The global roofing materials market is experiencing steady growth, driven by rising residential and commercial construction activities, urbanization, and increasing demand for energy-efficient and aesthetically pleasing architectural solutions. According to Mordor Intelligence, the roofing market is projected to grow at a CAGR of approximately 5.8% from 2023 to 2028, with Asia-Pacific emerging as a key growth region due to rapid infrastructure development and shifting consumer preferences toward durable, weather-resistant, and visually distinctive roofing systems. Among specialized styles, Japanese-inspired roofing—characterized by its minimalist design, sloping profiles, use of natural materials like clay tiles or metal, and integration with modern architectural aesthetics—has gained traction beyond Japan, particularly in North America, Europe, and high-end sustainable developments. This growing appeal has spurred innovation among manufacturers who blend traditional craftsmanship with advanced material science. Below, we explore the top 8 Japanese-style roofing manufacturers leading this niche segment, selected based on product quality, technological integration, geographic reach, and market influence.

Top 8 Japanese Style Roofing Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Palram Americas

Domain Est. 1999

Website: palram.com

Key Highlights: Palram is the leading polycarbonate manufacturer and PVC supplier. Explore our wide range of thermoplastic technology solutions….

#2 East Wind (Higashi Kaze), Inc.

Domain Est. 1998

Website: eastwindinc.com

Key Highlights: East Wind (Higashi Kaze), Inc. designs and builds traditional Japanese architecture, adapted to meet western architectural expectations….

#3 LAMIT ROOFING TILES

Domain Est. 2012

Website: lamitroof.com

Key Highlights: Lamit focuses on providing durable tiles, clean designs, and roofing solutions that suit Kerala’s unique climate. As one of the leading roof tile manufacturers, ……

#4 MARUEI KAWARA CO., LTD. EISHIRO tiles

Website: eishiro.co.jp

Key Highlights: It matches any design, from Japanese classical to modern style buildings. Roman LL40 Perfect flat design, it makes simple and flat roof, and it shows the color ……

#5 Moldings

Domain Est. 2002

Website: niscs.nipponsteel.com

Key Highlights: A beautiful roof harmonious with Japanese style/Western style: This is a beautiful metal roof in a new era incorporating the design of Japanese tile roofs ……

#6 Cupa Pizarras

Domain Est. 2003

Website: cupapizarras.com

Key Highlights: Cupa Pizarras world leader in natural slate for roofing and cladding, known for its unmatched durability and exceptional aesthetic appeal….

#7 Palmex International: Tropical Roofing

Domain Est. 2003

Website: palmex-international.com

Key Highlights: Our Palmex Exotic collection offers a variety of artificial Thatch roofing, surface and decor materials imitating the natural materials found worldwide. Whether ……

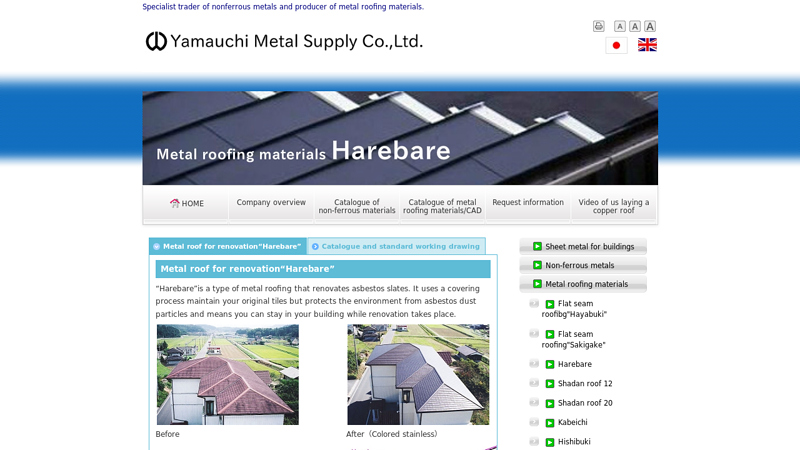

#8 Metal roof for renovation“Harebare”

Website: yamauchi-metal.co.jp

Key Highlights: “Harebare”uses the flat seam roofing often used in shrines, temples, and tearooms. It creates the image of traditional Japan with its luxury style. Strong ……

Expert Sourcing Insights for Japanese Style Roofing

2026 Market Trends for Japanese Style Roofing

The Japanese-style roofing market is poised for significant evolution by 2026, driven by a confluence of cultural appreciation, sustainability demands, and architectural innovation. While maintaining its deep roots in tradition, this niche sector is adapting to modern global challenges and aesthetic preferences.

Growing Global Demand for Authentic Aesthetics

By 2026, the appeal of Japanese architecture—particularly its minimalist, nature-integrated design—will continue to expand beyond East Asia. Homeowners and architects in North America, Europe, and Oceania will increasingly seek authentic Japanese roofing elements such as kawara (clay tiles), shibafuki (tiled roofs with decorative ridge details), and sugawara (thatched roofs, though less common due to regulations). This demand will be fueled by the popularity of Zen-inspired living spaces, wellness architecture, and biophilic design, positioning Japanese-style roofs as symbols of tranquility and harmony with nature.

Emphasis on Sustainable and Eco-Friendly Materials

Sustainability will be a dominant trend shaping the Japanese roofing market in 2026. Traditional materials like clay and wood are already naturally sustainable, but manufacturers will innovate with recycled content, lower-firing-temperature ceramics, and responsibly sourced timber. Additionally, integration with green roofing systems and solar tiles that mimic traditional kawara profiles will gain traction, allowing modern buildings to meet energy efficiency standards while preserving visual authenticity.

Technological Integration and Material Innovation

Advancements in material science will lead to lighter, more durable alternatives that emulate traditional Japanese tiles. Composite materials and fiber-reinforced polymers will offer the appearance of clay or wood with improved resistance to earthquakes, typhoons, and temperature fluctuations—critical in Japan and export markets with similar climate challenges. Smart roofing systems incorporating moisture sensors and automated ventilation, inspired by traditional Japanese passive design, will begin emerging in high-end residential and hospitality projects.

Preservation and Heritage Restoration

In Japan, government and private investment in the restoration of historic properties—temples, shrines, and traditional homes—will sustain a steady demand for skilled artisans and authentic roofing techniques. By 2026, digital modeling and 3D printing may be used to replicate rare or damaged tiles, supporting preservation efforts while addressing the shortage of traditional craftsmen.

Hybrid Architectural Designs

The blending of Japanese roofing styles with contemporary Western or modernist architecture will become more prevalent. Designers will reinterpret sloped eaves, wide overhangs, and layered rooflines in new materials and forms, creating hybrid structures that honor tradition while meeting modern functionality. This trend will be especially visible in luxury homes, boutique hotels, and cultural centers.

In summary, the 2026 Japanese-style roofing market will reflect a balance between reverence for heritage and adaptation to modernity. Driven by aesthetic appeal, environmental responsibility, and technological progress, it will continue to influence global architectural trends while preserving its cultural essence.

Common Pitfalls When Sourcing Japanese-Style Roofing (Quality, IP)

Sourcing authentic Japanese-style roofing—such as kawara (clay tiles), hinoki cypress wood shakes, or modern composites inspired by traditional designs—can present unique challenges, particularly concerning quality consistency and intellectual property (IP) protection. Understanding these pitfalls is crucial for architects, builders, and developers aiming to maintain authenticity and durability.

Quality Inconsistencies in Manufacturing and Materials

One of the most significant risks when sourcing Japanese-style roofing is encountering inconsistent product quality. While traditional Japanese roofing is renowned for craftsmanship and longevity, overseas or mass-produced versions may cut corners. Issues include variable clay composition in kawara tiles leading to cracking, uneven glazing, or poor water resistance. Wood shakes may use substandard timber or inadequate treatment, reducing lifespan and increasing fire risk. Additionally, inconsistent firing temperatures or curing processes can compromise structural integrity. Buyers often assume “Japanese-style” implies Japanese quality, but many products are manufactured in countries with less stringent standards, resulting in premature deterioration.

Lack of Authentic Certification and Traceability

Many suppliers claim their products are “authentic” or “imported from Japan,” but without proper certification or traceability, these claims can be misleading. Genuine Japanese roofing materials—especially kawara—are often region-specific and crafted by skilled artisans using time-honored techniques. However, third-party manufacturers may replicate the appearance without adhering to traditional methods. The absence of verifiable documentation (e.g., manufacturer origin, artisan certification, material provenance) makes it difficult to ensure authenticity. This lack of transparency can lead to compromised aesthetics and performance, undermining architectural integrity.

Intellectual Property and Design Infringement Risks

Japanese architectural designs, including specific tile patterns, interlocking systems, and ornamental features, may be protected under intellectual property laws—both in Japan and internationally. Some traditional designs are registered as geographical indications or protected under design patents. Sourcing clones or unauthorized reproductions of patented tile profiles or decorative elements can expose importers and builders to legal liability, especially in markets with strong IP enforcement. Additionally, using counterfeit or imitation products may violate local building codes or heritage regulations, particularly in restoration projects or culturally sensitive developments.

Supply Chain and Logistical Challenges

Authentic Japanese roofing materials often involve complex supply chains. Long lead times, high shipping costs, and import regulations can delay projects and inflate budgets. Furthermore, damage during transit is common with fragile clay tiles, and inadequate packaging or handling can result in high breakage rates. Limited supplier access to original Japanese manufacturers may force buyers to rely on intermediaries, increasing the risk of miscommunication, quality degradation, and counterfeit goods entering the supply chain.

Inadequate Technical Support and Installation Guidance

Traditional Japanese roofing systems often require specialized installation techniques, such as precise lapping, specific underlayment, or custom flashing details. Sourcing materials without accompanying technical documentation or trained installers can lead to improper installation, leaks, and structural failure. Many overseas suppliers fail to provide detailed installation guides or engineering certifications required for compliance with local building codes, creating performance and liability risks.

Conclusion

To avoid these pitfalls, buyers should verify supplier credentials, request material samples and test reports, confirm IP compliance, and work with partners experienced in traditional Japanese construction. Engaging directly with Japanese manufacturers or certified distributors can ensure quality, authenticity, and legal compliance in sourcing Japanese-style roofing.

Logistics & Compliance Guide for Japanese Style Roofing

Japanese style roofing, characterized by its elegant curves, traditional materials like clay tiles (kawara), and meticulous craftsmanship, requires specific attention to logistics and regulatory compliance—especially when sourcing materials, transporting components, or constructing outside of Japan. This guide outlines essential considerations for successful and compliant project execution.

Material Sourcing & Procurement

When sourcing traditional Japanese roofing materials such as fired clay tiles, wooden bargeboards (chidori-hafu), or copper decorative elements, it’s vital to work with reputable suppliers who adhere to Japanese industrial standards (JIS). Verify that materials meet durability, fire resistance (JIS A 5401 for roofing tiles), and weather resistance criteria. For international projects, consider lead times of 8–12 weeks for custom-made tiles shipped from Japan. Ensure suppliers provide certificates of origin and material compliance documentation to support customs clearance and building inspections.

Transportation & Handling

Japanese clay tiles are fragile and heavy (typically 4–6 kg per tile). Use wooden crates with internal dividers and shock-absorbing materials during shipping. For air or sea freight, comply with International Maritime Dangerous Goods (IMDG) Code where applicable and ensure proper moisture protection during ocean transport. Domestic delivery should use suspension-equipped trucks to minimize vibration. On-site, store tiles under cover on level, elevated platforms to prevent moisture absorption and breakage. Handle tiles with padded gloves and avoid stacking more than 10 layers high.

Import Regulations & Customs Compliance

When importing Japanese roofing materials, verify classification under the Harmonized System (HS) code—typically 6906.90 for ceramic roofing tiles. Import duties and VAT vary by country; for example, the U.S. applies a 4.5% duty on clay tiles from Japan under HTS 6906.90.00. Ensure all shipments include a commercial invoice, packing list, and JIS certification. Some countries (e.g., Australia, EU) require additional biosecurity or CE marking documentation for wood components to prevent pest introduction.

Building Code & Structural Compliance

Japanese-style roofs often feature steep pitches (30–45 degrees) and extended eaves, which impact structural load calculations. Confirm that local building codes (e.g., International Building Code in the U.S., NCC in Australia) permit the roof design and weight distribution. Reinforced rafters and trusses may be necessary to support the 50–60 kg/m² load of traditional kawara tiles. Wind uplift resistance must be evaluated, especially in hurricane- or typhoon-prone regions. Engage a structural engineer to certify compliance with seismic and snow load requirements as applicable.

Fire Safety & Environmental Regulations

Clay tiles are non-combustible and meet Class A fire ratings in most jurisdictions, but wooden structural components must be treated with fire-retardant coatings where required. In wildfire-prone areas (e.g., California, southern Australia), ember-resistant underlayment and eave protection may be mandated. For environmental compliance, ensure kiln emissions from tile manufacturing adhere to local environmental protection standards if production occurs domestically. Recycling broken tiles as aggregate is encouraged under green building practices (e.g., LEED, CASBEE).

Installation Standards & Labor Certification

Traditional Japanese roofing requires skilled artisans familiar with interlocking tile patterns (nagare-buki, hitomezan) and hip-and-valley detailing. Verify that installers hold recognized certifications—such as Japan’s Traditional Craftsman License (Dentō Kōgeishi) or equivalent local credentials. Follow manufacturer instructions for underlayment, battens, and flashing integration. Conduct third-party inspections after underlayment and final tile installation to ensure compliance with waterproofing and wind resistance standards.

Documentation & Project Handover

Maintain comprehensive records including material certifications, customs declarations, structural engineering reports, and installation logs. Provide the end client with a compliance dossier containing maintenance guidelines—e.g., annual inspection for moss, tile integrity, and fastener corrosion. Register the roofing system with local building authorities if required by jurisdiction, especially for heritage or high-value residential projects.

By adhering to these logistics and compliance protocols, Japanese style roofing projects can achieve both aesthetic authenticity and regulatory approval across international markets.

In conclusion, sourcing Japanese-style roofing offers a unique blend of aesthetic elegance, durability, and cultural authenticity that can significantly enhance the architectural character of a building. Whether utilizing traditional materials such as clay tiles (kawara), slate, or modern interpretations with lightweight composite alternatives, Japanese roofing systems reflect centuries of craftsmanship and adaptation to environmental conditions. When sourcing these materials, it is essential to consider factors such as climate compatibility, structural requirements, availability, and compliance with local building codes. Partnering with reputable suppliers, artisans, or import specialists experienced in Japanese construction techniques ensures quality and authenticity. Ultimately, investing in Japanese-style roofing not only delivers visual harmony and timeless appeal but also embodies a respect for tradition, craftsmanship, and sustainable design principles.