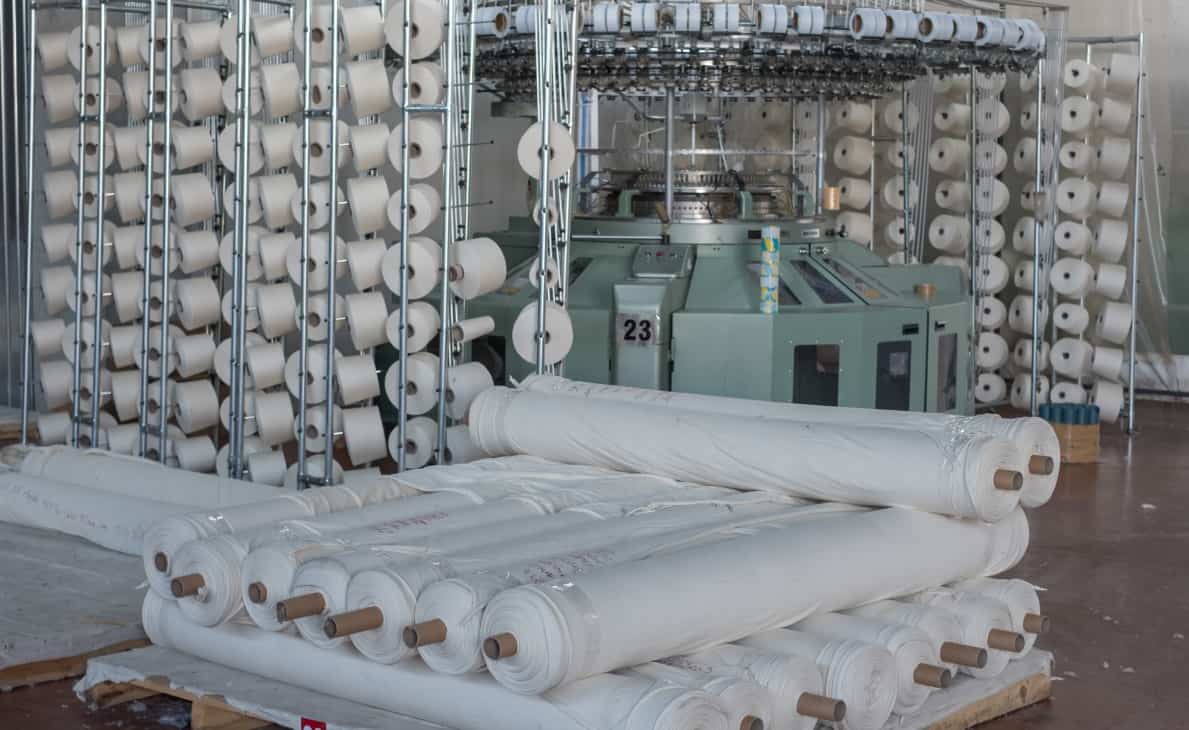

The global interlock fabric market is experiencing steady growth, driven by rising demand from the apparel, activewear, and hosiery sectors. According to a report by Mordor Intelligence, the global knit fabric market—which includes interlock knits—is projected to grow at a CAGR of over 5.8% from 2023 to 2028, fueled by increasing consumer preference for comfortable, stretchable textiles. Interlock fabric, known for its softness, durability, and double-knit construction, has become a staple in high-quality t-shirts, baby clothing, and sportswear. Expanding manufacturing capabilities in Asia-Pacific, particularly in China, India, and Bangladesh, coupled with advancements in sustainable textile production, are further accelerating market development. As brands prioritize both performance and sustainability, the demand for premium interlock fabrics continues to rise—making it essential to identify the leading manufacturers shaping this competitive landscape.

Top 10 Interlock Fabric Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

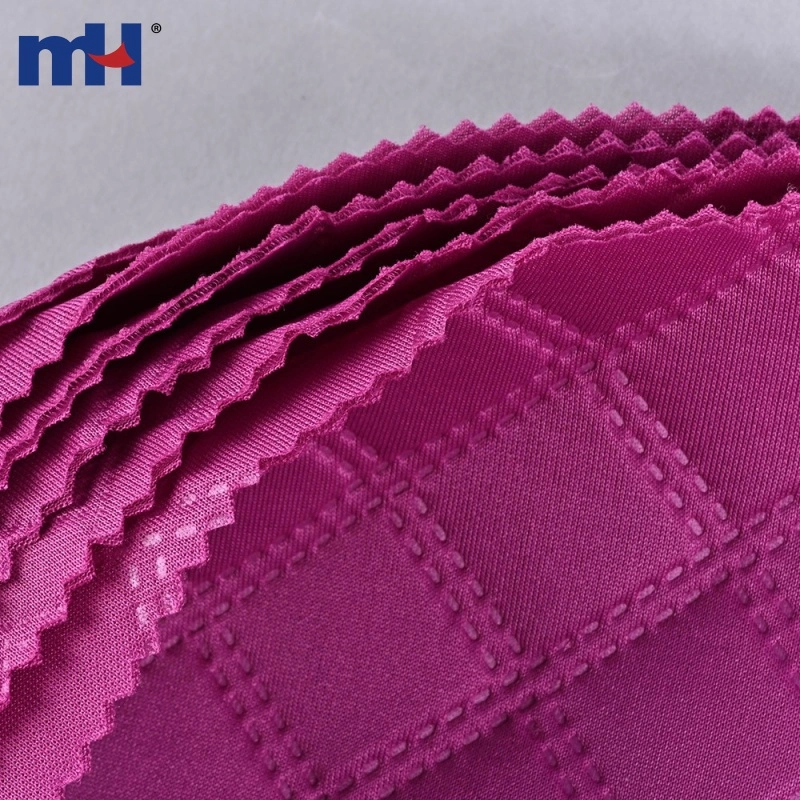

#1 MH Interlock Fabric Manufacturer

Domain Est. 2001

Website: mh-chine.com

Key Highlights: MH is a leading manufacturer and wholesale supplier of Interlock Fabric. We offer customization, OEM processing, and international wholesale supply ……

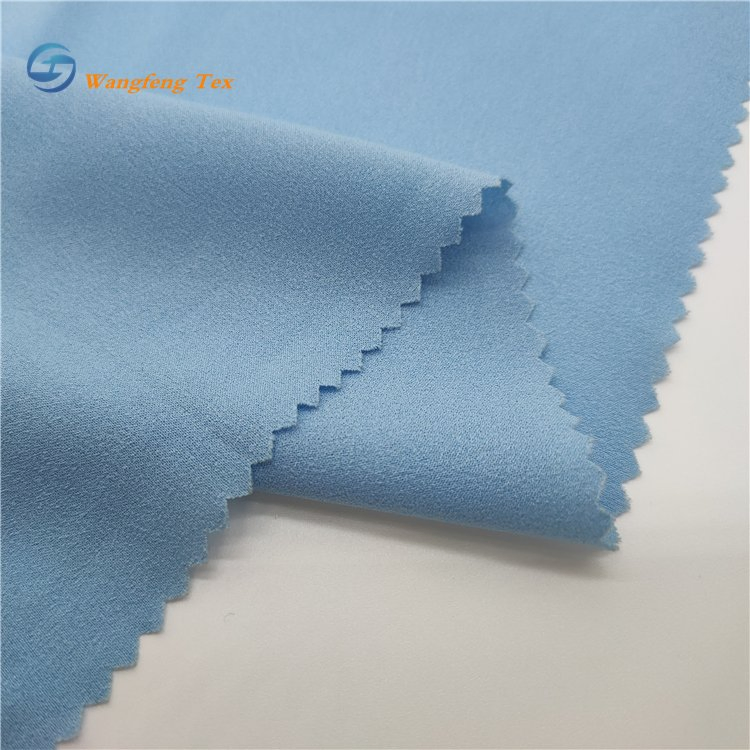

#2 China Interlock Fabric Manufacturers

Domain Est. 2015

Website: phkchina.com

Key Highlights: China Interlock Fabric manufacturers – Select high quality Interlock Fabric products in best price on Hangzhou PHK Knitting Co., Ltd…..

#3 China Interlock Fabric Factory and Manufacturers

Domain Est. 2021

Website: fuzhoutextile.com

Key Highlights: Interlock Fabric – Manufacturers, Factory, Suppliers from China. We are commitment to offer the competitive price ,outstanding products quality, as well as ……

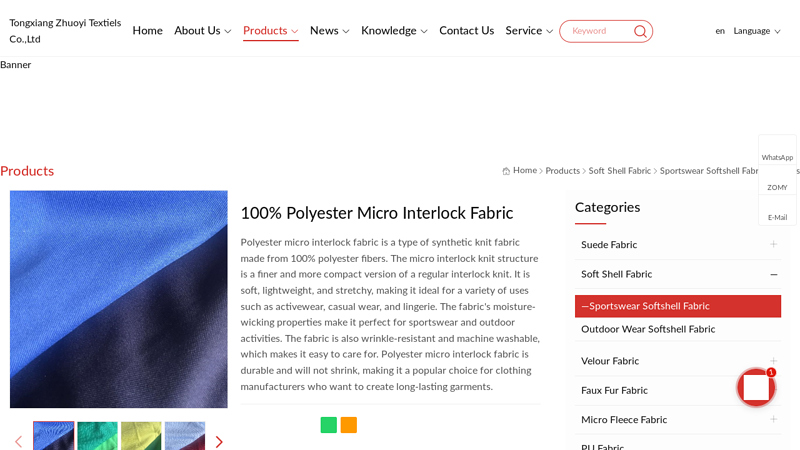

#4 100% Polyester Micro Interlock Fabric

Domain Est. 2017

Website: zhuoyifabric.com

Key Highlights: Polyester micro interlock fabric is durable and will not shrink, making it a popular choice for clothing manufacturers who want to create long-lasting garments….

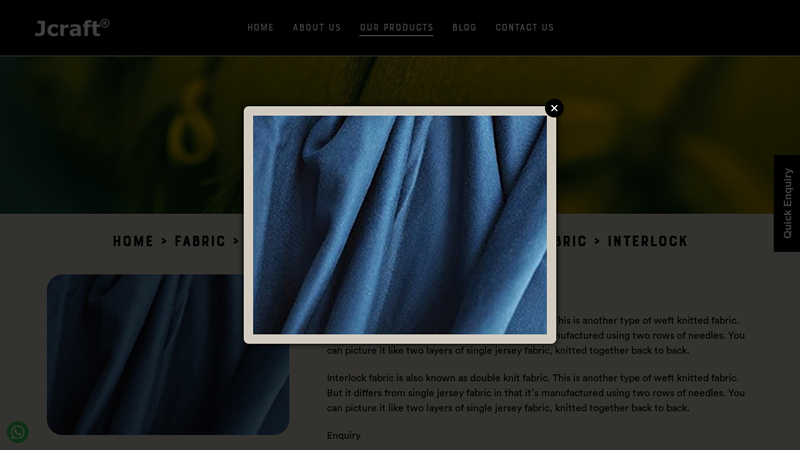

#5 Organic Cotton Interlock Fabric Manufacturer

Domain Est. 2021

Website: jcrafteco.com

Key Highlights: We are an organic cotton interlock fabric manufacturer, with a strong focus on customer service and quality. Our products are available to the general ……

#6 Interlock Fabric

Domain Est. 2021

Website: delantex.com

Key Highlights: Interlock fabric offered by China manufacturer Delantex. Buy high quality Interlock fabric right now!…

#7 Interlock Fabric, Double Knit Fabric

Domain Est. 2002

Website: eysan.com.tw

Key Highlights: EYSAN provides various kind of interlock, aka double knit fabric, including plain, pique, mesh double knitted fabric with different kinds of yarn….

#8 Interlock Knit Fabric By The Yard

Domain Est. 2014

#9 Interlock – Manifutura

Domain Est. 2017

#10 Interlock Knit

Domain Est. 2023

Website: runtangtex.com

Key Highlights: Interlock knit fabric is a type of knitted textile known for its comfort and smooth / polished appearance. A popular choice for various types of clothing….

Expert Sourcing Insights for Interlock Fabric

H2: 2026 Market Trends for Interlock Fabric

Interlock fabric, a double-knit textile known for its softness, stability, and excellent drape, is poised for significant evolution in 2026. Driven by shifting consumer demands, technological advancements, and global sustainability imperatives, the market will experience both challenges and opportunities. Here’s a comprehensive analysis of key trends shaping the interlock fabric landscape in 2026:

1. Sustainability as a Non-Negotiable Imperative:

* Dominant Driver: Environmental and social responsibility will be the top priority. Consumers and brands demand transparency and verifiable eco-credentials.

* Key Developments:

* Rise of Recycled Fibers: Interlock fabric made from recycled polyester (rPET) and recycled cotton will dominate, reducing reliance on virgin resources and plastic waste. Expect significant growth in mechanically and chemically recycled feedstocks.

* Biodegradable & Bio-based Innovations: Increased R&D and commercialization of interlock knits using bio-based synthetics (e.g., bio-PET, PTT from corn) and inherently biodegradable fibers like TENCEL™ Lyocell, Modal, and innovative plant-based polymers. Compostability certifications will gain importance.

* Water & Energy Reduction: Adoption of closed-loop dyeing systems (like Dope Dyeing/ Solution Dyeing), low-impact dyes, and energy-efficient knitting and finishing processes will be standard, not optional. Waterless dyeing technologies may see wider pilot applications.

* Circularity Focus: Design for disassembly, take-back schemes for garment recycling, and development of mono-material interlock fabrics (easier to recycle) will gain traction. Certification schemes (e.g., GOTS, GRS, Oeko-Tex, Higg Index) will be crucial for market access.

2. Performance Enhancement & Functionalization:

* Beyond Basics: Interlock will move beyond simple comfort to incorporate advanced functionalities demanded by activewear, athleisure, and technical apparel.

* Key Developments:

* Smart Textiles Integration: Limited but growing integration of conductive yarns or coatings into interlock structures for biometric monitoring (heart rate, temperature) or heating elements, primarily in premium activewear and medical applications.

* Enhanced Performance: Wider use of interlock knits with inherent moisture-wicking, quick-drying, UV protection, odor control (using natural minerals or antimicrobial treatments), and improved abrasion resistance, often achieved through fiber selection (e.g., Coolmax, Polygiene-treated) or specialized finishes.

* Thermoregulation: Development of interlock fabrics with phase-change materials (PCMs) or breathable, insulating structures for adaptive comfort across seasons.

3. Digitalization & Supply Chain Transformation:

* Efficiency & Transparency: Technology will reshape how interlock is produced, tracked, and brought to market.

* Key Developments:

* AI & Predictive Analytics: Used for demand forecasting, optimizing production schedules (minimizing waste), predictive maintenance for knitting machines, and quality control (automated defect detection).

* Blockchain for Traceability: Increased use of blockchain to provide immutable proof of origin, fiber content, and ethical labor practices from farm/factory to finished garment, meeting consumer demand for authenticity.

* Digital Sampling & 3D Design: Wider adoption of virtual prototyping using 3D design software, drastically reducing physical sample production, lead times, and material waste in the design phase.

4. Evolving Consumer Preferences & End-Use Applications:

* Comfort Reigns Supreme: The core appeal of interlock – softness, drape, and comfort – remains paramount, especially in loungewear and basic apparel.

* Key Developments:

* Athleisure & Activewear Dominance: Interlock’s stability and comfort make it ideal for the continued growth of high-performance basics, leggings, tops, and sports bras. Blends with elastane (spandex/Lycra) will be essential.

* Luxury & Premiumization: Increased use of high-quality natural fibers (Pima cotton, Merino wool, silk blends) and sophisticated finishes (brushing, peaching, garment dyeing) to position interlock in premium and sustainable fashion lines.

* Unisex & Inclusive Sizing: Growth in demand for versatile, comfortable basics drives interlock use in gender-neutral collections and expanded size ranges.

* Baby & Children’s Wear: Continued strong demand due to softness, durability, and comfort, with a heightened focus on non-toxic dyes and finishes (Oeko-Tex Standard 100 Class I).

5. Regional Shifts & Supply Chain Resilience:

* Geopolitical & Economic Factors: Supply chains will adapt to reduce risk and improve responsiveness.

* Key Developments:

* Nearshoring/Reshoring: Some production, particularly for faster fashion cycles or brands emphasizing “local,” may shift closer to key consumer markets (e.g., US, EU) to reduce lead times and carbon footprint, though cost remains a major factor.

* Asia-Pacific Dominance (with Nuance): China, India, Bangladesh, and Vietnam will remain major producers, but with increasing focus on upgrading technology and sustainability standards to meet international requirements. Vietnam and India may see growth due to trade diversification.

* Cost Volatility Management: Fluctuations in raw material (especially cotton, oil-based synthetics) and energy prices will necessitate hedging strategies, long-term contracts, and continued focus on operational efficiency.

Conclusion for H2 2026:

By H2 2026, the interlock fabric market will be characterized by a deep integration of sustainability into its core operations, moving beyond marketing to become a fundamental requirement for competitiveness. Performance and functionality will be increasingly embedded, blurring the lines between basic knits and technical textiles. Digitalization will enhance efficiency, transparency, and responsiveness. While comfort remains the bedrock, the fabric’s application will expand into higher-value segments driven by innovation. Success will belong to producers and brands that can demonstrably deliver on eco-credentials, leverage technology for efficiency and traceability, innovate with performance features, and navigate complex global supply chains with resilience. The “standard” interlock will increasingly be replaced by specialized, sustainable, and traceable variants meeting the sophisticated demands of the modern market.

Common Pitfalls When Sourcing Interlock Fabric: Quality and Intellectual Property Issues

Sourcing interlock fabric—commonly used in t-shirts, activewear, and underwear due to its softness and stability—can be fraught with challenges, particularly concerning quality consistency and intellectual property (IP) risks. Buyers must be vigilant to avoid costly mistakes.

Quality Inconsistencies and Defects

One of the most frequent issues in sourcing interlock fabric is inconsistent quality across production batches. Interlock fabric, being a double-knit structure, requires precise tension and alignment during knitting. Poor manufacturing practices can lead to skewing, spiraling, or uneven dye uptake. Buyers often encounter variations in hand feel, weight (GSM), shrinkage, and pilling resistance, especially when sourcing from suppliers who lack rigorous quality control. Additionally, substandard raw materials (e.g., low-grade cotton or recycled fibers without proper blending) can compromise the fabric’s durability and comfort.

Lack of Traceability and Certification

Many suppliers fail to provide full traceability of fiber origin or certifications for sustainable and ethical production (e.g., GOTS, OEKO-TEX, or BCI). This is a significant pitfall for brands committed to environmental and social responsibility. Without verifiable documentation, companies risk reputational damage and non-compliance with regulations in markets like the EU or the U.S., where supply chain transparency is increasingly mandated.

Intellectual Property Infringement Risks

Sourcing interlock fabric with proprietary finishes, patterns, or performance technologies (such as moisture-wicking or antimicrobial treatments) can expose buyers to IP violations. Some suppliers may replicate branded fabric technologies without proper licensing, especially in regions with lax IP enforcement. Using such fabrics—even unknowingly—can result in legal disputes, product recalls, and financial penalties. Brands must ensure that suppliers have legitimate rights to any patented or trademarked fabric innovations.

Hidden Minimum Order Quantities and Lead Time Delays

Suppliers may advertise competitive prices but conceal high minimum order quantities (MOQs) or extended lead times. For interlock fabric, which often requires custom dyeing or finishing, unexpected delays can disrupt production schedules. Relying on a single supplier without contingency plans further amplifies this risk, particularly in volatile supply chain environments.

Conclusion

To mitigate these pitfalls, buyers should conduct thorough due diligence, request physical samples, audit supplier facilities, and include clear quality and IP clauses in contracts. Partnering with reputable, transparent suppliers and investing in third-party testing can safeguard both product integrity and brand reputation.

Logistics & Compliance Guide for Interlock Fabric

Interlock fabric, a popular double-knit textile known for its softness, stability, and excellent drape, requires specific considerations during logistics and compliance processes. This guide outlines key steps and requirements to ensure smooth transportation, regulatory adherence, and quality preservation.

Product Characteristics and Handling

Interlock fabric is sensitive to moisture, tension, and contamination. It must be handled carefully to prevent deformation, creasing, or staining. Rolls should be stored horizontally on pallets in a clean, dry, and temperature-controlled environment. Avoid direct sunlight and exposure to water or chemicals during storage and transit.

Packaging Requirements

Ensure interlock fabric is tightly rolled onto cardboard or plastic cores and wrapped with protective polyethylene film. Use durable outer packaging such as kraft paper or corrugated cardboard to prevent abrasion. Label each roll with product details, batch number, weight, and handling instructions (e.g., “Fragile,” “This Side Up”). Pallets must be securely stretch-wrapped and banded to prevent shifting.

Transportation and Shipping

Use enclosed, dry freight containers or vehicles to protect fabric from weather and contamination. Maintain consistent temperature and humidity during transit to avoid moisture absorption or fiber degradation. For international shipments, comply with Incoterms (e.g., FOB, CIF) clearly defined in contracts. Choose carriers experienced in textile logistics to minimize handling risks.

Import/Export Compliance

Verify tariff classifications under the Harmonized System (HS Code). Interlock fabric typically falls under HS Code 6005.37 (Cotton, knitted or crocheted, of cotton) or similar, depending on fiber composition. Accurately declare fiber content, weight, and value on commercial invoices. Ensure compliance with destination country regulations, including labeling laws (e.g., fiber content, country of origin) and product safety standards.

Documentation Checklist

Essential documents include:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin (if required for trade agreements)

– Textile Declaration (fiber content)

– Phytosanitary Certificate (if applicable for raw materials)

– REACH, CPSIA, or OEKO-TEX certifications (for chemical compliance)

Regulatory and Sustainability Standards

Adhere to chemical restrictions under regulations such as:

– REACH (EU): Registration, Evaluation, Authorisation and Restriction of Chemicals

– CPSIA (USA): Consumer Product Safety Improvement Act (for children’s apparel)

– OEKO-TEX Standard 100: Certification for harmful substances

Maintain documentation proving compliance, especially for fabrics intended for apparel or sensitive applications.

Quality Control and Inspection

Conduct pre-shipment inspections to verify fabric width, weight (GSM), color consistency, and absence of defects. Use AQL (Acceptable Quality Level) sampling standards where applicable. Retain batch samples for traceability and dispute resolution.

Storage and Inventory Management

Store fabric in a climate-controlled warehouse (18–22°C, 50–60% RH) away from direct heat sources. Implement a first-in, first-out (FIFO) inventory system to prevent aging or degradation. Monitor for signs of mold, pests, or static buildup, especially in synthetic blends.

Returns and Reverse Logistics

Establish clear return policies for damaged or non-conforming shipments. Inspect returned goods promptly and document defects. Coordinate with suppliers or customers for replacements or credits, ensuring all compliance data is retained for audit purposes.

By following this guide, businesses can ensure interlock fabric is transported securely, meets global compliance standards, and maintains quality from production to end use.

Conclusion for Sourcing Interlock Fabric:

Sourcing interlock fabric requires a strategic approach that balances quality, cost, sustainability, and reliability. As a versatile and widely used knit fabric known for its softness, durability, and excellent drape, interlock is ideal for a range of apparel, from casual wear to baby clothing and sportswear. Successful sourcing involves evaluating suppliers based on fabric composition (e.g., cotton, polyester, or blends), production standards, certifications (such as OEKO-TEX, GOTS, or BCI), and ethical practices.

Proximity to manufacturing hubs, minimum order quantities (MOQs), and lead times are crucial factors to consider, especially for small to medium-sized businesses. Building strong relationships with trusted suppliers, conducting sample testing, and performing regular quality audits ensure consistent product standards. Additionally, embracing sustainable sourcing practices not only meets growing consumer demand for eco-friendly products but also supports long-term brand integrity.

In conclusion, effective sourcing of interlock fabric hinges on thorough due diligence, clear communication, and a commitment to quality and sustainability—key elements for maintaining competitiveness and delivering high-value products in the global apparel market.