The global threaded rod market is experiencing steady growth, driven by rising construction activities, infrastructure development, and demand from industrial manufacturing. According to Grand View Research, the global threaded rod market size was valued at USD 5.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth is fueled by increased adoption in structural support systems, HVAC installations, and seismic bracing solutions, particularly in emerging economies. As demand for high-precision, corrosion-resistant, and load-bearing fasteners rises, interior applications—especially in commercial buildings and retrofit projects—are becoming a key segment. With stringent building codes and a growing emphasis on safety and durability, manufacturers specializing in interior threaded rods are expanding their product offerings and geographic reach. This list highlights the top 10 interior threaded rod manufacturers leading innovation, quality, and market share in this evolving landscape.

Top 10 Interior Threaded Rod Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Threaded Rod Hangers for Wood

Domain Est. 1996

Website: nutty.com

Key Highlights: Keep your project on schedule. Buy 3/8 x 6 SDS Plus Carbide Tipped Masonry Drill with guaranteed same-day shipping from the Nutty Company Inc.Missing: interior manufacturer…

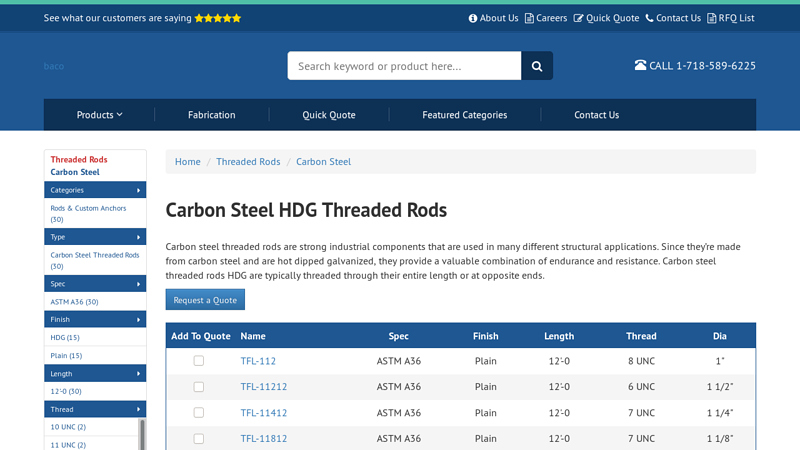

#2 Carbon Steel Threaded Rods

Domain Est. 1996

Website: bacoent.com

Key Highlights: Carbon Steel HDG Threaded Rods. Carbon steel threaded rods are strong industrial components that are used in many different structural applications….

#3 Threaded Rod Manufacturers

Domain Est. 1999

Website: mockbee.com

Key Highlights: C.M. Mockbee manufactures and distributes threaded rods, offering a variety of materials and finishes, and tailored to meet your needs. Contact us now!…

#4 Anchor rod / Internal thread anchor

Domain Est. 2010

Website: fischerfixingsusa.com

Key Highlights: Threaded rods and internal thread anchors are system components for chemical fixing solutions. The fixing elements, together with the injection mortar or …Missing: interior manu…

#5 Aluminum Threaded Rod Studs Manufacturer T&Y Hardware

Domain Est. 2020

Website: tfasteners.com

Key Highlights: High quality low price aluminum threaded rod stud bolts, complete specifications, fast delivery, free samples provided,Launch an inquiry now….

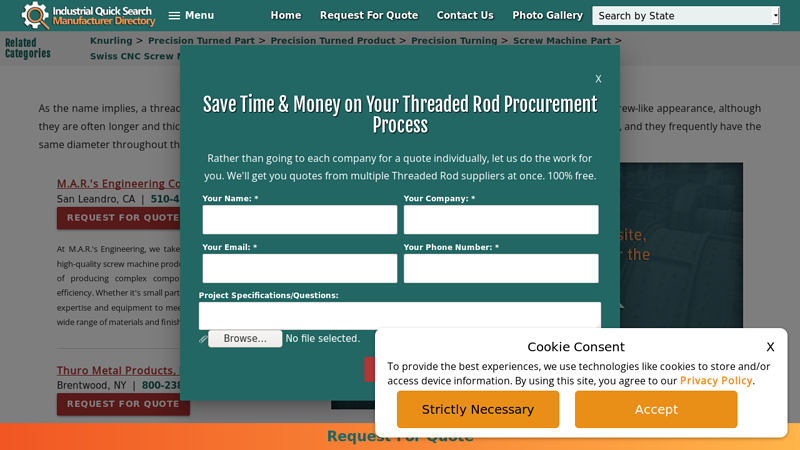

#6 Leading Threaded Rod Manufacturers

Website: screwmachinecompanies.com

Key Highlights: Locate the leading threaded rod manufacturers and suppliers in the USA whose companies are ISO certified, and have many years of experience….

#7 Internally Threaded Rods

Domain Est. 1994

Website: mcmaster.com

Key Highlights: Choose from our selection of internally threaded connecting rods, hollow female threaded rods, and more. Same and Next Day Delivery….

#8 Steel Threaded Rods

Domain Est. 2001

Website: madar.com

Key Highlights: High-quality 3-meter steel threaded rods (all-thread/studding) in diameters 6mm to 16mm. Ideal for construction, fastening, and support applications. In stock….

#9 Threaded Rods and Studs

Domain Est. 2002

Website: apf.com

Key Highlights: All-Pro Fasteners manufactures threaded rods and studs from a wide range of metals, with coatings choices to meet any requirement….

#10 Plain & Threaded Rod

Domain Est. 1996

Website: doitbest.com

Key Highlights: 2-day deliveryExplore a wide selection of premium Plain & Threaded Rod at Do it Best, including Threaded Rod, Coupler Nut, Solid Rod. ✓ Same day pick-up or home delivery….

Expert Sourcing Insights for Interior Threaded Rod

H2: 2026 Market Trends for Interior Threaded Rod

The interior threaded rod market is poised for notable shifts by 2026, driven by evolving construction practices, material innovations, and regional economic developments. These trends reflect broader industry movements toward sustainability, efficiency, and resilience in building infrastructure.

1. Increased Demand in Residential and Commercial Construction

By 2026, the global expansion of urban infrastructure and rising investments in residential and commercial real estate are expected to drive demand for interior threaded rods. These rods are essential in applications such as suspended ceiling systems, mechanical support installations, and structural anchoring. Post-pandemic recovery in construction sectors across North America, Europe, and parts of Asia-Pacific will further accelerate adoption.

2. Shift Toward Corrosion-Resistant and High-Strength Materials

With a growing emphasis on building longevity and safety, manufacturers are increasingly offering threaded rods made from stainless steel, galvanized steel, and epoxy-coated alloys. These materials offer enhanced resistance to moisture and corrosion—critical for interior environments with variable humidity, such as basements, utility rooms, and HVAC installations. By 2026, high-performance materials are projected to capture a larger market share, especially in regions with stringent building codes.

3. Growth in Retrofitting and Renovation Projects

The trend toward sustainable development is fueling a surge in building retrofitting and renovation, particularly in mature markets like the U.S. and Western Europe. Interior threaded rods are frequently used in modular upgrades, seismic retrofitting, and MEP (mechanical, electrical, plumbing) system support. The preference for non-invasive, adaptable fastening solutions will bolster demand for precision-threaded rods in these applications.

4. Technological Advancements in Manufacturing and Customization

Automation and digital manufacturing technologies are enabling faster, more accurate production of threaded rods in custom lengths and diameters. By 2026, just-in-time manufacturing and BIM (Building Information Modeling) integration will allow suppliers to offer tailored solutions that reduce waste and improve installation efficiency—key factors in cost-sensitive construction environments.

5. Regional Market Dynamics

Asia-Pacific is expected to lead market growth due to rapid urbanization in countries like India and Vietnam. Meanwhile, North America will see steady demand driven by infrastructure renewal programs and green building standards such as LEED and ENERGY STAR, which favor durable, low-maintenance materials like threaded rod systems.

6. Sustainability and Regulatory Pressures

Environmental regulations and green building certifications will influence material sourcing and lifecycle assessments. Recyclability and low embodied carbon are becoming key selection criteria. By 2026, manufacturers that offer eco-certified threaded rods or utilize recycled steel content are likely to gain competitive advantage.

In summary, the interior threaded rod market in 2026 will be shaped by construction growth, material innovation, and sustainability imperatives. Companies that adapt to these trends through product diversification, technological integration, and regional targeting will be well-positioned for success.

Common Pitfalls When Sourcing Interior Threaded Rod (Quality and IP)

Sourcing interior threaded rod involves more than just selecting the right diameter and length—overlooking critical quality and IP (Ingress Protection) factors can lead to structural failures, safety hazards, and costly replacements. Here are key pitfalls to avoid:

Poor Material Quality and Non-Compliant Grades

One of the most frequent issues is procuring threaded rods made from substandard or non-compliant materials. Some suppliers offer rods labeled as “grade A” or “high-strength” without adhering to recognized standards like ASTM A36, ASTM A193, or ISO 898-1. Using rods with insufficient tensile strength or poor corrosion resistance compromises structural integrity, especially in load-bearing interior applications such as suspended ceilings or mechanical supports. Always verify material certifications and request mill test reports to confirm compliance.

Inadequate Corrosion Resistance for the Environment

Even in interior settings, environmental conditions such as humidity, chemical exposure (e.g., cleaning agents), or HVAC condensation can lead to corrosion over time. Sourcing carbon steel rods without appropriate surface protection—such as zinc plating, hot-dip galvanizing, or stainless steel (e.g., 304 or 316)—can result in premature rusting and weakening. Avoid assuming all indoor applications are low-risk; assess the actual environment and specify corrosion-resistant materials accordingly.

Misunderstanding or Ignoring IP Ratings

While IP ratings are commonly associated with electrical enclosures, they are relevant when threaded rods are used in assemblies exposed to dust or moisture, such as in data centers, laboratories, or utility rooms. For example, if a rod is part of a support system near HVAC units or in areas washed down during cleaning, an inadequate IP rating for the full assembly (including nuts, washers, and rod ends) may allow dust or water ingress, leading to corrosion or electrical hazards. Ensure that the complete fastening system meets required IP standards for the installation environment.

Inconsistent Thread Quality and Tolerance

Low-quality threaded rods often feature inconsistent thread pitch, burrs, or damaged threads, making installation difficult and reducing clamping force. Poor thread quality increases the risk of cross-threading, galling, or premature fatigue failure. Always inspect sample rods for thread accuracy and smooth engagement with matching nuts. Specify rods manufactured to standards such as ISO 68-1 or ASME B1.1 to ensure dimensional consistency.

Lack of Traceability and Certification

Reputable projects—especially in commercial, healthcare, or institutional buildings—require full traceability of materials. Sourcing rods without proper documentation (e.g., heat numbers, test reports, or third-party certifications) can result in compliance failures during inspections or audits. Avoid suppliers who cannot provide full traceability or who operate outside quality management systems like ISO 9001.

Cost-Driven Sourcing Without Long-Term Evaluation

Opting for the lowest-cost option may seem economical initially but often leads to higher lifecycle costs due to maintenance, replacement, or structural issues. Cheap rods may not meet load specifications or degrade faster, undermining safety and performance. Perform a total cost of ownership analysis that includes durability, maintenance, and risk mitigation rather than focusing solely on upfront price.

Avoiding these pitfalls requires due diligence in supplier selection, clear specification of material and performance standards, and verification through testing and documentation. Ensuring quality and appropriate IP considerations from the outset safeguards safety, compliance, and long-term reliability in interior construction projects.

Logistics & Compliance Guide for Interior Threaded Rod

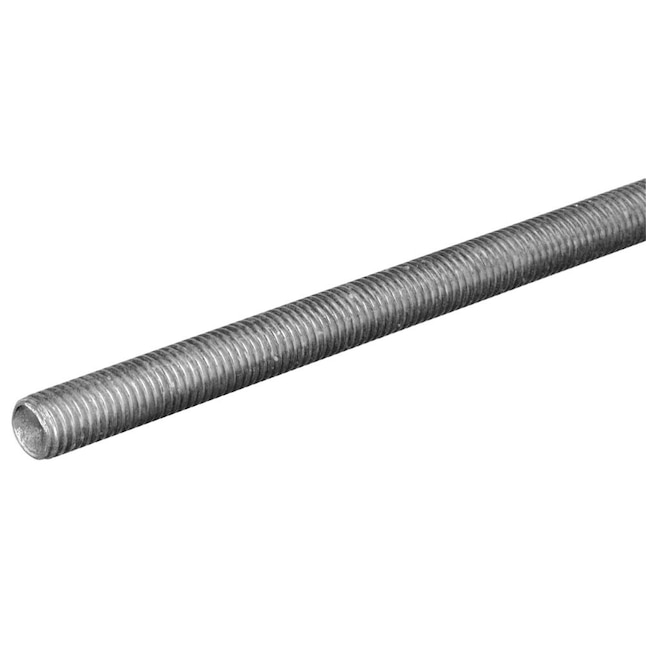

Product Overview

Interior threaded rod, commonly made from materials such as carbon steel, stainless steel, or zinc-plated steel, is a versatile fastening solution used in construction, HVAC, plumbing, and electrical installations. It features continuous threading along its entire length and is typically used with nuts, washers, and couplers to support structures, suspend piping, or anchor components within interior environments.

Regulatory Compliance

Interior threaded rod must comply with relevant national and international standards to ensure safety, durability, and performance. Key compliance considerations include:

Material and Performance Standards

- ASTM A307 Grade A/B: Covers carbon steel threaded rod for general applications; Grade A for general use and Grade B for high-strength bolting.

- ASTM A193 Grade B7: Applies to alloy steel rods for high-temperature service, often used in structural and mechanical applications.

- ASTM F1554: Specifies requirements for anchor bolts, including threaded rods used in concrete anchoring. Grades 36, 55, and 105 define strength levels.

- ASME B1.1: Standard for unified inch screw threads (UN and UNR thread forms), governing thread dimensions and tolerances.

- ISO 898-1: International standard for mechanical properties of bolts, screws, and studs, applicable to metric threaded rods.

Corrosion Resistance & Coatings

- Zinc plating (electro-galvanized) is common for indoor use to resist mild corrosion.

- Stainless steel rods (e.g., 304 or 316) must comply with ASTM A363 or ASTM A193 Type B8/B8M for corrosion resistance.

- Verify coating thickness and adhesion per ASTM B633 for electroplated zinc coatings.

Building & Safety Codes

- Compliance with the International Building Code (IBC) and International Mechanical Code (IMC) may be required depending on application (e.g., seismic bracing, suspended ceilings).

- Rods used in seismic zones must meet ICC-ES AC156 or AC391 evaluation service reports for dynamic load performance.

- Fire safety compliance may require non-combustible materials per ASTM E84 or NFPA 101.

Packaging and Labeling Requirements

Proper packaging and labeling ensure product integrity and regulatory traceability:

- Rods should be bundled securely using steel or plastic strapping, protected from moisture and physical damage.

- Each bundle must include a legible label indicating:

- Material grade (e.g., ASTM A307, Grade B)

- Diameter and length

- Manufacturer name or trademark

- Heat or lot number for traceability

- ASTM or ISO compliance markings

- Metric and imperial units must be clearly defined to avoid installation errors.

Shipping and Handling

Efficient logistics practices minimize damage and ensure timely delivery:

- Use palletized shipments for bulk orders; rods should be stacked evenly and shrink-wrapped.

- Protect ends with plastic caps or protective sleeves to prevent thread damage.

- Avoid exposure to rain or high humidity during transit—interior rods are not weather-rated.

- Follow OSHA and local regulations for manual handling; use mechanical aids for heavy loads.

Import/Export Considerations

When shipping internationally, ensure compliance with destination country regulations:

- Verify HTS Code (Harmonized Tariff Schedule) for accurate classification (e.g., 7318.15.00 for threaded steel rods).

- Provide Certificates of Compliance or Mill Test Reports (MTRs) upon request.

- Check for REACH (EU) or RoHS compliance if applicable, particularly for coated products.

- Ensure packaging meets ISPM 15 standards if using wooden pallets for international shipments.

Storage Guidelines

- Store in a dry, indoor environment away from corrosive chemicals or excessive humidity.

- Elevate bundles off the floor using pallets to prevent moisture absorption.

- Avoid direct contact with dissimilar metals to prevent galvanic corrosion.

- Rotate stock using First-In, First-Out (FIFO) inventory practices.

Quality Assurance and Documentation

- Maintain traceability through batch/lot records and inspection reports.

- Conduct periodic audits of supplier certifications and material test reports.

- Implement internal quality checks for thread accuracy, straightness, and surface finish.

Conclusion

Adhering to this logistics and compliance guide ensures that interior threaded rod meets safety, performance, and regulatory requirements throughout its supply chain. Proper handling, documentation, and standards compliance contribute to reliable installations and long-term structural integrity.

Conclusion for Sourcing Interior Threaded Rod:

Sourcing interior threaded rods requires a careful evaluation of material quality, dimensional specifications, corrosion resistance, and compliance with industry standards such as ASTM A307 or ASTM F1554. It is essential to work with reputable suppliers who can provide certified materials, consistent lead times, and technical support. Factors such as thread type (UNC/UNF), length, diameter, and plating or coating (e.g., zinc, hot-dip galvanized) must align with the intended application—whether for structural support, mechanical assemblies, or building interiors. Additionally, considering total cost of ownership, including shipping, minimum order quantities, and potential for bulk discounts, contributes to a cost-effective procurement strategy. By prioritizing reliability, traceability, and supplier responsiveness, organizations can ensure the timely delivery of high-quality threaded rods that meet project specifications and performance requirements.