The global hydraulic equipment market is experiencing steady growth, driven by increasing demand across industrial manufacturing, construction, and automotive sectors. According to Mordor Intelligence, the hydraulic equipment market was valued at USD 33.5 billion in 2023 and is projected to grow at a CAGR of over 4.2% through 2029. This expansion is fueled by the rising need for efficient power transmission systems, particularly in heavy machinery and material handling applications. Within this landscape, hydraulic jacks remain a fundamental component, essential for lifting and lowering heavy loads with precision and reliability. As industries prioritize operational efficiency and safety, the demand for high-performance jacks from trusted manufacturers continues to rise. Based on market presence, product innovation, and global reach, the following five companies stand out as leading hydraulic jack service manufacturers shaping the industry’s future.

Top 5 Jacks Hydraulic Services Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Hydraulic Cylinders, Jacks, Rams

Domain Est. 1995

Website: enerpac.com

Key Highlights: Free delivery over $100Enerpac provides the largest selection of hydraulic cylinders, jacks and rams, fully supported and available through the most extensive network of distributo…

#2 HYJACKS.COM/JACKS BASICS PAGE/H7.HTM

Domain Est. 1996

Website: hyjacks.com

Key Highlights: Every hydraulic jack has six main components: 1. A RESERVOIR to hold hydraulic fluid. 2. A PUMP that draws fluid from the resevoir on it’s up, ……

#3 Products

Domain Est. 1997

Website: usjack.com

Key Highlights: US Jack carries hydraulic jacks, garage jacks, scissor jacks, and more. Each product we sell is 100% USA made, and ready to give you the powerful lift you need….

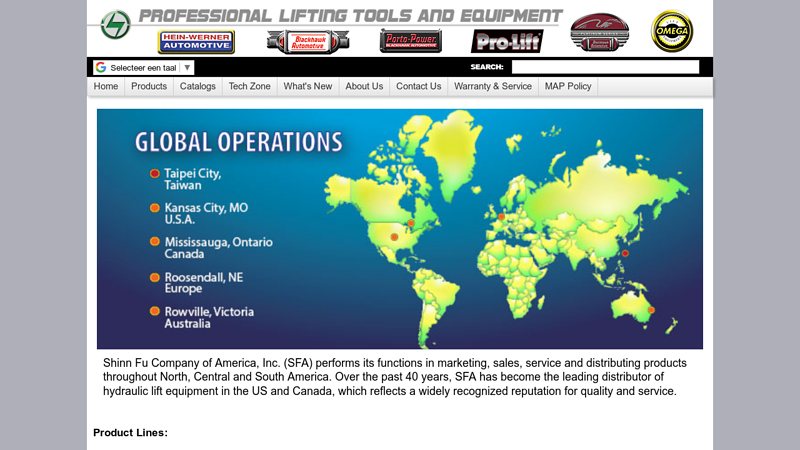

#4 Shinn Fu America Homepage

Domain Est. 2002

Website: bonecreeper.com

Key Highlights: Service Jacks · Long Chassis Service Jacks · Truck Axle Jacks and Accessories · Transmission Jacks and Accessories · Forklift Jacks · Air Jacks….

#5 » Jack’s Hydraulics

Website: jackshydraulics.com.au

Key Highlights: Welcome to Jack’s Hydraulics and our range of services. Hydraulic products from almost all major brands. Product application and technical support….

Expert Sourcing Insights for Jacks Hydraulic Services

H2: Market Trends Forecast for Jacks Hydraulic Services (2026)

As the industrial and construction sectors continue to evolve, Jacks Hydraulic Services is positioned to experience significant shifts in demand, competition, and operational dynamics by 2026. A comprehensive analysis of macroeconomic indicators, technological advancements, and sector-specific developments reveals several key market trends that will shape the company’s strategic outlook.

-

Increased Demand in Infrastructure and Renewable Energy

With global governments prioritizing infrastructure modernization and clean energy initiatives, hydraulic services are expected to see growing demand in sectors such as wind turbine maintenance, hydroelectric power, and large-scale construction projects. In the U.S., the continued rollout of the Infrastructure Investment and Jobs Act will drive public and private investments in transportation, water systems, and energy grids—key markets for hydraulic system installation and repair. Jacks Hydraulic Services can capitalize on this trend by expanding service offerings to support green energy infrastructure. -

Adoption of Smart Hydraulics and IoT Integration

The industrial sector is rapidly embracing Industry 4.0 technologies. By 2026, smart hydraulic systems equipped with sensors, predictive maintenance algorithms, and remote monitoring capabilities will become standard. Jacks Hydraulic Services must invest in training and technology to offer IoT-enabled diagnostics and preventative maintenance solutions. Early adopters will gain a competitive advantage through improved uptime, customer satisfaction, and service efficiency. -

Labor Shortages and Upskilling Imperatives

The skilled trades workforce continues to age, and a persistent shortage of certified hydraulic technicians is expected through 2026. Jacks Hydraulic Services will need to proactively address talent acquisition through apprenticeship programs, partnerships with technical schools, and competitive compensation models. Emphasizing continuous training in digital tools and automation will be essential to maintaining service quality and operational reliability. -

Regional Market Expansion and Mobile Service Models

Urbanization and industrial decentralization are leading to increased demand for mobile hydraulic repair services in rural and emerging industrial zones. Jacks Hydraulic Services can leverage this trend by expanding its fleet and service radius, particularly in regions with growing mining, agriculture, and manufacturing activity. A network of mobile service units will enhance response time and customer retention. -

Sustainability and Regulatory Pressures

Environmental regulations targeting fluid leakage, energy efficiency, and waste management will tighten by 2026. Hydraulic service providers will face greater scrutiny over the use of biodegradable fluids and recycling practices. Jacks Hydraulic Services can differentiate itself by adopting eco-friendly practices, obtaining relevant certifications (e.g., ISO 14001), and marketing sustainable service solutions to environmentally conscious clients. -

Competitive Landscape and Consolidation

The hydraulic services industry is seeing increased consolidation, with larger firms acquiring regional players to expand geographic reach and service capabilities. Jacks Hydraulic Services may face intensified competition from both national chains and specialized niche providers. To remain competitive, the company should focus on customer service excellence, niche market specialization (e.g., mobile equipment or marine hydraulics), and strategic partnerships.

Conclusion

By 2026, Jacks Hydraulic Services will operate in a more technologically advanced, competitive, and sustainability-driven market environment. Success will depend on the company’s ability to adapt to digital transformation, secure skilled labor, meet evolving regulatory standards, and align with infrastructure and energy trends. Proactive investment in innovation and workforce development will be critical to maintaining market relevance and achieving long-term growth.

Common Pitfalls When Sourcing Hydraulic Jack Services (Quality and Intellectual Property)

Sourcing hydraulic jack services—whether for repair, calibration, custom design, or system integration—can pose significant risks if not managed carefully. Two critical areas where organizations often encounter problems are quality assurance and intellectual property (IP) protection. Overlooking these aspects can lead to equipment failure, safety hazards, legal disputes, and loss of competitive advantage.

Quality-Related Pitfalls

One of the most frequent challenges in sourcing hydraulic jack services is ensuring consistent quality. Poor workmanship or substandard components can compromise system performance and safety.

Lack of Certified Expertise and Standards Compliance

Many service providers may lack proper certifications (e.g., ISO 9001, ASME, or OEM-specific qualifications), leading to inconsistent or unsafe repairs. Always verify the provider’s adherence to industry standards and request documentation of quality control processes.

Use of Non-OEM or Counterfeit Parts

Unscrupulous vendors may replace original components with inferior or counterfeit parts to cut costs. These parts often fail prematurely under high pressure, resulting in downtime or hazardous failures. Require transparency in sourcing and insist on OEM or approved equivalent parts.

Inadequate Testing and Documentation

A common gap is the absence of post-service pressure testing, load testing, or performance validation. Without documented proof of testing, there’s no assurance the jack will perform as expected in the field. Insist on comprehensive test reports and certification of compliance.

Intellectual Property-Related Pitfalls

When engaging hydraulic service providers for custom designs or modifications, IP risks can arise if proper safeguards are not in place.

Ambiguous Ownership of Design Improvements

Without a clear contract, modifications or enhancements made by the service provider may be claimed as their own IP. This can prevent your organization from freely using or replicating the design. Ensure contracts explicitly state that all work product and derivative designs are your property.

Unprotected Sensitive Technical Information

Sharing detailed schematics, pressure specifications, or system integration data exposes your proprietary systems. If the vendor lacks confidentiality protocols or non-disclosure agreements (NDAs), your IP could be exposed to competitors. Always execute a robust NDA before disclosure.

Reuse of Custom Designs for Competitors

Some vendors may reuse custom solutions developed for one client across multiple customers. Without IP clauses prohibiting such reuse, your competitive innovation could end up in the hands of rivals. Include exclusivity and non-compete terms where appropriate.

By proactively addressing these quality and IP pitfalls through due diligence, clear contracts, and stringent supplier vetting, organizations can mitigate risks and ensure reliable, secure hydraulic jack services.

Logistics & Compliance Guide for Jacks Hydraulic Services

This guide outlines the key logistics and compliance procedures to ensure safe, efficient, and legally compliant operations at Jacks Hydraulic Services.

1. Vehicle and Equipment Transportation

All hydraulic equipment, tools, and replacement parts must be transported in company-approved vehicles equipped with secure tie-down points, protective covers, and spill containment measures. Load securement must comply with the National Highway Traffic Safety Administration (NHTSA) and Department of Transportation (DOT) regulations. Drivers must complete pre-trip and post-trip vehicle inspections using the company checklist and report any defects immediately.

2. Hazardous Materials Handling

Hydraulic fluids, solvents, and lubricants are classified as hazardous materials under OSHA and DOT regulations. All containers must be properly labeled, stored in compliant secondary containment trays, and transported in accordance with 49 CFR. Employees handling hazardous materials must be trained annually in Hazard Communication (HazCom) standards and maintain up-to-date Safety Data Sheets (SDS) on all job sites and in company vehicles.

3. Regulatory Compliance

Jacks Hydraulic Services must comply with federal, state, and local regulations including but not limited to:

– Occupational Safety and Health Administration (OSHA) standards

– Environmental Protection Agency (EPA) regulations for fluid disposal

– Department of Transportation (DOT) rules for vehicle operation and cargo

– Local environmental ordinances regarding waste discharge

All regulatory documentation must be kept current, and compliance audits will be conducted quarterly.

4. Waste Management and Fluid Disposal

Used hydraulic fluid and contaminated materials must be collected in sealed, labeled containers and disposed of through certified waste management vendors. No fluids may be drained into storm drains, soil, or regular trash. A log must be maintained for all waste pickups, including date, volume, disposal method, and vendor certification.

5. Driver and Operator Certification

All drivers must possess a valid commercial driver’s license (CDL) if required by vehicle class, along with a clean driving record. Hydraulic technicians must be certified in equipment operation and hold current training in lockout/tagout (LOTO), confined space entry (if applicable), and high-pressure system safety. Certification records are maintained in the HR compliance database and reviewed annually.

6. Documentation and Recordkeeping

Accurate records must be maintained for:

– Vehicle maintenance and inspections

– Employee training and certifications

– Hazardous material inventories and disposal logs

– Customer service reports and compliance checklists

All documents must be stored securely for a minimum of five years, either digitally or in physical files, and made available for regulatory audits upon request.

7. Emergency Response Procedures

In the event of a spill, equipment failure, or workplace injury, personnel must follow the Jacks Hydraulic Services Emergency Action Plan. This includes immediate containment, notification of the on-site supervisor, and, if necessary, reporting to relevant authorities (e.g., National Response Center for spills over reportable quantities). Emergency contact numbers and spill kits must be accessible in all vehicles and service locations.

8. Customer Site Compliance

Prior to beginning work at customer locations, crews must obtain necessary permits, review site-specific safety plans, and adhere to the client’s safety protocols. Any non-compliance issues must be reported to management before work proceeds.

By adhering to this guide, Jacks Hydraulic Services ensures operational efficiency, legal compliance, and the highest standards of safety and environmental responsibility.

In conclusion, sourcing hydraulic jack services requires a careful evaluation of several key factors to ensure reliability, safety, and cost-effectiveness. It is essential to partner with a reputable provider that offers certified technicians, quality equipment, and comprehensive service capabilities such as maintenance, repair, and emergency support. Considering factors like industry experience, response time, compliance with safety standards, and customer reviews can significantly impact operational efficiency and reduce downtime. By strategically selecting a hydraulic jack service provider that aligns with your operational needs and quality standards, you ensure long-term equipment performance, enhanced safety, and improved productivity across your projects.