The global hand tools market, including specialty pliers such as J clip pliers used extensively in automotive, HVAC, and industrial applications, is witnessing steady growth driven by rising demand from maintenance and repair sectors. According to Grand View Research, the global hand tools market size was valued at USD 14.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.8% from 2023 to 2030. This growth is fueled by increasing infrastructure development, automotive production, and industrial automation. Within this landscape, J clip pliers — designed for quick and secure fastening of J-clips in wire harnesses and panel attachments — represent a niche but essential segment. With stringent quality requirements and growing OEM demand, leading manufacturers are investing in precision engineering and durable materials to meet evolving industry standards. Based on production capacity, R&D investment, and global market presence, the following eight companies stand out as top manufacturers of J clip pliers.

Top 8 J Clip Pliers Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Lawson Products

Domain Est. 1997

Website: lawsonproducts.com

Key Highlights: Explore top-quality industrial supplies, fasteners, and MRO solutions. Shop Lawson Products, your trusted partner for all your industrial supply ……

#2 R10 J

Domain Est. 2001

Website: deckermfg.com

Key Highlights: In stockThe R10 J-Klip plier is used with our J-Klips and is made in the USA. Price: $6.05. QTY. Add to Cart. (800) 541-1107. Industrial Fasteners · Farm Products ……

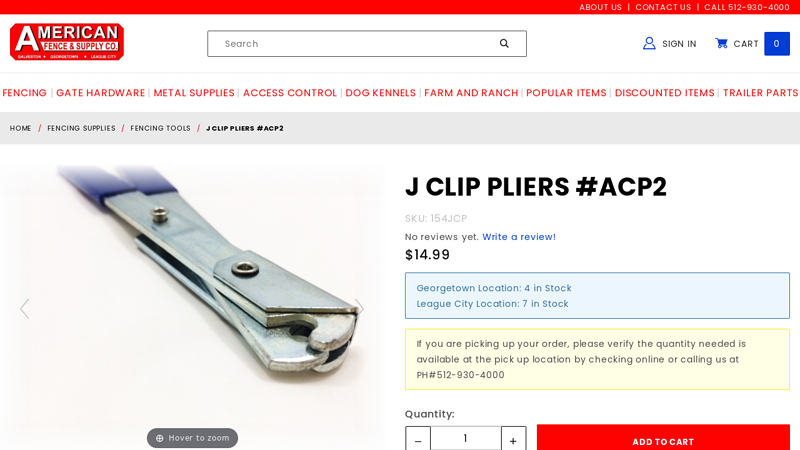

#3 J CLIP PLIERS #ACP2

Domain Est. 1997

#4 Cage Clip Pliers

Domain Est. 1998

Website: kwcages.com

Key Highlights: In stock Free deliveryCage Clip Pliers. Special jaws hold cage clips (j clips). Squeeze to roll and close clips to join wire cage panels together….

#5 J-Clip Fastening Pliers

Domain Est. 2000

Website: wildlifecontrolsupplies.com

Key Highlights: “J” Style Pliers which uses a J-Clip that measures 5/16″W x 1/2″L. Great for repairing traps, making your own cages, bird traps, bird cages, etc….

#6 Decker J Clips and Pliers

Domain Est. 2008

Website: purplemartinproducts.com

Key Highlights: J-Clips (#DJC). Decker J-Clips are made from 24 gauge galvanized steel and approximately 500 pieces per pound. For assembly or repair of cages, pens, ……

#7 J

Domain Est. 2011

Website: greatnortherncageco.com

Key Highlights: J-Clip Pliers (heavy duty with cushioned handle). $15.00. J-Clip Pliers (heavy duty with cushioned handle) quantity. Add ……

#8 J

Domain Est. 2015

Expert Sourcing Insights for J Clip Pliers

2026 Market Trends for J Clip Pliers: Key Drivers and Future Outlook

The market for J Clip Pliers—a specialized tool primarily used in automotive repair for installing and removing J-shaped retaining clips on brake lines, electrical connectors, and trim components—is poised for notable shifts by 2026. Driven by broader automotive industry trends, technological advancements, and evolving consumer demands, the J Clip Pliers market will face both challenges and opportunities. Below is an analysis of the key trends expected to shape this niche tool segment.

Automotive Electrification and Changing Service Needs

The accelerating shift toward electric vehicles (EVs) will significantly impact the demand for J Clip Pliers. Unlike internal combustion engine (ICE) vehicles, EVs have fewer traditional brake systems, reduced under-hood complexity, and different wiring harness configurations. As a result, the frequency of J clip usage may decline in pure EVs, potentially reducing the volume of J Clip Pliers required for routine maintenance. However, hybrid vehicles and transitional fleets will continue to rely on these tools through 2026, maintaining a baseline demand.

Additionally, EV service workflows emphasize high-voltage safety and specialized diagnostic tools, pushing technicians to adopt multifunctional and insulated toolsets. J Clip Pliers designed with insulation, ergonomic enhancements, and compatibility with EV-specific components will gain competitive advantage.

Growth of the Aftermarket and DIY Repair Culture

Despite automotive OEMs pushing for centralized service models, the aftermarket repair sector is expected to grow steadily through 2026, fueled by longer vehicle lifespans and cost-conscious consumers. J Clip Pliers remain essential in brake and trim repair, areas frequently addressed in independent and home garages. The rise of online tutorials, YouTube repair guides, and e-commerce platforms makes access to specialized tools like J Clip Pliers easier for do-it-yourself (DIY) enthusiasts.

Manufacturers that focus on user-friendly designs, value bundles, and compatibility with common vehicle models will capture a larger share of the DIY segment. Marketing strategies emphasizing ease of use and durability will be key differentiators.

Tool Consolidation and Multi-Functionality

Tool manufacturers are increasingly responding to technician demand for efficiency and space-saving solutions. By 2026, we expect to see more J Clip Pliers integrated into multi-tool systems or combined with related functions such as retaining ring pliers or hose clamp tools. While dedicated J Clip Pliers will remain necessary for precision work, hybrid tools that include J clip functionality may appeal to mobile mechanics and smaller workshops seeking versatility.

This trend could pressure standalone J Clip Plier sales but opens opportunities for innovation in modular and convertible tool designs.

Emphasis on Ergonomics and Durability

As occupational health and technician comfort gain importance, tool ergonomics will be a critical selling point. By 2026, J Clip Pliers featuring cushioned grips, lightweight alloys, and improved leverage mechanics will be in higher demand. Brands investing in ergonomic research and user feedback will strengthen their market position. Additionally, durability remains paramount—high-grade steel, corrosion resistance, and long warranty periods will continue to influence purchasing decisions among professional users.

Supply Chain Localization and Sustainability

Ongoing supply chain volatility and a growing focus on sustainability may push manufacturers to localize production and adopt eco-friendly materials. J Clip Pliers made with recycled metals or packaged in minimal, recyclable materials could gain favor among environmentally conscious buyers and large fleet service centers adopting green policies. Reshoring or nearshoring production may also reduce lead times and increase supply reliability.

Conclusion

By 2026, the J Clip Pliers market will be shaped by the transition to electric mobility, the resilience of the aftermarket, and rising expectations for tool performance and design. While traditional demand may plateau or slightly decline due to vehicle electrification, opportunities exist in product innovation, ergonomic enhancements, and strategic positioning within the DIY and hybrid vehicle service ecosystems. Manufacturers that adapt swiftly to these trends—offering durable, specialized, and user-centric tools—will maintain relevance and competitiveness in the evolving automotive tool landscape.

Common Pitfalls When Sourcing J Clip Pliers (Quality and Intellectual Property)

Sourcing J clip pliers—commonly used in upholstery, furniture assembly, and automotive trim installation—can present several challenges, especially when balancing cost, quality, and legal compliance. Below are key pitfalls related to quality and intellectual property (IP) to watch for.

Poor Material and Build Quality

Many low-cost J clip pliers, particularly from unverified suppliers, are manufactured using substandard materials such as low-grade steel or brittle alloys. This leads to premature wear, tool deformation, or even breakage during use. Inferior heat treatment processes can further compromise durability, reducing tool life and increasing replacement costs over time.

Inconsistent Manufacturing Tolerances

Inconsistent production standards can result in pliers with misaligned jaws or improper spring tension. This affects the tool’s ability to grip and install J clips securely, leading to user frustration and potential damage to workpieces. Without strict quality control protocols, batch-to-batch variations are common, making reliability a major concern.

Lack of Ergonomic Design

Cheaply sourced pliers often neglect ergonomic considerations, featuring uncomfortable or poorly shaped handles. This can cause hand fatigue and reduced productivity, especially during extended use. Investing in tools with proper grip design and balanced weight distribution is crucial for user safety and efficiency.

Counterfeit or IP-Infringing Products

Some suppliers may offer J clip pliers that mimic the design of well-known branded tools (e.g., those from Stanley, Trimax, or other established manufacturers). These counterfeit products often infringe on design patents or trademarks, exposing buyers to legal risks, especially in regulated markets like the EU or North America. Using or importing such tools may lead to customs seizures, fines, or reputational damage.

Absence of IP Documentation and Compliance

When sourcing from manufacturers, especially in regions with lax IP enforcement, suppliers may be unable or unwilling to provide proof of legitimate design rights or licensing. This lack of transparency increases the risk of inadvertently procuring tools that violate intellectual property laws, particularly if the product is resold under a private label.

Limited After-Sales Support and Warranties

Low-cost suppliers often offer little to no warranty or customer support. If quality issues arise post-purchase, resolving them can be difficult or impossible, especially when dealing with overseas vendors. This lack of accountability undermines long-term value and increases total cost of ownership.

Conclusion

To avoid these pitfalls, conduct thorough due diligence on suppliers, request product samples, verify material specifications, and ensure IP compliance through legal review when necessary. Partnering with reputable manufacturers and demanding transparency in both quality and intellectual property rights is essential for sustainable, risk-free sourcing.

Logistics & Compliance Guide for J Clip Pliers

This guide outlines the essential logistics and compliance considerations for the safe, efficient, and legal handling, storage, transportation, and use of J Clip Pliers.

Product Identification and Specifications

Ensure accurate identification of the J Clip Pliers, including:

– Manufacturer name and model number

– Material composition (e.g., high-carbon steel, insulated handles)

– Dimensions and weight

– Intended use (e.g., automotive HVAC, sheet metal work)

– Safety certifications (e.g., CE, ANSI, RoHS if applicable)

Packaging and Labeling Requirements

Use robust, protective packaging to prevent damage during transit. Label each package clearly with:

– Product name and SKU

– Quantity per unit

– Handling symbols (e.g., “Fragile,” “This Side Up”)

– Manufacturer and distributor contact information

– Compliance markings (e.g., CE, UKCA, or other regional symbols)

– Batch or lot number for traceability

Storage Conditions

Store J Clip Pliers in a:

– Dry, temperature-controlled environment to prevent corrosion

– Secure area to avoid theft or unauthorized access

– Organized system (e.g., shelving with labels) for easy inventory management

Avoid exposure to moisture, extreme temperatures, or corrosive chemicals.

Transportation and Shipping

Adhere to the following during transport:

– Use cushioned packaging and secure palletization to prevent movement

– Comply with carrier-specific requirements (e.g., IATA for air, IMDG for sea if applicable)

– Declare contents accurately on shipping documents

– Follow regional regulations for tool shipments (e.g., no hazardous materials classification for standard pliers)

Regulatory Compliance

Verify and maintain compliance with relevant standards and regulations:

– CE Marking (EU): Ensure conformity with the Machinery Directive or relevant EU directives

– RoHS (EU): Confirm restricted substance compliance if applicable

– REACH (EU): Register and report chemical substances if required

– OSHA (USA): Tools should meet safety standards for workplace use

– ANSI/ASME Standards: Follow dimensional and safety guidelines where applicable

– UKCA (UK): Required for tools sold in Great Britain post-Brexit

– Customs Documentation: Include commercial invoices, packing lists, and certificates of origin for international shipments

Import/Export Controls

For cross-border movement:

– Classify the product under the correct HS Code (e.g., 8203.20 for pliers)

– Obtain necessary export licenses if shipping to restricted countries

– Comply with import duties and VAT regulations in the destination country

– Maintain records for audit and customs inspection

Workplace Safety and Training

Ensure users are trained on:

– Proper use of J Clip Pliers to avoid injury

– Inspection for wear or damage before use

– Appropriate personal protective equipment (PPE)

– Safe handling and storage practices on job sites

Environmental and Disposal Considerations

Dispose of damaged or obsolete tools responsibly:

– Recycle metal components through certified e-waste or scrap metal programs

– Follow local regulations for disposal of packaging materials

– Avoid landfill dumping where recycling options exist

Documentation and Recordkeeping

Maintain records for:

– Product certifications and test reports

– Batch tracking and warranty information

– Shipping and customs documentation

– Safety data sheets (SDS) if applicable (e.g., for lubricants or coatings)

Audit and Continuous Compliance

Conduct periodic audits to:

– Verify ongoing compliance with updated regulations

– Review supply chain partners for adherence to standards

– Update documentation and training materials as needed

By following this guide, distributors, retailers, and end users can ensure the legal, safe, and efficient lifecycle management of J Clip Pliers across global markets.

In conclusion, sourcing J clip pliers requires careful consideration of several key factors to ensure quality, reliability, and cost-effectiveness. It is essential to evaluate suppliers based on product quality, manufacturing standards, pricing, delivery times, and after-sales support. Whether sourcing locally or internationally, establishing strong relationships with reputable suppliers—particularly those specializing in automotive or tire service tools—can significantly impact long-term operational efficiency. Additionally, verifying compatibility with specific J clip types and adherence to industry safety standards is crucial. By conducting thorough research, obtaining samples, and comparing options, businesses can make informed procurement decisions that balance performance and value, ultimately supporting smoother repair and maintenance workflows.