The global thermocouple market is experiencing steady expansion, driven by rising demand for precision temperature sensing across industries such as manufacturing, energy, and pharmaceuticals. According to Grand View Research, the global thermocouple market size was valued at USD 2.3 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.1% from 2023 to 2030. Mordor Intelligence corroborates this trend, highlighting increased industrial automation and process optimization as key growth catalysts. Within this landscape, J type thermocouples—known for their high thermoelectric sensitivity and reliability in reducing atmospheres—represent a critical segment. As demand for accurate and durable temperature measurement solutions grows, a select group of manufacturers has emerged as leaders in producing high-performance J type thermocouples. The following list identifies the top 10 manufacturers based on product range, technical innovation, global reach, and market presence.

Top 10 J Type Thermocouple Range Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Thermocouple Type Comparison Chart

Domain Est. 1992

Website: te.com

Key Highlights: Type J Thermocouple This is the second most common thermocouple. It is a good choice for general purpose applications if moisture is not present….

#2 Type J Thermocouples

Domain Est. 1995

Website: emerson.com

Key Highlights: Type J Thermocouples offer reliable temperature measurement solutions for engineers and procurement specialists. Learn about their features, applications, ……

#3 Thermocouple Types J, K, and T

Domain Est. 1995

Website: dataq.com

Key Highlights: 30-day returns12-foot (3.66m) type J beaded teflon-coated thermocouple. Maximum operating temperature of 500°F (260°C) on the coating of the wires. 24-Gauge teflon wrap for ……

#4 Thermocouple Types

Domain Est. 1995

Website: pyromation.com

Key Highlights: Explore thermocouple types: Type J, Type K, Type N, Type T, Type E, Type R, Type S, Type B and Type C. See specs and applications from Pyromation….

#5 Thermocouple Types

Domain Est. 1996

Website: jkem.com

Key Highlights: J, K, or T refers to the calibrated temperature range: J[black]: 0 – 800° C; K [yellow] -50 – 1200° C; T [blue] -200 – 250° C; (RTD: -200 – 400° C). For ……

#6 Thermocouples

Domain Est. 1996

Website: wika.com

Key Highlights: WIKA offers a comprehensive portfolio of thermocouples with multiple temperature ranges, connection heads, output signals, and safety certifications….

#7 J Type Thermocouple

Domain Est. 1999

Website: clevelandelectriclabs.com

Key Highlights: Rating 5.0 (5) Dec 8, 2025 · Type J thermocouples have a temperature range from approximately -210°C to 1,200°C (-346°F to 2,192°F). This makes them suitable for a variety ……

#8 Thermocouple Type K, J, T, E, R, S, B, C, RTD Sensors & RTD …

Domain Est. 1999

Website: thermometricscorp.com

Key Highlights: Thermocouples: Type J, K, N, R, S, B, T, E. Temperature Range (- 200 to 2316)°C · RTDs: operate in a temperature range of (-200 to 1000) °C · Bearing Sensors ……

#9 24 AWG PFA Insulated Type J Thermocouple (No Plug)

Domain Est. 2000

Website: madgetech.com

Key Highlights: Description. 72″ Type J thermocouple with PFA insulated lead wire. No plug – stripped ends. Specifications. Temperature Sensor, Thermocouple….

#10 Thermocouple

Domain Est. 2011

Website: thermocoupleinfo.com

Key Highlights: Type J Thermocouple (Iron/Constantan): The type J is also very common. It has a smaller temperature range and a shorter lifespan at higher temperatures than ……

Expert Sourcing Insights for J Type Thermocouple Range

H2: Market Trends for J Type Thermocouple Range in 2026

The global market for J Type Thermocouples is projected to experience steady growth by 2026, driven by evolving industrial demands, technological advancements, and the continued need for reliable temperature measurement in cost-sensitive applications. As industries prioritize efficiency, safety, and process optimization, the J Type thermocouple—known for its affordability, moderate temperature range (−40°C to +750°C), and compatibility with iron-constantan systems—remains a preferred choice in specific sectors.

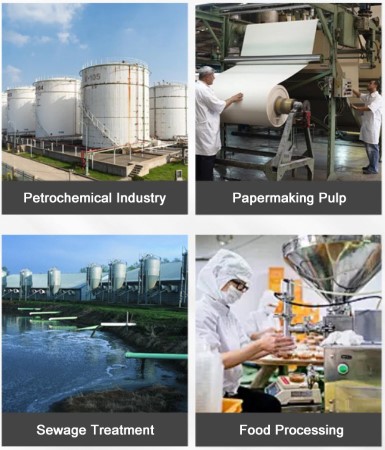

1. Industrial Automation and Process Control Expansion

The rise of Industry 4.0 and smart manufacturing is increasing the integration of temperature sensors in automated systems. J Type thermocouples are widely used in food processing, plastics, and light manufacturing due to their reliability in oxidizing environments and low-cost deployment. By 2026, expanded automation in emerging economies is expected to boost demand for J Type sensors, particularly in small-to-medium enterprises (SMEs) seeking cost-effective monitoring solutions.

2. Growth in Asia-Pacific Manufacturing Hubs

Countries such as China, India, and Vietnam are expanding their industrial infrastructure, particularly in chemicals, textiles, and consumer goods—sectors where J Type thermocouples are commonly deployed. Favorable government policies and increased foreign direct investment are expected to sustain demand. Local production of thermocouples and related instrumentation will likely reduce costs and enhance regional supply chain resilience.

3. Energy Efficiency and Sustainability Initiatives

As industries adopt energy-efficient practices, accurate temperature monitoring becomes critical. J Type thermocouples play a role in monitoring heating systems, boilers, and heat treatment processes. While not suitable for high-temperature applications like K or N types, J Type sensors are being optimized for improved accuracy and longevity in moderate-temperature operations, aligning with sustainability goals through preventive maintenance and reduced energy waste.

4. Competition from Alternative Sensors and Digitalization

Despite their advantages, J Type thermocouples face competition from resistance temperature detectors (RTDs) and infrared sensors, especially where higher precision or non-contact measurement is required. Additionally, the integration of digital communication protocols (e.g., HART, Foundation Fieldbus) and wireless sensor networks may shift preference toward smart sensors. However, the simplicity and ruggedness of J Type thermocouples ensure their relevance in analog and legacy systems still prevalent in many industries.

5. Material and Design Improvements

Manufacturers are focusing on enhancing the oxidation resistance of the iron leg in J Type thermocouples, which is a known limitation in reducing atmospheres. By 2026, expect incremental innovations in sheathing materials (e.g., mineral-insulated cables) and protective coatings to extend service life and broaden applicability.

Conclusion

By 2026, the J Type thermocouple market will maintain a stable presence, particularly in cost-driven and moderate-temperature industrial applications. While not at the forefront of high-tech sensor development, its proven performance, ease of use, and economic value will ensure continued adoption—especially in developing regions and traditional manufacturing sectors. Strategic improvements in durability and integration with digital systems will determine its long-term competitiveness in a rapidly evolving sensor landscape.

Common Pitfalls Sourcing J Type Thermocouple Range (Quality, IP)

Sourcing J Type thermocouples requires careful attention to specifications and supplier reliability to ensure accurate temperature measurement and long-term durability. Overlooking key quality and Ingress Protection (IP) factors can lead to premature failure, measurement inaccuracies, and increased maintenance costs.

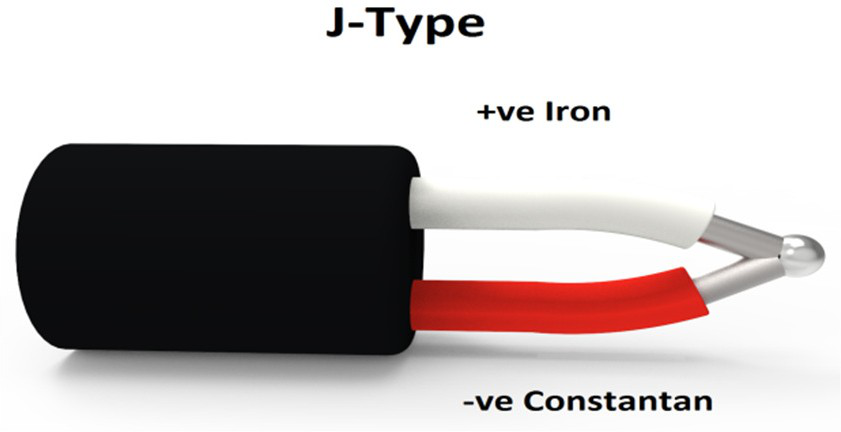

Poor Quality Materials and Construction

Using substandard iron (positive leg) and constantan (negative leg) alloys compromises thermoelectric output consistency and increases susceptibility to oxidation, especially above 500°C. Low-quality sheathing materials (e.g., thin or impure stainless steel) reduce corrosion resistance and mechanical strength, leading to sensor degradation in harsh environments. Inadequate insulation (e.g., low-grade magnesium oxide) can result in signal leakage, reduced accuracy, and short circuits.

Misunderstanding Ingress Protection (IP) Ratings

Selecting a thermocouple with an insufficient IP rating for the application environment exposes internal components to moisture, dust, and chemicals. For instance, using an IP54-rated sensor in a washdown environment requiring IP67 or IP69K can lead to moisture ingress, causing calibration drift or complete failure. Conversely, over-specifying IP ratings unnecessarily increases cost without performance benefits.

Inadequate Calibration and Traceability

Purchasing thermocouples without proper calibration certificates or NIST traceability risks measurement inaccuracies. Non-standard or undocumented tolerances (e.g., exceeding ASTM E230 Class 2 limits) result in unreliable data, particularly in regulated industries like food processing or pharmaceuticals.

Incorrect Sheath and Junction Selection

Choosing the wrong sheath diameter, length, or tip configuration (grounded, ungrounded, exposed) affects response time and mechanical durability. For example, an exposed junction may offer fast response but is vulnerable to abrasion and contamination, while a grounded junction may be prone to electrical noise in high-voltage environments.

Neglecting Environmental Compatibility

J Type thermocouples are prone to rust in humid environments and should not be used in vacuum or reducing atmospheres due to selective oxidation of iron. Sourcing sensors without considering ambient conditions—such as thermal cycling, vibration, or chemical exposure—leads to shortened lifespan and unreliable performance.

Unverified Supplier Credentials

Procuring from suppliers without recognized quality certifications (e.g., ISO 9001) or lacking technical support increases the risk of receiving counterfeit or non-compliant products. Transparent documentation, responsive support, and proven industry experience are essential for ensuring long-term reliability.

Logistics & Compliance Guide for J Type Thermocouple Range

This guide outlines the essential logistics and compliance considerations for the handling, transportation, storage, and regulatory adherence of J Type Thermocouples. Ensuring proper procedures are followed guarantees product integrity, safety, and legal compliance across the supply chain.

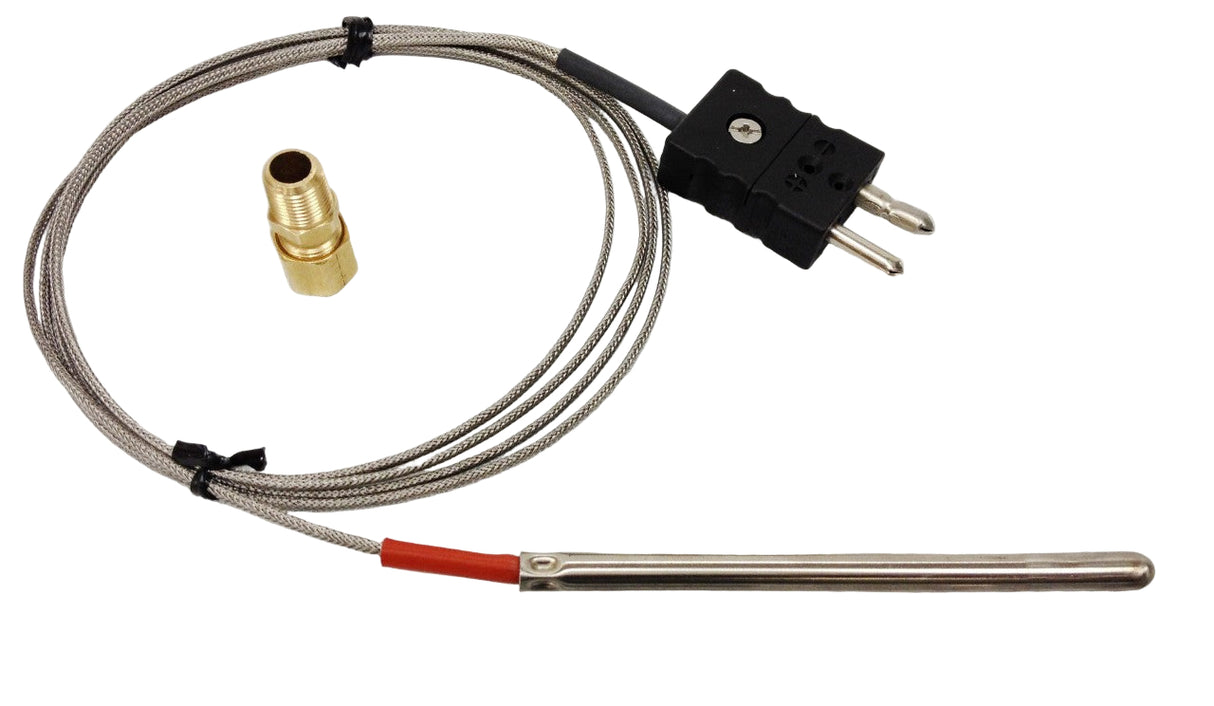

Product Overview

J Type Thermocouples consist of iron (positive leg) and constantan (negative leg), offering a temperature measurement range of approximately -210°C to +760°C. They are commonly used in oxidizing or inert atmospheres but are not recommended for vacuum or sulfur-rich environments due to iron oxidation and sulfidation risks. Typical applications include industrial furnaces, plastics processing, and general-purpose temperature sensing.

Packaging and Handling

Proper packaging and handling are critical to prevent mechanical damage, contamination, and degradation of thermocouple wire and junctions.

- Primary Packaging: Each thermocouple should be individually wrapped in anti-static or non-abrasive material to prevent wire scratching or shorting.

- Secondary Packaging: Use rigid corrugated cardboard boxes with internal dividers or foam inserts to minimize movement during transit. Clearly label with “Fragile” and “This Side Up” indicators.

- Environmental Protection: Include desiccant packs to control moisture, especially for thermocouples with exposed junctions or mineral-insulated (MI) cable variants.

- Handling Procedures: Personnel must wear gloves to avoid skin oils contaminating metal surfaces. Avoid bending or kinking wires beyond the specified minimum bend radius.

Storage Conditions

To maintain accuracy and longevity, J Type Thermocouples must be stored under controlled conditions.

- Temperature: Store between 10°C and 30°C.

- Humidity: Relative humidity should not exceed 60% to prevent oxidation of the iron conductor.

- Environment: Keep in a clean, dry, and well-ventilated area away from corrosive chemicals, especially sulfur compounds, salts, and strong acids.

- Shelving: Store in original packaging on elevated, non-metallic shelves to avoid floor moisture and physical damage.

Transportation Requirements

Transportation must ensure product integrity and comply with relevant domestic and international regulations.

- Domestic Shipments: Use reputable carriers with tracking capabilities. Secure loads to prevent shifting. Avoid extreme temperature exposure (e.g., unrefrigerated trailers in summer or winter).

- International Shipments:

- Comply with IATA, IMDG (if applicable), and national transport regulations.

- Include proper documentation: commercial invoice, packing list, and certificate of conformance.

- Declare as “Electrical Measuring Equipment – Non-Hazardous” unless otherwise specified.

- Labeling: Packages must display:

- Product name and model numbers

- Quantity per pack

- Storage and handling symbols (e.g., moisture-sensitive, fragile)

- Manufacturer and destination information

Regulatory Compliance

J Type Thermocouples must meet various international and regional standards to ensure safety, performance, and market access.

- Electromagnetic Compatibility (EMC):

- Comply with IEC 61326-1 for industrial electrical equipment.

- CE marking required for sale in the European Economic Area (EEA).

- RoHS Compliance:

- Must conform to EU Directive 2011/65/EU restricting hazardous substances (e.g., lead, mercury, cadmium).

- Provide RoHS Declaration of Conformity upon request.

- REACH Regulation:

- Ensure no unauthorized Substances of Very High Concern (SVHC) are present above threshold levels.

- NIST Traceability:

- Calibration certificates, when provided, must be traceable to NIST or equivalent national standards.

- Customs and Import Regulations:

- Harmonized System (HS) Code: Typically 9025.19 (measuring instruments for temperature).

- Check destination country requirements for electrical product certification (e.g., UKCA, CCC, PSE).

Quality Assurance and Documentation

Maintain comprehensive records to support compliance and traceability.

- Certificates:

- Certificate of Conformance (CoC)

- Calibration certificate (if applicable)

- Material test reports (for wire composition)

- Lot Traceability: Each batch should be assigned a unique lot number linked to manufacturing and testing data.

- Audit Readiness: Retain documentation for a minimum of 5 years to support regulatory audits.

Disposal and Environmental Responsibility

Dispose of thermocouples and packaging in accordance with local and international environmental regulations.

- Waste Classification: J Type Thermocouples are generally non-hazardous electronic waste (e-waste).

- Recycling: Iron and copper-nickel (constantan) components can often be recycled through certified e-waste processors.

- Packaging: Use recyclable materials wherever possible and label packaging with recycling symbols.

Summary

Adherence to this logistics and compliance guide ensures that J Type Thermocouples are handled safely, stored correctly, transported securely, and meet all applicable regulatory standards. Maintaining rigorous documentation and quality control supports customer trust, regulatory compliance, and operational efficiency throughout the product lifecycle.

Conclusion for Sourcing J-Type Thermocouple Range:

After evaluating technical requirements, environmental conditions, and supplier capabilities, sourcing J-type thermocouples proves to be a reliable and cost-effective solution for temperature measurement within the range of 0°C to 750°C, particularly in reducing or vacuum atmospheres where their iron-constantan construction offers good performance and stability. Their high output signal (approximately 50 µV/°C) ensures good sensitivity and compatibility with standard instrumentation.

Key considerations in the sourcing decision include selecting suppliers with certification to international standards (e.g., ASTM E230, IEC 60584), ensuring proper sheath material (such as 304 or 316 stainless steel) for the operating environment, and confirming calibration traceability for critical applications. While J-type thermocouples are not suitable for oxidizing environments at high temperatures due to iron oxidation, their advantages in moderate-temperature industrial processes—such as in chemical plants, resins, and vacuum furnaces—make them a preferred choice.

In conclusion, for applications within their operational limits, J-type thermocouples offer a robust, accurate, and economical temperature sensing option. Careful supplier selection based on quality, consistency, and technical support will ensure long-term reliability and optimal performance across the desired measurement range.