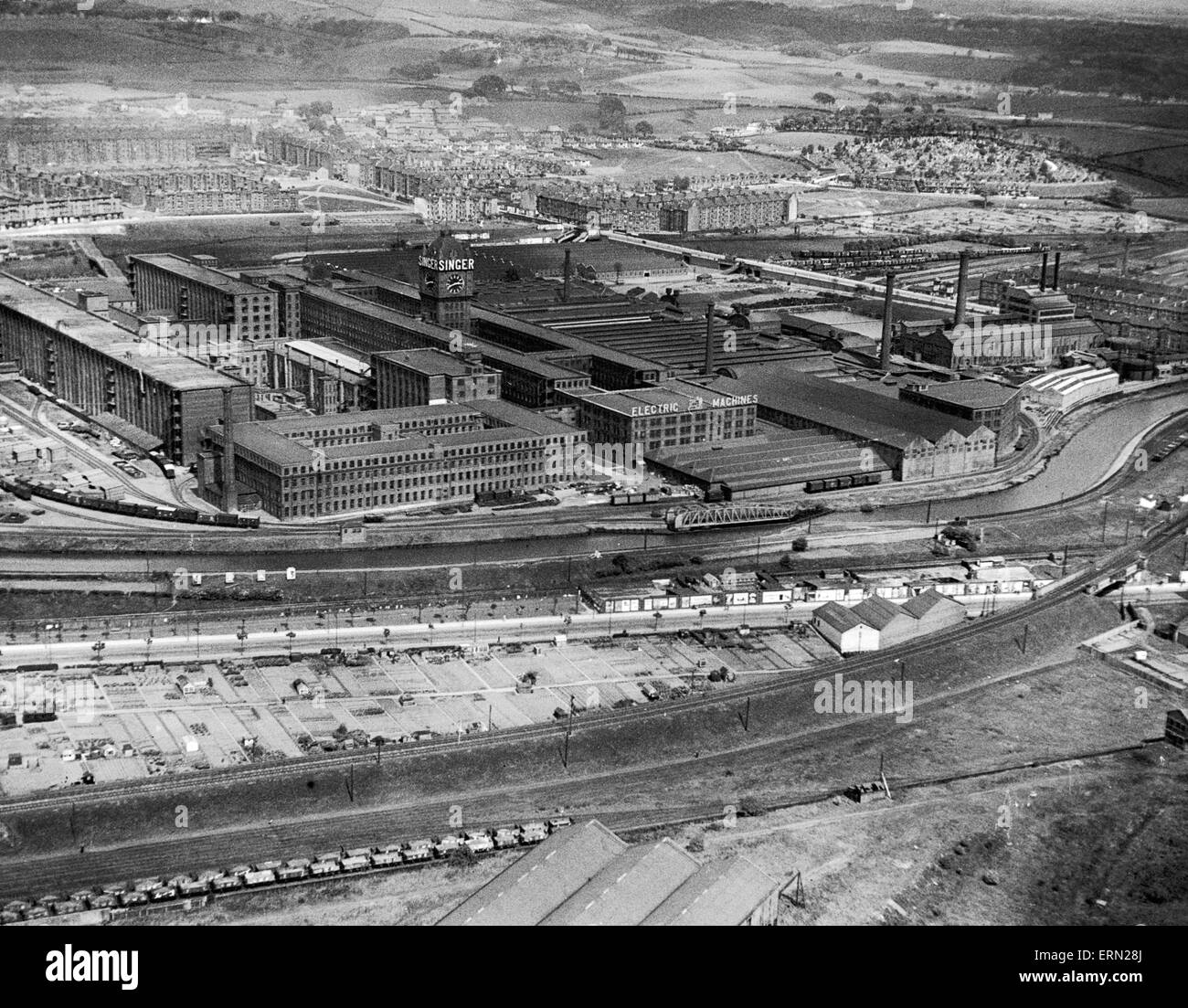

The global industrial sewing machine market is experiencing steady growth, driven by rising demand from the apparel, automotive, and technical textiles sectors. According to a report by Grand View Research, the global industrial sewing machine market was valued at USD 4.2 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by increasing automation in garment manufacturing, rising labor costs, and the need for high-speed, precision stitching in industrial applications. As leading manufacturers innovate with computerized controls, energy-efficient designs, and IoT integration, competition is intensifying among key players. In this evolving landscape, eight industrial Singer sewing machine manufacturers stand out for their technological advancements, production capacity, and global market reach—shaping the future of industrial stitching solutions.

Top 8 Industrial Singer Sewing Machines Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Singer Industrial Sewing Machine Models and Accessories

Domain Est. 1996

Website: ismacs.net

Key Highlights: Comprehensive reference guide to Singer industrial sewing machine models from 1900-1970, featuring specialized machines for manufacturing and their ……

#2 Industrial Sewing Machines, singeronline.com

Domain Est. 1998

Website: singeronline.com

Key Highlights: Free delivery over $35 · 30-day returnsThe Industrial Sewing Machines Featured Here are High-Performance Precision Machines Designed for Commercial Sewing Applications of any Kind…

#3 About Us Company Page

Domain Est. 2000

Website: singermachines.co.uk

Key Highlights: We are singermachines.co.uk, the original Singer Sewing Machine online shop. We are not the manufacturer of Singer sewing machines (SVP Worldwide), nor are we ……

#4 Singer Industrial Sewing Machines

#5 SINGER – Sewing & Embroidery

Domain Est. 1995

Website: uk.singer.com

Key Highlights: SINGER sewing, embroidery, heavy duty, overlock and serger machines are easy to use yet packed with powerful features for every type of sewist….

#6 Singer Equipment Co.

Domain Est. 1999

Website: singerequipment.com

Key Highlights: From commercial kitchen design and construction to one-stop wholesale supply, Singer delivers a history of success across the foodservice industry….

#7 SVP Worldwide

Domain Est. 2006

Website: svpworldwide.com

Key Highlights: Since 1851, SINGER® has been one of the leading brands of consumer and artisan sewing machines, and one of the world’s most trusted and recognizable brands….

#8 Singer Sewing Info

Domain Est. 2011

Website: singersewinginfo.co.uk

Key Highlights: Singer sewing machine information site for sewing machines incl. 221, 222K. Also covers accessories, Toy sewing machines (TSM)and antique sewing machines….

Expert Sourcing Insights for Industrial Singer Sewing Machines

H2: 2026 Market Trends for Industrial Singer Sewing Machines

The global market for industrial Singer sewing machines is poised for notable transformation by 2026, influenced by technological advancements, shifting manufacturing landscapes, and growing demand across key end-use industries. Several emerging trends are expected to shape the trajectory of Singer’s industrial sewing machine segment over the next few years.

1. Increasing Automation and Smart Manufacturing Integration

By 2026, automation will play a central role in the adoption of industrial sewing machines. Singer is anticipated to expand its portfolio of computerized and IoT-enabled sewing systems that support Industry 4.0 initiatives. These smart machines offer real-time performance monitoring, predictive maintenance, and seamless integration with enterprise resource planning (ERP) systems, especially appealing to large-scale apparel and textile manufacturers aiming to boost efficiency and reduce downtime.

2. Growth in the Apparel and Technical Textiles Sectors

The rising demand for fast fashion and customized garments, particularly in Asia-Pacific and emerging markets, will drive the need for high-speed, durable industrial sewing machines. Additionally, the expansion of technical textiles—used in automotive, medical, and protective gear applications—will create new opportunities for Singer to cater to specialized stitching requirements, such as heavy-duty seams and precision embroidery.

3. Sustainability and Energy Efficiency Focus

Environmental regulations and consumer pressure are pushing manufacturers toward sustainable production methods. In response, Singer is expected to emphasize energy-efficient motor systems, reduced waste through precision stitching, and longer product lifecycles in its industrial machines. By 2026, eco-conscious features will likely become a key differentiator in procurement decisions, especially among Western brands committed to green supply chains.

4. Regional Market Shifts and Localization Strategies

While traditional manufacturing hubs like China and India remain critical, rising labor costs and geopolitical factors are prompting production diversification into countries like Vietnam, Bangladesh, and Ethiopia. Singer may adapt by strengthening local distribution networks, offering region-specific machine configurations, and providing enhanced after-sales support to maintain competitiveness in these evolving markets.

5. Enhanced Training and Digital Support Services

As machines become more complex, demand for technical support and operator training will grow. Singer is likely to invest in digital platforms offering remote diagnostics, online training modules, and augmented reality (AR)-assisted maintenance by 2026. These services will help manufacturers maximize uptime and optimize workforce capabilities, particularly in regions with skill shortages.

6. Competitive Pressure from Regional and Niche Brands

Singer will face intensified competition from cost-effective alternatives offered by Chinese and European manufacturers. To retain market share, the brand may focus on its legacy of reliability, superior build quality, and brand trust—especially in mid-to-high-end industrial segments.

In summary, the 2026 outlook for industrial Singer sewing machines reflects a market driven by innovation, sustainability, and globalization. By embracing digital transformation and responding to sector-specific demands, Singer is well-positioned to maintain relevance in an increasingly competitive and dynamic industrial textile machinery landscape.

Common Pitfalls When Sourcing Industrial Singer Sewing Machines (Quality and Intellectual Property)

Sourcing industrial Singer sewing machines can be a smart investment for manufacturing operations, but it comes with significant risks—especially concerning product quality and intellectual property (IP) rights. Being aware of these common pitfalls helps avoid costly mistakes and potential legal issues.

Misidentifying Genuine vs. Counterfeit Machines

One of the most prevalent risks is purchasing counterfeit or imitation machines falsely branded as “Singer.” Many suppliers, especially on international marketplaces, sell machines that resemble Singer models but are produced by unauthorized manufacturers. These counterfeit units often use substandard materials and lack the precision engineering of authentic Singer equipment, leading to poor stitch quality, frequent breakdowns, and higher long-term maintenance costs. Buyers may not realize they’ve purchased a fake until operational issues arise.

Confusion Around Brand Ownership and Licensing

The Singer brand has changed hands multiple times, and industrial machine production is no longer handled directly by the original company. Today, authorized industrial models may be manufactured under license by third parties in specific regions. However, unauthorized manufacturers often exploit brand recognition by producing “Singer-style” machines without proper licensing. This creates IP infringement risks for buyers who import or distribute these machines, particularly in regions with strict trademark enforcement.

Compromised Build Quality in Lower-Cost Alternatives

Even machines that are not outright counterfeit may be inferior clones or “Singer-compatible” models marketed as budget alternatives. These often feature weaker motors, lower-grade metal components, and inconsistent tension control. While they may appear functional initially, their reduced durability leads to downtime and increased repair costs, ultimately offsetting any initial savings.

Lack of Warranty and After-Sales Support

Genuine industrial Singer machines typically come with manufacturer warranties and access to technical support, spare parts, and service networks. Counterfeit or unlicensed versions usually lack these benefits. Buyers may find it difficult or impossible to source genuine replacement parts or obtain qualified repairs, resulting in extended machine downtime and lost productivity.

IP Infringement Risks in Import and Distribution

Importing or reselling machines that infringe on Singer’s trademarks or patented designs can expose businesses to legal action, customs seizures, and financial penalties. Customs authorities in many countries actively monitor for IP violations, and companies found distributing counterfeit industrial equipment may face fines, reputational damage, or forced product recalls.

Inadequate Verification of Supplier Credentials

Many buyers source machines through third-party suppliers or online platforms without verifying the supplier’s authorization to sell genuine Singer products. Lack of due diligence—such as checking for official distributor certifications or contacting Singer directly—increases the risk of inadvertently purchasing infringing or low-quality machines.

Overlooking Regional Trademark Protections

Trademark rights are territorial. A machine legally sold under the Singer name in one country may infringe on registered trademarks in another. Companies sourcing globally must ensure that the machines they import are authorized for sale in their target market to avoid IP violations.

Conclusion

To mitigate these risks, buyers should purchase industrial Singer sewing machines only through authorized distributors, verify product authenticity with Singer’s official channels, and conduct thorough due diligence on suppliers. Prioritizing genuine equipment protects both operational efficiency and legal compliance.

Logistics & Compliance Guide for Industrial Singer Sewing Machines

Overview

Industrial Singer sewing machines are heavy-duty equipment used in manufacturing, garment production, and textile industries. Proper logistics handling and compliance with international and local regulations are essential to ensure safe transportation, customs clearance, and operational legality. This guide provides structured guidance for shipping, handling, and regulatory compliance.

Packaging and Handling Requirements

Industrial sewing machines must be securely packaged to prevent damage during transit. Key practices include:

– Use of sturdy wooden crates or palletized packaging with corner protectors.

– Internal cushioning with foam, bubble wrap, or air bags to protect sensitive components.

– Securing motors, needles, and control panels with protective caps or fasteners.

– Labeling packages with “Fragile,” “This Side Up,” and weight specifications.

– Compliance with ISTA (International Safe Transit Association) standards for testing.

Transportation Methods

Choose the appropriate shipping mode based on urgency, distance, and cost:

– Air Freight: For urgent deliveries; requires compliance with IATA Dangerous Goods Regulations if batteries or lubricants are included.

– Ocean Freight (FCL/LCL): Cost-effective for bulk shipments; machines must be moisture-protected and secured against saltwater exposure.

– Land Freight (Truck/Rail): Suitable for regional distribution; ensure shock absorption and proper load securing using straps or load locks.

Customs Clearance and Documentation

To ensure smooth customs processing, include the following documents:

– Commercial Invoice (specifying item description, value, quantity, and HS code).

– Packing List (with dimensions, weight, and packaging details).

– Bill of Lading (for ocean) or Air Waybill (for air).

– Certificate of Origin (may be required for tariff preferences).

– Import License (if required by destination country).

– Technical Specifications Sheet (for classification and compliance verification).

Harmonized System (HS) Code Classification

Industrial Singer sewing machines typically fall under:

– HS Code 8452.21 – Sewing machines, for apparel and textile production.

Accurate classification ensures correct duty assessment and compliance with trade agreements.

Import Regulations and Duties

Compliance with destination country regulations is critical:

– Verify local import restrictions or licensing requirements (e.g., India’s BIS certification or China’s CCC mark may apply to electrical components).

– Calculate applicable duties, VAT, or GST based on declared value and HS code.

– Be aware of anti-dumping measures in markets like the EU or USA on machinery from certain countries.

Electrical and Safety Compliance

Industrial sewing machines must meet electrical safety standards in the destination market:

– CE Marking (EU): Compliance with Machinery Directive 2006/42/EC and Low Voltage Directive 2014/35/EU.

– UL/ETL Listing (USA/Canada): Required for electrical safety approval.

– RoHS Compliance: Restriction of hazardous substances in electrical equipment (EU and others).

– Provide user manuals in the local language and include safety warnings and emergency stop details.

Environmental and Disposal Regulations

Adhere to environmental standards for packaging and end-of-life disposal:

– Use recyclable or biodegradable packaging materials where possible.

– Follow WEEE (Waste Electrical and Electronic Equipment) directives in the EU for responsible disposal.

– Include information on proper oil and lubricant disposal in user manuals.

After-Sales Service and Warranty Compliance

Ensure logistics support for spare parts and service:

– Maintain a parts logistics network in key markets.

– Comply with local consumer protection laws regarding warranty duration and service response times.

– Register products with local authorities if required (e.g., Brazil’s INMETRO or Russia’s EAC certification).

Risk Management and Insurance

Protect shipments with comprehensive logistics insurance covering:

– Physical damage, theft, and moisture exposure.

– Customs rejection or delays.

– General Average (for ocean freight).

Ensure declared value reflects replacement cost including freight and duties.

Conclusion

Shipping and deploying industrial Singer sewing machines globally requires meticulous planning in logistics and strict adherence to compliance standards. By following this guide, businesses can minimize delays, reduce costs, and ensure legal and safe delivery of equipment to end users. Regular updates on trade regulations and coordination with certified freight forwarders and customs brokers are recommended.

In conclusion, sourcing industrial singer sewing machines requires a careful evaluation of production needs, machine specifications, and supplier reliability. These robust and high-performance machines are essential for efficient garment manufacturing and other heavy-duty sewing applications. By prioritizing genuine Singer quality, considering both new and certified pre-owned options, and establishing relationships with authorized dealers or reputable suppliers, businesses can ensure long-term durability, performance, and return on investment. Additionally, factoring in after-sales service, warranty, and technical support enhances operational continuity. Ultimately, a strategic sourcing approach enables manufacturers to integrate reliable, high-speed sewing solutions that support scalability, precision, and competitive advantage in the global market.