The global ultrasonic cleaning equipment market is experiencing robust expansion, driven by rising demand for precision cleaning solutions across industries such as automotive, healthcare, electronics, and aerospace. According to a 2023 report by Mordor Intelligence, the market was valued at USD 2.15 billion in 2022 and is projected to grow at a CAGR of 5.8% through 2028, reaching an estimated value of USD 3.02 billion. This growth is fueled by advancements in cleaning technology, increasing regulatory standards for hygiene and contamination control, and the integration of automation in manufacturing processes. As industries continue to prioritize efficiency, repeatability, and environmental sustainability, the role of industrial sonic cleaners has become increasingly critical. In this evolving landscape, a select group of manufacturers has emerged as leaders, combining innovation, scalability, and reliability to meet global demand. Below are the top 10 industrial sonic cleaner manufacturers shaping the future of precision cleaning.

Top 10 Industrial Sonic Cleaner Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Crest Ultrasonics

Domain Est. 1996

Website: crest-ultrasonics.com

Key Highlights: Based in the U.S., Crest Ultrasonics is one of the largest private industrial ultrasonic cleaner manufacturers in the world. Call for equipment & chemicals….

#2 Industrial Ultrasonic Cleaner Manufacturer

Domain Est. 1997

Website: upcorp.com

Key Highlights: Ultrasonic Power Corp. manufactures and supplies top-of-the-line industrial and commercial ultrasonic cleaners. Contact our team for a quote today!…

#3 Skymen Ultrasonic

Domain Est. 2022

Website: skymensonic.com

Key Highlights: Skymen, leading ultrasonic cleaner manufacturer, provides professional ultrasonic cleaners for household, commercial, and industrial cleaning worldwide….

#4 L&R Manufacturing

Domain Est. 1996

Website: lrultrasonics.com

Key Highlights: L&R, the leader in manufacturing and distribution of Ultrasonic Cleaning systems. Serving dental, medical, jewelry, watches, firearms, industrial, rescue, ……

#5 Ultrasonic Processors & Equipment

Domain Est. 1996 | Founded: 1969

Website: sonics.com

Key Highlights: Ultrasonic Welding. Made in the USA since 1969. Sonics is a global leader in the design, development and manufacturing of high-powered ultrasonic equipment….

#6 Designer/Manufacturer of ultrasonic cleaning machines

Domain Est. 1996

Website: fisa.com

Key Highlights: FISA Group has specialized in R&D, design, engineering, production, sales and technical support of custom-built ultrasonic cleaning and coating machines ……

#7 UCM Precision Cleaning

Domain Est. 1998

Website: ucm-ag.com

Key Highlights: UCM is manufacturer of ultrasonic precision parts cleaning machines. Its globally leading solutions help companies around the world in achieving highest ……

#8 Ultrasonic Parts Cleaner

Domain Est. 2000

Website: sonicpro.com

Key Highlights: Ultrasonics International offers Ultrasonic Parts Cleaners, Ultrasonic Fire Restoration Equipment and Industrial Ultrasonic Cleaning Systems….

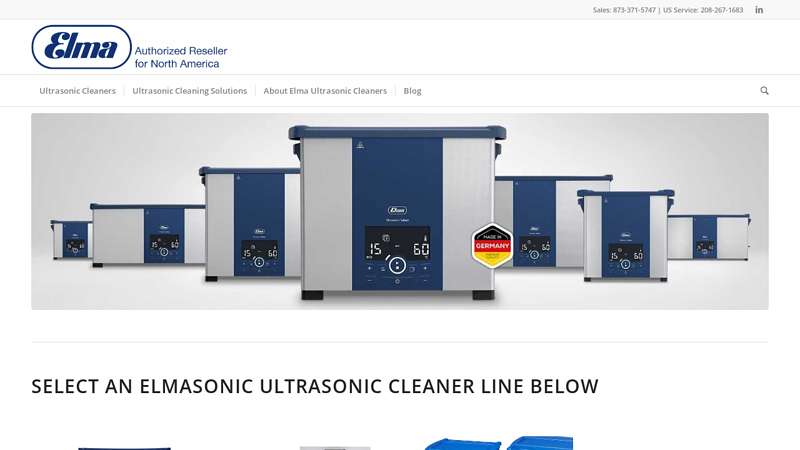

#9 Elma Ultrasonic Cleaners

Domain Est. 2009

Website: elmaultrasonic.com

Key Highlights: Elma Ultrasonic Cleaners provide the best solutions for highly sensitive lab applications and industrial/manufacturing parts cleaning….

#10 Ultrasonic Tabletop Cleaners for Laboratories

Domain Est. 1995

Website: emerson.com

Key Highlights: Keep laboratory equipment clean and contaminant-free with ultrasonic cleaning baths. CPX and M Series tabletop cleaners from Bransonic offer superior features….

Expert Sourcing Insights for Industrial Sonic Cleaner

H2: 2026 Market Trends for Industrial Sonic Cleaners

The industrial sonic cleaner market is poised for significant transformation by 2026, driven by technological advancements, evolving industrial demands, and a heightened focus on sustainability. Key trends shaping the landscape include:

1. Technological Advancements & Smart Integration:

Industrial sonic cleaning systems will increasingly incorporate IoT connectivity, AI-driven process optimization, and real-time monitoring capabilities. By 2026, predictive maintenance algorithms and cloud-based analytics will enable manufacturers to optimize cleaning cycles, reduce downtime, and ensure consistent cleaning quality—especially vital in high-precision sectors like aerospace, medical devices, and semiconductors.

2. Demand from High-Tech Manufacturing:

Growth in sectors such as electric vehicles (EVs), renewable energy (e.g., solar panel and battery production), and advanced electronics will drive demand for precision cleaning. Sonic cleaners capable of removing microscopic contaminants from complex components (e.g., fuel injectors, battery contacts, optical sensors) will see rising adoption, emphasizing reliability and repeatability.

3. Sustainability and Eco-Friendly Solutions:

Environmental regulations and corporate ESG goals will push the market toward water-based, biodegradable cleaning chemistries and energy-efficient ultrasonic systems. Closed-loop recycling and reduced solvent usage will become standard, with manufacturers offering “green” cleaning solutions that minimize waste and environmental impact.

4. Customization and Modular Designs:

As industrial applications diversify, one-size-fits-all systems will give way to modular, scalable sonic cleaners tailored to specific workflows. Customizable frequency ranges (e.g., dual-frequency or swept-frequency systems), tank sizes, and automation integration will allow industries to adapt cleaning processes to unique part geometries and production volumes.

5. Expansion in Emerging Markets:

Asia-Pacific—particularly China, India, and Southeast Asia—will lead market growth due to rapid industrialization, infrastructure development, and expanding manufacturing bases. Local production of sonic cleaning equipment and rising investments in healthcare and electronics will fuel regional demand.

6. Regulatory Compliance and Industry Standards:

Stringent cleanliness standards in pharmaceuticals, food processing, and medical device manufacturing will require validated cleaning processes. By 2026, industrial sonic cleaners will increasingly come with documentation packages and compliance features (e.g., 21 CFR Part 11 compliance) to meet regulatory audits and quality assurance requirements.

In summary, the 2026 industrial sonic cleaner market will be defined by smarter, greener, and more adaptable systems, serving a broadening array of high-precision industries and global manufacturing hubs. Companies that innovate in automation, sustainability, and application-specific solutions will be best positioned to capture market share.

Common Pitfalls When Sourcing Industrial Sonic Cleaners (Quality & IP)

Sourcing industrial sonic (ultrasonic) cleaners involves more than just comparing prices and specifications. Critical risks related to quality control and intellectual property (IP) can lead to operational failures, legal disputes, and reputational damage. Being aware of these common pitfalls is essential for making informed procurement decisions.

Poor Build Quality and Material Selection

Many low-cost suppliers use substandard materials—such as thin-gauge stainless steel, inferior transducers, or weak tank welds—that degrade quickly under industrial use. This leads to premature failure, contamination risks, and inconsistent cleaning performance. Always verify material specifications (e.g., 304 or 316L stainless steel) and request third-party test reports or samples before bulk orders.

Inaccurate or Misrepresented Cleaning Performance

Some suppliers exaggerate key performance metrics like ultrasonic frequency (e.g., claiming 40 kHz when it’s actually 25 kHz), power density, or cleaning capacity. This can result in ineffective cleaning for your specific application (e.g., medical device cleaning or precision parts). Demand independent performance validation and conduct on-site testing if possible.

Lack of Compliance with Industry Standards

Industrial applications often require adherence to standards such as ISO 9001, CE, UL, or specific safety regulations. Sourcing from non-compliant suppliers risks equipment failure, safety hazards, or non-approval in regulated environments (e.g., pharmaceuticals or aerospace). Confirm certifications and audit the manufacturer’s quality management system.

Inadequate After-Sales Support and Spare Parts Availability

Many overseas or low-cost suppliers lack robust technical support, making troubleshooting difficult. Moreover, spare parts (especially transducers or generators) may be unavailable or incompatible, leading to extended downtime. Ensure the supplier offers clear service agreements and maintains an accessible inventory of critical components.

Intellectual Property (IP) Infringement Risks

Purchasing from suppliers that replicate patented designs or use counterfeit control systems exposes your company to legal liability. Some manufacturers reverse-engineer branded models, violating IP rights. Always vet suppliers for original design capabilities and request documentation proving IP legitimacy (e.g., design patents, trademarks).

Hidden Technology Limitations

Some ultrasonic cleaners use outdated or poorly integrated technology, such as analog generators without frequency sweeping or digital feedback, reducing cleaning efficiency and lifespan. Suppliers may not disclose these limitations. Request detailed technical documentation and evaluate control system sophistication.

Insufficient Documentation and Traceability

Poor record-keeping on manufacturing processes, component sourcing, or calibration data undermines quality traceability and compliance audits. This is especially critical in regulated industries. Require full documentation packages, including material certifications, test logs, and calibration reports.

By proactively addressing these pitfalls—through rigorous supplier vetting, independent testing, and robust contractual safeguards—businesses can ensure they source reliable, compliant, and legally sound industrial sonic cleaning solutions.

Logistics & Compliance Guide for Industrial Sonic Cleaner

Product Overview and Classification

The Industrial Sonic Cleaner is a heavy-duty cleaning device utilizing high-frequency sound waves to remove contaminants from industrial parts and components. It is typically used in manufacturing, maintenance, and repair operations. The equipment falls under industrial machinery and is subject to specific transportation, handling, and regulatory compliance standards.

Regulatory Compliance Requirements

Industrial Sonic Cleaners must comply with several international and regional regulations:

– Electrical Safety Standards: Must meet IEC 60204-1 (Safety of Machinery – Electrical Equipment of Machines) and relevant regional standards such as UL 60950-1 (USA) or CE marking requirements under the EU Machinery Directive (2006/42/EC).

– EMC Compliance: Complies with electromagnetic compatibility standards such as FCC Part 15 (USA) and EN 55011 (EU) to prevent interference with other electronic devices.

– RoHS and REACH: Adheres to Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulations for material safety.

– WEEE Directive (EU): Must be labeled and registered for proper end-of-life disposal and recycling.

Ensure all compliance documentation, including Declaration of Conformity (DoC), is available prior to shipment.

Packaging and Handling Instructions

Proper packaging is critical to prevent damage during transport:

– Use wooden crates or heavy-duty corrugated cardboard with internal foam or padding to secure the unit.

– Remove or secure all loose components (baskets, power cords) using anti-vibration fasteners.

– Clearly label packages with “Fragile,” “This Side Up,” and “Do Not Stack” indicators.

– Include desiccant packs to prevent moisture buildup during transit.

Handle with mechanical equipment (e.g., forklift or pallet jack); the unit is heavy and should not be manually lifted.

Transportation and Shipping

- Mode of Transport: Suitable for road, sea, and air freight. Air transport requires special approval due to battery or electrical components (if applicable).

- Hazardous Materials: The cleaner itself is non-hazardous, but cleaning solutions (if shipped with the unit) may be classified as hazardous. Verify SDS (Safety Data Sheet) before shipping.

- UN Number and Packaging Group: If transporting with flammable or corrosive cleaning agents, comply with IATA (air), IMDG (sea), or ADR (road) regulations.

- Export Controls: Check for ITAR or dual-use regulations if the equipment contains advanced technology subject to export restrictions.

Import and Customs Clearance

- HS Code: Use Harmonized System code 8479.89 (Machines of a kind used in industrial cleaning processes). Confirm local classification with customs broker.

- Required Documentation: Commercial invoice, packing list, bill of lading/air waybill, certificate of origin, and compliance certificates (CE, UL, etc.).

- Duties and Taxes: Rates vary by country. Consult local authorities or customs agent for accurate assessment.

- Inspection Requirements: Some countries may require pre-shipment inspection or conformity assessment (e.g., SONCAP for Nigeria, SASO for Saudi Arabia).

Installation and On-Site Compliance

- Installation must be performed by qualified personnel in accordance with local electrical codes (e.g., NEC in the USA, IEC in Europe).

- Ensure proper grounding and use of GFCI protection where required.

- Maintain clear ventilation space around the unit to prevent overheating.

- Conduct initial safety inspection and document operational compliance with OSHA (USA) or equivalent workplace safety regulations.

Maintenance and Environmental Considerations

- Follow manufacturer-recommended maintenance schedules for transducers, tanks, and electrical systems.

- Dispose of used cleaning solutions in accordance with local environmental regulations (e.g., EPA in the USA, Environment Agency in the UK).

- Recycle metal and electronic components through certified e-waste handlers.

Training and Documentation

Provide operators with training on safe operation, emergency shutdown, and compliance with PPE (Personal Protective Equipment) requirements. Retain records of training, maintenance, and compliance audits for minimum of five years.

Emergency and Incident Response

- In case of electrical fault or fluid leak, shut down immediately and isolate power.

- Equip facility with spill kits if using hazardous cleaning agents.

- Report any non-compliance or safety incidents to relevant authorities as required by local law.

Adherence to this guide ensures safe, legal, and efficient deployment of Industrial Sonic Cleaners across global operations.

Conclusion:

Sourcing an industrial sonic cleaner requires a thorough evaluation of application needs, equipment specifications, and supplier reliability. It is essential to prioritize cleaning efficiency, tank capacity, frequency range, material durability, and safety features to ensure optimal performance and longevity. Conducting due diligence on potential suppliers—assessing their reputation, technical support, warranty offerings, and compliance with industry standards—helps mitigate risks and ensures long-term satisfaction. By aligning the selection process with operational requirements and total cost of ownership, organizations can effectively integrate a reliable and efficient ultrasonic cleaning solution that enhances productivity, maintains quality standards, and supports sustainable manufacturing practices.