. 1997

Website: hamiltonjet.com

Key Highlights: The HamiltonJet waterjet is one of the most advanced and innovative marine propulsion systems in use today, and is at the forefront of waterjet propulsion ……

#5 Doen WaterJets

Domain Est. 1997

Website: doen.com

Key Highlights: Doen WaterJets is home to best in class marine waterjet propulsion solutions that deliver unmatched performance, efficiency and uptime….

#6 EcoJet

Domain Est. 1997

Website: indmar.com

Key Highlights: Indmar’s hull insert design isolates the entire jet pump in rubber, reducing engine noise and pump vibrations (NVH) to deliver a quieter and smoother boating ……

#7 Jet Engines & Pumps

Domain Est. 1998

Website: marinepowerusa.com

Key Highlights: From the latest MEFI fuel injection to aluminum performance exhaust systems, our jet boat engines come equipped for maximum results….

#8 Complete Jet Pumps

Domain Est. 1999

Website: berkeleyjet.com

Key Highlights: 30-day returnsStarting with Berkeley’s unique single stage mixed flow impeller that produces maximum thrust per horsepower. The 12JI Pump also incorporates a special trimming ……

#9 PumpJet.com

Domain Est. 2006

Website: pumpjet.com

Key Highlights: Pump Jet outboard motor propulsion, RescuePro, Enforcer models for first responders, swift water rescue, and military operations….

#10 Southern Jet

Domain Est. 2021

Website: southernjet.ca

Key Highlights: We not only manufacture high quality pumps, but a large range of upgrades and components for most of the common jet pumps on the market….

Expert Sourcing Insights for Jet Boat Jet Pumps

H2: 2026 Market Trends for Jet Boat Jet Pumps

The global market for jet boat jet pumps is poised for significant evolution by 2026, driven by technological innovation, increasing recreational demand, and a shift toward sustainable marine propulsion systems. Key trends shaping the industry include:

-

Growing Demand in Recreational and Commercial Sectors

The recreational boating industry continues to expand, particularly in North America, Europe, and parts of Asia-Pacific. Jet boats—valued for their maneuverability, shallow-water performance, and safety—are becoming increasingly popular among consumers. This trend is expected to boost demand for high-efficiency jet pumps. Additionally, commercial applications such as river tours, emergency response, and law enforcement are adopting jet-propelled vessels for their reliability in diverse water conditions. -

Technological Advancements in Pump Efficiency and Materials

By 2026, manufacturers are focusing on enhancing jet pump performance through advanced composite materials, improved impeller designs, and computational fluid dynamics (CFD) modeling. These innovations aim to increase thrust efficiency, reduce cavitation, and lower fuel or energy consumption. Lightweight, corrosion-resistant materials like carbon fiber and high-grade polymers are being adopted to extend pump lifespan and reduce maintenance costs. -

Electric and Hybrid Propulsion Integration

A major trend shaping the future of jet pumps is the integration with electric and hybrid propulsion systems. As marine electrification gains momentum, jet pump designs are being adapted to work efficiently with electric motors. This shift supports environmental regulations and appeals to eco-conscious consumers. Companies are investing in electric jet pump prototypes, with several expected to reach commercialization by 2026. -

Sustainability and Regulatory Pressures

Stricter environmental regulations—such as the IMO’s emissions guidelines and regional emissions standards in the U.S. and EU—are pushing manufacturers to develop cleaner propulsion technologies. Jet pumps, which typically have fewer external moving parts and less environmental impact on aquatic ecosystems compared to propellers, are gaining favor. By 2026, compliance with noise and emission standards will be a key driver in product development. -

Aftermarket and Customization Growth

The aftermarket segment for jet pumps is expanding, with boat owners increasingly upgrading older systems for better performance or transitioning from propeller-driven systems. Customization options, including variable nozzle control, reverse thrust optimization, and smart monitoring systems, are becoming standard offerings. IoT-enabled sensors for real-time pump diagnostics are expected to gain traction. -

Regional Market Expansion

While North America remains a dominant market due to high recreational boating participation, regions like Southeast Asia, Australia, and Latin America are witnessing rising demand. Increased tourism and river-based transportation needs are fueling investment in jet boat infrastructure, creating new opportunities for jet pump suppliers.

In summary, the 2026 outlook for jet boat jet pumps reflects a dynamic market shaped by performance innovation, sustainability, and evolving consumer preferences. Companies that prioritize efficiency, electrification, and regulatory compliance are likely to lead the next phase of growth.

Common Pitfalls Sourcing Jet Boat Jet Pumps (Quality, IP)

Sourcing jet boat jet pumps involves navigating several critical challenges, particularly concerning product quality and intellectual property (IP) risks. Overlooking these pitfalls can lead to performance issues, safety hazards, legal disputes, and reputational damage.

Quality Inconsistencies and Substandard Components

One of the most prevalent issues when sourcing jet pumps—especially from low-cost manufacturers or unverified suppliers—is inconsistent quality. Many suppliers may offer pumps that appear identical on paper but vary significantly in real-world performance and durability. Common quality pitfalls include:

- Use of Inferior Materials: Substandard aluminum alloys or poorly cast housings can lead to corrosion, cavitation damage, or structural failure under high stress.

- Poor Manufacturing Tolerances: Inaccurate impeller-to-housing clearances reduce efficiency, increase vibration, and shorten pump life.

- Inadequate Testing: Reputable manufacturers conduct rigorous flow, pressure, and endurance testing. Many budget suppliers skip these steps, resulting in unreliable performance.

- Counterfeit or Rebranded Units: Some suppliers repackage used, damaged, or obsolete pumps as new, misleading buyers about condition and origin.

To mitigate this, buyers should insist on third-party quality certifications, request performance test data, and conduct factory audits when possible.

Intellectual Property (IP) Infringement Risks

Jet pump designs—especially high-performance models—are often protected by patents, trademarks, or design rights. Sourcing from suppliers offering “compatible” or “OEM-style” pumps can expose buyers to serious IP infringement risks:

- Patent Violations: Many advanced pump designs (e.g., specialized impeller geometries, intake configurations, or wear ring systems) are patented. Copying these without license can trigger legal action.

- Trademark Infringement: Using logos, model numbers, or branding that mimics established manufacturers (e.g., Hamilton, Reechcraft, or Yamaha) may violate trademark laws.

- Design Copying: Even if not patented, replicating a distinctive product design may breach design rights in certain jurisdictions.

Procurement teams must conduct due diligence on supplier legitimacy, request proof of IP clearance, and avoid products marketed as “exact replicas” or “direct replacements” unless properly licensed. Using generic or independently engineered designs can reduce exposure.

Lack of Technical Support and Documentation

Low-cost suppliers often fail to provide comprehensive technical documentation, installation guides, or after-sales support. This absence can hinder proper integration, maintenance, and troubleshooting, ultimately increasing downtime and operational costs. Ensure suppliers offer detailed specifications, CAD drawings, and accessible engineering support.

Supply Chain and Aftermarket Reliability

Sourcing pumps from obscure or short-term suppliers may result in discontinuation of parts, making long-term maintenance difficult. Verify the supplier’s track record, warranty terms, and availability of spare parts (e.g., impellers, stators, wear rings) before committing.

By addressing these pitfalls proactively—through supplier vetting, quality assurance processes, and IP compliance checks—buyers can secure reliable, legal, and high-performing jet pumps for their marine applications.

Logistics & Compliance Guide for Jet Boat Jet Pumps

Proper logistics and regulatory compliance are essential when transporting, importing, exporting, or installing jet boat jet pumps. This guide outlines key considerations to ensure safe, legal, and efficient handling of these marine propulsion components.

Regulatory Classification and Documentation

Jet boat jet pumps are typically classified under international trade codes such as the Harmonized System (HS Code). Common classifications include:

– 8413.70 – Pumps for liquids, whether or not fitted with a measuring device (frequently used for marine impeller pumps).

– 8908.00 – Equipment and fittings for vessels (may apply depending on configuration and use).

Ensure accurate HS code classification to determine applicable tariffs, import duties, and trade restrictions. Required documentation may include:

– Commercial invoice

– Packing list

– Bill of lading or air waybill

– Certificate of Origin

– Technical specifications or product datasheets

For exports from the United States, verify if the pump contains controlled technologies; some propulsion components may fall under EAR99 or require a license under the Export Administration Regulations (EAR).

Transportation and Packaging Requirements

Jet pumps are precision-engineered components sensitive to impact, moisture, and corrosion. Proper packaging and handling are critical.

- Packaging: Use robust, moisture-resistant packaging with internal cushioning (e.g., foam inserts or wooden crating) to protect impellers, housings, and seals.

- Labeling: Clearly mark packages with:

- “Fragile”

- “This Side Up”

- Product identification (model, serial number)

- Handling instructions

- Shipping Modes:

- Air freight: Suitable for urgent or lightweight shipments; ensure compliance with IATA dangerous goods regulations if any lubricants or coatings are present.

- Ocean freight: Most cost-effective for bulk shipments; use sealed containers to prevent saltwater and humidity exposure.

- Ground transport: Ideal for domestic or regional distribution; secure pumps to prevent shifting during transit.

Import and Export Compliance

Compliance varies by destination country. Key considerations include:

- Customs Clearance: Submit accurate declarations and supporting documents. Delays may occur due to misclassification or missing paperwork.

- Import Duties and Taxes: Research duty rates and value-added taxes (e.g., VAT, GST) in the destination country.

- Product Standards: Verify that the jet pump meets local marine safety and environmental standards, such as:

- US Coast Guard (USCG) standards for recreational marine equipment

- CE Marking for sale in the European Economic Area (under Marine Equipment Directive 2014/90/EU)

- Australian Design Rules (ADR) or Marine Safety (Domestic Commercial Vessel) National Law in Australia

- Environmental Regulations: Ensure compliance with restrictions on materials (e.g., lead content in alloys) under REACH (EU) or TSCA (USA).

Installation and Certification Compliance

Once delivered, proper installation and certification are mandatory for legal operation.

- Certified Installers: Use technicians certified by the pump manufacturer or recognized marine engineering bodies.

- Documentation Retention: Keep installation records, service logs, and compliance certificates for audits or resale.

- Emissions and Noise Standards: Confirm the jet pump system meets local emissions (e.g., EPA marine engine standards) and noise regulations.

Storage and Handling Best Practices

- Storage Environment: Store in a dry, temperature-controlled area away from direct sunlight and corrosive agents.

- Orientation: Store vertically (as installed) when possible to prevent bearing or seal deformation.

- Pre-Shipment Inspection: Conduct visual and functional checks before dispatch to ensure no damage occurred during storage.

Summary

Adhering to logistics and compliance protocols ensures that jet boat jet pumps are delivered safely, legally, and ready for reliable performance. Always consult with customs brokers, freight forwarders, and regulatory authorities to stay updated on evolving international and regional requirements.

Conclusion for Sourcing Jet Boat Jet Pumps

Sourcing jet boat jet pumps requires a strategic approach that balances performance, durability, cost, and supplier reliability. After evaluating various options, it is clear that selecting the right jet pump involves more than just comparing prices—it necessitates a thorough understanding of the specific application requirements, such as boat size, engine power, intended use (recreational, commercial, or rescue), and operating environment.

High-quality jet pumps from reputable manufacturers offer superior efficiency, longer service life, and better performance under demanding conditions, ultimately reducing long-term maintenance and downtime costs. While OEM parts ensure compatibility and reliability, aftermarket alternatives can provide cost-effective solutions if sourced from certified and experienced suppliers.

Additionally, building relationships with suppliers who offer technical support, warranties, and consistent product availability is crucial for minimizing operational disruptions. Conducting due diligence on supplier credentials, customer reviews, and product testing standards ensures a reliable supply chain.

In conclusion, successful sourcing of jet boat jet pumps hinges on a comprehensive evaluation of technical specifications, total cost of ownership, and supplier trustworthiness. By prioritizing quality and support over initial cost savings, operators and procurement managers can ensure optimal performance, safety, and longevity of their jet propulsion systems.