The global market for force measurement instruments is experiencing robust growth, driven by increasing demand for precision testing across industries such as automotive, aerospace, manufacturing, and healthcare. According to a report by Mordor Intelligence, the global force sensors market was valued at USD 1.34 billion in 2023 and is projected to grow at a CAGR of over 6.8% from 2024 to 2029. This expansion is fueled by advancements in sensor technology, rising automation, and stringent quality control standards requiring accurate force data. As industrial processes become more data-centric, the reliance on high-precision force measurement instruments has intensified, elevating the importance of reliable manufacturers in the space. In this landscape, nine key players have emerged as leaders, combining innovation, accuracy, and global reach to dominate the sector. These manufacturers not only define industry benchmarks but also shape the future of force measurement through continuous R&D and integration with digital and IoT-enabled systems.

Top 9 Instrument To Measure Force Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Force and Pressure Instruments

Domain Est. 1996

Website: cooperinstruments.com

Key Highlights: Cooper Instruments is a manufacturer & supplier of force & pressure instruments, including load cell instrumentation. Request a quote today!…

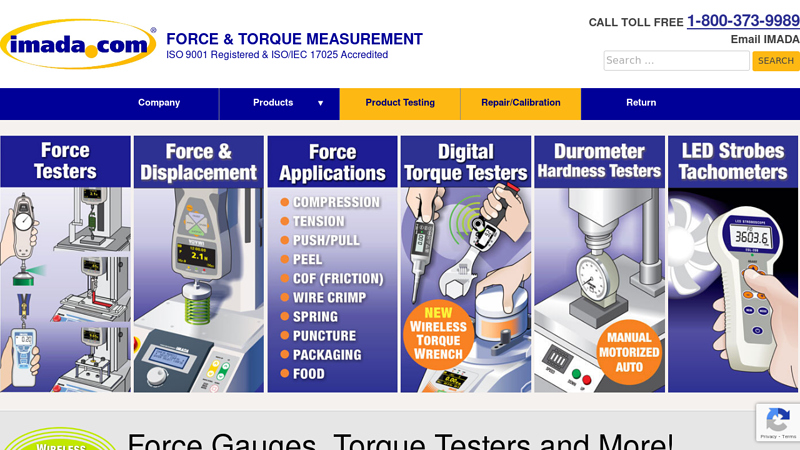

#2 Imada Inc.

Domain Est. 1997

Website: imada.com

Key Highlights: Imada offers the best force, torque and speed measurement products including: force gauges, force testers, torque testers, torque wrench calibrators & more….

#3 Mark

Domain Est. 1996

Website: mark-10.com

Key Highlights: Mark-10 manufactures universal test machines (UTM), tensile and materials testers, torque, force and COF test stand equipment and gauges in the US….

#4 Force measuring instruments

Domain Est. 1996

Website: wika.com

Key Highlights: A force measuring instrument consists of a force transducer and a display of the measured value. Learn more about the WIKA products and their application ….

#5 Pressure Mapping, Force Measurement, & Tactile Sensors

Domain Est. 1996

Website: tekscan.com

Key Highlights: Our patented force measurement, pressure mapping, and tactile sensing solutions provide you with actionable information to optimize your product designs….

#6 Tension, Torque, Force, Thickness, Speed, Hardness Gauges …

Domain Est. 1996

Website: checkline.com

Key Highlights: Checkline offers precision tension meters, tachometers, stroboscopes, force gauges, torque testers, wall thickness gauges, durometers, textile test ……

#7 Force instruments

Domain Est. 1997

Website: mecmesin.com

Key Highlights: The Basic Force Gauge (BFG) is the core digital instrument for tension and compression measurement from Mecmesin, covering load ranges from 10 to 2500 N. A ……

#8 Products(Force tester)

Domain Est. 2000

Website: forcegauge.net

Key Highlights: Force gauges, also known as push-pull gauge or push-pull scale, are measuring equipment that measures the load (force) acting on a sample….

#9 Tools in Force Measurement

Domain Est. 2021

Website: force-channel.com

Key Highlights: For your best force measurement discovery. As a Force Measurement Solution Provider, we have supported better manufacturing for over 70 years….

Expert Sourcing Insights for Instrument To Measure Force

2026 Market Trends for Instruments to Measure Force

The global market for instruments to measure force—including load cells, force gauges, torque sensors, and multi-axis sensors—is poised for significant evolution by 2026. Driven by technological innovation, expanding industrial automation, and heightened quality control demands, several key trends are shaping the industry landscape.

Advancements in Sensor Technology and Miniaturization

By 2026, sensor technology is expected to achieve greater precision, durability, and miniaturization. The integration of micro-electromechanical systems (MEMS) and nanotechnology enables the development of smaller, more sensitive force measurement devices suitable for compact or embedded applications in robotics, medical devices, and consumer electronics. Enhanced materials, such as advanced alloys and composite substrates, improve resistance to temperature fluctuations, corrosion, and mechanical overload, expanding usability in harsh environments. These advancements allow manufacturers to offer higher accuracy with lower power consumption, supporting the growth of IoT-connected and portable force measurement solutions.

Increased Integration with IoT and Industry 4.0

The convergence of force measurement instruments with the Industrial Internet of Things (IIoT) is a dominant trend leading into 2026. Smart sensors equipped with wireless connectivity (e.g., Bluetooth, Wi-Fi, 5G) and onboard data processing capabilities are becoming standard. These instruments enable real-time monitoring, predictive maintenance, and remote diagnostics across manufacturing, aerospace, and automotive sectors. Integration with cloud platforms and enterprise data systems allows for seamless data analytics, improving process efficiency and quality assurance. As Industry 4.0 adoption grows, force measurement systems are increasingly embedded into automated production lines, contributing to closed-loop control and smart factory ecosystems.

Rising Demand in Automotive and Aerospace Testing

The automotive and aerospace industries are key drivers of force measurement demand, particularly with the rise of electric vehicles (EVs) and advanced materials. By 2026, rigorous testing of EV battery packs, motor components, and structural integrity will require high-precision force instrumentation. Similarly, aerospace manufacturers are adopting lightweight composites and additive manufacturing techniques, necessitating detailed force analysis during production and fatigue testing. Multi-axis force sensors capable of measuring complex load conditions will see increased deployment in crash testing, flight control systems, and structural health monitoring.

Growth in Medical and Biomechanical Applications

The healthcare sector is emerging as a high-growth area for force measurement instruments. Surgical robotics, prosthetics, rehabilitation devices, and biomechanical research rely on ultra-precise force feedback systems. By 2026, demand will surge for tactile sensors and micro-load cells used in minimally invasive surgery tools and wearable health monitors. Regulatory emphasis on patient safety and device reliability will further incentivize investment in calibrated, traceable force measurement solutions within medical manufacturing and R&D.

Expansion of Automation and Quality Control in Manufacturing

As global manufacturing emphasizes automation and zero-defect production, the need for in-line force verification is accelerating. Force measurement instruments are being integrated into assembly lines for tasks such as press-fitting, screw tightening, and material handling. In sectors like electronics and pharmaceuticals, where precision is critical, automated force testing ensures product consistency and compliance with standards such as ISO 9001 and Six Sigma. This trend supports the development of rugged, easy-to-calibrate instruments with user-friendly software interfaces for non-specialist operators.

Sustainability and Energy Efficiency Initiatives

Sustainability concerns are influencing the design and deployment of force measurement systems. Manufacturers are focusing on energy-efficient sensor electronics and recyclable materials in product construction. Additionally, force sensors play a role in optimizing energy usage—such as monitoring load conditions in wind turbines or ensuring efficient operation in industrial machinery. By 2026, equipment with lower environmental impact and longer operational lifespans will be increasingly favored, especially in regulated industries.

Regional Market Dynamics and Supply Chain Resilience

Geographically, Asia-Pacific—particularly China, Japan, and India—is expected to lead market growth due to rapid industrialization and investments in automation. North America and Europe will remain strong markets, driven by innovation in high-tech manufacturing and aerospace. However, supply chain disruptions have prompted a shift toward localized production and dual sourcing of critical components. By 2026, companies offering modular, easily serviceable force measurement instruments with transparent supply chains will gain competitive advantage.

In conclusion, the 2026 force measurement instrument market will be defined by smarter, smaller, and more connected technologies serving a broadening array of high-tech industries. Success will depend on innovation in sensor performance, seamless digital integration, and responsiveness to evolving industrial and regulatory demands.

Common Pitfalls When Sourcing an Instrument to Measure Force (Focus on Quality and IP)

Sourcing a force measurement instrument—such as a load cell, force gauge, or torque sensor—requires careful evaluation beyond just specifications. Overlooking quality and intellectual property (IP) aspects can lead to performance issues, compliance risks, and long-term costs. Here are key pitfalls to avoid:

Choosing Based Solely on Price Without Assessing Quality

Prioritizing the lowest initial cost often leads to instruments with inferior materials, poor calibration accuracy, or inconsistent performance. Low-cost sensors may use substandard strain gauges or adhesives, leading to signal drift, reduced lifespan, or failure under stress. Always evaluate build quality, certifications (e.g., ISO, NIST traceability), and supplier reputation.

Ignoring Calibration and Traceability Documentation

A high-quality force instrument must come with proper calibration documentation that is traceable to international standards (e.g., NIST, PTB). Failing to verify calibration certificates can result in measurement inaccuracies that compromise product testing or regulatory compliance. Ensure the supplier provides up-to-date, accredited calibration reports.

Overlooking Environmental and Application Suitability

Not all force instruments perform reliably under the same conditions. Using a sensor not rated for temperature extremes, humidity, or mechanical shock can degrade accuracy and damage the device. Carefully match the IP (Ingress Protection) rating—such as IP65 or IP67—to your operating environment to ensure durability against dust and moisture.

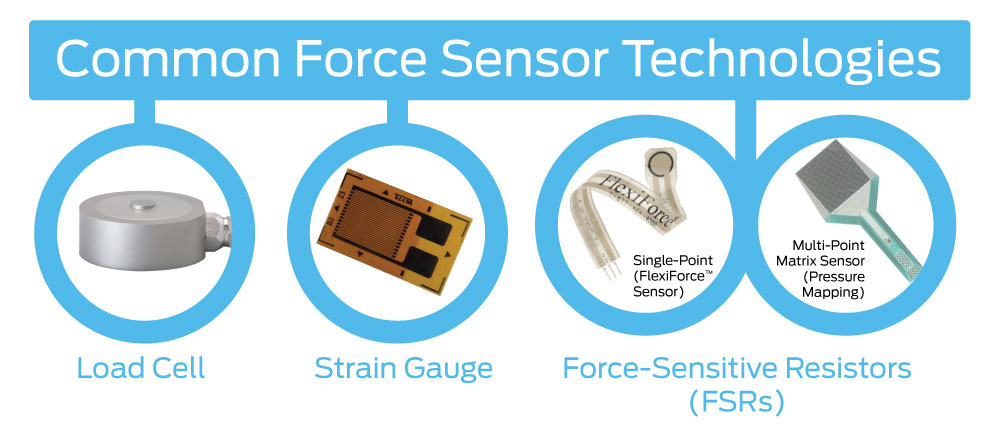

Assuming All Sensors Are Interchangeable

Different force measurement technologies (e.g., strain gauge, piezoelectric, capacitive) have distinct strengths and limitations. Assuming interchangeability without understanding signal output, response time, or load characteristics can result in poor data quality. Select the technology best suited to your specific application requirements.

Neglecting Intellectual Property and Licensing Risks

When integrating force sensors into proprietary systems or products, ensure the supplier’s technology does not infringe on third-party patents. Using a sensor with embedded IP that is not properly licensed may expose your company to legal challenges. Verify freedom-to-operate and review licensing terms, especially for smart or digital sensors with proprietary firmware.

Failing to Verify Long-Term Support and Spare Parts Availability

A high-quality instrument is only valuable if supported over time. Sourcing from a supplier without a clear roadmap for spare parts, firmware updates, or technical support risks system downtime. Confirm the supplier’s ability to provide long-term service and documentation access.

Skipping Supplier Audits or Due Diligence

Relying on datasheets alone without vetting the manufacturer’s quality management systems (e.g., ISO 9001 certification) increases the risk of receiving non-conforming products. Conduct supplier audits or request evidence of their production controls, testing procedures, and failure rate data.

Avoiding these pitfalls ensures you source a force measurement instrument that delivers reliable, accurate data while protecting your investment and intellectual property.

Logistics & Compliance Guide for Instrument to Measure Force

This guide outlines key logistics and compliance considerations for the shipment, handling, and regulatory adherence of instruments designed to measure force (e.g., load cells, force gauges, tensile testers).

Regulatory Classification & Documentation

Accurately classifying the instrument ensures compliance with international trade regulations. Most force measurement instruments fall under Harmonized System (HS) Code 9026.20 (Instruments and apparatus for physical or chemical analysis, for measuring or checking viscosity, porosity, expansion, surface tension, etc.). Confirm the specific HS code with local customs authorities. Required documentation typically includes a commercial invoice, packing list, bill of lading or air waybill, and potentially a certificate of origin. For instruments with embedded electronics, additional declarations may be needed under regional electronic waste directives.

Calibration & Certification Requirements

Force measurement instruments often require pre-shipment calibration to meet industry or customer specifications. Maintain traceable calibration certificates compliant with ISO/IEC 17025 standards. If intended for use in regulated industries (e.g., aerospace, medical devices, automotive), instruments may need certification from bodies such as NIST (National Institute of Standards and Technology) or UKAS (United Kingdom Accreditation Service). Ensure calibration documentation is included with the shipment and archived for audit purposes.

Packaging & Handling Procedures

Protect the instrument from physical shock, moisture, and temperature extremes during transit. Use custom-fitted, shock-absorbent packaging with internal immobilization to prevent movement. Include desiccants if shipping to humid environments. Clearly label packages as “Fragile,” “This Side Up,” and “Do Not Stack” as appropriate. Avoid exposing the instrument to excessive vibration or magnetic fields during handling and transport. Provide handling instructions in the user documentation.

Import/Export Controls

Verify if the instrument or its components are subject to export control regulations such as the U.S. Export Administration Regulations (EAR) or International Traffic in Arms Regulations (ITAR). Most general-purpose force measurement devices are EAR99 (low concern), but specialized high-precision or military-grade instruments may require export licenses. Check destination country import restrictions, especially for dual-use technologies. Obtain necessary export licenses or authorizations before shipment.

Environmental & Safety Compliance

Ensure compliance with environmental directives such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) if shipping to the European Union. Confirm the instrument does not contain restricted substances above permissible levels. For battery-powered devices, adhere to IATA dangerous goods regulations if lithium batteries are installed or shipped separately. Include appropriate safety data sheets (SDS) if applicable.

After-Sales Service & Maintenance Logistics

Plan for return logistics if repair or recalibration is required. Establish clear processes for Return Merchandise Authorization (RMA), including packaging requirements and return shipping. Maintain a supply chain for spare parts and ensure service technicians are trained per manufacturer and regulatory standards. Document all service activities for compliance and warranty tracking.

Regional Compliance Considerations

Different markets may impose additional requirements. For example, CE marking is mandatory in the EU for instruments falling under the Measuring Instruments Directive (MID) or EMC Directive. In Canada, compliance with Measurement Canada regulations may apply for legal-for-trade applications. In China, the CCC (China Compulsory Certification) mark may be required. Conduct a market-specific compliance review prior to entry.

In conclusion, selecting an appropriate instrument to measure force requires careful consideration of several key factors including the required accuracy, measurement range, environmental conditions, application context, and cost. Devices such as load cells, force gauges, and strain gauges are commonly used, with each offering distinct advantages depending on the specific use case. Calibration, reliability, and ease of integration with data acquisition systems are also critical for ensuring consistent and precise measurements. Ultimately, the choice of instrument should align with the technical demands of the application while maintaining cost-effectiveness and long-term durability. Proper sourcing involves evaluating reputable manufacturers, verifying compliance with industry standards, and confirming technical support availability to ensure optimal performance and measurement integrity.