The global air compressor market was valued at approximately USD 33.5 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 4.2% from 2024 to 2030, driven by rising industrial automation, infrastructure development, and expanding manufacturing activities worldwide (Grand View Research, 2024). As one of the leading brands in the sector, Ingersoll Rand continues to play a pivotal role in shaping performance standards—particularly in the 20-gallon air compressor segment, which balances portability, power, and reliability for both commercial and industrial applications. Fueled by regional production scaling and technological advancements in energy efficiency, the demand for high-quality 20-gallon models has led to a growing ecosystem of manufacturers producing Ingersoll Rand-compatible or branded units. Based on market trends and product availability, the following analysis highlights the top four manufacturers behind Ingersoll Rand’s 20-gallon air compressors, evaluated on output capacity, durability, service network, and alignment with current industry benchmarks.

Top 4 Ingersoll Rand 20 Gallon Air Compressor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Air Compressors

Domain Est. 2001

Website: ingersollrand.com

Key Highlights: Ingersoll Rand offers high-quality industrial air compressors and compressed air services for a wide range of industries….

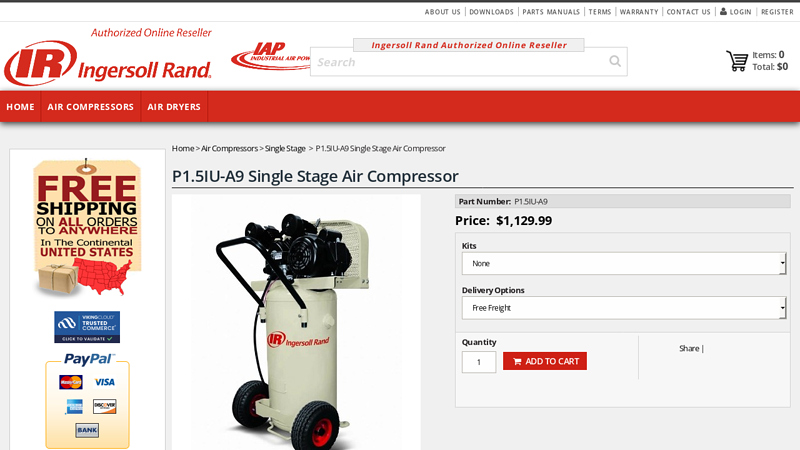

#2 Ingersoll Rand P1.5IU

Domain Est. 2013

Website: ingersollrandcompressedair.com

Key Highlights: Factory prewired. Horsepower: 2 hp. Tank size: 20 gal. Capacity @ 90 psi / 135 psi: 5.2 / 4.6 cfm. Maximum pressure: 135 psi. Height: 43 in. Width: 23 in. Depth ……

#3 20 Gallon Cast Iron Air Compressors

Domain Est. 2003

Website: aircompressorsdirect.com

Key Highlights: Free delivery over $199Learn More About Ingersoll Rand P1.5IU-A9-H. Ingersoll Rand Garage Mate 2-HP 20-Gallon (Belt Drive) Cast-Iron Air Compressor….

#4 Ingersoll Rand P1.5IU-A9-H

Domain Est. 2008

Website: autotoolworld.com

Key Highlights: In stock Rating 5.0 2 Oversized belt wheel provides reliable design and cooler operation; Durable cast-iron cylinders, heads, and frame are designed for continuous operation and …

Expert Sourcing Insights for Ingersoll Rand 20 Gallon Air Compressor

H2: Projected 2026 Market Trends for the Ingersoll Rand 20 Gallon Air Compressor

As the industrial and commercial air compression market evolves through 2026, the Ingersoll Rand 20 Gallon Air Compressor is expected to maintain a strong market position driven by technological advancements, growing demand across key industries, and strategic brand positioning. Several macroeconomic, technological, and sector-specific trends are shaping the outlook for this product line.

-

Increased Demand in Industrial and Construction Sectors

The Ingersoll Rand 20 Gallon model, known for its durability and reliability, is widely used in construction, manufacturing, and automotive repair. With global infrastructure investments rising—particularly in North America and parts of Asia-Pacific—demand for dependable, mid-sized air compressors is projected to grow. The U.S. Infrastructure Investment and Jobs Act and similar initiatives worldwide are expected to stimulate construction activity, directly benefiting sales of industrial tools like the Ingersoll Rand 20 Gallon unit. -

Shift Toward Energy Efficiency and Sustainability

Regulatory pressures and corporate sustainability goals are pushing demand for energy-efficient equipment. While the traditional 20-gallon piston compressor may face competition from variable speed drive (VSD) and oil-free models, Ingersoll Rand is likely to enhance this model with improved motor efficiency or offer hybrid solutions. By 2026, buyers will increasingly favor compressors with lower total cost of ownership (TCO), including energy consumption and maintenance. Ingersoll Rand’s reputation for robust engineering positions it well to meet these demands through incremental innovation. -

Expansion in Small and Medium-Sized Enterprises (SMEs)

The 20-gallon compressor is ideal for small workshops and mobile operations. As entrepreneurship and small manufacturing grow—fueled by nearshoring and decentralized production—this segment will drive demand. Ingersoll Rand may leverage its distribution network and service support to capture market share among SMEs seeking trusted, long-lasting equipment. -

Digital Integration and IoT-Enabled Monitoring

While the standard 20-gallon model is mechanical, Ingersoll Rand could introduce smart monitoring add-ons by 2026—such as pressure sensors, usage tracking, or remote diagnostics via mobile apps. Competitors are already integrating IoT features into industrial tools, and customer expectations are shifting. Even retrofit solutions could differentiate Ingersoll Rand’s offerings in a competitive market. -

Aftermarket and Service Revenue Growth

Beyond unit sales, the 2026 outlook includes rising importance of service, parts, and maintenance contracts. Ingersoll Rand’s extensive service network and genuine parts ecosystem will enhance customer retention. Predictive maintenance tools tied to compressor usage data could further boost aftermarket revenue. -

Competitive Landscape and Pricing Pressure

The air compressor market remains competitive, with players like Campbell Hausfeld, Dewalt, and Quincy offering similar capacity models. Price sensitivity among DIY and small commercial users may pressure margins. However, Ingersoll Rand’s brand equity—built on industrial-grade performance—allows for a premium pricing strategy, especially in professional segments. -

Global Supply Chain Resilience

Post-pandemic supply chain adjustments continue to affect manufacturing costs and delivery timelines. By 2026, Ingersoll Rand is expected to have optimized its sourcing and production, potentially localizing more components to reduce lead times and tariffs, especially in North America and Europe.

Conclusion:

The Ingersoll Rand 20 Gallon Air Compressor is poised to remain a staple in the mid-tier industrial air compression market through 2026. While facing challenges from technological disruption and competition, its success will hinge on Ingersoll Rand’s ability to balance reliability with innovation, support sustainability goals, and expand service offerings. The company’s focus on durability, coupled with gradual digital and efficiency enhancements, will likely sustain demand across construction, manufacturing, and small business sectors.

Common Pitfalls When Sourcing an Ingersoll Rand 20 Gallon Air Compressor: Quality and Intellectual Property Concerns

When sourcing an Ingersoll Rand 20 Gallon Air Compressor—whether for resale, industrial use, or integration into systems—buyers often encounter pitfalls related to product quality and intellectual property (IP) risks. Being aware of these issues helps prevent costly mistakes and legal complications.

H2: Quality-Related Pitfalls

-

Counterfeit or Replica Units

Ingersoll Rand is a reputable brand, making its products a frequent target for counterfeiters. Fake 20-gallon compressors may mimic the appearance but use substandard motors, tanks, and pressure switches. These units often fail prematurely, pose safety hazards, and lack compliance with safety standards like ASME or OSHA. -

Used or Refurbished Units Marketed as New

Some suppliers sell refurbished or salvaged compressors as “new in box.” These units may have worn components, undocumented repair history, or compromised tank integrity, leading to reduced performance and reliability. -

Inconsistent Performance Specifications

Counterfeit or off-brand versions may claim identical specs (e.g., 155 PSI, 5.4 CFM) but deliver significantly lower actual output. This mismatch disrupts operations relying on consistent air delivery, especially in industrial environments. -

Lack of Safety Certifications

Genuine Ingersoll Rand compressors meet rigorous safety and quality standards. Illegitimate units may lack UL, CSA, or ASME certification, increasing liability risks and potential rejection by inspectors or insurance providers. -

Poor After-Sales Support and Warranty Fraud

Fake units often come with forged warranty cards or non-transferable warranties that cannot be validated. Buyers may find themselves without technical support, spare parts, or service networks.

H2: Intellectual Property (IP) Risks

-

Trademark Infringement

Unauthorized use of the Ingersoll Rand name, logo, or model numbers on non-genuine products constitutes trademark infringement. Sourcing such units—knowingly or unknowingly—can expose buyers or resellers to legal liability, especially in regulated markets. -

Patented Design and Component Replication

Ingersoll Rand holds patents on critical compressor components (e.g., pump designs, cooling systems). Imitators that copy these features may infringe on IP rights, potentially implicating downstream distributors or integrators if they contribute to or benefit from infringement. -

Gray Market Imports

Some suppliers source authentic Ingersoll Rand units from international markets and resell them without authorization. While the product may be genuine, this practice often violates distribution agreements and IP licensing terms, leading to warranty voidance and brand enforcement actions. -

Misrepresentation in Product Listings

Online marketplaces frequently host listings that reference Ingersoll Rand trademarks to attract traffic, even when selling incompatible or imitation products. This misleading use of IP can result in takedown notices or legal action from the brand owner. -

Supply Chain Transparency Gaps

Lack of traceability in the supply chain increases the risk of inadvertently sourcing IP-infringing products. Without verified documentation (e.g., invoices from authorized dealers, serial number validation), buyers may face compliance audits or customs seizures.

Best Practices to Avoid Pitfalls

– Purchase only from authorized Ingersoll Rand distributors or certified resellers.

– Verify product authenticity via serial number checks on the official Ingersoll Rand website.

– Request certificates of authenticity, compliance, and warranty documentation.

– Audit suppliers for IP compliance, especially when sourcing in bulk.

– Avoid deals that seem too good to be true—significant price deviations often signal counterfeit or gray market goods.

By addressing these quality and IP-related concerns proactively, businesses can ensure reliable performance, regulatory compliance, and legal safety when sourcing Ingersoll Rand 20 Gallon Air Compressors.

H2: Logistics & Compliance Guide for Ingersoll Rand 20 Gallon Air Compressor

1. Product Identification & Specifications

* Model: Ingersoll Rand 20 Gallon Air Compressor (Specific model numbers vary by series, e.g., SS4F2, SSR4, etc. – Always verify the exact model).

* Key Specifications:

* Tank Capacity: 20 Gallons (75.7 Liters).

* Power Source: Typically 115V or 230V, 60 Hz, Single-Phase (Verify specific model requirements).

* Motor Horsepower (HP): Varies (e.g., 2 HP, 3 HP, 5 HP – Check model).

* Maximum Pressure: Typically 135-165 PSI (Pounds per Square Inch).

* Air Delivery (CFM): Varies by model and pressure (e.g., 5.5 CFM @ 90 PSI, 4.2 CFM @ 135 PSI – Check model).

* Dimensions: Approx. Height: 30-36 in, Width: 20-24 in, Depth: 24-30 in (Varies significantly by model).

* Weight: Approx. 120-180 lbs (54-82 kg) (Varies significantly by model).

* Primary Materials: Steel tank, cast iron pump components, steel/aluminum frame, copper/aluminum windings, plastic components.

2. Logistics Handling & Transportation

* Packaging:

* Typically shipped in a heavy-duty corrugated cardboard box on a wooden pallet.

* Protects against moisture, dust, and impact during transit.

* Includes foam, cardboard inserts, or plastic wraps to secure internal components and prevent movement.

* Handling:

* WEIGHT: Use mechanical lifting equipment (pallet jack, forklift) for palletized units. Never attempt to manually lift the compressor itself.

* Manual Movement: If moving the compressor off the pallet, use a hand truck/dolly rated for the weight. Tilt carefully and ensure secure straps.

* Orientation: Transport and store upright only. Tipping can damage internal components (oil, valves) and void warranty.

* Securing: Secure units on pallets and within transport vehicles using straps to prevent shifting.

* Storage:

* Environment: Store indoors in a clean, dry, well-ventilated area. Protect from extreme temperatures, moisture, dust, and corrosive atmospheres.

* Position: Store upright on a level surface.

* Duration: For long-term storage (>30 days), drain the tank completely to prevent internal corrosion. Consider additional protective measures per manufacturer’s long-term storage guidelines.

* Shipping Documentation: Ensure Bill of Lading (BOL) accurately reflects:

* Correct model numbers and quantities.

* Total weight and dimensions (pallet + compressor).

* Proper handling instructions (“Fragile,” “This Side Up,” “Do Not Tip,” “Heavy Item”).

* Appropriate freight class (based on weight, density, and handling characteristics – typically Class 70-92.5 for heavy machinery).

3. Regulatory Compliance

* Safety Standards (Design & Manufacturing):

* ASME Boiler and Pressure Vessel Code (Section VIII, Division 1): The pressure tank is ASME certified and stamped. This is critical for safety and legality. The tank must have an ASME U-stamp or U2-stamp.

* OSHA 29 CFR 1910.169: General requirements for compressed air systems in the workplace (applies to end-user operation, but design must facilitate compliance).

* NFPA 99: Health Care Facilities Code (if used in healthcare settings).

* UL/ETL Listing: The electrical components (motor, switch) are typically listed by a Nationally Recognized Testing Laboratory (NRTL) like UL or Intertek (ETL) to relevant safety standards (e.g., UL 1004 for motors, UL 508 for controllers).

* Electrical Compliance:

* NEMA Standards: Motor enclosure (e.g., ODP – Open Drip Proof, TEFC – Totally Enclosed Fan Cooled) meets NEMA standards for environmental protection.

* NEC (National Electrical Code – NFPA 70): Installation must comply with NEC requirements for branch circuit sizing, disconnect means, grounding, and wiring methods. Use a dedicated circuit as specified in the manual.

* Environmental & Chemical Compliance:

* RoHS (Restriction of Hazardous Substances): Applies to electrical/electronic components (Pb, Cd, Hg, Cr6+, PBB, PBDE limits). Ingersoll Rand complies with RoHS directives.

* REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals): Applies to substances in articles within the EU. Ingersoll Rand provides necessary compliance information.

* Prop 65 (California): Warning labels may be present regarding exposure to chemicals like lead or phthalates (common in older paints or certain plastics) which may be present in trace amounts on the compressor.

* Operational Compliance (User Responsibility):

* Pressure Relief Valve: MANDATORY. The compressor must have a correctly sized, ASME-certified pressure relief valve installed, set to open at or below the tank’s Maximum Allowable Working Pressure (MAWP). This valve MUST NEVER BE PLUGGED OR DISABLED. Test it regularly (per manual).

* Drain Valve: Manual or automatic drain must be used regularly to remove condensate, preventing corrosion and water contamination in the air line.

* Oil Disposal: Used compressor oil is hazardous waste. Dispose of it properly per local, state, and federal regulations (EPA, RCRA). Never pour down drains or on the ground.

* Noise: Compressors generate significant noise. Comply with OSHA noise exposure limits (29 CFR 1910.95) through engineering controls, administrative controls, or hearing protection for personnel.

4. Key Compliance Documentation

* ASME Data Plate: Permanently attached to the tank. Lists MAWP, tank test pressure, manufacturer, date, serial number, and ASME code stamp. CRITICAL for inspection and compliance.

* Instruction Manual: Contains vital safety, installation, operation, maintenance, and compliance information. Includes electrical specs, lubrication requirements, and pressure relief valve details.

* Safety Labels: Applied to the unit (e.g., warning labels for high pressure, hot surfaces, electrical shock, noise, pinch points).

* NRTL Listing Marks: UL, ETL, or equivalent mark on electrical components/enclosure.

* RoHS/REACH Declarations: Available from Ingersoll Rand upon request for supply chain compliance.

* Prop 65 Warning (if applicable): Usually on the manual or packaging.

5. Critical Logistics & Compliance Reminders

* Verify Model: Specifications, weight, and compliance details are model-specific. Always confirm the exact model.

* Upright Handling: This is paramount for safety and preventing damage.

* ASME Tank: The presence and integrity of the ASME stamp are non-negotiable for safe operation and legal compliance.

* Pressure Relief Valve: Its function is critical safety equipment. Regular testing and maintenance are mandatory.

* Proper Disposal: Follow hazardous waste regulations for used oil and potentially the unit itself at end-of-life (check local rules).

* Consult Manuals: The Ingersoll Rand instruction manual is the authoritative source for safe operation and maintenance procedures.

Disclaimer: This guide provides general information. Always refer to the specific Ingersoll Rand model’s official Instruction Manual and applicable local, state, federal, and international regulations for definitive requirements. Compliance responsibilities are shared between the manufacturer, distributor, and end-user.

In conclusion, sourcing an Ingersoll Rand 20-gallon air compressor is a sound investment for professionals and serious DIY enthusiasts seeking reliable, durable, and high-performance pneumatic power. Renowned for their robust engineering, industrial-grade build quality, and long-term durability, Ingersoll Rand compressors offer consistent performance, low maintenance, and excellent air delivery, making them ideal for automotive, construction, manufacturing, and workshop applications.

When sourcing this model, it is important to purchase from authorized dealers, certified resellers, or trusted online platforms to ensure authenticity, access to warranties, and manufacturer support. Comparing pricing, availability, and customer service across suppliers can further optimize value and post-purchase support. Additionally, considering energy efficiency, noise levels, portability, and intended usage will help in selecting the right configuration—such as belt-driven vs. direct drive, oil-lubricated vs. oil-free models—within the 20-gallon lineup.

Ultimately, sourcing the Ingersoll Rand 20-gallon air compressor ensures a blend of performance, reliability, and longevity that supports productivity and operational efficiency, justifying its place as a trusted choice in both commercial and demanding home workshop environments.