The global industrial hardware market, including critical components like jaw jaw turnbuckles, has experienced steady expansion driven by rising demand in construction, marine, rigging, and infrastructure sectors. According to a 2023 report by Mordor Intelligence, the global turnbuckle market is projected to grow at a CAGR of 4.8% from 2023 to 2028, fueled by increasing infrastructure investments, particularly in Asia-Pacific and North America. Complementing this, Grand View Research estimates that the broader rigging hardware market—encompassing turnbuckles, shackles, and hoisting equipment—will expand at a CAGR of 5.2% over the same period, reaching a market value of USD 14.6 billion by 2028. With stringent safety standards and growing emphasis on load control in material handling, demand for high-quality, ASME- and OSHA-compliant jaw jaw turnbuckles continues to rise. As manufacturers enhance product durability, load capacity, and corrosion resistance, competitive differentiation is emerging through engineering precision and certification adherence. This growing, quality-sensitive market sets the stage for identifying the top 10 jaw jaw turnbuckle manufacturers leading in innovation, reliability, and global reach.

Top 10 Jaw Jaw Turnbuckle Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Galvanized Jaw & Jaw Turnbuckle

Domain Est. 1996

Website: nutty.com

Key Highlights: Both the jaw and jaw turnbuckle are drop forged into molds to create a strong, continuous piece of metal. They are then hot-dipped galvanized for a protective ……

#2 Jaw and Jaw Turnbuckle

Domain Est. 1998

Website: suncorstainless.com

Key Highlights: These turnbuckles are made from grade 316 stainless steel for maximum corrosion resistance and durability, making them ideal for marine and industrial use….

#3 2

Domain Est. 2005

Website: uscargocontrol.com

Key Highlights: In stock Free deliveryManufacturer name: Van Beest ; Material: Drop-forged high tensile steel ; Pin size: 2-3/4″ ; Product weight: 216.1 lbs. ; Rated for Overhead Lifting: Yes….

#4 Large Heavy Duty Turnbuckles

Domain Est. 2021

Website: murphylift.com

Key Highlights: Murphy Industrials supplies a full line of large heavy duty turnbuckles, including jaw & jaw, eye & eye, hook & hook, eye & jaw, and hook & eye, available in ……

#5 Jaw/Jaw Turnbuckles Archives

Domain Est. 1996

Website: fehr.com

Key Highlights: Jaw/Jaw Galvanized Turnbuckle – 1 in. Login to See Pricing ; Jaw/Jaw Galvanized Turnbuckle – 1/4 in X 4 in. Code: 9JJ250X04. Login to See Pricing ; Jaw/Jaw ……

#6 Turnbuckle: Jaw

Domain Est. 1997

Website: sapsis-rigging.com

Key Highlights: In stock3/8″ x 6″ Jaw – Jaw Turnbuckle Domestic Manufacture Hot Galvanized, Drop-forged. Jaw fittings are heat treated. Quick Links. Quick Links….

#7 Select™ Jaw

Domain Est. 2003

#8 Jaw and Jaw Turnbuckles

Domain Est. 2008

Website: pattersonmfg.com

Key Highlights: Discover reliable jaw-to-jaw turnbuckles at Patterson Manufacturing. Explore sturdy solutions for precise tension control in your rigging….

#9 Jaw-Jaw Turnbuckles

Domain Est. 2009

Website: hhilifting.com

Key Highlights: 2–5 day delivery 10-day returnsJaw-jaw turnbuckles are used to create adjustable tension between two fixed connection points, typically in assemblies where bolts or pins are alread…

#10 JJ (jaw

Domain Est. 2016

Website: tor-industries.com

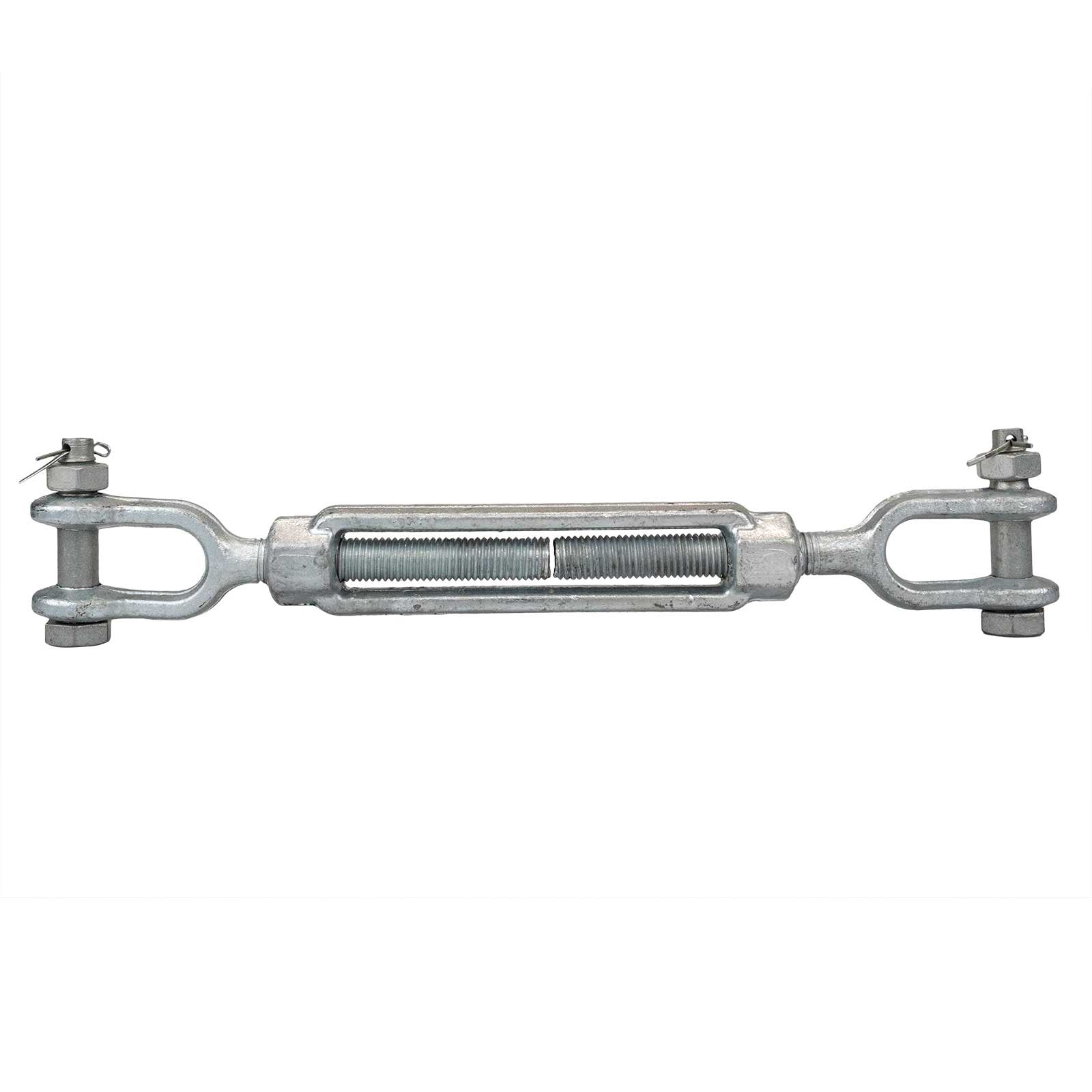

Key Highlights: JJ turnbuckle is made from high-quality steel and designed to adjust the tension of wire ropes and chains when forming the guys….

Expert Sourcing Insights for Jaw Jaw Turnbuckle

H2: 2026 Market Trends for Jaw Jaw Turnbuckle

The global market for rigging and lifting hardware is poised for steady expansion through 2026, driven by infrastructural development, renewable energy projects, and industrial modernization. Within this landscape, the Jaw Jaw Turnbuckle—a critical component used for tensioning, aligning, and securing cables and structural elements—is expected to witness notable growth and transformation. Below are key market trends anticipated to shape the Jaw Jaw Turnbuckle industry by 2026:

-

Rising Demand in Construction and Infrastructure

With governments worldwide investing in urban development, bridge construction, and transportation networks, the need for reliable rigging hardware is increasing. Jaw Jaw Turnbuckles are extensively used in structural tensioning applications, particularly in suspension systems and facade bracing. Emerging economies in Asia-Pacific and Africa are expected to drive significant demand due to ongoing large-scale infrastructure projects. -

Growth in Renewable Energy Sectors

The expansion of wind and solar energy installations is creating new applications for turnbuckles. In offshore wind farms, Jaw Jaw Turnbuckles are used in mooring systems and tower stabilization. As global renewable energy capacity targets intensify, the demand for durable, corrosion-resistant turnbuckles—often made from stainless steel or galvanized materials—will rise. -

Emphasis on Product Safety and Compliance

Regulatory standards for workplace safety and equipment certification (e.g., OSHA, CE, ASME) are becoming stricter. By 2026, manufacturers of Jaw Jaw Turnbuckles are expected to focus more on compliance with international load-rating standards, traceability, and third-party testing. Products with clear load ratings, safety certifications, and serialized tracking will gain preference among industrial buyers. -

Material and Design Innovation

To meet performance demands in harsh environments, manufacturers are investing in advanced materials such as marine-grade stainless steel, high-tensile alloys, and corrosion-protective coatings. Additionally, ergonomic and lightweight designs are being introduced to improve ease of installation and reduce worker fatigue—especially in aerial and offshore applications. -

Digitalization and Supply Chain Efficiency

The integration of digital tools in procurement and inventory management is streamlining distribution. By 2026, B2B e-commerce platforms and digital catalogs will play a larger role in the sale of industrial hardware, including Jaw Jaw Turnbuckles. Smart packaging with QR codes for product verification and usage instructions may become standard, enhancing customer experience and supply chain transparency. -

Regional Market Shifts

While North America and Europe remain mature markets with replacement-driven demand, the Asia-Pacific region—particularly China, India, and Southeast Asia—is expected to emerge as the fastest-growing market. Local manufacturing hubs and government “Make in India” or “Belt and Road” initiatives are accelerating industrial activity, boosting local consumption of rigging equipment. -

Sustainability and Circular Economy Pressures

Environmental concerns are beginning to influence industrial procurement. By 2026, companies may face pressure to offer recyclable or long-life turnbuckle solutions with reduced environmental impact. Some manufacturers may adopt closed-loop recycling programs or sustainable packaging to align with corporate ESG goals.

In summary, the Jaw Jaw Turnbuckle market in 2026 will be shaped by infrastructure growth, renewable energy expansion, regulatory rigor, and technological advancements. Stakeholders who prioritize quality, compliance, and innovation are likely to capture greater market share in this evolving industrial landscape.

Common Pitfalls When Sourcing Jaw Jaw Turnbuckles (Quality and IP)

Sourcing Jaw Jaw Turnbuckles may seem straightforward, but overlooking critical quality and intellectual property (IP) factors can lead to safety risks, project delays, and legal complications. Being aware of these common pitfalls helps ensure reliable, compliant, and safe procurement.

Inadequate Material and Manufacturing Standards

One of the most frequent quality issues arises from sourcing turnbuckles made from substandard materials or produced without adherence to recognized manufacturing standards (e.g., ASTM, ISO, or ASME). Low-grade steel or improper heat treatment can compromise tensile strength and corrosion resistance, leading to premature failure under load.

Lack of Third-Party Certification

Many suppliers claim compliance with industry standards but fail to provide verifiable certification from accredited testing bodies. Without proper documentation—such as mill test reports (MTRs) or third-party inspection certificates—there is no assurance of performance under real-world conditions.

Counterfeit or Non-Compliant Products

Some suppliers, particularly in unregulated markets, offer counterfeit or imitation turnbuckles bearing false branding or certifications. These products may visually resemble genuine items but fall short in structural integrity, potentially violating safety regulations and increasing liability exposure.

Ignoring Load and Working Load Limit (WLL) Verification

A common oversight is assuming that the advertised Working Load Limit (WLL) is accurate. Some sourced turnbuckles are overrated, meaning they cannot safely support the claimed load. Always verify load ratings through independent testing or trusted supply channels.

Poor Finish and Corrosion Protection

Inadequate surface treatment—such as subpar galvanization or lack of protective coating—leads to rapid corrosion, especially in marine or humid environments. This reduces service life and increases maintenance costs.

Intellectual Property (IP) Infringement Risks

Sourcing generic or copycat turnbuckles that replicate patented designs or branded products can expose buyers to IP infringement claims. Even if unintentional, using counterfeit or imitation-branded hardware may result in legal action, shipment seizures, or reputational damage.

Insufficient Traceability and Documentation

Reliable sourcing requires full traceability, including batch numbers, material origin, and manufacturing records. Lack of documentation complicates quality audits, recall management, and compliance with industry regulations, particularly in construction, marine, and aerospace sectors.

Overlooking Supplier Due Diligence

Relying on suppliers without proper vetting—such as failure to audit production facilities or assess quality management systems (e.g., ISO 9001 certification)—increases the risk of inconsistent quality and supply chain disruptions.

Conclusion

To avoid these pitfalls, prioritize suppliers with proven track records, transparent certifications, and adherence to international standards. Conduct thorough due diligence, request test reports, and ensure that both quality and IP considerations are addressed during the sourcing process.

Logistics & Compliance Guide for Jaw Jaw Turnbuckle

This guide outlines the essential logistics considerations and compliance requirements for the safe and legal handling, transportation, storage, and use of Jaw Jaw Turnbuckles. Adherence to these guidelines ensures operational safety, regulatory compliance, and product integrity.

Product Overview

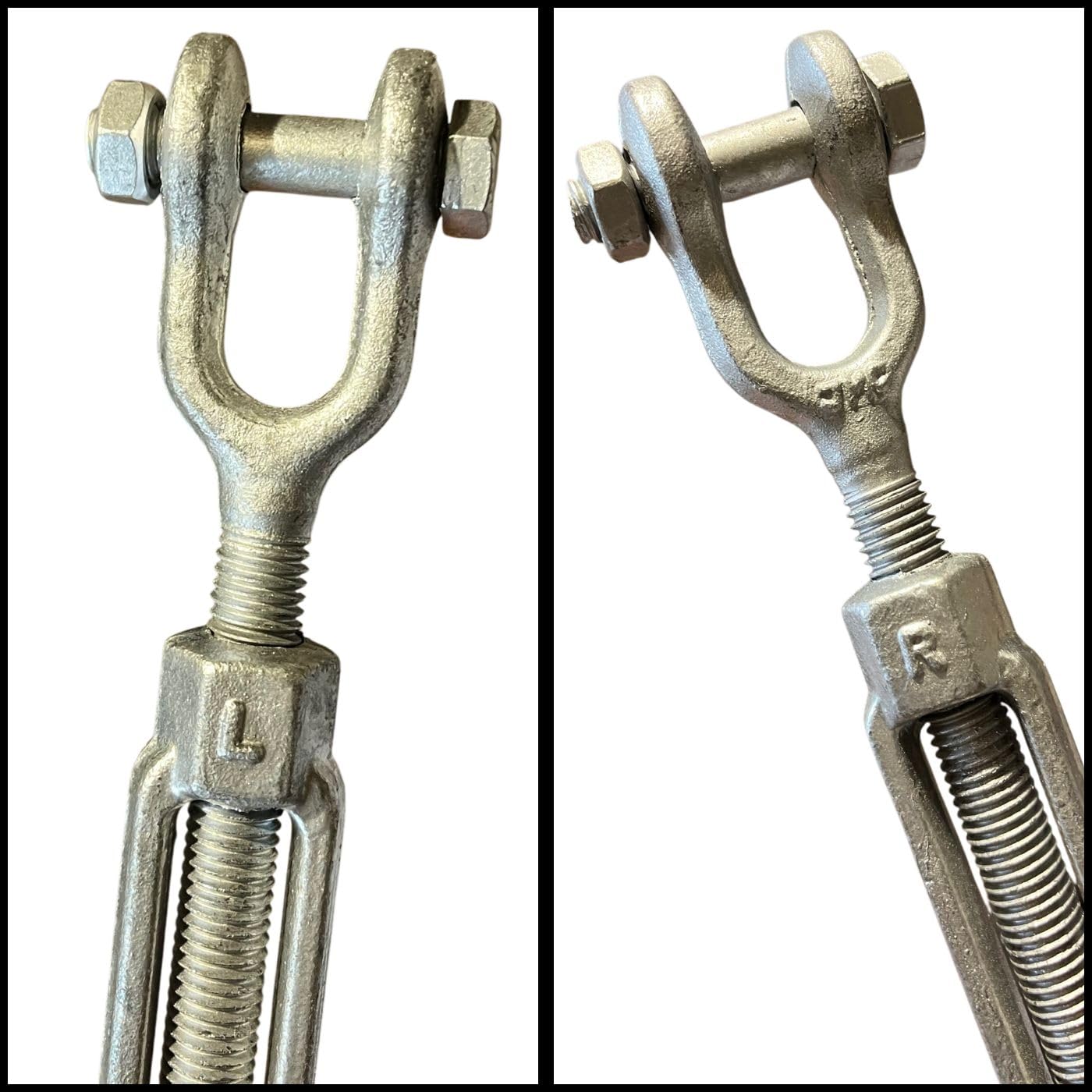

Jaw Jaw Turnbuckles are mechanical devices used to tension or adjust the length of rigging systems. They typically feature two eye-end (jaw) fittings connected by a central threaded body, allowing for precise adjustment. Commonly used in marine, rigging, construction, and industrial applications, these turnbuckles must meet specific strength and safety standards.

Regulatory Compliance

Jaw Jaw Turnbuckles are subject to various international and national regulations depending on their application and region of use:

- OSHA (Occupational Safety and Health Administration): In the U.S., OSHA 29 CFR 1910 and 1926 govern safe use in lifting and rigging operations. Turnbuckles must be rated for the intended load and inspected regularly.

- ASME B30.26: Standards for below-the-hook lifting devices, including rigging hardware like turnbuckles. Requires identification markings, load ratings, and safe operating practices.

- EN 13157 (European Standard): Applies to cranes and lifting accessories, including mechanical couplings such as turnbuckles. Ensures design, testing, and marking compliance in the EU.

- Lifting Equipment Directive (EU): 2006/42/EC may apply depending on integration into lifting systems. CE marking is required for products sold in the EEA.

- DNV, ABS, LR (Marine Applications): For marine and offshore use, certification from classification societies may be required to verify suitability for harsh environments.

Ensure all products are clearly marked with:

– Working Load Limit (WLL)

– Manufacturer identification

– Material grade

– Compliance markings (e.g., CE, ABS, DNV)

Packaging & Handling

Proper packaging and handling are critical to prevent damage and maintain product integrity:

- Packaging: Turnbuckles should be packed in protective materials (e.g., cardboard boxes, shrink-wrapped bundles) to prevent thread damage and corrosion. Large or heavy batches should be palletized and secured with strapping.

- Labeling: Each package must include:

- Product description and part number

- Quantity

- Net weight

- WLL and compliance marks

- Handling instructions (e.g., “Do Not Drop”, “Protect from Moisture”)

- Handling: Use appropriate lifting equipment (e.g., forklifts, cranes with soft slings) when moving pallets. Avoid dragging or dropping packages to prevent deformation or thread damage.

Storage Requirements

To maintain performance and prevent degradation:

- Environment: Store in a dry, well-ventilated area away from corrosive substances, salt spray, and excessive humidity. Ideal temperature range: 10°C to 30°C (50°F to 86°F).

- Positioning: Store vertically or horizontally on racks to avoid thread contact with the floor or other objects. Keep off the ground using pallets.

- Inventory Management: Follow FIFO (First In, First Out) principles to prevent long-term storage that may lead to corrosion or outdated stock.

Transportation Guidelines

Transport Jaw Jaw Turnbuckles in compliance with local and international shipping regulations:

- Domestic (e.g., U.S., EU): Secure loads on trucks or railcars to prevent shifting. Use dunnage and edge protectors where necessary.

- International Shipping:

- Declare as “Industrial Hardware” or “Rigging Equipment” on shipping documents.

- Comply with IMDG Code if transported by sea (though turnbuckles are typically non-hazardous).

- Provide Material Safety Data Sheet (MSDS) if requested, though most are exempt due to inert materials (e.g., carbon or stainless steel).

- Documentation: Include packing list, commercial invoice, and certificates of compliance (e.g., test reports, material certification) as required.

Inspection & Maintenance

Prior to shipment and after receipt, inspect turnbuckles for compliance and safety:

- Pre-Shipment Inspection:

- Verify thread integrity and absence of cracks or deformation.

- Confirm correct WLL marking and traceability.

- Check for corrosion or surface damage.

- In-Service Use:

- Inspect before each use for wear, distortion, or thread damage.

- Never exceed the WLL.

- Lubricate threads periodically if used in dynamic applications.

- Remove from service if any defect is found.

Disposal & Environmental Considerations

- End-of-Life: Recycle turnbuckles through certified metal recycling facilities. Do not dispose of in landfills.

- Environmental Impact: Typically made from recyclable steel or stainless steel. Packaging should be minimized and use recyclable materials where possible.

Training & Documentation

Ensure personnel involved in handling, using, or inspecting Jaw Jaw Turnbuckles are trained in:

- Safe rigging practices

- Reading load ratings and compliance marks

- Inspection procedures

- Regulatory requirements for their industry

Maintain records of:

– Certificates of Conformance (CoC)

– Material Test Reports (MTR)

– Inspection logs

– Training certifications

By following this guide, organizations can ensure the safe, compliant, and efficient logistics management of Jaw Jaw Turnbuckles across their lifecycle.

Conclusion for Sourcing Jaw-Jaw Turnbuckle

In conclusion, sourcing jaw-jaw turnbuckles requires a comprehensive approach that balances quality, cost, reliability, and compliance with industry standards. These essential rigging components play a critical role in tensioning and securing applications across construction, marine, rigging, and industrial sectors. Therefore, selecting the right supplier involves evaluating factors such as material quality (typically grade 5 or 8 carbon steel or stainless steel), load capacity, finish (e.g., zinc-plated or hot-dip galvanized for corrosion resistance), and adherence to recognized standards such as ASME B30.26 or ISO 3730.

Establishing partnerships with reputable manufacturers or suppliers who provide certification, consistent quality control, and transparent traceability ensures long-term performance and safety. Additionally, considering lead times, minimum order quantities, and logistical capabilities contributes to a resilient supply chain. By prioritizing suppliers with proven track records and the ability to meet specific technical and regulatory requirements, organizations can ensure reliable, safe, and cost-effective procurement of jaw-jaw turnbuckles for their operational needs.