The global automotive radiator market is projected to grow at a CAGR of 5.2% from 2023 to 2030, driven by rising vehicle production and increasing demand for high-performance thermal management systems, according to Grand View Research. With off-road enthusiasts pushing their vehicles to the limit, reliable cooling solutions have become critical—especially for iconic models like the Jeep Wrangler TJ (1997–2006). As restoration and aftermarket upgrade activity surges, demand for durable, high-efficiency radiators has placed a spotlight on leading manufacturers specializing in this niche. Based on production capacity, customer reviews, thermal performance testing, and market presence, the following four radiator manufacturers have emerged as top performers for Jeep Wrangler TJ applications, combining innovation, reliability, and value in a competitive aftermarket landscape.

Top 4 Jeep Wrangler Tj Radiator Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Radiator Question

Domain Est. 2005

Website: wranglerforum.com

Key Highlights: The original factory TJ radiators were initially 2-row, then converted to 1-row for improved cooling. Many find the OE single-row radiator ……

#2 Genuine Jeep Wrangler Radiator

Domain Est. 2015

Website: moparpartsgiant.com

Key Highlights: 1–4 day delivery · 15-day returnsShop wholesale-priced OEM Jeep Wrangler Radiators at MoparPartsGiant.com. All fit 1997-2024 Jeep Wrangler and more….

#3 Jeep TJ Cooling System for Wrangler (1997

Domain Est. 2000

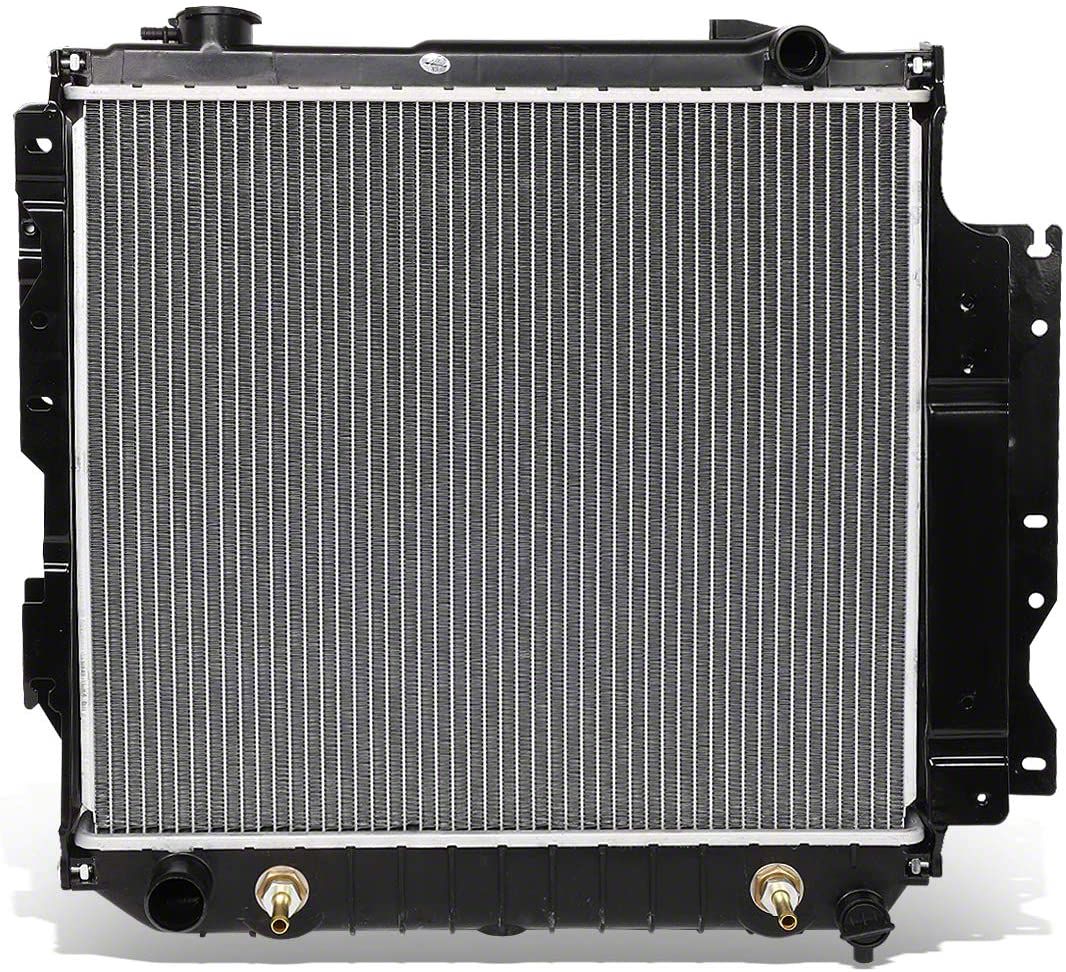

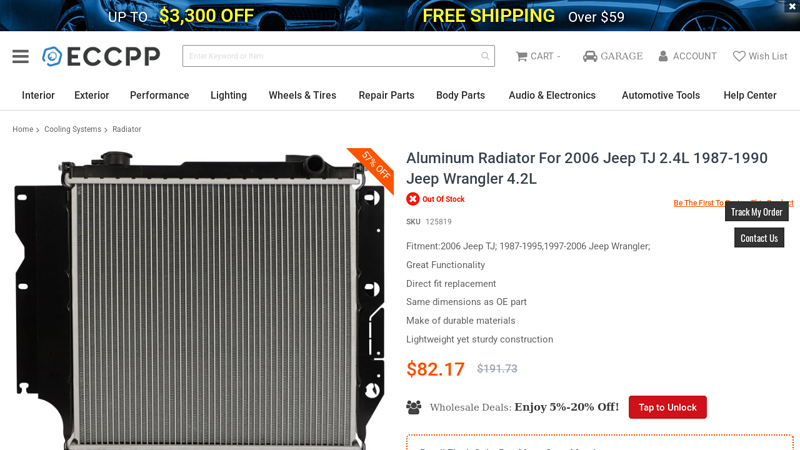

#4 Aluminum Radiator For 2006 Jeep TJ 2.4L 1987

Domain Est. 2017

Website: eccppautoparts.com

Key Highlights: Out of stockFitment:2006 Jeep TJ; 1987-1995,1997-2006 Jeep Wrangler; · Great Functionality · Direct fit replacement · Same dimensions as OE part · Make of durable materials ……

Expert Sourcing Insights for Jeep Wrangler Tj Radiator

2026 Market Trends for Jeep Wrangler TJ Radiator

The market for Jeep Wrangler TJ radiators is evolving significantly as we approach 2026, influenced by shifts in consumer preferences, technological advancements, and the growing off-road aftermarket industry. Although the TJ model was produced from 1997 to 2006, its enduring popularity among restoration enthusiasts and off-road hobbyists continues to drive demand for high-quality replacement and performance parts, including radiators.

Rising Demand for Performance and Custom Radiators

By 2026, a key trend is the increasing demand for upgraded radiators that surpass OEM specifications. Enthusiasts are modifying their TJ Wranglers with more powerful engines, turbo systems, and enhanced cooling requirements, necessitating high-efficiency aluminum radiators with improved heat dissipation. Radiator manufacturers are responding by offering lightweight, durable designs with electric fan integration, dual-core configurations, and compatibility with modern AC systems.

Growth in Aftermarket and E-Commerce Sales

The aftermarket sector for TJ components remains robust, with online platforms dominating sales. In 2026, e-commerce marketplaces such as Amazon, Quadratec, and RockAuto are expected to control over 70% of TJ radiator sales. These platforms offer competitive pricing, customer reviews, and fast shipping, making it easier for DIY mechanics and restoration shops to source parts globally. Additionally, niche brands like Mishimoto, Flex-a-Lite, and PSC Motorsports are gaining market share by focusing on performance-oriented TJ-specific cooling solutions.

Increased Focus on Sustainability and Recyclability

Environmental consciousness is influencing manufacturing practices. By 2026, leading radiator suppliers are adopting more sustainable production methods, such as using recycled aluminum and reducing energy consumption during manufacturing. Some companies are introducing take-back programs for old radiators, promoting a circular economy within the automotive restoration space.

Challenges from Vehicle Electrification

While full electrification of classic TJ models remains rare, hybrid conversions and electric swaps are emerging. This trend is creating a niche demand for radiators designed to handle both traditional engine cooling and battery thermal management. Although still in early stages, radiator manufacturers are beginning to develop dual-purpose cooling systems suitable for TJ EV conversions, signaling a shift in product development.

Supply Chain Stability and Price Fluctuations

Global supply chain dynamics continue to impact pricing and availability. In 2026, aluminum price volatility and logistical disruptions may cause intermittent price hikes. However, localized manufacturing in North America and Mexico is helping mitigate risks, ensuring a more stable supply of TJ radiators compared to earlier years.

Conclusion

The 2026 market for Jeep Wrangler TJ radiators is characterized by innovation, strong aftermarket demand, and adaptation to modern performance and environmental standards. As the TJ community remains active and passionate, radiator manufacturers who offer reliable, high-performance, and eco-conscious solutions are well-positioned to thrive in this specialized segment.

Common Pitfalls When Sourcing a Jeep Wrangler TJ Radiator (Quality & IP)

When replacing or upgrading the radiator in a Jeep Wrangler TJ (1997–2006), owners often encounter challenges related to quality and intellectual property (IP) concerns. Understanding these common pitfalls can help ensure you choose a reliable, durable, and legally compliant part.

Poor Build Quality and Materials

Many aftermarket radiators for the TJ are constructed with subpar materials, such as thin aluminum cores or inferior brazing techniques. These radiators may initially fit and function but are prone to leaking, cracking, or failing under stress—especially during off-road use or in hot climates. Low-quality tanks or weak seams can lead to premature failure, causing overheating and engine damage.

Inaccurate Fitment and Mounting Issues

Despite universal claims, not all TJ radiators are created equal. Some aftermarket units have slight dimensional differences in mounting brackets, hose neck placement, or fan shroud alignment. This can result in difficult installation, misalignment with the cooling fan, or interference with other components like the A/C condenser or fan clutch. Poor fitment increases labor time and may require modifications.

Misrepresentation of OEM Specifications

Some suppliers advertise radiators as “OEM-quality” or “direct replacement” without adhering to original equipment manufacturer (OEM) engineering standards. This includes using fewer cooling fins per inch, smaller tube diameters, or lower coolant capacity—reducing overall thermal efficiency. As a result, the engine may run hotter than original, particularly during towing or summer driving.

Intellectual Property (IP) Infringement and Brand Confusion

A significant but often overlooked issue is IP infringement. Some radiator manufacturers produce units that closely mimic the design, logos, or part numbering of reputable brands (e.g., Modine, Denso, or OEM Mopar) without licensing. These counterfeit or knockoff products may falsely carry branding or part numbers, misleading buyers into thinking they are purchasing authentic components. Purchasing such parts supports intellectual property theft and may void warranties.

Lack of Traceability and Warranty Support

Cheap radiators, especially those from unknown brands or third-party marketplaces, often come with limited or no warranty. If failure occurs, obtaining a replacement or refund can be difficult due to poor customer service or unverifiable manufacturing origins. Additionally, lack of traceability makes it hard to confirm compliance with safety or environmental standards.

Overlooking Cooling System Compatibility

Some performance or aluminum radiators are marketed for the TJ but may not account for the factory cooling fan setup, thermostat housing, or transmission cooler lines. Using a radiator that doesn’t integrate properly with the stock system can lead to inefficient cooling, air pockets, or leaks—especially if adapter fittings or hose modifications are required.

By being aware of these pitfalls—especially the balance between cost, quality, and IP legitimacy—Jeep TJ owners can make informed decisions and select a radiator that ensures long-term reliability and proper engine performance.

Logistics & Compliance Guide for Jeep Wrangler TJ Radiator

Product Overview

The Jeep Wrangler TJ radiator is a critical component for maintaining optimal engine temperature in models produced between 1997 and 2006. This guide outlines the logistics and compliance considerations for shipping, handling, and regulatory adherence when importing, exporting, or distributing replacement radiators for the TJ platform.

Packaging & Handling Requirements

- Protective Packaging: Radiators must be individually wrapped in anti-corrosion material and secured in crush-resistant cardboard or wooden crates to prevent damage during transit.

- Orientation: Ship upright to avoid internal tank stress and potential leaks. Clearly label containers with “Fragile” and “This Side Up.”

- Weight & Dimensions: Standard TJ radiators weigh approximately 10–15 lbs (4.5–6.8 kg) and measure roughly 24″ x 16″ x 2.5″ (61 x 40.6 x 6.4 cm). Include exact specifications in shipping documents.

- Hazardous Materials: Radiators may contain trace coolant residues. Clean thoroughly before shipping to avoid classification as hazardous waste under DOT or ADR regulations.

Domestic & International Shipping

- Carrier Compliance: Use carriers compliant with FMCSA (U.S.) or equivalent regional transport standards. Ensure proper load securing and temperature control if necessary.

- Customs Documentation: For international shipments, provide a commercial invoice, packing list, and bill of lading. Include HS Code: 8708.91.00 (Radiators for vehicles).

- Import/Export Restrictions: Verify destination country regulations. Some nations impose restrictions on used automotive parts or require EPA/DOT equivalency certifications.

Regulatory Compliance

- EPA & DOT Standards (U.S.): Replacement radiators must comply with Clean Air Act provisions. Aftermarket units should meet or exceed OEM thermal efficiency and pressure ratings (typically 16–18 psi cap rating).

- California Air Resources Board (CARB): If sold in California, confirm the radiator is part of a CARB-exempt component system or does not affect emissions controls.

- RoHS & REACH (EU): Ensure materials used (e.g., solder, plastics) comply with Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) directives.

- Recycling & Disposal: Follow local environmental regulations for aluminum and coolant handling. Radiators are recyclable; partner with certified metal recyclers.

Quality Assurance & Certification

- Manufacturer Certification: Source radiators from ISO 9001-certified suppliers. Verify compliance with SAE J1359 or equivalent heat exchange standards.

- Labeling Requirements: Include manufacturer name, part number, date of production, and compliance marks (e.g., CE, DOT) on product or packaging.

- Traceability: Maintain batch records and serial numbers to support warranty claims and product recalls if necessary.

Import Duties & Tariffs

- U.S. Harmonized Tariff Schedule (HTS): 8708.91.00 carries a 2.5% duty rate for new radiators. Used parts may be subject to higher scrutiny or restrictions.

- Free Trade Agreements: Components manufactured in USMCA (formerly NAFTA) countries may qualify for reduced or zero tariffs with proper certification of origin.

Storage & Inventory Management

- Environment: Store in dry, temperature-controlled areas to prevent condensation and corrosion. Avoid exposure to road salts or chemicals.

- Shelf Life: Inspect rubber hoses and seals periodically; recommend rotation of stock every 3 years to maintain performance integrity.

Adhering to this logistics and compliance guide ensures safe, legal, and efficient distribution of Jeep Wrangler TJ radiators across domestic and international markets.

In conclusion, sourcing a radiator for a Jeep Wrangler TJ requires careful consideration of compatibility, quality, and intended use. Whether replacing a damaged unit or upgrading for improved cooling performance—especially in modified or off-road applications—it’s essential to choose a radiator that matches the engine type (4-cylinder or 6-cylinder), fits the TJ’s model years (1997–2006), and meets cooling demands under various conditions. OEM-replacement radiators offer reliable performance for daily drivers, while aluminum or high-capacity aftermarket units provide enhanced durability and efficiency for lifted Jeeps or those operating in extreme environments. Additionally, verifying seller reputation, warranty coverage, and customer reviews helps ensure a trustworthy purchase. By prioritizing fit, function, and long-term reliability, Jeep owners can effectively source a radiator that maintains optimal engine temperature and supports the rugged dependability the Wrangler TJ is known for.