The global sandblasting equipment market is experiencing robust growth, driven by increasing demand across industries such as automotive, construction, shipbuilding, and surface preparation. According to a report by Mordor Intelligence, the market was valued at USD 2.85 billion in 2023 and is projected to grow at a CAGR of 5.4% from 2024 to 2029. Similarly, Grand View Research estimates that the market will expand at a CAGR of over 5.2% through 2030, fueled by rising infrastructure development and stringent regulations on surface treatment in manufacturing. With this expanding landscape, identifying reliable and innovative manufacturers has become crucial for businesses aiming to maintain efficiency, safety, and environmental compliance. Based on market presence, technological advancements, product range, and global reach, the following list highlights the top 10 industrial sandblasting equipment manufacturers leading the industry.

Top 10 Industrial Sandblasting Equipment Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Industrial Shot Blast Machines & Equipment Manufacturer

Domain Est. 1998

Website: vikingcorporation.com

Key Highlights: Industrial shot blast machines and equipment engineered for foundry, forge, fabrication, and cylinder applications worldwide….

#2 Sandblast Solutions Inc.

Domain Est. 2014

Website: sandblastinc.com

Key Highlights: Sandblast Solutions provides surface preparation equipment, rentals, blasting gear, coatings, abrasives and more. Trusted nationwide for industrial job site ……

#3 Empire Abrasive Air Blast Equipment

Domain Est. 1997

Website: empire-airblast.com

Key Highlights: We are a leader in air-blast technology, including manual and modified cabinets, blast rooms, automated blast systems, and robotic blast systems….

#4 JH Norton Company Inc.

Domain Est. 1998 | Founded: 1973

Website: nortonsandblasting.com

Key Highlights: 3-day delivery 30-day returnsSince 1973, JH Norton Company Inc. supplies many types and sizes of sandblasting equipment, abrasive blasting parts, and accessories….

#5 Clemtex

Domain Est. 2001

Website: clemtex.com

Key Highlights: Discover top-quality abrasive blasting equipment … Explore our wide range of sandblasting tools, media, and safety gear for industrial and commercial needs….

#6 Clemco Industries

Domain Est. 1999

Website: clemcoindustries.com

Key Highlights: Clemco is a global leader in abrasive blasting, cleaning, shot peening, and surface preparation solutions, serving industries from aerospace and energy to ……

#7 BlastOne USA

Domain Est. 2002

Website: blastone.com

Key Highlights: BlastOne USA | Blasting & Coating Equipment | Abrasives | Supplier. Inquire | Catalog | Call Us @ 1-800-999-1881 FREE SHIPPING ON ORDERS OVER $100!…

#8 Schmidt Abrasive Blasting Equipment

Domain Est. 2010

Website: schmidtabrasiveblasting.com

Key Highlights: Lightweight and most portable in the AmphiBlast family. Wet or dry blast with a single unit. Minimal water usage. Set and forget switching between machine ……

#9 Dustless Blasting®

Domain Est. 2011

Website: dustlessblasting.com

Key Highlights: Remove virtually any coating from any surface, with NO dust plume. Start your mobile blasting business or improve your existing one with Dustless Blasting….

#10 Eclipse Surface Technologies I Abrasive Blasting Equipment

Domain Est. 2017

Website: eclipseblast.com

Key Highlights: Abrasive blasting systems built for every industry and application. Made with precision and craftsmanship, right here in the USA. Click below for details….

Expert Sourcing Insights for Industrial Sandblasting Equipment

2026 Market Trends for Industrial Sandblasting Equipment

The industrial sandblasting equipment market is poised for significant transformation by 2026, driven by technological advancements, evolving regulatory standards, and shifting industrial demands. This analysis explores key trends expected to shape the market landscape in the coming years.

Increasing Demand from Key End-Use Industries

Industries such as automotive, aerospace, shipbuilding, and infrastructure continue to be primary drivers of sandblasting equipment demand. As global infrastructure projects expand—particularly in emerging economies—the need for surface preparation and coating removal remains strong. In the automotive sector, the push for lightweight materials and improved corrosion resistance is increasing the use of sandblasting in manufacturing and refinishing processes. Similarly, the aerospace industry’s emphasis on precision surface treatment for turbine blades and fuselage components supports sustained equipment demand.

Technological Advancements and Automation

By 2026, automation and digital integration are expected to redefine sandblasting operations. Robotic sandblasting systems are gaining traction due to their ability to enhance precision, reduce labor costs, and improve worker safety. These systems, often integrated with AI-driven path planning and real-time monitoring, offer consistent results and reduced media waste. Additionally, the adoption of IoT-enabled equipment allows for remote diagnostics, predictive maintenance, and performance tracking, improving operational efficiency across industrial facilities.

Shift Toward Eco-Friendly and Sustainable Practices

Environmental regulations are becoming more stringent worldwide, pushing manufacturers and end-users to adopt greener sandblasting solutions. Closed-loop recycling systems, which reclaim and reuse abrasive media, are becoming standard in modern equipment. Moreover, the market is witnessing a rise in the use of alternative, less toxic abrasives such as garnet, glass beads, and soda-based media. Equipment designed for lower dust emissions and equipped with advanced filtration systems will be increasingly favored to comply with OSHA and EU environmental directives.

Growth in Refurbishment and Maintenance Activities

With aging industrial infrastructure across North America and Europe, there is a growing emphasis on maintenance, repair, and overhaul (MRO) activities. Sandblasting plays a critical role in the refurbishment of pipelines, storage tanks, bridges, and offshore platforms. The cost-effectiveness of extending asset life through surface restoration rather than replacement is encouraging investment in high-efficiency sandblasting equipment, particularly portable and modular units suitable for on-site operations.

Regional Market Dynamics

Asia-Pacific is expected to dominate market growth by 2026, fueled by rapid industrialization in countries like India, Vietnam, and Indonesia. Government initiatives in infrastructure and manufacturing are creating robust demand for surface treatment technologies. In contrast, North America and Europe will focus more on upgrading existing facilities with advanced, compliant equipment. Latin America and the Middle East show moderate growth, supported by oil & gas and construction sectors.

Rising Focus on Operator Safety and Ergonomics

Workplace safety remains a top priority, prompting innovations in protective gear and equipment design. By 2026, sandblasting systems will increasingly feature ergonomic nozzles, vibration-reducing handles, and remote-controlled operation to minimize operator fatigue and exposure to hazardous dust. Integrated personal protective systems and real-time air quality monitoring will become standard in high-end models.

Conclusion

The industrial sandblasting equipment market in 2026 will be characterized by smarter, safer, and more sustainable solutions. As industries demand higher efficiency and compliance, equipment manufacturers must innovate to meet evolving needs. Companies that invest in automation, environmental performance, and user-centric design are likely to lead the market in the next few years.

Common Pitfalls When Sourcing Industrial Sandblasting Equipment (Quality and Intellectual Property)

Sourcing industrial sandblasting equipment involves significant investment and long-term operational impact. Overlooking key quality and intellectual property (IP) concerns can lead to performance issues, safety risks, legal complications, and financial losses. Below are major pitfalls to avoid:

Poor Build Quality and Substandard Materials

Choosing equipment based solely on price often leads to units constructed with inferior materials and workmanship. Thin-walled blast pots, poorly welded enclosures, or low-grade seals can result in premature wear, leaks, and frequent breakdowns. This reduces equipment lifespan, increases downtime, and raises total cost of ownership.

Inadequate Safety Features and Non-Compliance

Low-quality or counterfeit equipment may lack essential safety mechanisms such as pressure relief valves, interlocks, or proper ventilation systems. Units that don’t meet recognized safety standards (e.g., ASME, CE, OSHA) pose serious risks to operators and can lead to regulatory penalties or workplace incidents.

Misrepresentation of Technical Specifications

Some suppliers exaggerate performance data such as airflow capacity (CFM), pressure ratings, or abrasive throughput. This can result in equipment that underperforms in real-world conditions, failing to meet production requirements and leading to inefficient blasting operations.

Lack of Genuine Components and Reverse-Engineered Designs

Certain manufacturers produce clones or reverse-engineered versions of patented sandblasting systems. These copies often use knock-off parts that don’t match OEM performance or durability. More critically, purchasing such equipment may expose buyers to intellectual property infringement claims, especially in regulated markets.

Unauthorized Use of Branded Technology

Suppliers may falsely claim compatibility with or integration of proprietary technologies (e.g., blast nozzles, control systems) from established brands. Using counterfeit or unauthorized versions can void warranties, compromise system efficiency, and expose companies to legal liability for IP violations.

Insufficient Documentation and Traceability

Reputable equipment should come with full technical documentation, material certifications, and traceability records. Sourcing from vendors who cannot provide these documents raises red flags about quality control and may indicate non-compliance with industry standards or regulatory requirements.

Limited Warranty and After-Sales Support

Equipment sourced from unreliable suppliers often comes with weak or unenforceable warranties. Lack of accessible technical support, spare parts, or service networks can leave operations stranded when maintenance or repairs are needed, leading to extended downtime.

Ignoring IP Rights in Custom or OEM Equipment

When sourcing custom-designed or OEM-manufactured blasting systems, failure to clarify IP ownership in contracts can result in disputes over design rights, modifications, or future production rights. Clear agreements must define who owns the design, tooling, and any improvements made during development.

Avoiding these pitfalls requires due diligence: vetting suppliers thoroughly, verifying certifications, inspecting equipment firsthand when possible, and consulting legal experts when IP concerns arise. Prioritizing quality and IP integrity ensures reliable performance, regulatory compliance, and long-term operational success.

Logistics & Compliance Guide for Industrial Sandblasting Equipment

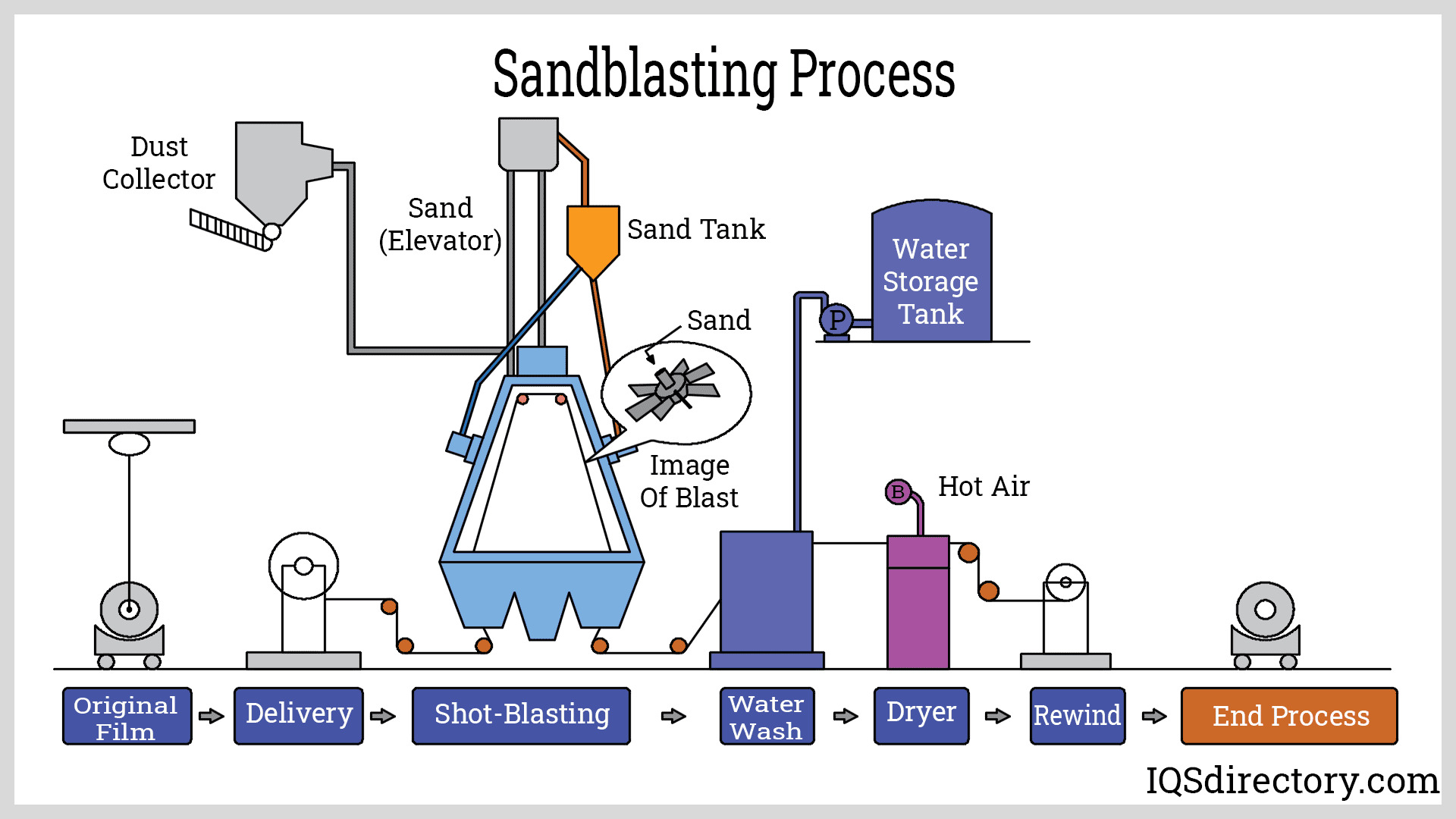

Overview of Industrial Sandblasting Equipment

Industrial sandblasting equipment is used for surface preparation and cleaning in various industries such as construction, manufacturing, and shipbuilding. It includes blast pots, air compressors, nozzles, abrasive media delivery systems, protective gear, and dust collection units. Proper logistics management and regulatory compliance are essential to ensure safe transportation, storage, and operation of this equipment.

Transportation and Shipping Logistics

Packaging Requirements

Sandblasting equipment must be securely packaged to prevent damage during transit. Large components like blast pots and compressors should be crated or palletized with protective corner boards and stretch-wrapped. Fragile parts such as nozzles and control valves should be boxed with cushioning materials.

Mode of Transport

Choose the appropriate transport method based on equipment size and destination:

– Truck freight is commonly used for domestic or regional shipments.

– Container shipping is suitable for international transport, especially for full equipment sets.

– Air freight may be used for urgent delivery of small or replacement parts.

Documentation

Ensure all shipments include:

– Commercial invoice

– Packing list

– Bill of lading (BOL)

– Material Safety Data Sheets (MSDS) for any hazardous components or abrasives

– Certificate of origin (if required for import)

Storage and Handling

Warehouse Storage

Store equipment in a dry, climate-controlled environment to prevent rust and corrosion. Keep abrasive materials in sealed containers away from moisture. Label all items clearly and follow first-in, first-out (FIFO) inventory practices.

Handling Procedures

Use proper lifting equipment (e.g., forklifts, hoists) when moving heavy components. Train personnel on safe handling techniques to avoid injury and equipment damage. Always follow manufacturer guidelines for assembly and disassembly.

Regulatory Compliance

Environmental Regulations

Sandblasting operations can generate hazardous dust and waste. Comply with regulations such as:

– U.S. Environmental Protection Agency (EPA) standards under the Clean Air Act

– Resource Conservation and Recovery Act (RCRA) for disposal of spent abrasives and contaminated materials

– Local air quality management rules

Use dust collection systems and containment enclosures to minimize emissions. Test abrasive waste for hazardous contaminants (e.g., lead, silica) before disposal.

Occupational Health and Safety Standards

Follow OSHA (Occupational Safety and Health Administration) guidelines, including:

– 29 CFR 1910.94 – Ventilation

– 29 CFR 1910.134 – Respiratory protection

– 29 CFR 1926.57 – Ventilation in construction (applicable to field blasting)

Provide appropriate personal protective equipment (PPE), including respirators, blast suits, face shields, and hearing protection.

International Compliance

For cross-border operations, adhere to:

– REACH and CLP regulations (EU) for chemical safety

– Transport of Dangerous Goods (TDG) regulations for shipping abrasive media

– Local labor and safety laws in the destination country

Obtain necessary permits for equipment import and operation.

Maintenance and Inspection

Pre-Use Checks

Inspect all equipment before deployment for signs of damage, wear, or leakage. Verify that safety valves, pressure gauges, and hoses are functional.

Scheduled Maintenance

Follow manufacturer-recommended maintenance schedules. Keep logs of repairs, part replacements, and compliance inspections. Replace worn nozzles and hoses promptly to maintain efficiency and safety.

Training and Certification

Ensure all operators are trained and certified in:

– Safe operation of sandblasting equipment

– Emergency shutdown procedures

– Hazardous waste handling

– Use of PPE and respiratory protection

Maintain training records and conduct periodic refresher courses.

Emergency Preparedness

Develop an emergency response plan that includes:

– Procedures for equipment malfunction

– Exposure to hazardous dust or pressurized components

– Fire or explosion risks (especially with compressed air systems)

Equip work areas with emergency shut-offs, eyewash stations, and fire extinguishers.

Conclusion

Effective logistics and compliance management for industrial sandblasting equipment ensures operational safety, regulatory adherence, and equipment longevity. By focusing on proper shipping, storage, maintenance, and training, organizations can minimize risks and maintain productivity in demanding industrial environments.

In conclusion, sourcing industrial sandblasting equipment requires careful consideration of several key factors to ensure optimal performance, safety, and long-term cost efficiency. It is essential to assess your specific application needs—such as the scale of operation, types of surfaces being treated, and required blast pressure—to select the most suitable equipment type, whether it be pressure blast systems, suction blast systems, or automated solutions. Evaluating suppliers based on reputation, service support, compliance with safety and environmental standards, and warranty offerings is crucial for reliable procurement. Additionally, factoring in operational costs, maintenance requirements, and the availability of consumables like abrasives will contribute to a sustainable and efficient operation. By conducting thorough research and due diligence, businesses can invest in sandblasting equipment that enhances productivity, ensures worker safety, and delivers a strong return on investment over time.