The global tube bending equipment market is experiencing steady expansion, driven by rising demand across automotive, construction, HVAC, and aerospace industries. According to a report by Mordor Intelligence, the market is projected to grow at a CAGR of 5.8% from 2024 to 2029, fueled by increased industrial automation and infrastructure development worldwide. Similarly, Grand View Research valued the market at USD 867.3 million in 2022 and forecasts a CAGR of 6.2% from 2023 to 2030, citing advancements in precision manufacturing and the growing need for efficient fluid transport systems. As demand rises, cost-effective solutions are becoming increasingly important—especially for small to mid-sized enterprises and workshops seeking reliable performance without high capital expenditure. This growing need has spurred competition among manufacturers, particularly in regions like Asia-Pacific and Eastern Europe, where production costs are lower and technological capabilities continue to improve. Below, we highlight the top 10 inexpensive yet dependable tube bender manufacturers that deliver value without compromising essential functionality.

Top 10 Inexpensive Tube Bender Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 JD Squared, Inc.

Domain Est. 1996 | Founded: 1982

Website: jd2.com

Key Highlights: US manufacturer of CNC rotary cutters and tables, benders, and notchers. Family-owned, made in the USA, serving metalworking pros since 1982….

#2 300 CNC Tube Benders

Domain Est. 2000

Website: hinesbending.com

Key Highlights: Hines Bending Systems, the #1 worldwide manufacturer of tube benders, pipe benders, and induction benders, delivers unparalleled quality and ……

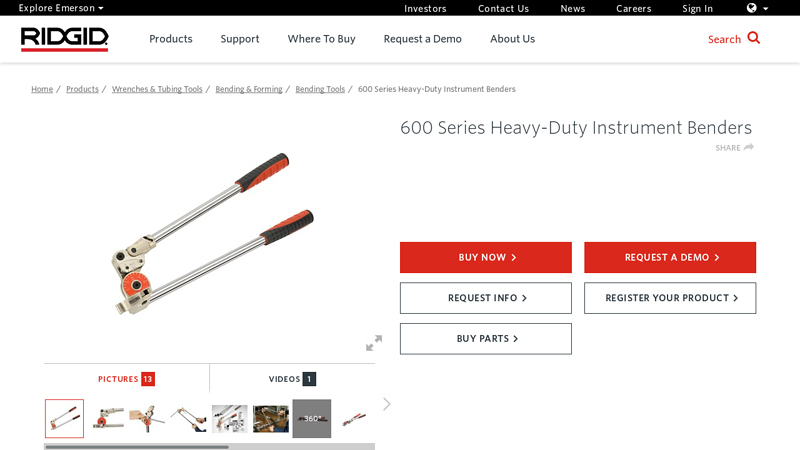

#3 600 Series Heavy

Domain Est. 1995

Website: ridgid.com

Key Highlights: Rating 3.3 (4) 600 Series Heavy-Duty Instrument Benders provide high quality bending performance for stainless steel and other hard tubing. Shop here….

#4 Tube and Pipe Benders

Domain Est. 1998

#5 Tubeshark

Domain Est. 1999

Website: tubeshark.com

Key Highlights: In the shop or in the field Tubeshark produces quality bends in a wide variety of materials without distortion, equal to machines costing thousands more….

#6 Pipe and Tube Benders

Domain Est. 2002

Website: huthbenders.com

Key Highlights: Huth Pipe and Tube Benders: Pipe Bending for Thousands of Applications. The value of portable, affordable, super strong tube and pipe benders was quickly ……

#7 American

Domain Est. 2003

#8 Alpine Bender

Domain Est. 2008

Website: alpinebender.com

Key Highlights: Alpine offers full line of premium mandrel tube/pipe benders at its highest values and with competitive pricing. Whether for low volume use or mass production ……

#9 Affordable Tube Benders, tube notchers, metal fabrication welding

Domain Est. 2009

Website: affordablebender.com

Key Highlights: Have a custom metal fabrication need? Hit us up here at Affordable Bender. We can fabricate almost anything to spec from a variety of different materials….

#10 Rogue Fabrication Tubing Bender

Domain Est. 2012

Website: roguefab.com

Key Highlights: Rogue Fabrication Manufactures Tubing and Pipe Benders, also the home of the World’s Most Affordable Mandrel Bender….

Expert Sourcing Insights for Inexpensive Tube Bender

H2: 2026 Market Trends for Inexpensive Tube Benders

The global market for inexpensive tube benders is poised for notable transformation and growth by 2026, driven by increasing demand across various manufacturing and construction sectors, technological advancements, and evolving consumer preferences. These cost-effective tools, essential for shaping metal, plastic, and composite tubing in automotive, HVAC, furniture, and DIY applications, are benefiting from broader industrial digitization and the rise of small-to-medium enterprises (SMEs) seeking affordable yet reliable machinery.

One of the key trends shaping the 2026 landscape is the rising adoption of semi-automatic and compact tube benders in emerging economies. Countries in Southeast Asia, India, and parts of Africa are experiencing rapid industrialization and infrastructure development, leading to heightened demand for affordable fabrication tools. Inexpensive tube benders offer an accessible entry point for workshops and startups, enabling cost-efficient production without the need for high-end CNC systems.

Another significant trend is the integration of modular and user-friendly designs. Manufacturers are focusing on ergonomics, portability, and ease of setup to appeal to non-specialist users and hobbyists. This shift is supported by the growing maker movement and home fabrication culture, where affordability and simplicity are prioritized. Enhanced instructional content, compatibility with common tube materials, and tooling interchangeability are becoming standard features in budget-friendly models.

Additionally, competition is intensifying among manufacturers in China, Taiwan, and Eastern Europe, pushing innovation while keeping prices low. This competitive pressure is accelerating improvements in durability, precision, and safety features—historically trade-offs in lower-cost models. As a result, inexpensive tube benders are increasingly perceived as viable alternatives to premium equipment for light to medium-duty applications.

Finally, sustainability and energy efficiency are beginning to influence design choices. By 2026, consumers and regulators are expected to favor equipment with lower power consumption and longer service life, prompting manufacturers to adopt greener materials and more efficient production methods—even in budget segments.

In conclusion, the 2026 market for inexpensive tube benders will be defined by affordability, accessibility, and incremental innovation, fueled by global industrial expansion, democratization of manufacturing tools, and demand from both professional and amateur users.

Common Pitfalls When Sourcing Inexpensive Tube Benders (Quality & IP Risks)

Sourcing low-cost tube benders can offer significant upfront savings, but it often comes with hidden risks that impact long-term performance, safety, and legal compliance. Being aware of these common pitfalls is essential to avoid costly mistakes.

Poor Build Quality and Material Selection

Inexpensive tube benders often use substandard materials and manufacturing processes. This can result in frames that flex or warp under load, leading to inconsistent bends and premature failure. Components like hydraulic seals, gears, and clamps may wear out quickly, increasing downtime and maintenance costs. Inferior heat treatment on bending dies can cause cracking or deformation, reducing tool life and compromising bend accuracy.

Inaccurate or Inconsistent Bending Performance

Low-cost machines frequently lack the precision engineering needed for repeatable, high-tolerance bends. Issues such as die slippage, poor alignment, or inadequate control systems can result in ovality, wrinkling, or wall thinning in the bent tube. This inconsistency affects product quality and may lead to increased scrap rates, negating any initial cost savings.

Lack of Safety Features and Compliance

Budget tube benders may not meet international safety standards (e.g., CE, OSHA, or ISO). Missing emergency stops, inadequate guarding, or faulty hydraulic systems can pose serious safety hazards to operators. Non-compliant equipment may also lead to workplace violations, fines, or liability issues, especially in regulated industries.

Limited Technical Support and Spare Parts Availability

Manufacturers of inexpensive benders—especially those from regions with weak after-sales infrastructure—often provide minimal technical support. Obtaining replacement parts can be slow or impossible, leading to extended downtime. User manuals may be poorly translated or incomplete, complicating setup and troubleshooting.

Intellectual Property (IP) Infringement Risks

Some low-cost tube benders, particularly those from certain overseas suppliers, may be counterfeit or unauthorized copies of patented designs. Purchasing such equipment can expose your company to legal liability, especially if the original IP holder pursues action against downstream users. Additionally, using infringing machinery may damage your company’s reputation and exclude you from certain markets or contracts requiring IP compliance.

Hidden Total Cost of Ownership

While the initial purchase price may be low, the total cost of ownership can far exceed that of a higher-quality machine. Frequent repairs, downtime, lower productivity, higher scrap rates, and shortened equipment lifespan all contribute to increased operational expenses over time. Investing in a reliable, well-supported machine often proves more economical in the long run.

Inadequate or Missing Documentation

Cheaply sourced equipment may come with incomplete or non-existent documentation, including operation manuals, maintenance schedules, and compliance certificates. This lack of documentation complicates training, servicing, and regulatory audits, and can void warranties or insurance coverage.

To mitigate these risks, conduct thorough due diligence: verify supplier credentials, request product certifications, inspect sample units if possible, and consult user reviews or industry forums. Prioritizing quality and IP compliance over initial cost can protect your operations, workforce, and business integrity.

Logistics & Compliance Guide for Inexpensive Tube Bender

Product Classification and Import Regulations

Determine the correct HS (Harmonized System) code for the tube bender, typically falling under machinery for processing metal (e.g., HS 8462.21 or 8462.29, depending on functionality). Verify country-specific import tariffs and regulations. Ensure compliance with local safety and electrical standards (e.g., CE for EU, UL for USA, CCC for China). Confirm whether the product requires certification or conformity assessment before entry.

Packaging and Shipping Requirements

Use durable, cost-effective packaging to protect the tube bender during transit. Include moisture barriers if shipping to humid regions. Label packages with handling instructions (e.g., “Fragile,” “This Side Up”) and include product identification, model number, and country of origin. Optimize package dimensions and weight to reduce shipping costs, especially for bulk orders. Choose reliable freight forwarders experienced in handling industrial equipment.

Customs Documentation

Prepare complete customs documentation including commercial invoice, packing list, bill of lading (or air waybill), and certificate of origin. The commercial invoice must detail product description, unit price, total value, and Incoterms (e.g., FOB, EXW). For regulated markets, include compliance certificates (e.g., CE Declaration of Conformity). Ensure all documents are accurate to avoid customs delays or penalties.

Regulatory Compliance and Safety Standards

Verify that the tube bender meets essential safety requirements in the destination market. For the European Union, ensure compliance with the Machinery Directive (2006/42/EC) and affix the CE mark. In the United States, adhere to OSHA and ANSI safety standards; UL or ETL listing may be required for electrical components. Include multilingual user manuals with safety instructions and maintenance guidelines.

Warranty and After-Sales Support Logistics

Establish clear warranty terms (e.g., 12 months) and define procedures for handling returns, repairs, or replacements. Designate regional service centers or partner with local distributors for support. Ship spare parts efficiently and maintain inventory of common components to minimize downtime for customers.

Environmental and Disposal Regulations

Ensure packaging materials comply with environmental regulations (e.g., EU Directive 94/62/EC on packaging waste). Provide guidance on proper disposal of the tube bender at end-of-life, including recycling of metal and electronic components. Comply with RoHS (Restriction of Hazardous Substances) if applicable, especially for electrical models.

Risk Management and Insurance

Obtain cargo insurance to cover loss or damage during transit. Assess geopolitical and supply chain risks, especially when sourcing from low-cost manufacturing regions. Implement quality control checks pre-shipment to reduce the risk of non-compliant or defective units entering the market.

In conclusion, sourcing an inexpensive tube bender requires a careful balance between cost, quality, and functionality. While budget-friendly options are available through online marketplaces, second-hand equipment dealers, and entry-level manufacturers—particularly from regions with lower production costs—it is essential to evaluate factors such as durability, precision, compatibility with required tube materials and sizes, and availability of technical support or replacement parts. Additionally, considering long-term value rather than upfront cost alone can prevent costly downtime or inadequate performance. By conducting thorough research, comparing specifications, and reading user reviews, businesses and individuals can successfully identify a cost-effective tube bender that meets their operational needs without compromising on reliability.