The global industrial touch screen monitor market is experiencing robust growth, driven by increasing automation across manufacturing, logistics, and energy sectors. According to Grand View Research, the global industrial HMI (Human-Machine Interface) market size was valued at USD 5.8 billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 6.4% from 2024 to 2030. This surge is fueled by the rising demand for real-time monitoring, improved operational efficiency, and the integration of Industry 4.0 technologies. As businesses prioritize rugged, reliable, and responsive interface solutions, the need for high-performance industrial touch screen monitors has become critical. In this evolving landscape, a select group of manufacturers has emerged as leaders—combining innovation, durability, and scalability to meet diverse industrial demands. Based on market presence, product breadth, and technological advancements, here are the top 8 industrial touch screen monitor manufacturers shaping the future of industrial automation.

Top 8 Industrial Touch Screen Monitor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Industrial Monitors with Touch Screens

Domain Est. 2012

Website: faytech.us

Key Highlights: 4–11 day deliveryfaytech North America is a leading manufacturer of industrial touchscreen displays & industrial monitors. See our pricing and specifications….

#2 Touch Screen Monitors & Displays

Domain Est. 1996

Website: elotouch.com

Key Highlights: Explore Elo’s reliable touch screen monitors and non-touch displays, built for retail, healthcare, hospitality, and industrial use….

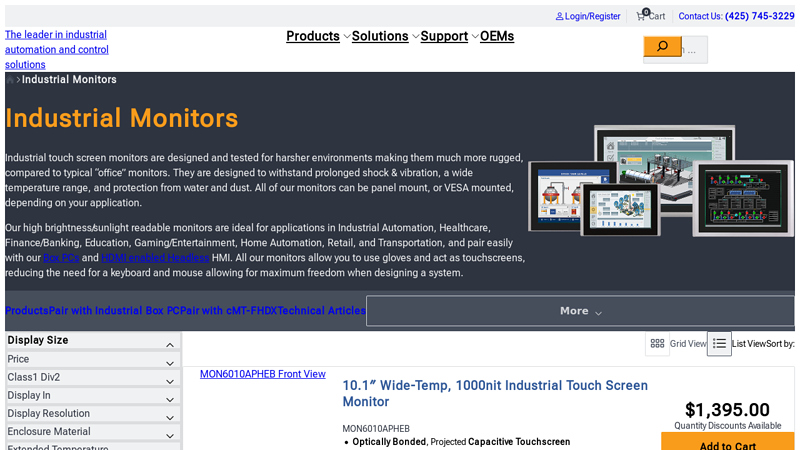

#3 Industrial Touch Screen Monitors

Domain Est. 2002

Website: maplesystems.com

Key Highlights: 30-day returnsIndustrial touch screen monitors are designed and tested for harsher environments making them much more rugged, compared to typical ……

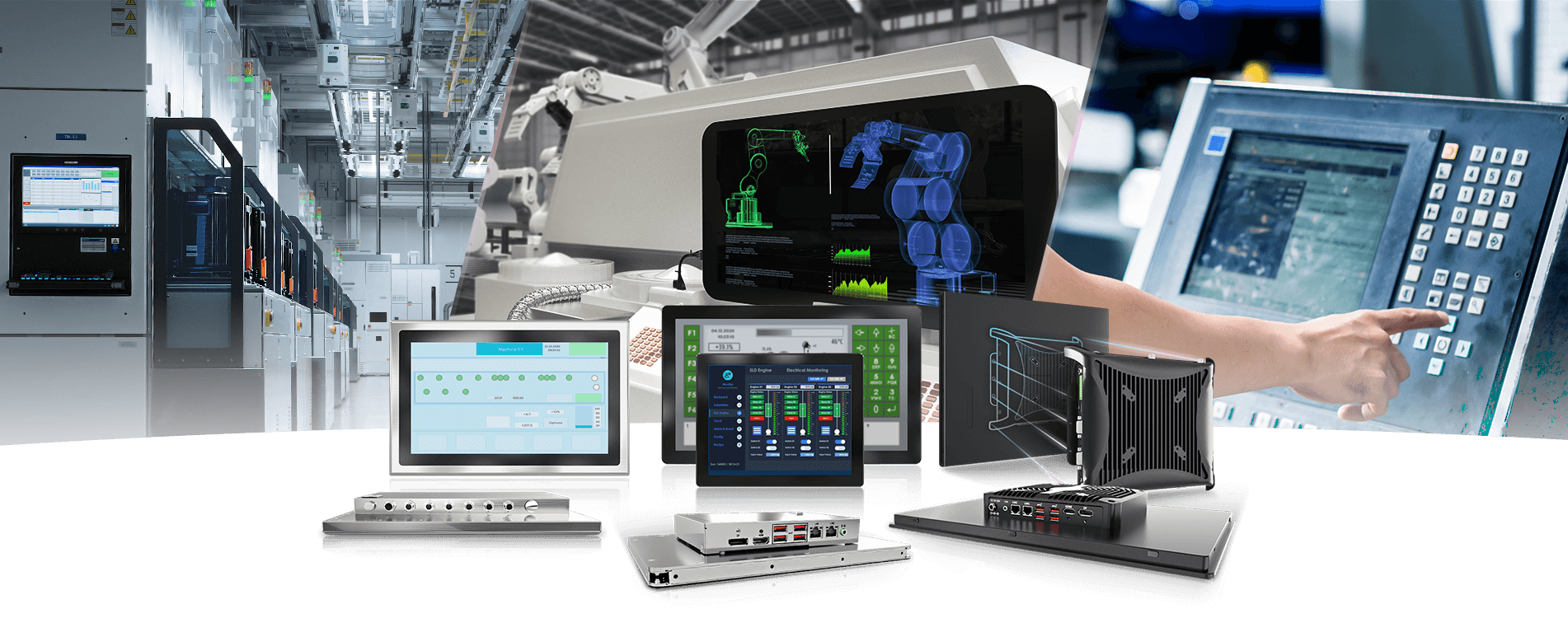

#4 Industrial Touch Panel Pcs and Monitors

Domain Est. 2004

Website: premioinc.com

Key Highlights: Our extensive lineup includes highly customizable and durable touch panel PCs engineered to withstand the harshest environments….

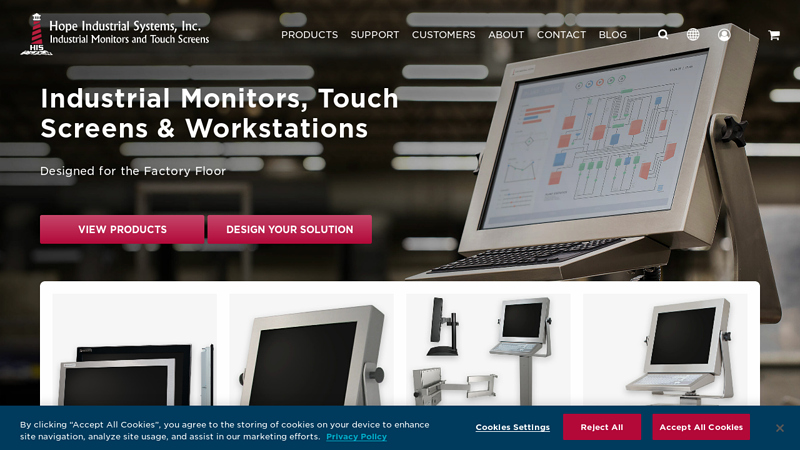

#5 Hope Industrial Systems

Domain Est. 2005

Website: hopeindustrial.com

Key Highlights: Affordable Rugged Industrial Touch Screens, Monitors, and Workstations. NEMA 4/4X and IP65/IP66 washdown certified. Standard 5-year Warranty….

#6 Industrial Monitors & Touch Screen Displays From 7″ to 65″

Domain Est. 2008

Website: tru-vumonitors.com

Key Highlights: TRU-Vu offers the largest selection of industrial LCD monitors and large touch screens in the world. We have an impressive line-up of over 175 off-the-shelf ……

#7 Industrial Touchscreen Displays, Rugged PC Monitors

Domain Est. 2010

Website: teguar.com

Key Highlights: 8-day deliveryTeguar’s industrial touchscreen monitors are rugged computer display solutions that meet the requirements for the most demanding industrial manufacturing ……

#8 Mimo

Domain Est. 2009

Website: mimomonitors.com

Key Highlights: Enhance your productivity with monitors and displays from Mimo. They are used in various industries, including hospitality and entertainment….

Expert Sourcing Insights for Industrial Touch Screen Monitor

2026 Market Trends for Industrial Touch Screen Monitor

Growing Demand in Automation and Industry 4.0

The industrial touch screen monitor market is poised for significant growth by 2026, driven primarily by the global expansion of Industry 4.0 and smart manufacturing initiatives. As factories increasingly adopt automation, real-time data monitoring, and interconnected systems, the need for reliable, durable human-machine interface (HMI) devices intensifies. Industrial touch screen monitors serve as critical control hubs in automated environments, enabling operators to manage machinery, monitor performance, and respond to alerts efficiently. According to market research, the global industrial HMI market is projected to grow at a CAGR of over 7% from 2022 to 2026, with touch screen monitors representing a dominant segment.

Advancements in Display and Touch Technology

By 2026, industrial touch screen monitors will feature next-generation technologies such as OLED, high-brightness LCDs, and advanced multi-touch capabilities. These improvements enhance visibility in challenging environments—such as direct sunlight or low-light conditions—and support glove or stylus input for use in protective gear. Capacitive touch technology is gaining favor over resistive due to its superior responsiveness, durability, and support for gesture-based controls. Additionally, integration with AI-driven diagnostics and predictive maintenance systems will make these monitors more intelligent, enabling proactive equipment management and reducing downtime.

Expansion in Key End-Use Industries

The manufacturing, logistics, energy, and healthcare sectors are expected to be major drivers of demand for industrial touch screen monitors. In manufacturing, monitors are embedded in robotic cells and assembly lines. In logistics, they are used in warehouse management systems and automated guided vehicles (AGVs). The energy sector utilizes these monitors in control rooms for power generation and distribution, while healthcare applications include medical equipment interfaces and patient data stations. Emerging markets in Asia-Pacific and Latin America are also contributing to increased adoption, particularly as industrial infrastructure modernizes.

Emphasis on Cybersecurity and Connectivity

With the rise of connected industrial systems, cybersecurity is becoming a top priority. By 2026, industrial touch screen monitors will increasingly incorporate secure boot processes, encrypted communication protocols, and integration with industrial IoT (IIoT) platforms that comply with international security standards. Connectivity features such as Ethernet, Wi-Fi 6, 5G readiness, and support for edge computing will enable seamless data exchange between monitors and central control systems, facilitating faster decision-making and remote monitoring.

Customization and Ruggedization Trends

Industrial environments demand robustness. As a result, manufacturers are focusing on ruggedized designs that withstand extreme temperatures, vibration, dust, and moisture. Customization options—such as screen size (ranging from 7” to 24”), mounting configurations (panel, wall, or arm), and compliance with IP65/NEMA 4 ratings—are becoming standard offerings. This trend allows businesses to deploy monitors tailored to specific operational needs, improving usability and longevity.

Sustainability and Energy Efficiency

Sustainability is emerging as a key consideration in industrial equipment procurement. By 2026, manufacturers of industrial touch screen monitors are expected to prioritize energy-efficient components, recyclable materials, and longer product lifecycles to meet corporate ESG (Environmental, Social, and Governance) goals. Low-power displays and adaptive brightness controls will help reduce energy consumption in continuous-operation settings.

Conclusion

The 2026 industrial touch screen monitor market will be shaped by digital transformation, technological innovation, and sector-specific demands. As industries move toward smarter, more connected operations, these monitors will evolve beyond simple display devices into intelligent, secure, and integral components of industrial ecosystems. Companies that invest in advanced, adaptable, and secure touch screen solutions will be well-positioned to capitalize on this growing market.

Common Pitfalls When Sourcing Industrial Touch Screen Monitors (Quality, IP Rating)

Sourcing industrial touch screen monitors requires careful consideration to ensure reliability and longevity in demanding environments. Overlooking key factors related to quality and Ingress Protection (IP) ratings can lead to costly failures and downtime. Below are common pitfalls to avoid:

Overlooking True Industrial-Grade Components

Many suppliers market commercial-grade monitors as “industrial,” but true industrial monitors use components designed for extended temperature ranges, shock, and vibration resistance. Using consumer-grade parts can result in premature failure under harsh conditions.

Misunderstanding IP Rating Requirements

A common mistake is selecting a monitor with an IP rating that doesn’t match the actual environmental exposure. For example, choosing IP65 instead of IP66 or IP69K in high-pressure washdown environments (e.g., food processing) can lead to water ingress and damage.

Ignoring NEMA Equivalents and Application Context

While IP ratings are widely used, some industries (especially in North America) rely on NEMA ratings. Failing to cross-reference IP with NEMA standards may result in inadequate protection against dust, water, or corrosion in specific applications.

Assuming Touchscreen Technology is Universally Suitable

Different touch technologies (resistive, capacitive, projected capacitive, infrared) have varying performance under gloves, moisture, or extreme temperatures. Choosing the wrong type—such as standard capacitive screens in wet or gloved environments—can severely impact usability.

Neglecting Build Quality and Sealing Integrity

Even with high IP ratings, poor manufacturing—such as inadequate gasketing, substandard bezel materials, or improper assembly—can compromise the seal over time. Quality varies significantly between manufacturers, so third-party certifications or independent testing may be necessary.

Overlooking Certification and Compliance Needs

Industrial settings often require certifications like UL, CE, or ATEX for hazardous environments. Sourcing a monitor without verifying compliance can lead to safety risks and regulatory non-compliance.

Focusing Only on Front Panel IP Rating

The IP rating typically applies only to the front of the monitor. If the back or sides are exposed to contaminants, insufficient sealing in those areas can allow dust or moisture ingress. Ensure full enclosure protection is considered.

Underestimating Thermal Management

Industrial environments can expose monitors to extreme temperatures. Without proper heat dissipation or wide operating temperature support, internal components can degrade rapidly, even if the IP rating suggests environmental resilience.

Choosing Based Solely on Price

Opting for the lowest-cost option often sacrifices durability, support, and long-term reliability. Lower-cost units may use inferior glass, weaker processors, or lack thorough testing, increasing total cost of ownership due to frequent replacements.

Failing to Verify Long-Term Availability and Support

Industrial projects often require long lifecycles. Sourcing from suppliers without product longevity guarantees or discontinuation risks can lead to maintenance challenges and compatibility issues years down the line.

Avoiding these pitfalls requires due diligence, clear understanding of environmental demands, and working with reputable suppliers who provide verifiable specifications and real-world performance data.

Logistics & Compliance Guide for Industrial Touch Screen Monitors

Overview

Industrial touch screen monitors are specialized electronic devices designed for harsh environments, offering durability, reliability, and long-term performance in industrial applications. Proper logistics planning and regulatory compliance are critical to ensure timely delivery, legal import/export, and safe operation. This guide outlines key considerations for the logistics and compliance of industrial touch screen monitors.

Packaging & Handling

Use robust, shock-resistant packaging materials such as double-wall corrugated cardboard with ESD (electrostatic discharge) protection. Include corner protectors and foam inserts to prevent vibration and impact damage during transit. Clearly label packages with “Fragile,” “This Side Up,” and “Protect from Moisture” indicators. Avoid stacking excessive weight on packages and ensure temperature-controlled environments when shipping through extreme climates.

Transportation & Shipping

Ship via freight carriers experienced in handling industrial electronics. Choose air freight for urgent deliveries or international shipments requiring faster turnaround; use sea freight for bulk orders to reduce costs. Ensure all shipments comply with IATA (air) or IMDG (sea) regulations if batteries or hazardous components are included. Maintain a chain of custody and use real-time tracking for high-value or mission-critical equipment.

Import/Export Compliance

Verify the HS (Harmonized System) code for industrial touch screen monitors—typically 8528.59.xx (varies by region and specification). Obtain necessary export licenses if shipping to embargoed or restricted countries. Comply with EAR (Export Administration Regulations) for U.S. exports and ensure end-use statements are available when required. Complete accurate commercial invoices, packing lists, and certificates of origin for customs clearance.

Regulatory Certifications

Ensure monitors meet essential compliance standards prior to market entry:

– CE Marking (EU): Complies with the EMC Directive, RoHS, and Low Voltage Directive.

– FCC (USA): Meets Part 15 Class A for industrial environments (EMI/RFI standards).

– UL/CSA (North America): Certified for safety under UL 61010-1 or similar standards.

– REACH (EU): Confirms absence of restricted hazardous substances.

– IP Rating: Verify environmental protection (e.g., IP65 for dust/water resistance).

Maintain up-to-date technical documentation and certificates for audit purposes.

Environmental & Safety Compliance

Adhere to RoHS (Restriction of Hazardous Substances) to limit lead, mercury, cadmium, and other harmful materials. Comply with WEEE (Waste Electrical and Electronic Equipment) directives by providing take-back or recycling options in applicable regions. Implement proper disposal protocols and ensure user manuals include EOL (end-of-life) handling instructions.

Documentation & Recordkeeping

Keep comprehensive records including:

– Product compliance certificates (CE, FCC, UL, etc.)

– Test reports from accredited laboratories

– Bill of Materials (BOM) with substance declarations

– Shipping and customs documentation

– Warranty and service information

Retain records for a minimum of 10 years to support audits and product traceability.

Conclusion

Effective logistics and strict compliance are essential for the successful deployment of industrial touch screen monitors globally. By adhering to packaging best practices, transportation standards, and regional regulations, manufacturers and distributors can ensure product integrity, avoid customs delays, and meet legal and environmental responsibilities. Regular audits and staying updated with regulatory changes will further mitigate risks and support long-term market access.

In conclusion, sourcing an industrial touch screen monitor requires careful consideration of several critical factors including durability, environmental resistance, touchscreen technology, connectivity options, scalability, and total cost of ownership. Industrial environments demand rugged, reliable displays capable of withstanding extreme temperatures, dust, moisture, and constant use. Choosing the right touch technology—such as resistive, capacitive, or projected capacitive—depends on user needs, gloved operation requirements, and precision. Additionally, compatibility with existing systems, future-proofing through modular design, and vendor support are essential for long-term performance and ease of maintenance.

Conducting thorough supplier evaluations, reviewing certifications (such as IP65 or NEMA), and testing units in real-world conditions can mitigate risks and ensure optimal performance. Ultimately, investing time and resources in selecting the right industrial touch screen monitor contributes to improved operational efficiency, reduced downtime, and a stronger return on investment across industrial applications such as manufacturing, automation, healthcare, and logistics.