The global industrial storage solutions market is experiencing robust growth, driven by increasing demand for efficient space management in commercial and industrial facilities. According to Grand View Research, the global storage and shelving market was valued at USD 97.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. A key segment within this market is industrial shoe racks, which are increasingly adopted in manufacturing plants, hospitals, educational institutions, and logistics centers to maintain hygiene, ensure safety compliance, and optimize floor space. As facility managers prioritize organized workforce environments, the need for durable, scalable, and ergonomic shoe storage systems has never been more critical. This rising demand has fueled innovation and competition among manufacturers, leading to a surge in high-capacity, corrosion-resistant, and customizable industrial shoe rack solutions. Based on market presence, production capability, product innovation, and global reach, we’ve identified the top 7 industrial shoe rack manufacturers shaping the future of workplace organization.

Top 7 Industrial Shoe Rack Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 SS Shoe Rack Manufacturer & Shoe Lockers

Domain Est. 2009

Website: kjpharmatech.com

Key Highlights: Rating 5.0 (55) We are renowned manufacturer of latest models of ss shoe rack, ss open shoe rack, ss shoe rack with lockers. based in Vadodara (Baroda), Gujarat, India….

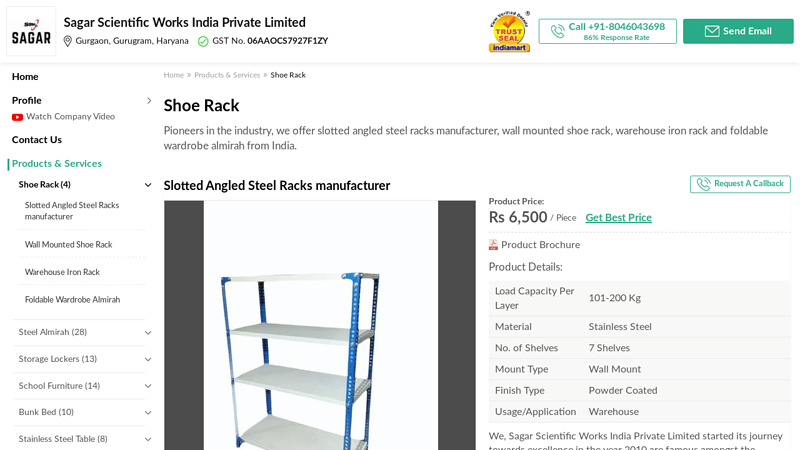

#2 Shoe Rack

Domain Est. 2011

Website: sagarscientific.com

Key Highlights: Slotted Angled Steel Racks manufacturer · Load Capacity Per Layer: 101-200 Kg · Material: Stainless Steel · No. of Shelves: 7 Shelves · Mount Type: Wall Mount ……

#3 Industrial Boot Rack

Domain Est. 2013

Website: cmpsol.com

Key Highlights: Durable & Hygienic Boot Storage Solutions. Our industrial boot racks are designed to properly store, ventilate and access work boots and safety footwear….

#4 Mehar Industries

Domain Est. 2019

Website: meharindustries.in

Key Highlights: Introducing Meher Industries, one of the leading manufacturers of metal shoe racks in India. We are located in Telangana and ship our shoe racks in all states ……

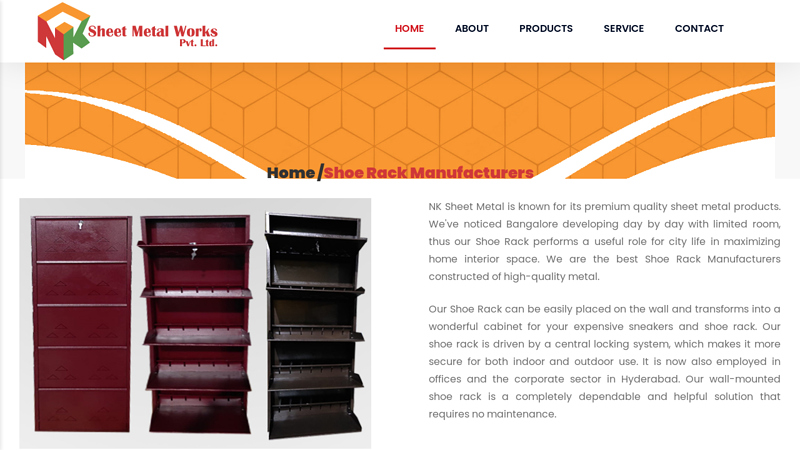

#5 Shoe Rack Manufacturers

Domain Est. 2020

Website: nkblr.com

Key Highlights: We are the best Shoe Rack Manufacturers constructed of high-quality metal. Our Shoe Rack can be easily placed on the wall and transforms into a wonderful ……

#6 Space Saving Shoe Rack

Domain Est. 2022

Website: benakaindustries.in

Key Highlights: Each unit is designed to save corridor space while accommodating a larger number of shoes. With their modern design and sturdy build, these racks not only serve ……

#7 Saniya Systems

Domain Est. 2023

Website: saniyasystems.net

Key Highlights: Saniya Industries’s Shoe Mate Shoe Rack is all metal Built product available in several sizes such as regular, Semi Jumbo and Jumbo sizes….

Expert Sourcing Insights for Industrial Shoe Rack

Market Trends for Industrial Shoe Racks in 2026

The industrial shoe rack market is poised for significant transformation in 2026, driven by evolving workplace safety standards, increased industrial automation, and a growing emphasis on hygiene and operational efficiency. These racks, essential in factories, warehouses, laboratories, and cleanrooms, are no longer simple storage solutions but integral components of facility management systems.

Rising Demand from Expanding Industries

The global expansion of manufacturing, pharmaceuticals, food processing, and logistics sectors—especially in emerging economies—will drive strong demand for industrial shoe racks. As these industries scale operations, the need for organized personal protective equipment (PPE) storage, including dedicated footwear zones, becomes critical. Stricter occupational health and safety regulations will further mandate the use of durable, compliant storage systems to minimize contamination and accident risks.

Integration of Smart Technology and IoT

A defining trend in 2026 will be the integration of smart features into industrial shoe racks. IoT-enabled racks equipped with RFID tags, access control, and usage tracking will allow facilities to monitor PPE compliance, schedule maintenance, and manage inventory in real time. Smart lockers with digital authentication will enhance security and accountability, especially in high-contamination or high-security environments.

Focus on Hygiene and Antimicrobial Materials

Post-pandemic emphasis on sanitation continues to influence design. Industrial shoe racks in 2026 will increasingly feature antimicrobial coatings, easy-to-clean surfaces (such as powder-coated steel or stainless steel), and modular designs that allow for disinfection between shifts. UV-C sanitization integration within racks may emerge as a premium feature in pharmaceutical and biotech facilities.

Sustainability and Modular Design

Environmental concerns are pushing manufacturers toward recyclable materials and energy-efficient production methods. Modular and customizable rack systems will gain traction, allowing businesses to adapt configurations based on workflow changes or facility expansions. This flexibility reduces waste and supports lean manufacturing principles.

Regional Growth and Supply Chain Localization

Asia-Pacific, particularly India and Southeast Asia, is expected to lead market growth due to rapid industrialization and government initiatives promoting manufacturing. Meanwhile, nearshoring trends in North America and Europe will boost local production of industrial storage solutions, reducing lead times and supporting sustainability goals.

In summary, the 2026 industrial shoe rack market will be characterized by smarter, cleaner, and more adaptable solutions tailored to the specific needs of modern industrial environments. Companies that innovate in technology integration, material science, and sustainable design will gain a competitive edge.

Common Pitfalls When Sourcing Industrial Shoe Racks (Quality and Intellectual Property)

Sourcing industrial shoe racks—especially for commercial, healthcare, or manufacturing environments—requires careful attention to both product quality and intellectual property (IP) considerations. Overlooking these aspects can lead to operational inefficiencies, legal risks, and reputational damage. Below are key pitfalls to avoid.

1. Compromising on Build Quality

One of the most frequent mistakes is prioritizing low cost over durability. Industrial environments demand robust materials like powder-coated steel, stainless steel, or high-impact polymers. Choosing racks made from substandard materials leads to premature wear, corrosion, or structural failure.

- Risk: Increased maintenance and replacement costs.

- Solution: Request material specifications, load capacity data, and third-party test reports before procurement.

2. Ignoring Load Capacity and Structural Design

Industrial shoe racks must support heavy use and often accommodate bulky footwear (e.g., steel-toe boots). Poorly engineered racks may collapse or deform under load.

- Risk: Safety hazards and workplace accidents.

- Solution: Verify weight ratings and ensure design includes reinforced joints and non-slip surfaces.

3. Overlooking Environmental Resistance

In facilities with high moisture, chemical exposure, or temperature fluctuations, standard finishes may degrade quickly.

- Risk: Rust, warping, or hygiene issues in sensitive areas (e.g., food processing).

- Solution: Specify corrosion-resistant coatings or stainless steel construction for harsh environments.

4. Neglecting Ergonomics and Accessibility

Poor layout or awkward height can reduce usability and discourage compliance with footwear storage policies.

- Risk: Low employee adoption and cluttered workspaces.

- Solution: Choose modular designs with adjustable shelves and easy access, considering user height and space constraints.

5. Failing to Verify Compliance with Safety Standards

Industrial products must often meet regional safety and fire codes (e.g., OSHA, CE, ISO standards).

- Risk: Regulatory non-compliance and facility penalties.

- Solution: Request compliance certifications and ensure labeling meets local requirements.

6. Infringing on Intellectual Property (IP)

Many industrial rack designs—especially patented modular systems or branded products—are protected by IP laws. Sourcing counterfeit or unlicensed copies poses serious legal risks.

- Risk: Legal action, shipment seizures, or forced redesigns.

- Solution: Work only with reputable suppliers, request proof of IP ownership or licensing, and avoid suspiciously low-priced “copycat” products.

7. Relying on Unverified Suppliers

Sourcing from unknown manufacturers, particularly through online marketplaces, increases the risk of receiving non-conforming or counterfeit goods.

- Risk: Poor quality, delayed deliveries, lack of after-sales support.

- Solution: Conduct supplier audits, request references, and use escrow or inspection services for large orders.

8. Not Protecting Your Own IP When Customizing

If you’re designing a custom shoe rack for your facility, failing to secure IP rights (e.g., design patents or trademarks) leaves your innovation vulnerable.

- Risk: Competitors replicating your design.

- Solution: Register unique designs and include IP clauses in supplier contracts to retain ownership.

Conclusion

Avoiding these common pitfalls ensures that your industrial shoe rack investment delivers long-term value, safety, and legal security. Prioritize quality verification, regulatory compliance, and IP diligence throughout the sourcing process.

Logistics & Compliance Guide for Industrial Shoe Rack

Product Classification and HS Code

Industrial shoe racks are typically classified under furniture or storage equipment for customs and import/export purposes. The Harmonized System (HS) code may vary by country but commonly falls under 9403.20 (Metal furniture for office, shop, or industrial use). Confirm the exact HS code with the destination country’s customs authority to ensure accurate tariff application and compliance.

Import/Export Documentation

Ensure the following documents are prepared and accurate for smooth logistics:

– Commercial Invoice

– Packing List

– Bill of Lading (for sea freight) or Air Waybill (for air freight)

– Certificate of Origin (if required under trade agreements)

– Import License (if applicable in the destination country)

Packaging and Labeling Requirements

Industrial shoe racks must be packaged to withstand handling and transport. Use sturdy materials such as corrugated cardboard, wooden crates, or palletized shrink-wrapping. Labels must include:

– Product name and model number

– Weight and dimensions

– Handling instructions (e.g., “Stackable,” “This Side Up”)

– Country of origin

– Barcodes or SKU identifiers (if used in distribution)

Transportation and Handling

Due to their size and weight, industrial shoe racks are typically shipped via:

– Full Container Load (FCL) or Less than Container Load (LCL) for sea freight

– Palletized freight for road or air transport

Ensure racks are securely stacked and braced to prevent shifting. Use edge protectors and corner boards to minimize damage during transit.

Regulatory Compliance

Verify compliance with destination country regulations, including:

– REACH (EU): Ensure no restricted substances (e.g., heavy metals) are present in coatings or materials.

– Proposition 65 (California, USA): Provide warnings if applicable chemicals (e.g., lead in coatings) are used.

– FIRA or BIFMA Standards (optional but recommended): Confirm structural safety and durability for commercial use.

Environmental and Safety Standards

- Use powder-coated or non-toxic finishes where possible to meet environmental standards.

- Comply with workplace safety standards if the racks are intended for use in industrial environments (e.g., slip-resistant feet, load capacity labeling).

- Provide assembly instructions and load ratings to ensure user safety.

Inspection and Quality Control

Conduct pre-shipment inspections to verify:

– Correct product specifications

– Absence of defects (welding issues, coating flaws)

– Compliance with packaging and labeling requirements

Third-party inspection services (e.g., SGS, Bureau Veritas) may be used for international shipments.

Returns and Reverse Logistics

Establish clear policies for damaged or non-compliant shipments. Include:

– Procedures for documenting damage upon delivery

– Return authorization (RMA) process

– Responsibility for return shipping costs (supplier vs. buyer)

Storage and Inventory Management

For distribution centers or warehouses:

– Store on flat, dry surfaces to prevent warping or corrosion.

– Use FIFO (First In, First Out) inventory practices to manage stock rotation.

– Monitor humidity levels if stored long-term to prevent rust on metal components.

Adhering to this guide ensures efficient logistics operations and full regulatory compliance for industrial shoe racks across global markets.

Conclusion for Sourcing Industrial Shoe Rack

Sourcing an industrial shoe rack requires a strategic approach that balances durability, functionality, space efficiency, and cost-effectiveness. After evaluating various suppliers, materials, and design options, it is evident that selecting the right shoe rack involves considering the specific needs of the industrial environment—such as heavy-duty use, ease of maintenance, and hygiene standards. Galvanized steel or powder-coated metal racks often emerge as ideal choices due to their strength and resistance to wear and corrosion.

Additionally, partnering with reliable suppliers who offer customization options, volume discounts, and timely delivery ensures long-term satisfaction and operational efficiency. Emphasizing sustainability and safety in material selection further aligns with modern industrial standards. In conclusion, a well-sourced industrial shoe rack not only enhances workplace organization and cleanliness but also contributes to improved safety and employee satisfaction, making it a valuable investment in any industrial facility.