The global insulated tool market is experiencing steady growth, driven by increasing demand for electrical safety across industries such as power distribution, utilities, and industrial maintenance. According to Mordor Intelligence, the insulated hand tools market was valued at USD 1.2 billion in 2023 and is projected to grow at a CAGR of over 4.8% from 2024 to 2029. This expansion is supported by stricter workplace safety regulations, rising investments in electrical infrastructure, and a growing emphasis on personal protective equipment (PPPE) compliance—particularly in high-voltage environments. As demand for VDE-certified and IEC 60900-compliant tools rises, manufacturers are prioritizing innovation in material engineering and precision manufacturing to deliver reliable, high-performance insulated tool sets. In this evolving landscape, identifying the top-producing companies becomes critical for professionals seeking durability, safety assurance, and international certification standards. The following list highlights the leading insulated tool set manufacturers shaping the industry through quality, compliance, and technological advancement.

Top 10 Insulated Tool Set Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Cementex

Domain Est. 1997

Website: cementexusa.com

Key Highlights: We are the only design-driven manufacturer of double-insulated hand tools in the market. Our performance standard is what the non-manufacturing competition ……

#2 Insulated Electrical Tools for Electricians

Domain Est. 1986

Website: fluke.com

Key Highlights: Free delivery over $50Fluke insulated electrical tools. 1000 Volt Certification, Lifetime Warranty. Safety is critical when working with electricity. Follow the right procedures….

#3 Southwire

Domain Est. 1994

Website: southwire.com

Key Highlights: Choose Southwire for your wire and cable needs – we offer high-performance products that are built to last….

#4 Insulated Tools

Domain Est. 1996

#5 Insulated Tools

Domain Est. 1997

Website: knipex.com

Key Highlights: There are two different types of insulation for tools at KNIPEX: the one-component handle sleeve and the multi-component sleeve. The former is made by immersion ……

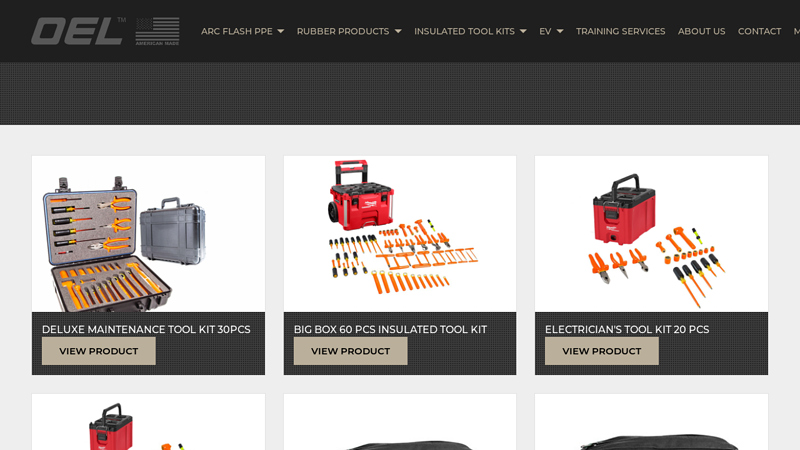

#6 Insulated Tool Kits

Domain Est. 1997

Website: oelsales.com

Key Highlights: DELUXE MAINTENANCE TOOL KIT 30PCS · BIG BOX 60 PCS INSULATED TOOL KIT · ELECTRICIAN’S TOOL KIT 20 PCS · ELECTRICIAN’S TOOL KIT EXTRA 27 PCS · BATTERY TORQUE SET 4 ……

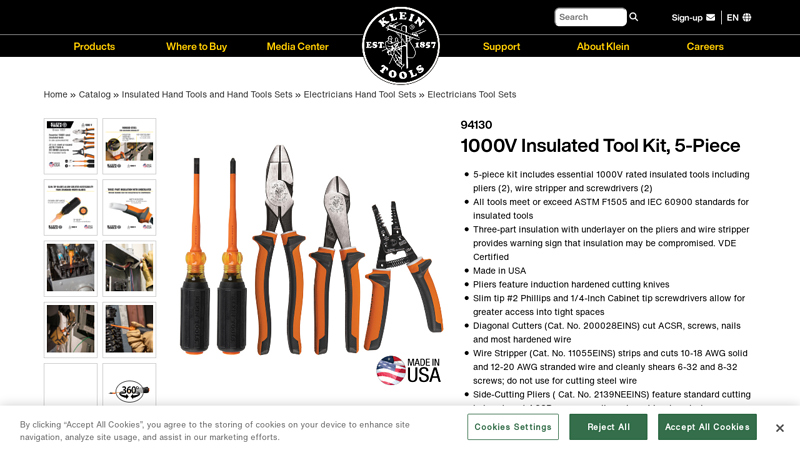

#7 1000V Insulated Tool Kit, 5

Domain Est. 1998

Website: kleintools.com

Key Highlights: 5-piece kit includes essential 1000V rated insulated tools including pliers (2), wire stripper and screwdrivers (2) · All tools meet or exceed ASTM F1505 and IEC ……

#8 Insulated Tool Sets (23 products)

Domain Est. 2005

Website: knipex-tools.com

Key Highlights: Insulated Tool Sets (23 products) ; 9K0080168US.jpg. 12 Pc 1000V Insulated Electrical Vehicle (EV) Set. 9K 00 80 168 US ; 989911S3US4.jpg. 10 Pc Socket Set, 3/8″ ……

#9 Insulated Hand Tools

Domain Est. 2012

Website: idealind.com

Key Highlights: 30-day returnsOur Insulated Hand Tools are double insulated, 1000V certified, meet ASTM F1505-01 & IE 60 900 standards, comply with OSHA 1910.335 ……

#10 Insulated Tools

Domain Est. 2017

Website: hausoftools.com

Key Highlights: Free delivery Free 30-day returnsWe carry the best insulated tools made by renowned toolmakers, meaning that these insulated tools will meet or exceed safety and testing standards….

Expert Sourcing Insights for Insulated Tool Set

H2: Projected 2026 Market Trends for Insulated Tool Sets

The global market for insulated tool sets is poised for significant evolution by 2026, driven by increasing safety regulations, growth in electrical infrastructure projects, and rising demand across industrial and utility sectors. Key trends shaping the market include:

-

Stringent Safety Regulations and Compliance Standards

Governments and occupational safety bodies worldwide, particularly in North America and Europe, are reinforcing electrical safety standards such as IEC 60900 and OSHA requirements. This regulatory push is compelling industries to adopt certified insulated tools, boosting market demand. By 2026, compliance will be a primary purchasing driver, especially in high-voltage environments. -

Expansion of Renewable Energy and Smart Grid Projects

The global shift toward renewable energy sources—solar, wind, and grid modernization—is increasing the need for safe electrical maintenance tools. Insulated tool sets are essential for working on live circuits in solar farms and smart grid installations. With major investments in clean energy infrastructure expected through 2026, demand for insulated tools will rise proportionally. -

Growth in Asia-Pacific Markets

Rapid urbanization, industrialization, and power grid expansion in countries like India, China, and Southeast Asian nations are fueling demand for insulated tools. Local manufacturing growth and government initiatives to improve electrical safety are creating new opportunities for both domestic and international tool manufacturers. -

Product Innovation and Ergonomic Design

By 2026, consumers will increasingly favor insulated tools with improved ergonomics, lightweight materials, and enhanced grip technology to reduce worker fatigue. Manufacturers are responding with innovations such as dual-material handles, anti-slip coatings, and modular tool kits tailored for specific applications. -

E-Commerce and Direct-to-Consumer Sales Growth

Online platforms are becoming a dominant channel for purchasing insulated tool sets, especially among independent electricians and small contractors. Brands are investing in digital marketing and direct sales models to reach a broader customer base, with subscription-based tool kits and customization options gaining traction. -

Sustainability and Eco-Friendly Manufacturing

Environmental concerns are influencing production practices. By 2026, leading manufacturers are expected to adopt recyclable packaging, reduce carbon footprints in manufacturing, and use sustainable materials—appealing to environmentally conscious buyers and corporate procurement policies. -

Integration with Smart Tools and IoT

Emerging trends include the development of “smart” insulated tools equipped with sensors to detect voltage or alert users to potential risks. While still in early stages, this technology is expected to gain momentum by 2026, particularly in industrial automation and utility maintenance sectors.

In conclusion, the 2026 insulated tool set market will be shaped by regulatory compliance, infrastructure development, technological innovation, and regional economic growth. Companies that prioritize safety certification, user-centric design, and digital engagement are likely to lead the market.

Common Pitfalls When Sourcing Insulated Tool Sets (Quality and IP)

Sourcing insulated tool sets—especially those rated for electrical safety (e.g., VDE, CAT III/CAT IV)—requires careful attention to both quality and intellectual property (IP) considerations. Overlooking these aspects can lead to safety hazards, legal issues, and reputational damage. Below are key pitfalls to avoid:

1. Prioritizing Price Over Safety Certification

One of the most dangerous mistakes is choosing cheaper insulated tool sets without verifying proper safety certifications. Tools must comply with international standards such as IEC 60900 (for insulated hand tools) and carry certification marks from recognized bodies (e.g., VDE in Germany, GS, or UL).

Pitfall: Accepting tools labeled as “1000V rated” without proof of third-party testing or certification. Counterfeit or non-compliant tools may look identical but fail under live conditions, risking electric shock or arc flash.

Best Practice: Require test reports, certification documents, and batch traceability. Purchase only from suppliers with verifiable compliance history.

2. Ignoring Material and Build Quality

Insulated tools must withstand mechanical stress, temperature fluctuations, and chemical exposure. Poor-quality tools may have thin insulation, weak crimping, or substandard steel, leading to early failure.

Pitfall: Tools with bubbles, seams, or inconsistent insulation thickness—these can compromise dielectric strength.

Best Practice: Conduct physical inspections or third-party lab testing. Verify insulation is molded under pressure (not dipped) and adheres fully to the metal tool.

3. Overlooking Intellectual Property (IP) Risks

Many reputable insulated tool brands (e.g., Wera, Knipex, Wiha) hold design patents, trademarks, and trade dress rights. Sourcing counterfeit or imitation products exposes buyers to IP infringement claims.

Pitfall: Sourcing “compatible” or “look-alike” tools that replicate protected designs, logos, or packaging. Even if not sold under the brand name, these may violate IP laws in many jurisdictions.

Best Practice: Work with suppliers who can provide IP indemnification or confirm tools are original equipment manufacturer (OEM) products. Avoid suppliers offering well-known branded tools at suspiciously low prices.

4. Relying on Inadequate Supplier Vetting

Many insulated tools are manufactured in regions with variable quality control. Without proper due diligence, buyers may receive inconsistent or unsafe products.

Pitfall: Sourcing from unknown manufacturers or trading companies without factory audits or quality management systems (e.g., ISO 9001).

Best Practice: Audit suppliers, request quality control protocols, and conduct pre-shipment inspections. Prefer suppliers with a track record in electrical safety tools.

5. Assuming All Insulated Tools Are Interchangeable

Not all insulated tools are suitable for every voltage class or environment. Using a tool outside its rated category (e.g., CAT II instead of CAT III) increases risk.

Pitfall: Sourcing generic sets without specifying required voltage, category, and application (e.g., utility vs. industrial).

Best Practice: Define technical requirements clearly in procurement documents. Ensure tools are clearly marked with ratings and meet the end-user’s operational standards.

6. Neglecting Traceability and Documentation

In regulated industries, traceability of safety equipment is critical. Missing or falsified documentation can invalidate insurance or compliance.

Pitfall: Receiving tools without individual test certificates, batch numbers, or calibration records.

Best Practice: Require full documentation with each shipment. Ensure each tool is laser-engraved with certification marks and batch identifiers.

Avoiding these pitfalls ensures that sourced insulated tool sets are not only cost-effective but also safe, compliant, and free from legal exposure.

Logistics & Compliance Guide for Insulated Tool Set

This guide outlines the essential logistics and compliance considerations for the safe and legal handling, transportation, storage, and use of an Insulated Tool Set. These tools are designed for use in live electrical environments and must be managed in accordance with international and regional safety standards.

Regulatory Standards and Certification

Insulated tool sets must comply with internationally recognized safety standards to ensure protection against electric shock. Key standards include:

- IEC 60900: The primary international standard for hand tools used on live parts. It specifies requirements for insulating material, mechanical strength, electrical insulation testing (withstands 10,000 V AC for 1 minute), and marking.

- VDE Certification: Required in many European countries. Tools bearing the VDE mark have been independently tested by the German Electrical Engineering Association and comply with IEC 60900. The VDE mark includes a lightning symbol and test voltage (typically 1,000 V AC).

- OSHA and NFPA 70E (USA): While OSHA does not specify tool insulation requirements directly, compliance with NFPA 70E (Standard for Electrical Safety in the Workplace) is required. NFPA 70E mandates the use of insulated tools when working within arc flash boundaries or on exposed energized parts.

Ensure all insulated tool sets are certified and clearly marked with compliance labels (e.g., VDE, IEC 60900). Maintain records of certification for audit and compliance purposes.

Packaging and Labeling

Proper packaging and labeling are critical for product integrity and regulatory compliance:

- Protective Packaging: Use shock-resistant and moisture-proof packaging to prevent damage during transit. Insulated tools should be stored in rigid cases or blister packs that prevent contact between tools and maintain insulation integrity.

- Labeling Requirements:

- Clearly display certification marks (e.g., VDE, IEC 60900).

- Include voltage rating (e.g., “Rated for 1,000 V AC”).

- Provide manufacturer name, model number, and date of manufacture.

- Include multilingual safety warnings (e.g., “Do not use above rated voltage,” “Inspect before each use”).

Transportation and Storage

Safe handling during logistics ensures tool reliability and worker safety:

- Temperature Control: Store and transport insulated tools in environments between -25°C and +70°C. Avoid prolonged exposure to direct sunlight or extreme heat, which can degrade insulation.

- Humidity: Maintain relative humidity below 80% to prevent moisture absorption in insulating materials.

- Handling: Avoid dropping or impacting tools, which may compromise insulation. Use padded containers during shipping.

- Stacking and Weight Limits: Follow manufacturer stacking guidelines. Do not exceed weight limits during storage or shipping to prevent deformation of packaging or tools.

Inspection and Maintenance Protocols

Regular inspection is mandatory to ensure ongoing compliance and safety:

- Pre-Use Inspection: Users must check each tool before use for:

- Cracks, cuts, or swelling in insulation.

- Embedded conductive particles.

- Loose or damaged components.

- Fading or missing certification markings.

- Periodic Testing: Insulated tools should undergo dielectric testing every 12 months or as required by local regulations. Testing must be performed by an accredited laboratory.

- Record Keeping: Maintain logs of inspections, tests, and maintenance. Retain records for a minimum of 3 years.

Import/Export Compliance

When shipping internationally, ensure compliance with destination country regulations:

- Customs Documentation: Include accurate HS codes (e.g., 8203.20 for hand tools), certificates of conformity, and safety data sheets if required.

- Restricted Substances: Confirm tools are free of restricted substances (e.g., RoHS compliance in the EU).

- Country-Specific Requirements: Some countries require local certification (e.g., KC Mark in South Korea, CCC in China). Verify requirements before shipment.

User Training and Documentation

End-user compliance relies on proper training:

- Provide safety manuals in the local language.

- Train personnel on:

- Correct use of insulated tools.

- Limitations (e.g., maximum voltage, environmental conditions).

- Inspection and reporting procedures.

- Distribute compliance checklists and safety posters at worksites.

Disposal and End-of-Life

Insulated tools that fail inspection or testing must be retired safely:

- Deactivation: Physically destroy the tool (e.g., cut insulation) to prevent reuse.

- Recycling: Follow local e-waste and metal recycling regulations. Insulation materials may require special handling.

- Documentation: Record disposal dates and methods for compliance audits.

By adhering to this logistics and compliance guide, organizations can ensure the safe, legal, and effective use of insulated tool sets across their operations.

Conclusion:

Sourcing an insulated tool set is a critical decision, especially for professionals working in electrical environments where safety is paramount. After evaluating various suppliers, product quality, certifications, and cost considerations, it is clear that investing in a high-quality, properly certified (e.g., VDE, IEC 60900) insulated tool set ensures both user safety and long-term value. While cost is a factor, compromising on quality can lead to serious safety hazards and higher expenses over time due to tool replacement or workplace incidents. Reliable suppliers with consistent quality control, warranty offerings, and compliance with international safety standards should be prioritized. Ultimately, sourcing insulated tools should balance safety, durability, and cost-effectiveness to support efficient and secure operations in any electrical trade setting.