The global infrared (IR) gas heater market is experiencing robust growth, driven by increasing demand for energy-efficient heating solutions across residential, commercial, and industrial sectors. According to a report by Mordor Intelligence, the global gas heater market was valued at USD 5.87 billion in 2023 and is projected to grow at a CAGR of 4.2% from 2024 to 2029. This expansion is fueled by rising energy costs, stricter environmental regulations, and a shift toward low-emission heating technologies—trends that have elevated the prominence of IR gas heaters due to their high thermal efficiency and targeted heating capabilities. As the market becomes increasingly competitive, innovation in design, fuel efficiency, and smart integration is setting leading manufacturers apart. Based on market presence, product range, technological advancements, and global reach, the following are the top 10 IR gas heater manufacturers shaping the industry’s future.

Top 10 Ir Gas Heater Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Solaronics: Infrared Heaters Manufacturer

Domain Est. 1997

Website: solaronicsusa.com

Key Highlights: Solaronics is a leading manufacturer of industrial radiant heaters with 60 years of expertise and personal experience in the industry….

#2 Fostoria

Domain Est. 2021

Website: fostoria-infrared.com

Key Highlights: Fostoria Infrared is a manufacturer of electric infrared ovens, industrial process heating equipment and control systems. We offer standard and customized ……

#3

Domain Est. 1996 | Founded: 1961

Website: infradyne.com

Key Highlights: Manufactures of fine quality outdoor heaters since 1961. Infrared Dynamics, Inc. developed the first infrared patio heater in California over 50 years ago….

#4 Infrared Heaters for , Construction, Patio & Factories

Domain Est. 1997

Website: sunstarheaters.com

Key Highlights: Vent-free room heaters and construction and patio heaters from SunStar bring warm heat to your home, office, workspace and factory….

#5 Infrared Radiant Heaters

Domain Est. 1997

Website: spaceray.com

Key Highlights: Space-Ray manufactures high efficiency infrared radiant heaters and forced air heaters for industrial, commercial, patio, agricultural, and leisure uses….

#6 Roberts

Domain Est. 1998

Website: robertsgordon.com

Key Highlights: Roberts Gordon Infrared Heating manufactures high quality, efficient radiant tube heaters for industrial and commercial applications….

#7 Superior Radiant Products

Domain Est. 1997

Website: superiorradiant.com

Key Highlights: Superior Radiant Products (SRP®) is an industry leader in the design and manufacture of energy efficient commercial infrared heaters….

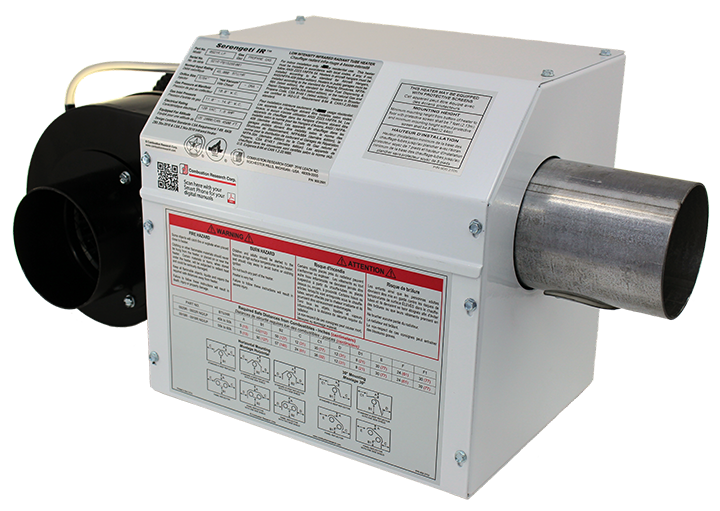

#8 to SUNHEAT® International

Domain Est. 1999 | Founded: 1954

Website: sunheat.com

Key Highlights: 30-day returnsCheck out all our made USA infrared heaters and fireplaces. … Thank you for taking the time to browse our website. We are family owned and operated since 1954 ……

#9 IR Energy

Domain Est. 2004

Website: irenergy.ca

Key Highlights: At IR Energy, we deliver sleek heating solutions that are designed to perform and endure. Every product embodies our commitment to excellence….

#10 Schwank

Domain Est. 2005

Website: schwankgroup.com

Key Highlights: Browse the extensive line of infrared radiant heaters: tube heaters, patio, and outdoor heating, electric heating, and luminous high-intensity heaters….

Expert Sourcing Insights for Ir Gas Heater

H2: Analysis of 2026 Market Trends for Infrared (IR) Gas Heaters

The global market for infrared (IR) gas heaters is poised for significant transformation by 2026, driven by evolving energy policies, technological advancements, and shifting consumer preferences toward energy efficiency and sustainability. This analysis explores key trends shaping the IR gas heater industry in 2026, with a focus on innovation, regulation, regional dynamics, and competitive positioning.

1. Increased Demand for Energy-Efficient Heating Solutions

Energy efficiency remains a top priority for both residential and industrial consumers. IR gas heaters, known for their direct heating mechanism and minimal heat loss, are gaining traction over conventional convection systems. By 2026, rising energy costs and carbon reduction targets are expected to accelerate adoption, especially in commercial and high-ceiling industrial applications such as warehouses, workshops, and agricultural facilities.

- Projected Growth: The global IR heating market is forecasted to grow at a CAGR of 6.8% from 2022 to 2026 (Source: MarketsandMarkets), with gas-powered IR systems capturing a significant share due to their cost-effectiveness and reliability.

- Efficiency Advantage: IR gas heaters typically offer thermal efficiencies exceeding 90%, making them attractive in regions with high electricity costs or unreliable grid infrastructure.

2. Regulatory Pressure and Decarbonization Efforts

Environmental regulations are reshaping the heating sector. While natural gas is a fossil fuel, it emits fewer greenhouse gases than coal or oil. However, by 2026, many countries—particularly in the EU and North America—are implementing stricter emissions standards and promoting low-carbon alternatives.

- Hybrid and Low-Carbon Gas Adoption: There is growing interest in blending natural gas with hydrogen (H₂). Pilot projects across Europe (e.g., in the UK and Germany) are testing up to 20% hydrogen blends in existing gas infrastructure. IR gas heaters capable of operating on H₂-enriched gas are expected to gain market share.

- H₂-Ready Heater Development: Major manufacturers (e.g., Honeywell, Rinnai, and Bosch) are investing in “H₂-ready” IR heater technologies that can transition to higher hydrogen concentrations, aligning with net-zero goals. By 2026, H₂-compatible models may account for 15–20% of new commercial IR gas heater installations in leading European markets.

3. Technological Innovations Enhancing Performance and Safety

Advancements in burner design, materials, and control systems are improving the safety, durability, and smart functionality of IR gas heaters.

- Smart Integration: IoT-enabled IR heaters with remote monitoring, adaptive thermostats, and predictive maintenance are becoming standard in new installations. By 2026, over 40% of high-end commercial IR gas heaters are expected to include smart controls.

- Ceramic and Metal Fiber Emitters: Improved emitter materials allow for faster warm-up times, longer lifespans, and better heat distribution, enhancing user experience and reducing operational costs.

4. Regional Market Dynamics

- Europe: Driven by the EU Green Deal and REPowerEU initiatives, Europe leads in adopting hydrogen-compatible and high-efficiency IR systems. Countries like Germany, France, and the Netherlands are likely to mandate H₂-readiness in new heating equipment by 2026.

- North America: The U.S. and Canada show strong demand in industrial and agricultural sectors. Federal tax incentives under the Inflation Reduction Act (IRA) for energy-efficient equipment are boosting IR heater adoption.

- Asia-Pacific: Rapid industrialization in China and India is fueling demand for cost-effective heating solutions. However, air quality concerns may push regulators toward cleaner alternatives, including electric IR or biogas-powered systems.

5. Sustainability and Circular Economy Considerations

By 2026, sustainability will influence product design and end-of-life management. Manufacturers are exploring recyclable components, modular designs, and service-based business models (e.g., heating-as-a-service) to reduce environmental impact.

Conclusion

By 2026, the IR gas heater market will be characterized by a dual focus: optimizing current gas-based systems for efficiency while preparing for a low-carbon future through hydrogen integration. The transition toward H₂-compatible technologies will be a critical differentiator for market leaders. Companies that invest in innovation, comply with evolving regulations, and align with decarbonization goals will be best positioned to capture growth in this dynamic sector.

When sourcing infrared (IR) gas heaters—especially those designed to operate with hydrogen (H₂) as a fuel—there are several common pitfalls related to quality and intellectual property (IP) that buyers, engineers, or project developers should be aware of. Below is a breakdown of these pitfalls and how to mitigate them, particularly in the context of using H₂ as the fuel source.

🔧 1. Quality-Related Pitfalls

a. Material Compatibility with Hydrogen

- Pitfall: Many standard IR gas heaters are designed for natural gas (methane), not H₂. Hydrogen causes embrittlement in certain metals (e.g., carbon steel), leading to premature failure.

- Risk: Cracking, leaks, or catastrophic failure under pressure/temperature cycles.

- Solution:

- Ensure materials (burner tubes, manifolds, valves) are compatible with H₂ (e.g., stainless steel 316L, Inconel).

- Verify compliance with hydrogen-ready design standards (e.g., ISO 11114-4, CGA G-9.1).

b. Incomplete Combustion & NOx Emissions

- Pitfall: H₂ burns faster and hotter than methane. Conventional IR heater designs may cause flame instability, flashback, or high NOx emissions.

- Risk: Poor efficiency, safety hazards, regulatory non-compliance.

- Solution:

- Demand H₂-specific burner design with flame stabilization and low-NOx technology.

- Require emissions data from independent testing on H₂ operation.

c. Lack of Certification for Hydrogen Use

- Pitfall: Supplier claims “H₂-compatible” without formal certification.

- Risk: Non-compliance with safety standards (e.g., ATEX, IECEx, local gas codes).

- Solution:

- Require third-party certification (e.g., TÜV, UL, DNV) for H₂ operation.

- Check conformity with EN 13611, EN 15502, or ASME B31.12 (hydrogen piping systems).

d. Poor Thermal Efficiency & Uniformity

- Pitfall: Generic or low-cost IR heaters may not deliver consistent radiant heat distribution when fueled by H₂.

- Risk: Uneven heating, reduced process efficiency.

- Solution:

- Request thermal imaging reports or CFD simulations showing heat distribution with H₂.

- Prefer emitters with gold-coated or specialized quartz tubes optimized for H₂’s spectral output.

e. Inadequate Safety Controls

- Pitfall: Missing or insufficient H₂-specific safety features (e.g., leak detection, flame supervision, purge cycles).

- Risk: Explosion hazard due to H₂’s wide flammability range (4–75% in air).

- Solution:

- Confirm integration with H₂ sensors, automatic shutoff valves, and proper ventilation interlocks.

- Verify compliance with IEC 60079 (explosive atmospheres).

💡 2. Intellectual Property (IP)-Related Pitfalls

a. Copying or Reverse-Engineered Designs

- Pitfall: Low-cost suppliers may replicate patented IR heater designs without licensing.

- Risk: Legal liability for buyer if using infringing equipment; poor performance/safety.

- Solution:

- Work only with reputable, transparent manufacturers.

- Ask for proof of IP ownership or licensing (patents, design registrations).

- Conduct due diligence via patent databases (e.g., Espacenet, USPTO).

b. Lack of Innovation Claims

- Pitfall: Suppliers claim “H₂-ready” based on minor modifications to natural gas heaters.

- Risk: Equipment fails under real H₂ conditions.

- Solution:

- Request technical documentation showing R&D investment in H₂ applications.

- Look for patents or white papers on H₂-specific combustion or materials.

c. Unclear IP Terms in Contracts

- Pitfall: Turnkey suppliers may retain IP rights to custom designs, limiting your future use or modification.

- Risk: Inability to service, duplicate, or upgrade systems without vendor lock-in.

- Solution:

- Negotiate IP clauses in procurement contracts.

- Specify that custom designs or modifications become your property or are licensed royalty-free.

d. Use of Proprietary Components Without Disclosure

- Pitfall: Critical parts (e.g., catalytic burners, control systems) may be proprietary with no spare availability.

- Risk: Downtime due to lack of replacements or reverse compatibility.

- Solution:

- Require full BOM (Bill of Materials) and access to spare parts.

- Ensure interchangeability or long-term supply agreements.

✅ Best Practices When Sourcing H₂-Fueled IR Heaters

- Demand H₂-Specific Testing Data: Ask for performance under 100% H₂, not just blends.

- Audit Manufacturer Facilities: Verify R&D capability and quality control processes.

- Use Framework Agreements with IP Clauses: Protect your interests in customization.

- Involve Third-Party Experts: Engage engineering consultants familiar with hydrogen systems.

- Prioritize Safety & Compliance: Never compromise on certifications.

Summary Table

| Pitfall | Risk | Mitigation Strategy |

|——–|——|———————|

| H₂ material incompatibility | Embrittlement, leaks | Use H₂-grade materials (e.g., 316L SS) |

| Poor combustion with H₂ | Flashback, high NOx | H₂-optimized burner design |

| No H₂ certification | Safety/legal issues | Require TÜV, UL, or DNV certification |

| IP infringement | Legal liability | Verify patents/licenses |

| Proprietary lock-in | Vendor dependency | Negotiate IP rights in contract |

| Inadequate safety systems | Explosion risk | H₂ sensors, purge systems, ATEX compliance |

By being vigilant about both technical quality and IP integrity, you can avoid costly failures and ensure safe, efficient, and legally sound deployment of hydrogen-powered IR gas heaters.

Certainly! Below is a comprehensive Logistics & Compliance Guide for an IR (Infrared) Gas Heater using Hydrogen (H₂) as fuel, tailored to ensure safe, efficient, and regulatory-compliant handling from manufacturing to installation and operation.

Logistics & Compliance Guide: Hydrogen-Powered Infrared (IR) Gas Heater

1. Introduction

This guide outlines the logistics and compliance requirements for the safe transport, storage, installation, and operation of Infrared (IR) gas heaters that use hydrogen (H₂) as the primary fuel. Given the unique properties of hydrogen—high flammability, low ignition energy, and high diffusivity—stringent safety, regulatory, and logistical controls are essential.

2. Key Specifications

| Parameter | Specification |

|———|—————|

| Fuel Type | Hydrogen (H₂), pure or blended (if applicable) |

| Purity Requirement | ≥ 99.97% (for fuel-grade H₂, per ISO 14687) |

| Operating Pressure | Typically 0.5–3 bar (system-dependent) |

| Heater Type | Infrared radiant (catalytic or surface combustion) |

| Applications | Industrial drying, space heating, process heating |

3. Regulatory Compliance Framework

3.1 International & Regional Standards

Ensure compliance with the following standards:

Fuel & Gas Safety

- ISO 14687:2019 – Hydrogen fuel quality standards

- ISO 16111:2018 – Transportable gas storage devices (e.g., hydrogen cylinders/tubes)

- ISO 19880 (series) – Gaseous hydrogen fueling stations

- EN 17124:2019 – Industrial infrared heaters

Equipment & Installation

- IEC 60079 (series) – Explosive atmospheres (ATEX for EU)

- NFPA 2:2023 – Hydrogen Technologies Code (USA)

- ASME B31.12 – Hydrogen Piping and Pipelines

- Local Building & Fire Codes – e.g., IBC, IMC, NFPA 1, 5000

Environmental & Emissions

- EU Emissions Trading System (EU ETS) – CO₂ reporting (H₂ is low-carbon)

- REACH & CLP (EU) – Chemical safety and labeling

- EPA Regulations (USA) – Air quality reporting (if applicable)

4. Logistics: Storage, Handling & Transportation

4.1 Hydrogen Supply Options

Choose one or more of the following supply methods:

– Compressed Gas (CGH₂) – High-pressure cylinders (200–350 bar)

– Tube Trailers – For bulk delivery (up to 400 bar)

– On-Site Generation – Electrolysis (green H₂)

4.2 Storage Requirements

- Location: Ventilated, outdoor, or explosion-proof indoor room

- Separation: Minimum 3 meters from ignition sources and combustibles

- Ventilation: Natural or forced, with H₂ sensors (≥ 1% LEL detection)

- Cylinder Storage: Upright, secured, valve caps in place

- Marking: “HYDROGEN – FLAMMABLE GAS” (per GHS and OSHA)

4.3 Transportation

- Vehicle Requirements: DOT 4L or TPED-compliant cylinders; Class 2.1 hazard placards

- Documentation: Safety Data Sheet (SDS), transport emergency card (TREM card)

- Routing: Avoid tunnels, dense urban areas (per ADR in EU)

- Training: Drivers and handlers certified in dangerous goods (e.g., IATA/ADR/IMDG/49 CFR)

✅ Best Practice: Use dedicated hydrogen delivery networks or partner with certified H₂ logistics providers.

5. Installation & Commissioning

5.1 Site Preparation

- Ventilation: Ensure adequate air exchange to prevent H₂ accumulation

- Gas Detection: Install H₂ sensors at ceiling level (H₂ rises)

- Explosion Relief: Vent panels or flame arrestors (if indoors)

- Piping: Use stainless steel (SS316) or H₂-compatible materials; avoid galvanic corrosion

5.2 Piping & Connections

- Leak Testing: Conduct with inert gas (N₂) before H₂ introduction

- Fittings: Use double ferrule or welded joints; avoid threaded connections where possible

- Shut-Off Valves: Manual and automatic (solenoid) with emergency override

5.3 Electrical Safety

- Zoning: Classify area per ATEX/NEC (Zone 1 or 2 for potential H₂ leaks)

- Equipment: Use Ex-rated (explosion-proof) controls and sensors

6. Operational Safety & Procedures

6.1 Startup & Shutdown

- Purge System: Use inert gas (N₂) before startup and after shutdown

- Ignition: Ensure flame supervision (UV/IR sensors) and fail-safe lockout

- Monitoring: Continuous H₂ flow, pressure, and temperature checks

6.2 Leak Detection & Response

- Routine Checks: Use leak detection spray or H₂ sensors

- Emergency Plan:

- Isolate fuel supply

- Evacuate area

- Ventilate

- Do not use electrical switches

- Use explosion-proof communication

6.3 Maintenance

- Frequency: Quarterly inspections; annual certification

- Personnel: Trained in H₂ systems and PPE (anti-static clothing, face shield)

- Tools: Non-sparking (brass or beryllium-free)

7. Training & Documentation

7.1 Required Training

- Hydrogen safety (NFPA 2 or equivalent)

- Equipment operation & emergency procedures

- First response for H₂ leaks/fires

- ATEX/NEC zone awareness

7.2 Documentation

- Risk Assessment (e.g., HAZOP for industrial use)

- Operating Manual (H₂-specific)

- Maintenance Logs

- SDS for H₂ (GHS-compliant)

- Compliance Certificates (e.g., CE, UL, CSA)

8. Environmental & Sustainability Considerations

- Emissions: H₂ combustion produces only H₂O (no CO₂, NOx if low-temp IR)

- Green Certification: Use renewable H₂ (e.g., from electrolysis using solar/wind)

- Carbon Reporting: Eligible for carbon credit schemes (e.g., EU ETS, CDM)

9. Emergency Response Planning

| Scenario | Response |

|——–|———|

| H₂ Leak (no fire) | Evacuate, ventilate, shut off supply, monitor with H₂ sensor |

| H₂ Fire | Evacuate, let burn under control, cool adjacent equipment, do not extinguish unless leak can be stopped |

| Explosion Risk | Activate emergency shutdown (ESD), alert emergency services |

🔷 Critical: Never attempt to extinguish a hydrogen fire until the fuel supply is isolated.

10. Compliance Checklist

| Item | Status (✓/✗) |

|——|————|

| H₂ storage meets ISO 16111/ADR | ☐ |

| Gas detection system installed | ☐ |

| Piping leak-tested with N₂ | ☐ |

| Equipment certified for H₂ use | ☐ |

| Operators trained in H₂ safety | ☐ |

| Emergency shutdown system tested | ☐ |

| SDS and operating manuals available | ☐ |

| Local permits obtained (fire, environmental) | ☐ |

11. Contacts & Resources

- Manufacturer Support: [Insert contact info]

- Local Fire Department: Notify of H₂ use

- Hydrogen Supplier: For delivery and safety data

- Regulatory Body: e.g., HSE (UK), OSHA (USA), DGUV (Germany)

Conclusion

Hydrogen-powered IR heaters offer clean, efficient heating but require rigorous logistics and compliance management. By adhering to international standards, implementing robust safety systems, and training personnel, organizations can safely leverage H₂ as a sustainable fuel.

🛡️ Safety First: Hydrogen is safe when handled correctly—design, install, and operate with caution and compliance.

Prepared by: [Your Company Safety/Engineering Team]

Version: 1.0

Date: April 2025

Review Cycle: Annual or after any system modification

Let me know if you’d like a PDF version, site-specific checklist, or a version tailored to a region (e.g., EU, USA, Asia).

Conclusion for Sourcing IR Gas Heaters

In conclusion, sourcing infrared (IR) gas heaters requires a strategic and well-informed approach that balances cost, quality, energy efficiency, safety, and supplier reliability. IR gas heaters offer significant advantages in terms of targeted heating, energy savings, and operational efficiency, especially in industrial, commercial, and semi-enclosed environments. When sourcing these heaters, it is essential to evaluate suppliers based on product certification, compliance with safety standards (e.g., CE, CSA, or local regulations), technical support, warranty terms, and after-sales service.

Prioritizing energy-efficient models not only reduces long-term operational costs but also supports environmental sustainability goals. Additionally, considering factors such as heating capacity, installation requirements, fuel type compatibility, and control system integration ensures optimal performance for the intended application.

Ultimately, a thorough supplier assessment, combined with clear specifications and market benchmarking, will enable businesses to make cost-effective and reliable sourcing decisions. Establishing strong partnerships with reputable manufacturers or distributors further ensures product consistency, timely delivery, and ongoing support—key elements for successful implementation and long-term satisfaction with IR gas heating solutions.