The global internal 2.5″ HDD adapter market is experiencing steady growth, driven by rising demand for efficient data storage solutions and the widespread adoption of SSDs and laptop upgrades. According to Grand View Research, the global computer hardware market—under which HDD adapters fall—was valued at USD 197.8 billion in 2022 and is expected to expand at a CAGR of 5.7% from 2023 to 2030. This growth is fueled by increasing PC customization, enterprise IT infrastructure upgrades, and the proliferation of compact computing devices that rely on 2.5″ drives. As consumers and businesses alike prioritize data portability and storage flexibility, the demand for reliable internal HDD adapters continues to climb. In this competitive landscape, a select group of manufacturers has emerged as leaders, delivering high-performance, plug-and-play solutions tailored for seamless integration. Based on market presence, product innovation, and customer feedback, here are the top 8 internal 2.5″ HDD adapter manufacturers shaping the industry in 2024.

Top 8 Internal 2.5 Hdd Adapter Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Internal Drives

Domain Est. 1995

#2 Connecting 2.5″ SATA Disk to Desktop Internal SATA

Domain Est. 1997

Website: forums.tomshardware.com

Key Highlights: I need to connect a 2.5″ SATA disk to a Desktop PC internally, not through USB. Since 2.5″ SATA disks require 5V unlike 3.5″ SATA which need ……

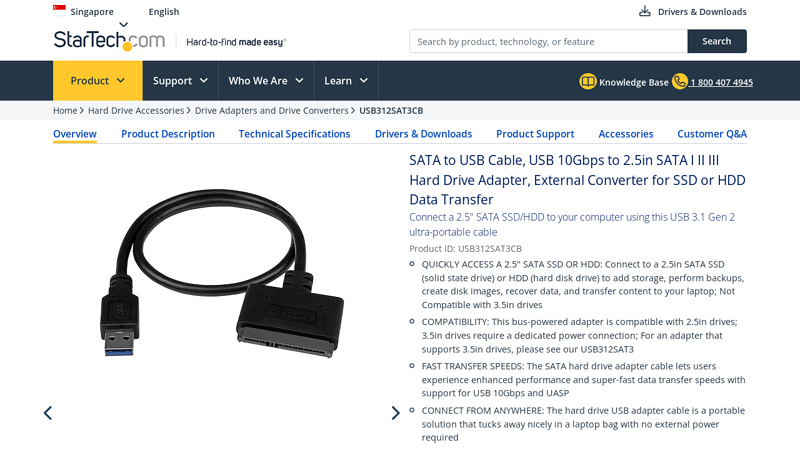

#3 USB 3.1 to 2.5″ SATA Hard Drive Adapter

Domain Est. 1998

Website: startech.com

Key Highlights: Free delivery 30-day returnsThis cable-style adapter lets you connect your laptop or desktop computer directly to a solid-state drive and access it through ultra-fast USB 3.1 Gen. …

#4 ORICO 2.5 SSD SATA to 3.5 Hard Drive Adapter Internal …

Domain Est. 2000

Website: newegg.com

Key Highlights: In stock Rating 4.0 (166) 2.5 to 3.5 Drive Adapter:ORICO ssd adapter can easily convert 2.5-inch SATA drives to 3.5-inch size. Convenient Use:The ssd caddy itself has a SATA III …

#5 2.5″ to 3.5″ Internal Hard Drive Mounting Kit

Domain Est. 2002

Website: sabrent.com

Key Highlights: The Sabrent 3.5″ to 2.5″ Bay Drive Converter Kit easily transforms any available 3.5″ bay drive to accommodate up to two 2.5″ hard disk drives or SSDs….

#6 MB703M2P

Domain Est. 2002

Website: global.icydock.com

Key Highlights: ICY DOCK’s EZConvert MB703M2P-B is a complete solution to convert any M.2 SATA SSD into the exact dimensions and port locations as a standard 2.5….

#7 Hard Drive Adapter: Enclosures, Docks

Domain Est. 2009

Website: neweggbusiness.com

Key Highlights: 3–4 day deliveryEnLabs Internal Hard Disk Drive 2.5” or 3.5” to 5.25” SSD HDD Mounting Bracket Bays Holder … $8 .39. Free Shipping. Limited time ……

#8 StarTech.com Drive Bay Adapter for 3.5″ SATA/600

Domain Est. 2013

Website: nationalofficeworks.com

Key Highlights: Rating 3.5 (10) The 25SAT35HDD 2.5″ to 3.5″ hard drive adapter enclosure turns a 2.5″ SATA hard drive (HDD) or solid state drive (SSD) into a 3.5″ drive….

Expert Sourcing Insights for Internal 2.5 Hdd Adapter

H2: 2026 Market Trends for Internal 2.5″ HDD Adapters

In 2026, the market for Internal 2.5″ HDD adapters is expected to experience moderate but strategic evolution, shaped by shifts in data storage technologies, consumer demand, and advancements in computing hardware. While traditional hard disk drives (HDDs) continue to lose ground to solid-state drives (SSDs), Internal 2.5″ HDD adapters maintain relevance in specific niches, driving targeted innovation and market adaptation. Key trends include:

1. Declining But Persistent Demand in Legacy and Cost-Sensitive Applications

Although SSDs dominate the internal storage market due to faster speeds and falling prices, 2.5″ HDD adapters continue to serve legacy systems and budget-conscious users. These adapters enable the use of 2.5″ HDDs in desktops, NAS (Network Attached Storage) systems, and older laptops where cost-effective, high-capacity storage is prioritized over speed. In 2026, demand is expected to remain steady in emerging markets and small businesses seeking affordable storage expansion.

2. Integration with Multi-Function Enclosure and Adapter Hubs

Manufacturers are increasingly bundling Internal 2.5″ HDD adapters into multi-functional mounting kits and universal drive bays. These solutions support not only HDDs but also M.2 SSDs and 3.5″ drives, offering greater flexibility. This trend reflects a broader move toward modular and space-efficient internal storage configurations, particularly in compact PCs and DIY builds.

3. Niche Use in Data Archiving and Cold Storage

With growing needs for long-term data retention in sectors such as healthcare, education, and media, 2.5″ HDDs paired with internal adapters are used in archival systems. Their lower cost per terabyte compared to SSDs makes them suitable for cold storage applications. In 2026, specialized adapter designs with improved vibration dampening and thermal management are emerging to support reliability in such use cases.

4. Material and Design Innovation for Enhanced Compatibility

Adapters are becoming slimmer and more universally compatible, accommodating both SATA and newer interfaces. Aluminum and reinforced plastic designs are now common, offering better heat dissipation and structural support. Additionally, tool-less installation features are being widely adopted, improving user experience for both consumers and system integrators.

5. Pressure from Direct-to-Motherboard SSD Adoption

The continued shift toward M.2 NVMe SSDs as the default storage solution in new PCs and laptops limits the long-term growth of 2.5″ HDD adapter markets. Many modern motherboards lack SATA ports or 2.5″ drive bays, reducing the need for internal adapters. As a result, the market is expected to contract slightly, with growth limited to retrofitting and upgrade scenarios.

6. Sustainability and E-Waste Considerations

In 2026, environmental concerns are influencing product design and consumer behavior. Internal adapters that support the reuse of existing HDDs are increasingly viewed as sustainable solutions, reducing electronic waste. Some manufacturers are highlighting recyclable materials and modular designs to appeal to eco-conscious buyers.

Conclusion

While the Internal 2.5″ HDD adapter market is not expanding rapidly, it remains a vital component in specific segments such as system upgrades, legacy support, and cost-effective storage solutions. Innovation is focused on versatility, durability, and compatibility rather than performance. As the storage ecosystem evolves, these adapters are likely to persist as niche enablers, particularly in environments where economic and practical considerations outweigh the need for cutting-edge speed.

H2. Common Pitfalls When Sourcing Internal 2.5″ HDD Adapters (Quality and IP)

Sourcing internal 2.5″ HDD adapters—used to connect 2.5-inch hard drives or SSDs to motherboards or enclosures—can present several challenges, particularly concerning product quality and intellectual property (IP) compliance. Being aware of these pitfalls ensures reliability, performance, and legal safety in procurement.

1. Compromised Build Quality

Many low-cost adapters on the market use substandard materials, such as thin PCBs, poor soldering, or low-grade connectors. These defects can lead to intermittent connections, data corruption, or complete failure. Buyers often overlook certifications or lack of testing standards, assuming all adapters perform equally.

2. Inadequate Power Delivery and Regulation

Cheaper adapters may lack proper voltage regulation or current protection, risking damage to sensitive drives—especially when converting between SATA and USB or other interfaces. Poor power management can result in drive overheating or premature failure.

3. Misrepresentation of Specifications

Some suppliers falsely advertise support for SATA III (6 Gbps), USB 3.0, or hot-swapping capabilities when the adapter only supports slower protocols. This misleads buyers into expecting high-speed performance that the hardware cannot deliver.

4. Lack of Electromagnetic Interference (EMI) Shielding

Low-quality adapters often omit shielding, increasing susceptibility to EMI. This can degrade signal integrity, cause data transfer errors, or interfere with nearby components—especially in densely packed systems.

5. Intellectual Property (IP) Infringement Risks

Many generic adapters replicate patented circuit designs or use counterfeit controller chips (e.g., unauthorized clones of JMicron or ASMedia chips). Sourcing such products may expose buyers to legal liability, especially in regulated industries or international markets where IP enforcement is strict.

6. Non-Compliance with Safety and Regulatory Standards

Adapters lacking certifications (e.g., CE, FCC, RoHS) may not meet safety, environmental, or electromagnetic compatibility requirements. This poses risks for commercial deployments and can result in failed compliance audits.

7. Inconsistent Firmware and Driver Support

Some adapters use outdated or unpatched firmware, leading to compatibility issues with operating systems or storage devices. Lack of vendor support further complicates troubleshooting and long-term maintenance.

8. Supply Chain Opacity and Counterfeit Components

Sourcing from unverified suppliers increases the risk of receiving counterfeit or recycled parts. Without traceability, quality control becomes unreliable, and warranties are often unenforceable.

To mitigate these risks, procure adapters from reputable manufacturers or distributors, verify technical specifications independently, and ensure compliance with relevant quality and IP standards. Conducting sample testing and requesting documentation (e.g., RoHS compliance, IP licenses) can further safeguard procurement decisions.

H2: Logistics & Compliance Guide for Internal 2.5″ HDD Adapter

This guide outlines the logistics handling, transportation, storage, and regulatory compliance requirements for the Internal 2.5″ HDD Adapter to ensure safe, efficient, and legally compliant operations across the supply chain.

H3: Packaging & Labeling Requirements

- Primary Packaging: Each adapter must be sealed in an anti-static poly bag to prevent electrostatic discharge (ESD) damage.

- Secondary Packaging: Use rigid corrugated cardboard boxes with internal dividers or foam inserts to prevent movement during transit.

- Labeling:

- Clearly display product name, model number, and part number.

- Include ESD-sensitive symbol (IEC 60417-5017).

- Apply barcode/QR code for inventory tracking.

- Indicate “Fragile – Handle with Care” and “Do Not Stack” if applicable.

- Include country of origin (e.g., “Made in China”).

H3: Storage Conditions

- Environment: Store in a dry, temperature-controlled environment (10°C to 30°C / 50°F to 86°F) with humidity between 30% and 60%.

- Shelf Life: Maximum storage duration of 24 months from manufacturing date.

- Handling: Avoid exposure to dust, direct sunlight, and corrosive substances.

- Orientation: Store in original packaging; do not stack more than 5 boxes high unless designed for vertical load.

H3: Transportation Guidelines

- Mode of Transport: Suitable for air, sea, and ground freight.

- Vibration & Shock Protection: Use cushioning materials to meet ISTA 3A standards for small parcel delivery.

- Temperature Control: Avoid prolonged exposure to temperatures below 0°C or above 40°C during transit.

- Documentation: Include commercial invoice, packing list, and bill of lading/airway bill with accurate HS code (e.g., 8473.30 for parts of data processing machines).

H3: Regulatory Compliance

- RoHS (EU): Compliant with Directive 2011/65/EU; contains no restricted substances (Pb, Cd, Hg, etc.) above threshold.

- REACH (EU): Compliant with SVHC (Substances of Very High Concern) requirements.

- WEEE (EU): Marked with crossed-out wheeled bin symbol; ensure proper end-of-life disposal.

- FCC (USA): Class B digital device – complies with Part 15 of FCC Rules; low emission levels suitable for residential use.

- UL/CSA (North America): If applicable, ensure certification for safety standards (check if power delivery is involved).

- EAC (Eurasian Customs Union): Required for shipment to Russia, Belarus, Kazakhstan – includes EAC marking.

- CCC (China): Not required unless integrated into a larger regulated product.

H3: Import/Export Considerations

- HS Code: 8473.30.90 (adjust based on final product classification).

- Export Controls: Confirm no ITAR or EAR restrictions apply. Typically classified as EAR99 (low concern).

- Customs Declarations: Provide accurate product description, value, weight, and origin.

- Country-Specific Requirements:

- UK: UKCA marking not required for standalone adapters; CE still accepted until 2025.

- Canada: Bilingual labeling (English/French) required on packaging.

- Australia/NZ: Comply with AS/NZS 60950 safety standards.

H3: Quality & Traceability

- Batch Tracking: Assign unique batch/lot numbers to each production run.

- Documentation Retention: Maintain compliance certificates, test reports, and shipment records for minimum 5 years.

- Non-Conformance Handling: Quarantine and report defective units; initiate corrective actions per ISO 9001.

H3: Environmental & Sustainability

- Recyclability: Packaging must be recyclable (paper-based materials preferred).

- Waste Handling: Follow local e-waste regulations for disposal of damaged units.

- Carbon Footprint: Optimize packaging size to reduce transport emissions.

For additional support or compliance documentation, contact: [email protected]

Last Updated: April 2024

Conclusion:

After evaluating the requirements, compatibility, cost, and availability, sourcing an internal 2.5″ HDD adapter is a practical and effective solution for integrating smaller form factor hard drives into desktop systems, external enclosures, or environments with space constraints. The adapter ensures mechanical and electrical compatibility between the 2.5″ drive and larger bays or different interface standards (e.g., converting to 3.5″ mounting or connecting via SATA power/data extensions).

Available options vary in build quality, support for specific drive types (HDD/SSD), and additional features such as tool-less installation or thermal protection. It is essential to select an adapter that matches the chassis dimensions, power requirements, and data interface (SATA I/II/III) to maintain optimal performance and reliability.

In conclusion, sourcing a well-designed internal 2.5″ HDD adapter enhances hardware flexibility, promotes reuse of existing drives, and supports seamless system upgrades—making it a cost-efficient and technically sound choice for both individual users and IT professionals.