The global market for automotive lifting and leveling equipment, including heavy-duty truck jacks, is experiencing steady growth driven by rising demand from both commercial and off-road vehicle sectors. According to Grand View Research, the global hydraulic jacks market was valued at USD 1.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030, fueled by advancements in vehicle modification technologies and increased adoption of lifted trucks in construction, mining, and recreational off-roading. Parallel insights from Mordor Intelligence highlight growing consumer preference for aftermarket vehicle customization, particularly in North America, where lifted trucks dominate key segments of the light-duty truck market. As demand for reliable, high-capacity jacking solutions rises in tandem with the popularity of lifted vehicles, manufacturers are innovating to meet rigorous performance, safety, and durability standards. Against this backdrop, we spotlight the top 10 manufacturers leading the way in producing jacks tailored specifically for lifted trucks—combining engineering excellence, load capacity, and real-world reliability supported by market trends and consumer data.

Top 10 Jacks For Lifted Trucks Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Torin Jacks

Domain Est. 2000 | Founded: 1995

Website: torinjacks.com

Key Highlights: Founded in 1995, Torin Inc. produces quality automotive products for service professionals. As a manufacturer, a marketer and a developer of automotive ……

#2 Hi-Lift® Jack Co.

Domain Est. 1996

Website: hi-lift.com

Key Highlights: Manufacturer of “The Original Power Tool” Hi-Lift® Jack along with accessories and other recovery related equipment designed for off-road, farm, and rescue….

#3 Crown Equipment Corporation

Domain Est. 1998

Website: crown.com

Key Highlights: Crown Equipment Corporation is a global manufacturer of material handling equipment, lift trucks … Pallet Jacks. Electric Pallet Jacks. Rider Pallet Trucks….

#4 Stan Design

Domain Est. 2016

Website: standesign.ca

Key Highlights: Get workshop efficiency and vehicle lifting solutions with Stan Design. Explore our range of floor jacks, bridge jacks, and pit jacks….

#5 FULTON

Domain Est. 1996

Website: fultonperformance.com

Key Highlights: Transom Tie Downs · XLT® Marine Trailer Jack, 1,500 lbs. · XLT® Marine Powered Trailer Jack, 2,500 lbs. · XLT® Marine Trailer Winch, Single‑Speed, 1,800 lbs….

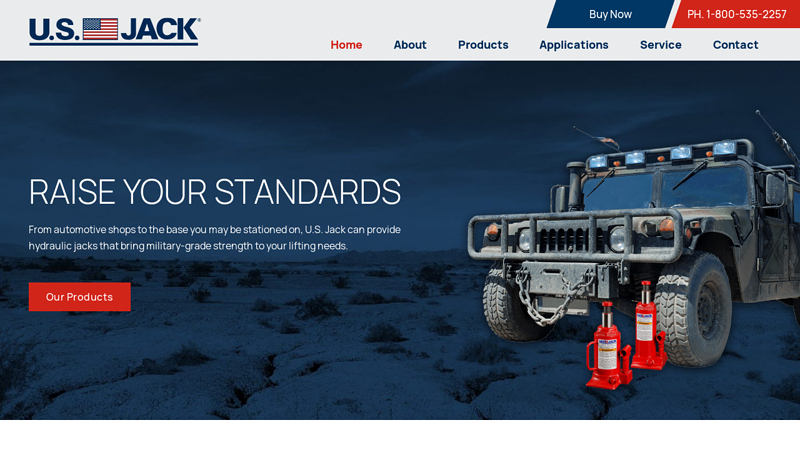

#6 U.S. Jack

Domain Est. 1997

Website: usjack.com

Key Highlights: U.S. Jack is the provider of durable and dependable hydraulic jacks that give you the strong lift you need, where you need it….

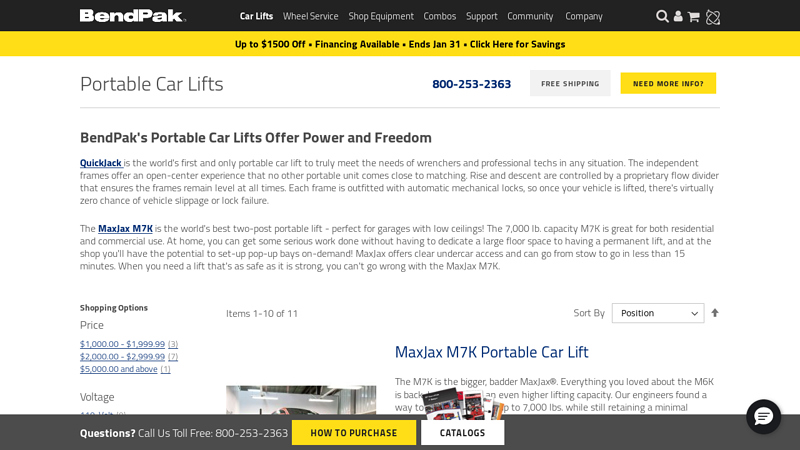

#7 Portable Car Lifts

Domain Est. 1997

Website: bendpak.com

Key Highlights: Free deliveryQuickJack is the world’s first and only portable car lift to truly meet the needs of wrenchers and professional techs in any situation….

#8 Pro Eagle Off Road Jacks

Domain Est. 1999

#9 Blackhawk Automotive Homepage Hydraulic Lifting Jacks …

Domain Est. 2004

Website: blackhawk-automotive.com

Key Highlights: With Blackhawk Automotive, SFA offers the most popular items in professional lifting under a brand name that has stood for quality and durability for years….

#10 Prolift Hydraulic Lift Equipment Homepage

Domain Est. 2011

Website: proliftproducts.com

Key Highlights: Service Jacks · Long Chassis Service Jacks · Truck Axle Jacks and Accessories · Transmission Jacks and Accessories · Forklift Jacks · Air Jacks….

Expert Sourcing Insights for Jacks For Lifted Trucks

H2: 2026 Market Trends for Jacks for Lifted Trucks

The market for jacks designed specifically for lifted trucks is poised for notable evolution by 2026, driven by the growing popularity of vehicle customization, advancements in lifting technology, and increasing demand for heavy-duty lifting solutions. As more consumers modify their trucks for off-road performance, enhanced ground clearance, and aesthetic appeal, the need for specialized jacking equipment capable of safely lifting taller, heavier vehicles becomes increasingly critical.

One major trend shaping the 2026 landscape is the rising demand for high-lift-capacity jacks with extended reach. Traditional floor jacks often lack the lift height required for trucks with significant suspension or body lifts. In response, manufacturers are innovating with longer lift ranges (up to 24 inches or more) and higher weight capacities (ranging from 3 to 20+ tons), ensuring compatibility with full-size pickups, SUVs, and off-road builds. Hydraulic and bottle jack designs tailored for lifted trucks are expected to gain market share, particularly among DIY enthusiasts and professional off-road shops.

Another key trend is the integration of improved safety features. By 2026, expect to see more jacks equipped with reinforced frames, wider bases for stability, non-slip saddle pads, and overload protection systems. These enhancements are driven by consumer awareness and regulatory scrutiny around vehicle maintenance safety, especially given the risks associated with lifting heavily modified trucks.

Additionally, e-commerce growth and online communities focused on truck customization are accelerating product awareness and demand. Brands are leveraging social media and influencer marketing to target off-road and truck modification audiences, leading to faster adoption of specialized tools like high-lift jacks. Retailers and manufacturers are also expanding their online presence with detailed compatibility guides and video demonstrations tailored to lifted truck owners.

Finally, sustainability and durability are becoming differentiators. Consumers are favoring long-lasting, serviceable jacks made from high-grade steel and corrosion-resistant materials. Modular designs that allow for part replacement (e.g., seals, handles, pumps) will likely gain traction, aligning with broader trends toward sustainable product lifecycles.

In summary, the 2026 market for jacks for lifted trucks is expected to be defined by innovation in lift height and capacity, enhanced safety features, strong digital engagement, and a focus on durable, long-term usability—reflecting the expanding ecosystem of truck customization and off-road culture.

Common Pitfalls When Sourcing Jacks for Lifted Trucks: Quality and Intellectual Property Concerns

Sourcing jacks for lifted trucks—especially heavy-duty models used in off-road or industrial applications—requires careful consideration to avoid compromising safety, performance, and legal compliance. Two major areas where buyers often encounter problems are product quality and intellectual property (IP) issues. Understanding these pitfalls can help prevent costly mistakes.

1. Compromised Quality Due to Substandard Materials and Manufacturing

One of the most common pitfalls when sourcing jacks for lifted trucks is receiving products made with inferior materials or poor workmanship. Lifted trucks require jacks with higher lift capacities, extended reach, and durable components to handle increased weight and ground clearance.

- Thin-Walled Cylinders and Weak Hydraulics: Low-quality jacks may use undersized hydraulic cylinders or subpar seals, leading to leaks, failure under load, or inconsistent performance.

- Inadequate Load Ratings: Some imported jacks are mislabeled with inflated load capacities that don’t meet industry standards (e.g., ASME or ISO), putting users at risk.

- Poor Welding and Structural Integrity: Jack frames and lift arms must withstand significant stress. Poor welding or use of low-grade steel can lead to catastrophic failure during use.

- Lack of Safety Certifications: Reputable jacks are tested and certified by third-party organizations. Sourcing from suppliers who cannot provide documentation (e.g., CE, ANSI, or CSA marks) increases liability.

To avoid this, always request product specifications, third-party test reports, and consider ordering samples for independent evaluation before bulk purchasing.

2. Intellectual Property (IP) Infringement and Counterfeit Products

Another significant risk when sourcing jacks—especially from overseas suppliers—is the potential for IP violations. Many low-cost manufacturers replicate patented designs, logos, or branding from well-known brands (e.g., Arcan, Powerbuilt, or Torin) without authorization.

- Replica or “Knock-Off” Designs: These jacks mimic the appearance and packaging of premium brands, misleading buyers into thinking they are purchasing genuine equipment.

- Use of Trademarked Names and Logos: Sellers may use brand names like “Super Lifter” or “Pro-Jack” in ways that suggest affiliation or endorsement, which can expose buyers to legal risk.

- Patent Infringement: Functional aspects like quick-lift mechanisms or swivel saddle designs may be protected by patents. Using or importing infringing products can lead to customs seizures or legal action.

To mitigate IP risks:

– Verify supplier authenticity through official distributor lists.

– Conduct IP clearance searches for private-label or OEM products.

– Include IP indemnification clauses in procurement contracts.

By addressing both quality and IP concerns proactively, businesses and end-users can ensure they source reliable, safe, and legally compliant jacks for lifted trucks.

Logistics & Compliance Guide for Jacks for Lifted Trucks

Overview

Jacks designed for lifted trucks must meet specific logistical and compliance requirements due to their specialized use, increased lifting capacity, and unique handling needs. This guide outlines best practices for shipping, storage, regulatory compliance, and safety standards to ensure efficient and lawful operations.

Product Classification and Specifications

Jacks for lifted trucks are typically high-capacity hydraulic or bottle jacks with extended lift ranges (often 20+ inches) and load ratings exceeding 10 tons. Accurate classification under the Harmonized System (HS Code) is essential—common codes include 8425.42 (hydraulic jacks) or 8425.49 (other jacks). Ensure specifications (capacity, lift height, weight, dimensions) are clearly documented for compliance and shipping.

Regulatory Compliance

Compliance with regional and international standards is mandatory:

– United States: Adhere to OSHA 29 CFR 1910.179 (overhead and hoisting equipment) and ANSI/ASME B30.1 (jacks and lifting devices).

– European Union: Conform to Machinery Directive 2006/42/EC and CE marking requirements.

– Canada: Comply with CSA standards (e.g., CSA Z1650 for lifting equipment).

Documentation must include test certificates, user manuals, and Declaration of Conformity where applicable.

Packaging and Labeling

- Use robust, weather-resistant packaging to protect jacks during shipping.

- Clearly label packages with:

- Product name and model

- Gross weight and dimensions

- Handling symbols (e.g., “Do Not Drop,” “This Side Up”)

- Compliance marks (CE, CSA, etc.)

- Include warning labels on the jack itself indicating max load, inspection dates, and safe use instructions.

Transportation and Shipping

- Coordinate freight using carriers experienced in handling heavy machinery.

- Secure jacks on pallets with strapping or shrink wrap to prevent shifting.

- For international shipments, ensure compliance with IMDG Code (if applicable), customs documentation, and import duties.

- Maintain load stability during transit—avoid stacking unless designed for it.

Storage Requirements

- Store jacks in a dry, temperature-controlled environment to prevent rust and seal degradation.

- Keep upright to avoid hydraulic fluid leakage.

- Implement a first-in, first-out (FIFO) inventory system to manage shelf life and inspection schedules.

Inspection and Maintenance

- Perform pre-shipment inspections for damage, leaks, and operational function.

- Maintain records of hydraulic pressure tests and safety checks per manufacturer guidelines.

- Recommend end-user inspection schedules (e.g., monthly visual checks, annual load testing).

Safety and Training

- Provide safety data sheets (SDS) if hydraulic fluid is classified as hazardous.

- Include multilingual user manuals outlining safe operation, weight limits, and emergency procedures.

- Encourage end-user training on jack use, especially for high-lift applications where instability risks increase.

Returns and Warranty Handling

- Establish clear return policies for damaged or non-compliant units.

- Track warranty claims and maintain logs for compliance audits.

- Ensure replacement parts meet original specifications and certifications.

Environmental and Disposal Compliance

- Follow EPA (U.S.) or WEEE (EU) directives for end-of-life disposal.

- Recycle hydraulic fluid and metal components through certified facilities.

- Avoid landfill disposal of pressurized or contaminated components.

Conclusion

Proper logistics and compliance management for jacks used with lifted trucks ensures safety, legal adherence, and customer satisfaction. By following this guide, distributors and manufacturers can reduce liability, improve efficiency, and maintain market access across regions.

In conclusion, sourcing jacks for lifted trucks requires careful consideration of lifting capacity, lift range, durability, and compatibility with the vehicle’s elevated ground clearance. Standard jacks may not provide sufficient height or support for lifted trucks, making high-lift jacks, long-reach floor jacks, or hydraulic bottle jacks with extension accessories more suitable options. Prioritizing safety, reliability, and ease of use is essential—choosing reputable brands and models specifically designed for heavy-duty or high-clearance vehicles ensures effective maintenance and reduces the risk of accidents. Ultimately, investing in the right jack tailored to the unique needs of a lifted truck enhances both convenience and safety during servicing and repairs.