The global laminate flooring market is experiencing robust growth, driven by rising demand for cost-effective, durable, and aesthetically versatile flooring solutions in residential and commercial spaces. According to a report by Mordor Intelligence, the laminate flooring market was valued at USD 33.8 billion in 2023 and is projected to reach USD 46.2 billion by 2029, growing at a CAGR of approximately 5.4% during the forecast period. This upward trajectory is fueled by expanding urbanization, increasing remodelling activities, and advancements in manufacturing technologies—particularly in the development of interlocking systems that simplify installation and improve durability. As sustainability and ease of installation become key purchasing factors, manufacturers are prioritizing innovation in click-and-lock mechanisms, wear layers, and eco-friendly core materials. Against this backdrop, identifying the top interlocking laminate flooring manufacturers offers valuable insights into industry leaders shaping product standards, driving technological adoption, and capitalizing on expanding global demand.

Top 10 Interlocking Laminate Flooring Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Armstrong Flooring™

Domain Est. 1999

Website: armstrongflooring.com

Key Highlights: An industry-leading manufacturer of innovative flooring products focusing on design, performance and durability for the home and commercial applications….

#2 Ultimate Floors

Domain Est. 2013

Website: ultimatefloors.net

Key Highlights: Explore top-quality SPC, laminate, LVT, and waterproof flooring at Ultimate Floors. Your wholesale solution for durable floors. Locations in LA & Houston.Missing: interlocking man…

#3 Laminate Flooring

Domain Est. 1997

Website: lumberliquidators.com

Key Highlights: Our laminate flooring combines the appearance of real hardwood with easy installation, low maintenance, and long-lasting performance for any room in your home….

#4 Karndean Luxury Vinyl flooring

Domain Est. 1998

Website: karndean.com

Key Highlights: Karndean Designflooring is a brand of luxury vinyl flooring known for replicating the look and feel of natural materials like wood and stone, offering ……

#5 Naturally Aged Flooring ™

Domain Est. 2004

Website: naturallyagedflooring.com

Key Highlights: Offering fast and easy glueless-locking floating installation plus easy maintenance, NorthShore flooring is built for long lasting, worry-free living….

#6 Everlife Luxury Vinyl Flooring

Domain Est. 2012

Website: msisurfaces.com

Key Highlights: Everlife Luxury Vinyl Flooring features easy-care stone look and wood-look luxury vinyl planks that provide a durable and affordable flooring solution….

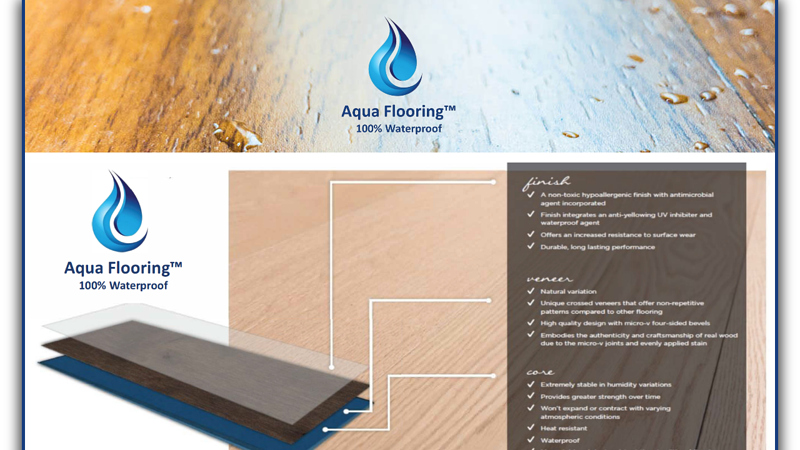

#7 Aqua Flooring™

Domain Est. 2013

Website: aquaflooring.com

Key Highlights: Aqua Flooring™ is the next generation of engineered hardwood floor! It combines the beauty and richness of hardwood and a patented rigid core, waterproof ……

#8 Unilin Technologies

Domain Est. 2014

Website: unilintechnologies.com

Key Highlights: Simple installation, ingenious engineering. Unilin’s commitment to designing locking systems prioritizes the secure connection between flooring panels while ……

#9 CFL Flooring

Domain Est. 2015

Website: cflflooring.com

Key Highlights: The CFL Group of companies has grown into a worldwide pioneer recognized globally as an innovator – committed to developing, manufacturing, and marketing ……

#10 Durato USA

Domain Est. 2017

Website: duratousa.com

Key Highlights: Our floors are completely resistant to water and moisture, and won’t swell, peel or buckle when exposed….

Expert Sourcing Insights for Interlocking Laminate Flooring

H2: 2026 Market Trends for Interlocking Laminate Flooring

The global interlocking laminate flooring market is poised for significant transformation by 2026, driven by evolving consumer preferences, technological advancements, and sustainable building practices. This analysis explores key market trends expected to shape the industry in the coming years.

1. Rising Demand for DIY-Friendly Flooring Solutions

Interlocking laminate flooring continues to gain popularity due to its ease of installation, particularly among do-it-yourself (DIY) consumers. By 2026, the trend toward home improvement and renovation—accelerated by the post-pandemic focus on residential spaces—is expected to boost demand for click-and-lock systems that require no glue or nails. Manufacturers are enhancing installation mechanisms to improve alignment and reduce gaps, further supporting this trend.

2. Growth in Sustainable and Eco-Conscious Products

Environmental sustainability is a major driver in flooring choices. By 2026, consumers are increasingly favoring laminate flooring made from recycled materials, low-emission adhesives, and sustainable core boards (e.g., wood from responsibly managed forests). Certifications such as FloorScore, CARB2, and FSC are becoming standard expectations. Innovations in bio-based laminates and recyclable wear layers are anticipated to enter the mainstream market.

3. Advancements in Realistic Aesthetics and Textures

Consumers are seeking laminate flooring that closely mimics natural materials like hardwood, stone, and tile. By 2026, improvements in high-definition printing, embossing, and surface texturing technologies will enable more authentic visuals and tactile experiences. Products with synchronized embossing (where texture matches the printed grain) are becoming a competitive differentiator.

4. Expansion of Waterproof and Water-Resistant Options

Traditional laminate flooring has been limited in moisture-prone areas like kitchens and bathrooms. However, by 2026, the market will see widespread adoption of waterproof interlocking laminates using polymer or stone-based cores (e.g., SPC and WPC hybrids). These products combine the look of laminate with enhanced durability, broadening their application in both residential and light commercial spaces.

5. E-Commerce and Direct-to-Consumer Sales Growth

Online retail platforms are transforming how consumers purchase flooring. By 2026, brands are expected to invest heavily in augmented reality (AR) tools that allow customers to visualize flooring in their homes, alongside detailed product comparisons and sample mailers. Direct-to-consumer models will reduce costs and increase accessibility, particularly in emerging markets.

6. Regional Market Expansion

While North America and Europe remain dominant markets, Asia-Pacific—especially China, India, and Southeast Asia—is expected to witness the fastest growth by 2026. Urbanization, rising disposable incomes, and government-backed housing programs are fueling demand for affordable, durable flooring solutions. Localized manufacturing and distribution networks will play a critical role in capturing this growth.

7. Integration of Smart and Functional Features

Though still in early stages, the incorporation of smart technologies into flooring is emerging. By 2026, some laminate products may integrate features like antimicrobial surfaces, improved thermal conductivity for underfloor heating compatibility, or even embedded sensors for smart home systems—particularly in premium segments.

Conclusion

By 2026, the interlocking laminate flooring market will be characterized by innovation, sustainability, and consumer-centric design. Companies that prioritize realistic aesthetics, environmental responsibility, ease of installation, and digital engagement will be best positioned to lead in this evolving landscape. As hybrid materials and smart functionalities gain traction, the line between laminate and luxury flooring will continue to blur, expanding market opportunities across geographies and applications.

Common Pitfalls When Sourcing Interlocking Laminate Flooring (Quality & IP)

Sourcing interlocking laminate flooring can be cost-effective and efficient, but it comes with significant risks if not managed carefully. Overlooking key aspects related to quality and intellectual property (IP) can lead to poor performance, customer dissatisfaction, legal disputes, and reputational damage. Below are common pitfalls to avoid:

Overlooking Core Quality Indicators

Many buyers focus only on appearance and price, ignoring critical quality metrics such as AC (Abrasion Class) rating, density (measured in kg/m³), and thickness. Low-density boards are more prone to warping and swelling, especially in high-moisture areas. Always verify product specifications through independent lab reports and ensure the flooring meets international standards (e.g., EN 13329 in Europe).

Ignoring Moisture Resistance Claims

While some laminate flooring markets itself as “water-resistant” or “hydro-proof,” these terms are often exaggerated. Most laminate is not waterproof—moisture can still penetrate through seams and cause swelling. Be wary of suppliers making unrealistic claims without third-party certification (e.g., IPX7 testing). Opt for products with sealed edges and proper moisture barriers if installing in kitchens or basements.

Falling for Fake or Misrepresented AC Ratings

The AC rating (ranging from AC1 to AC5) indicates durability and suitability for residential or commercial use. Unscrupulous suppliers may mislabel lower-grade products as AC4 or AC5. Always request test reports from accredited labs and cross-check with recognized certification bodies to validate claims.

Overlooking Embossing and Texture Quality

High-quality laminate flooring often features precise embossing that matches the grain of the wood design (known as “embossed in register” or EIR). Poorly executed embossing results in a flat, artificial look. Request physical samples and inspect the texture under natural light to evaluate authenticity and craftsmanship.

Assuming All Click Systems Are Equal

Interlocking systems (e.g., Uniclic, Drop & Lock) vary significantly in ease of installation and long-term stability. Inferior locking mechanisms can lead to gaps, squeaking, or disengagement over time. Test the click mechanism during sampling and prioritize suppliers using proven, patented systems—even if they cost more.

Neglecting Intellectual Property (IP) Risks

Many Chinese and overseas manufacturers produce laminate designs that closely copy branded patterns (e.g., Tarkett, Pergo, or Quick-Step). Sourcing such products can expose your business to IP infringement lawsuits, customs seizures, and distribution bans. Always demand proof of design ownership or licensing agreements from suppliers and conduct IP clearance checks.

Skipping Sample Testing and Factory Audits

Relying solely on product photos or supplier claims is risky. Always order full-size samples to assess color, texture, thickness, and lock strength. For large orders, conduct third-party factory audits to verify production standards, material sourcing, and consistency.

Underestimating VOC and Emission Standards

Laminate flooring can emit formaldehyde and other volatile organic compounds (VOCs). Products that don’t comply with safety standards (e.g., CARB Phase 2, E1, or E0) can pose health risks and fail customs inspections. Require up-to-date test reports for formaldehyde emissions and ensure compliance with destination market regulations.

Failing to Secure IP Indemnification in Contracts

Even if a supplier claims their designs are original, include contractual clauses that require them to indemnify you against IP claims. Without this protection, your business may be liable for legal costs and damages if infringement occurs.

Choosing Aesthetics Over Performance

Attractive visuals can be misleading. A floor may look premium but lack structural integrity or wear layer protection. Balance visual appeal with technical performance by verifying wear layer thickness (typically 0.2–0.6 mm for AC3–AC5) and overall construction quality.

By proactively addressing these pitfalls—validating quality claims, verifying IP legitimacy, and insisting on transparency—buyers can source reliable, compliant, and legally safe interlocking laminate flooring that meets both performance and market expectations.

Logistics & Compliance Guide for Interlocking Laminate Flooring

Product Overview

Interlocking laminate flooring is a popular flooring solution known for its durability, ease of installation, and cost-effectiveness. Composed of multiple layers—including a high-density fiberboard (HDF) core, a photographic layer, and a protective wear layer—this flooring uses a click-together system that eliminates the need for adhesives. Due to its composition and international trade demand, specific logistics and compliance considerations are essential for manufacturers, distributors, and importers.

Packaging and Handling Requirements

Proper packaging is critical to prevent damage during transit. Laminate flooring planks should be securely packed in sturdy cardboard boxes with internal dividers to avoid edge chipping. Boxes must be palletized and stretch-wrapped for stability. Handling instructions such as “This Side Up,” “Fragile,” and “Do Not Stack” should be clearly marked. Moisture-resistant wrapping is recommended, especially for sea freight, to prevent warping or swelling from humidity exposure.

Transportation Modes and Considerations

Interlocking laminate flooring can be shipped via ocean, air, or ground freight, depending on volume and urgency. Ocean freight is most common for bulk shipments due to cost efficiency. When shipping by sea, use moisture-barrier pallet wraps and silica gel desiccants to prevent condensation damage. For air freight, weight and dimensional constraints must be managed. Ground transport should avoid extreme temperature fluctuations and ensure secure loading to prevent shifting.

Storage Conditions

Store laminate flooring in a dry, climate-controlled environment with temperatures between 60°F and 80°F (15°C–27°C) and relative humidity between 30% and 50%. Avoid direct sunlight and contact with concrete floors unless a vapor barrier is used. Keep packages sealed until ready for installation to minimize moisture absorption.

Import/Export Regulations

Compliance with international trade regulations is required. Exporters must provide accurate Harmonized System (HS) codes—typically 4412.31 or 4412.32 for laminate flooring under wood-based panels. Required documentation includes commercial invoices, packing lists, bills of lading, and certificates of origin. Importers must verify country-specific requirements, including duties, tariffs, and product standards.

Environmental and Safety Compliance

Laminate flooring may contain formaldehyde in the resin binders. Compliance with emission standards is mandatory:

– CARB Phase 2 (U.S.): Limits formaldehyde emissions to ≤ 0.05 ppm.

– EPA TSCA Title VI: Aligns with CARB standards for products sold in the U.S.

– E1 Standard (EU): Maximum emission of 0.1 mg/m³ (equivalent to ≤ 0.062 ppm).

Manufacturers must provide test reports or certifications (e.g., FloorScore, Greenguard) to demonstrate compliance. Products exceeding limits may be subject to fines, recalls, or import bans.

Wood Packaging Material (ISPM 15)

Pallets and dunnage made of raw wood must comply with International Standards for Phytosanitary Measures No. 15 (ISPM 15). This requires heat treatment or fumigation and the application of an official ISPM 15 mark. Non-compliant wood packaging can lead to shipment delays or rejection at customs.

Labeling and Product Marking

Each box must include:

– Product name and specifications (thickness, dimensions, wear layer rating)

– Batch/lot number

– Country of origin

– Installation instructions

– Compliance markings (e.g., CARB Phase 2, CE mark for EU)

– Recyclability information and disposal guidelines

End-of-Life and Recycling Considerations

Laminate flooring is not biodegradable and is difficult to recycle due to composite materials. Compliance with waste regulations (e.g., EU Waste Framework Directive) may require producers to participate in take-back schemes or report on product disposal. Encourage proper disposal through certified waste handlers.

Certification and Third-Party Testing

To ensure compliance and market access, obtain third-party testing from accredited laboratories for:

– Formaldehyde emissions

– Abrasion resistance (AC rating: AC1–AC6)

– Moisture swelling

– Impact and stain resistance

Maintain up-to-date test reports for audits or customs inspections.

Conclusion

Successful logistics and compliance for interlocking laminate flooring require attention to packaging, environmental controls, regulatory standards, and documentation. Proactive adherence to international and regional requirements ensures smooth transit, avoids penalties, and supports sustainable and safe product distribution.

Conclusion for Sourcing Interlocking Laminate Flooring

Sourcing interlocking laminate flooring offers a cost-effective, durable, and easy-to-install solution for both residential and commercial projects. Its click-together installation system reduces labor costs and eliminates the need for adhesives, making it ideal for DIY enthusiasts and professional contractors alike. When sourcing, it is essential to prioritize quality by evaluating core board density, AC wear rating, water resistance, and compliance with environmental standards such as CARB2 or E1 for low emissions.

Supplier reliability, product consistency, and access to comprehensive warranties are key factors in ensuring long-term satisfaction. Sourcing from reputable manufacturers or distributors—whether domestically or internationally—can provide competitive pricing without compromising performance. Additionally, considering aesthetic options such as color, texture, and plank dimensions ensures the flooring aligns with design objectives.

In conclusion, a strategic sourcing approach that balances quality, cost, and sustainability will result in a successful flooring solution that meets functional demands and delivers lasting value.