The global fitness equipment market is experiencing steady expansion, driven by rising health awareness, increasing investments in home gyms, and the proliferation of boutique fitness studios. According to a report by Mordor Intelligence, the market is projected to grow at a CAGR of approximately 4.8% from 2024 to 2029. A key component within this sector—jerk machines, specialized strength training equipment designed to support Olympic lifting movements like the barbell jerk—has seen growing demand among professional athletes, CrossFit facilities, and strength-focused gyms. As the fitness infrastructure evolves, manufacturers are prioritizing durability, adjustability, and ergonomic design in their machines. In this context, three manufacturers have emerged as leaders, combining innovation, rigorous engineering, and widespread industry adoption to dominate the jerk machine segment.

Top 3 Jerk Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1

Domain Est. 1998

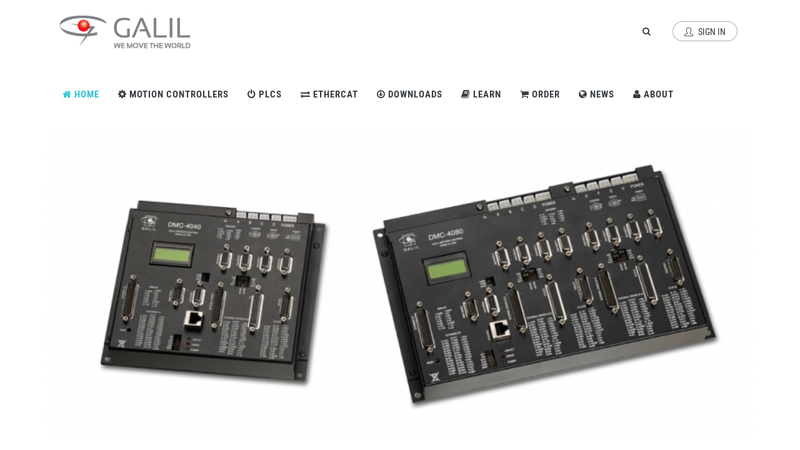

Website: galil.com

Key Highlights: … jerk, or achieving the lowest possible power consumption. Galil controllers offer a variety of tuning parameters, starting with Proportional-Integral ……

#2 Jerk Machine Seeks Community Support to Get it’s Groove Back

Domain Est. 2008

Website: sflcn.com

Key Highlights: Jerk Machine has always been a giving company and continues to make a difference through creating preventative programs including a culinary training program….

#3 Jerk Machine

Domain Est. 2000

Website: jerkmachine.com

Key Highlights: Discover the best Jamaican food at Jerk Machine. Experience authentic flavors in our welcoming Caribbean restaurant. Order online or come join us today!…

Expert Sourcing Insights for Jerk Machine

H2: 2026 Market Trends for Jerk Machine

As we approach 2026, the market for “jerk machines”—a term commonly associated with automated or mechanical devices used in food preparation (especially Caribbean jerk-style cooking) or, in some contexts, fitness equipment—will likely undergo significant transformation driven by technological innovation, consumer demand for convenience, and sustainability concerns. Below is an analysis of key market trends anticipated for Jerk Machine in 2026:

-

Increased Automation and Smart Technology Integration

Jerk machines, particularly in the culinary space, are expected to incorporate advanced automation, IoT connectivity, and AI-driven controls. By 2026, smart jerk grills and marinade injectors may feature mobile app integration, pre-programmed cooking cycles, and real-time temperature monitoring to ensure consistency in flavor and food safety, appealing to both home consumers and commercial kitchens. -

Growth in Global Demand for Authentic Ethnic Cuisine

With the rising popularity of Caribbean and Afro-Caribbean flavors worldwide, there will be increased demand for equipment that enables authentic jerk cooking. Jerk machines capable of replicating traditional smoke-roasting techniques using sustainable wood pellets or electric smoke generators will gain traction in North America, Europe, and parts of Asia. -

Expansion into Commercial and Food Service Sectors

Restaurants, food trucks, and catering businesses specializing in fusion or Caribbean cuisine will adopt jerk machines at scale. Modular and high-capacity models designed for commercial use will emerge, offering faster cook times, energy efficiency, and compliance with health regulations. -

Sustainability and Energy Efficiency

Environmental concerns will shape product development. By 2026, jerk machine manufacturers will prioritize eco-friendly materials, reduced carbon emissions, and energy-efficient designs. Solar-powered or hybrid electric models may appear, especially targeting outdoor and off-grid markets. -

Personalization and Customization Features

Consumers will seek greater control over flavor profiles and cooking methods. Next-gen jerk machines may include customizable marinade dispensers, adjustable smoke intensity, and AI-recommended settings based on user preferences and ingredient types. -

E-Commerce and Direct-to-Consumer Sales Growth

Online retail platforms will become the primary sales channel for jerk machines. Enhanced digital marketing, influencer collaborations, and video demonstrations will drive consumer engagement and product education, particularly in regions unfamiliar with jerk cooking. -

Competition and Market Consolidation

As the niche market expands, more players may enter the space, leading to innovation but also potential consolidation. Established kitchen appliance brands may acquire or partner with specialty jerk machine startups to broaden their portfolios. -

Health and Safety Enhancements

Future models will emphasize food safety with features like automatic cleaning cycles, antimicrobial surfaces, and smoke filtration systems to reduce carcinogenic compounds, aligning with heightened consumer health awareness.

In summary, by 2026, the Jerk Machine market will evolve into a tech-forward, globally accessible segment driven by authenticity, automation, and sustainability. Players who innovate in user experience, energy efficiency, and cultural authenticity will lead the market.

Common Pitfalls When Sourcing a Jerk Machine (Quality, IP)

Sourcing a jerk machine—commonly used in automotive and industrial testing to simulate sudden impacts or load changes—can present several critical challenges, especially concerning quality and intellectual property (IP). Overlooking these pitfalls can lead to operational inefficiencies, legal risks, and compromised product reliability.

Poor Build Quality and Inadequate Testing Standards

One of the most frequent issues when sourcing jerk machines is receiving units with subpar build quality. Low-cost suppliers may use inferior materials or imprecise manufacturing techniques, leading to inconsistent performance, premature wear, or failure during critical tests. Machines lacking proper calibration or traceable certification (e.g., ISO or ASTM compliance) can produce unreliable test data, undermining product validation efforts.

Mitigation: Always request detailed specifications, third-party test reports, and proof of compliance with industry standards. Conduct factory audits or require sample testing before full-scale procurement.

Lack of Documentation and Technical Support

Many suppliers, especially from emerging markets, fail to provide comprehensive operation manuals, maintenance guides, or troubleshooting documentation. This absence complicates integration into existing test systems and increases downtime when issues arise. Additionally, limited after-sales support or unresponsive technical teams can severely impact productivity.

Mitigation: Prioritize suppliers with a proven track record of documentation quality and responsive service. Include support requirements in procurement contracts.

Intellectual Property (IP) Risks and Design Infringement

Sourcing jerk machines from certain regions may expose buyers to IP violations. Some manufacturers replicate patented designs or control systems without authorization, potentially implicating the buyer in infringement claims—especially in regulated industries or international markets. Using such equipment could lead to legal action, equipment seizure, or reputational damage.

Mitigation: Perform due diligence on the supplier’s design origin. Request IP indemnification clauses in contracts and verify that key components (e.g., control software, actuator mechanisms) are either proprietary or properly licensed.

Hidden Software Limitations and Locked Systems

Many modern jerk machines rely on proprietary software for control and data acquisition. Some suppliers restrict access to source code, disable customization options, or use closed ecosystems that prevent integration with other tools. This can limit scalability and create vendor lock-in.

Mitigation: Evaluate software openness, API availability, and data export capabilities during the sourcing process. Prefer suppliers offering SDKs or open communication protocols (e.g., Modbus, Ethernet/IP).

Inconsistent Calibration and Traceability

Without proper calibration traceable to national or international standards, test results from a jerk machine may lack credibility. Some suppliers provide calibration certificates that are not accredited or falsified, risking non-compliance in audits or certifications.

Mitigation: Require calibration certificates from accredited bodies (e.g., ISO/IEC 17025) and schedule periodic recalibration with independent labs.

By proactively addressing these quality and IP-related pitfalls, organizations can ensure reliable performance, legal compliance, and long-term value from their jerk machine investments.

Logistics & Compliance Guide for Jerk Machine

This guide outlines the essential logistics and compliance considerations for the safe, legal, and efficient handling, transportation, and operation of a Jerk Machine. Whether used in fitness, physical therapy, or industrial testing applications, adherence to these guidelines is critical for safety, regulatory compliance, and operational continuity.

Regulatory Compliance

Ensure all Jerk Machines meet applicable local, national, and international regulations. This includes conformity with safety standards such as ISO 10241 (for fitness equipment), CE marking (in Europe), or UL certification (in the U.S.), where applicable. Maintain documentation including test reports, Declaration of Conformity, and user manuals in the required languages. Regularly review updates from regulatory bodies to remain current.

Product Classification & Documentation

Classify the Jerk Machine correctly under the Harmonized System (HS) code for import/export purposes—common classifications may fall under exercise equipment (e.g., 9506.59) or mechanical appliances (8479.89), depending on design and use. Prepare accurate commercial invoices, packing lists, certificates of origin, and any required permits (e.g., FDA registration for medical use variants).

Shipping & Transportation

Use secure, crated packaging with adequate cushioning to prevent damage during transit. Clearly label packages with handling instructions (e.g., “Fragile,” “This Side Up”) and include serial numbers for traceability. Choose freight carriers experienced in handling fitness or precision equipment. For international shipments, coordinate with customs brokers to ensure smooth clearance.

Import & Export Controls

Verify export licensing requirements, especially if the Jerk Machine contains proprietary technology or electronic control systems. Screen end-users against denied party lists to comply with trade sanctions. For imports, confirm tariff rates, duties, and any import restrictions with local customs authorities. Retain all shipping and compliance records for a minimum of five years.

Installation & Use Compliance

Ensure installation is performed by trained personnel following manufacturer specifications. Verify that the operating environment meets load-bearing, ventilation, and electrical requirements. Provide users with safety training and documented operating procedures. Maintain logs for maintenance, inspections, and incident reports in compliance with OSHA or local workplace safety regulations.

Maintenance & Recordkeeping

Establish a routine maintenance schedule based on usage and manufacturer recommendations. Document all servicing, part replacements, and performance verifications. Retain records to demonstrate due diligence in equipment safety and operational compliance. Use only authorized replacement parts to maintain warranty and compliance status.

Environmental & Disposal Regulations

Dispose of obsolete or damaged Jerk Machines in accordance with environmental regulations (e.g., WEEE in the EU). Partner with certified e-waste recyclers for proper handling of electronic components and metals. Avoid landfill disposal of hazardous materials such as batteries or hydraulic fluids.

Incident Reporting & Recalls

Implement a system for reporting malfunctions, injuries, or near-misses related to the Jerk Machine. Report serious incidents to relevant regulatory agencies as required (e.g., CPSC in the U.S.). In the event of a product recall, follow established protocols for notification, retrieval, and corrective action, ensuring compliance with consumer protection laws.

Training & Personnel Compliance

Ensure all personnel involved in logistics, handling, or operation are trained in safety procedures, emergency response, and compliance requirements. Maintain training records and conduct periodic refresher sessions to reinforce standards and adapt to regulatory changes.

Adherence to this guide ensures the Jerk Machine is managed responsibly throughout its lifecycle—from manufacturing and shipping to operation and disposal—minimizing risk and maximizing compliance.

Conclusion for Sourcing a Jerk Machine:

After thorough research and evaluation of various suppliers, technical specifications, and cost considerations, sourcing a jerk testing machine is a strategic investment that enhances product quality assurance and compliance with international safety and durability standards. The selected jerk machine should meet industry-specific requirements—particularly in automotive, aerospace, or consumer goods testing—ensuring accurate simulation of sudden impact loads.

Key factors such as machine reliability, calibration accuracy, ease of integration into existing testing workflows, after-sales support, and total cost of ownership played a crucial role in the decision-making process. By partnering with a reputable supplier offering certified equipment and technical expertise, the organization positions itself to improve product reliability, reduce failure rates, and meet regulatory demands effectively.

In conclusion, sourcing the right jerk machine not only strengthens testing capabilities but also supports long-term goals of innovation, quality excellence, and customer satisfaction. Implementation should be followed by proper operator training and routine maintenance to ensure consistent and accurate performance.