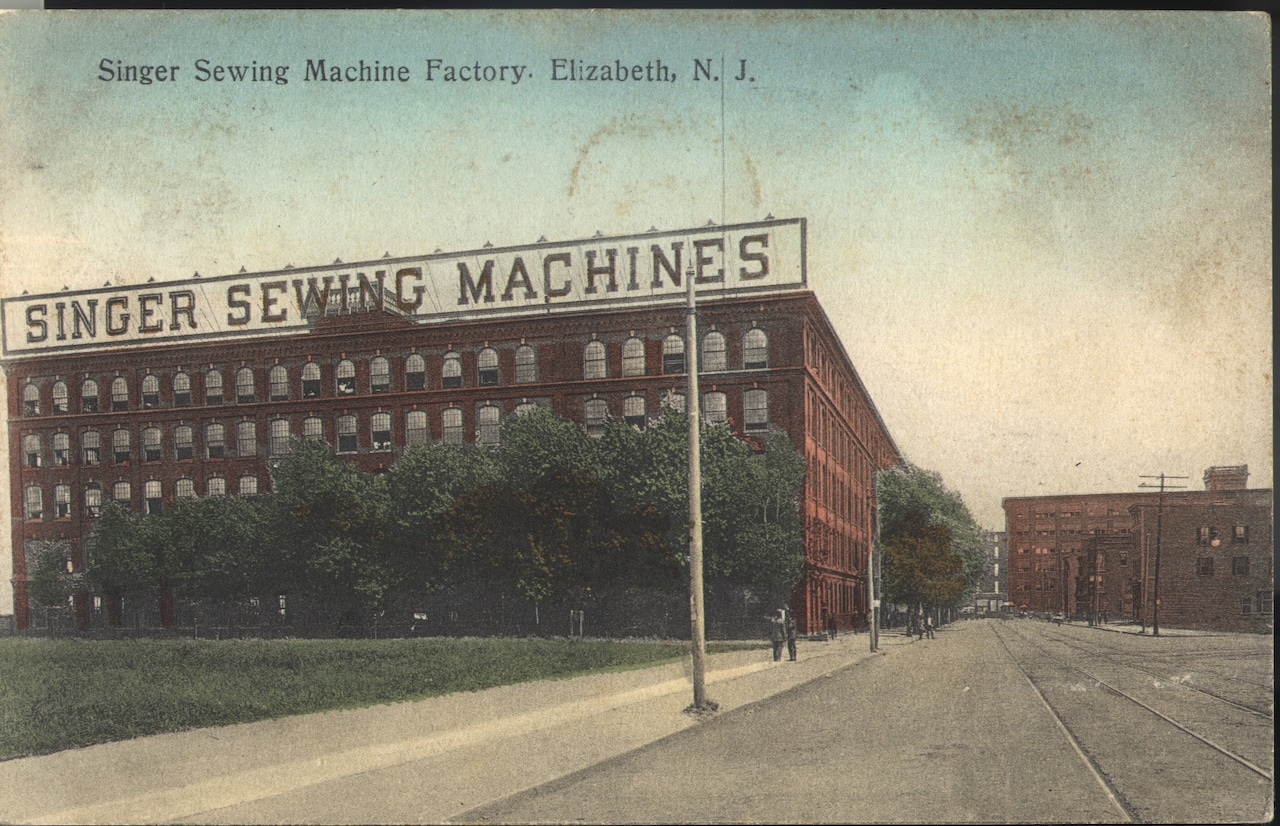

The global industrial sewing machine market is experiencing steady expansion, driven by rising demand from the apparel, automotive, and technical textiles sectors. According to Grand View Research, the market was valued at USD 4.9 billion in 2023 and is projected to grow at a compound annual growth rate (CAGr) of 5.8% from 2024 to 2030. This growth is fueled by increasing automation in garment manufacturing, the need for high-speed and precision stitching, and the expansion of fast fashion supply chains, particularly across Asia-Pacific. As a key player in this landscape, industrial Singer sewing machines continue to represent a blend of legacy innovation and modern engineering, serving large-scale producers and niche manufacturers alike. With intensifying competition and technological advancements—such as servo motors, IoT integration, and energy-efficient designs—evaluating the top manufacturers behind these machines provides critical insight for sourcing decisions, production optimization, and long-term operational efficiency.

Top 10 Industrial Singer Sewing Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 , Commercial & Industrial Sewing Machines Chicago

Domain Est. 2007

Website: singerfactorydistributor.com

Key Highlights: Singer Factory Distributor Regional Sales & Service Center in Chicago offers great prices, award winning service and financing options….

#2 Singer Industrial Sewing Machine Models and Accessories

Domain Est. 1996

Website: ismacs.net

Key Highlights: Comprehensive reference guide to Singer industrial sewing machine models from 1900-1970, featuring specialized machines for manufacturing and their ……

#3 Industrial Sewing Machines, singeronline.com

Domain Est. 1998

Website: singeronline.com

Key Highlights: The Industrial Sewing Machines Featured Here are High-Performance Precision Machines Designed for Commercial Sewing Applications of any Kind….

#4 Singer India

Domain Est. 2004

Website: singerindia.com

Key Highlights: SINGER INDIA is a well-reputed Brand for more than 170 years. Singer is amongst the leading manufacturers of singer sewing machines, home & personal care ……

#5 Singer Industrial Sewing Machines

#6 Heavy Duty Sewing Machines

Domain Est. 1995

Website: singer.com

Key Highlights: Free delivery over $35SINGER® Heavy Duty machines are distinguished by their interior metal frame for durability, a 60% stronger motor for faster sewing speeds ( ……

#7 SINGER – Sewing & Embroidery

Domain Est. 1995

Website: europe.singer.com

Key Highlights: Welcome to the official SINGER website. SINGER sewing machines, embroidery machines, heavy duty machines, overlock machines and serger machines are easy to ……

#8 Singer Equipment Co.

Domain Est. 1999

Website: singerequipment.com

Key Highlights: From commercial kitchen design and construction to one-stop wholesale supply, Singer delivers a history of success across the foodservice industry….

#9 SVP Worldwide

Domain Est. 2006

Website: svpworldwide.com

Key Highlights: Since 1851, SINGER® has been one of the leading brands of consumer and artisan sewing machines, and one of the world’s most trusted and recognizable brands….

#10 Singer Sewing Info

Domain Est. 2011

Website: singersewinginfo.co.uk

Key Highlights: Singer sewing machine information site for sewing machines incl. 221, 222K. Also covers accessories, Toy sewing machines (TSM)and antique sewing machines….

Expert Sourcing Insights for Industrial Singer Sewing Machine

H2: 2026 Market Trends for Industrial Singer Sewing Machines

The industrial sewing machine market, particularly for established brands like Singer, is poised for notable transformation by 2026. Driven by technological innovation, shifting manufacturing demands, and sustainability imperatives, several key trends are expected to shape the landscape for industrial Singer sewing machines.

-

Increased Automation and Smart Technology Integration

By 2026, industrial Singer sewing machines are anticipated to feature greater integration of automation and IoT (Internet of Things) capabilities. Smart sewing systems with real-time performance monitoring, predictive maintenance alerts, and connectivity to factory management software will become standard. These enhancements improve operational efficiency, reduce downtime, and support Industry 4.0 initiatives in textile and apparel manufacturing. -

Demand from Emerging Markets

Growth in the textile and garment sectors across Southeast Asia, Africa, and South America will drive demand for reliable and cost-effective industrial sewing solutions. Singer, with its global brand recognition and durable product line, is well-positioned to capture market share in these regions. Localized service networks and affordable industrial models will be critical to maintaining competitiveness. -

Focus on Energy Efficiency and Sustainability

As environmental regulations tighten, manufacturers will prioritize energy-efficient machinery. Industrial Singer sewing machines are expected to incorporate low-power consumption motors, reduced noise emissions, and eco-friendly materials in construction. Sustainability will also influence product lifecycle management, with greater emphasis on repairability and parts availability. -

Customization and Specialization

The rise of niche apparel markets—such as activewear, technical textiles, and made-to-order fashion—will fuel demand for specialized industrial sewing machines. Singer is likely to expand its range of machines tailored for specific applications (e.g., heavy-duty stitching, leatherwork, or seamless joining), offering modular features that allow customization based on production needs. -

Competition and Market Consolidation

Singer will face intensified competition from both global players (e.g., Juki, Brother, and Pfaff) and emerging regional manufacturers offering lower-cost alternatives. To maintain relevance, Singer may pursue strategic partnerships, digital service platforms, or direct-to-manufacturer sales models to enhance value beyond the hardware. -

Workforce Training and Digital Interfaces

With increasing machine complexity, user-friendly interfaces and integrated training modules will become essential. Industrial Singer machines may include augmented reality (AR) guides or touchscreen dashboards to simplify operation and reduce the learning curve for semi-skilled labor, addressing workforce shortages in the manufacturing sector.

Conclusion:

By 2026, the industrial Singer sewing machine market will be defined by smarter, more efficient, and adaptable machines. Success will depend on Singer’s ability to innovate while maintaining its reputation for reliability and accessibility. Companies that embrace digital transformation and sustainability will lead the next phase of industrial textile production.

Common Pitfalls When Sourcing Industrial Singer Sewing Machines (Quality & IP)

Sourcing industrial Singer sewing machines can be a strategic move for manufacturers and workshops seeking reliable, high-performance equipment. However, navigating this market comes with significant risks—particularly concerning product quality and intellectual property (IP) rights. Being aware of these common pitfalls is essential to avoid costly mistakes and protect your business.

Falling for Counterfeit or Replica Machines

One of the most prevalent risks is inadvertently purchasing counterfeit or replica industrial Singer machines. These machines often mimic the iconic Singer design and branding but lack the engineering, durability, and precision of authentic products. Counterfeits are typically manufactured with substandard materials and components, leading to frequent breakdowns, poor stitch quality, and increased downtime. Worse, they may not comply with safety regulations, posing risks to operators.

Confusing Brand Licensing with Authentic Manufacturing

Singer is a globally recognized brand, and its name is often licensed or misused by third-party manufacturers, especially in regions with lax IP enforcement. You may encounter machines labeled “Singer” that are not produced or authorized by the legitimate rights holder (currently Singer Corporation or its licensed partners). These machines may bear a superficial resemblance to genuine models but lack the proprietary technology and quality control that define authentic industrial Singer equipment.

Overlooking Component and Build Quality

Even machines that appear authentic may vary drastically in quality depending on the manufacturing source. Some suppliers offer machines with inferior motors, thread tension systems, or metal frames that wear out quickly under industrial use. Poorly calibrated machines lead to inconsistent stitching, wasted materials, and higher maintenance costs. Always verify build materials, component specifications, and seek third-party quality certifications before purchase.

Ignoring Intellectual Property Infringement Risks

Purchasing from unauthorized suppliers—especially those offering “Singer-style” machines at suspiciously low prices—can expose your business to IP infringement claims. Using or reselling counterfeit or IP-violating machinery may result in legal action, product seizures, or reputational damage. It’s critical to ensure that the supplier is an authorized distributor and can provide documentation proving the legitimacy of the machines.

Relying Solely on Online Marketplaces Without Verification

Platforms like Alibaba, eBay, or other B2B marketplaces are common sources for industrial machines, but they are also rife with misleading listings. Sellers may use genuine Singer product images while shipping inferior or fake units. Without proper due diligence—such as requesting proof of authorization, inspecting machines in person, or using third-party inspection services—you risk receiving non-compliant or unsafe equipment.

Skipping Due Diligence on Suppliers

Failing to vet suppliers thoroughly increases the likelihood of encountering scams or low-quality products. Red flags include lack of verifiable business addresses, refusal to provide references, absence of official distributor agreements, and poor communication. Always verify the supplier’s credentials, check for customer reviews, and, if possible, conduct factory audits before placing bulk orders.

Assuming All “Industrial” Singer Machines Are Equal

Not all industrial Singer machines are built for the same applications. Machines designed for heavy-duty leatherwork differ significantly from those used in garment manufacturing. Sourcing the wrong model—due to misrepresentation or lack of technical understanding—can lead to inefficiencies and equipment failure. Ensure the machine specifications match your production needs and verify compatibility with required accessories and maintenance support.

By recognizing and addressing these pitfalls, businesses can make informed decisions when sourcing industrial Singer sewing machines—ensuring both high quality and compliance with intellectual property standards.

Logistics & Compliance Guide for Industrial Singer Sewing Machine

Product Classification & Documentation

Ensure accurate classification of the industrial Singer sewing machine under the Harmonized System (HS) Code. Typical classification may fall under HS 8452.21 (Sewing machines, other than book-sewing machines of heading 8440, and parts and accessories thereof). Confirm the exact code with local customs authorities, as variations exist by region. Maintain complete documentation, including commercial invoice, packing list, bill of lading/airway bill, certificate of origin, and technical specifications.

Packaging & Handling Requirements

Package the sewing machine securely using robust wooden crates or heavy-duty cardboard with internal cushioning to prevent damage during transit. Include protective covers for the needle, arm, and control panel. Clearly label each package with handling instructions such as “Fragile,” “This Side Up,” and “Do Not Stack.” Ensure weight and dimensions are accurately declared for freight calculation and handling.

Import/Export Regulations

Verify export controls in the country of origin and import regulations in the destination country. Some regions may require import licenses, conformity assessments, or pre-shipment inspections. Check for any restrictions or duties applicable to textile machinery. For shipments to the EU, ensure compliance with CE marking requirements. For the U.S., comply with regulations enforced by U.S. Customs and Border Protection (CBP) and the Federal Motor Carrier Safety Administration (FMCSA) for domestic transport.

Electrical & Safety Compliance

Confirm that the machine meets the electrical standards of the destination market (e.g., UL listing for the U.S., CE for Europe, CCC for China). Voltage, plug type, and frequency must match local specifications. Include multilingual safety instructions and user manuals. Machines must comply with relevant safety standards such as IEC 60204-1 (safety of machinery – electrical equipment of machines).

Environmental & RoHS Compliance

Ensure the industrial sewing machine complies with environmental directives such as the EU’s Restriction of Hazardous Substances (RoHS) directive, which limits the use of specific hazardous materials in electrical equipment. Provide a Declaration of Conformity (DoC) and, if required, a Substance Declaration Report. Properly label products to indicate compliance.

Warranty & After-Sales Support Logistics

Include warranty documentation and service information in the shipment. Coordinate with local distributors or service agents to ensure spare parts availability and technical support. Clearly communicate warranty terms, including coverage duration, service procedures, and conditions for returns or repairs.

Transportation & Freight Options

Choose appropriate freight mode (air, sea, or land) based on urgency, cost, and destination. For international shipments, engage a freight forwarder experienced in heavy machinery logistics. Ensure cargo insurance covers full replacement value against loss or damage. Monitor shipments using tracking systems and maintain communication with all parties involved.

Customs Clearance & Duties

Prepare for customs clearance by submitting all required documentation in advance. Pay close attention to tariff rates, import taxes, and any applicable anti-dumping duties. Use a licensed customs broker in the destination country to facilitate smooth clearance and avoid delays. Retain records for a minimum of five years for audit purposes.

End-of-Life & WEEE Considerations

If applicable, comply with waste electrical and electronic equipment (WEEE) regulations in regions like the EU. Provide end-of-life disposal guidance and, where required, register with national WEEE compliance schemes. Encourage recycling and responsible disposal through customer education and take-back programs.

Summary

Proper logistics and compliance management are critical for the successful international distribution of industrial Singer sewing machines. Adherence to documentation, safety, environmental, and customs requirements ensures timely delivery, legal compliance, and customer satisfaction. Regularly review regulatory updates and maintain strong coordination with logistics partners and regulatory bodies.

Conclusion for Sourcing Industrial Singer Sewing Machines:

Sourcing industrial Singer sewing machines presents a strategic opportunity for businesses seeking durable, high-performance equipment designed for heavy-duty applications. Singer’s long-standing reputation for quality, innovation, and reliability makes their industrial models a trusted choice across various sectors, including apparel manufacturing, upholstery, and automotive textiles. When sourcing these machines, it is essential to evaluate specific operational needs—such as stitch type, speed, and material compatibility—to select the most suitable model. Additionally, partnering with authorized distributors or reputable suppliers ensures authenticity, access to warranties, technical support, and after-sales service. Cost considerations should balance upfront investment with long-term productivity gains and reduced maintenance expenses. Ultimately, sourcing industrial Singer sewing machines contributes to enhanced manufacturing efficiency, product consistency, and overall operational success in competitive production environments.