The global industrial safety gates and mezzanine systems market is experiencing robust growth, driven by increasing emphasis on workplace safety, rising industrial automation, and expanding warehouse and logistics infrastructure. According to Grand View Research, the global industrial safety market was valued at USD 5.8 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.7% from 2023 to 2030. This expansion is further fueled by stringent occupational health and safety regulations across North America and Europe, as well as growing investments in manufacturing and e-commerce fulfillment centers that require elevated work platforms and reliable fall protection systems. Mezzanine safety gates, in particular, are critical components in minimizing workplace accidents in multi-level facilities, with demand rising for automated and customizable solutions. As the need for compliance with OSHA and ANSI standards intensifies, manufacturers specializing in industrial safety gates are scaling innovation and production capacity—making the identification of leading players essential for informed procurement and facility planning.

Top 9 Industrial Safety Gates Mezzanine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

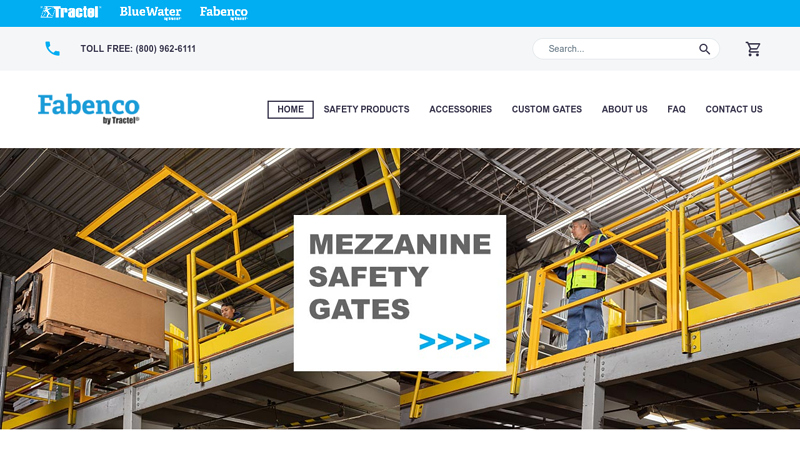

#1 Fabenco Industrial Safety Gates and OSHA Fall Protection Equipment

Domain Est. 1996

Website: tractel.com

Key Highlights: Fabenco safety gates are easy-to-install and save our customers the time and expense of fabricating gates for OSHA fall protection compliance….

#2 Industrial Mezzanines, Modular Offices, Material Lifts, Safety Gates

Domain Est. 1998

Website: amezz.com

Key Highlights: Mezzanines designed for your specific need. A free-standing steel mezzanine floor can double your manufacturing, storage, production or office space….

#3 Durable Mezzanine Safety Gates

Domain Est. 1995

Website: cogan.com

Key Highlights: Our mezzanine safety gates are easily adaptable to keep your process running smoothly. Choose from four different models to best suit your needs….

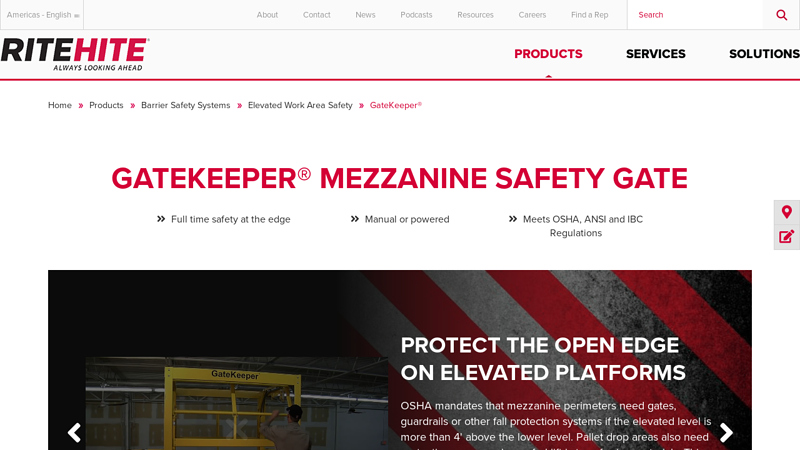

#4 GateKeeper®

Domain Est. 1995

Website: ritehite.com

Key Highlights: Improving upon traditional mezzanine swing gates, the GateKeeper helps prevent falls by ensuring an elevated access point is always guarded by one gate….

#5 Mezzanine Gates

Domain Est. 1998

Website: bluffmanufacturing.com

Key Highlights: Bluff Swing Gates are made up of heavy-duty welded steel, standard in powder coated safety yellow & meets OSHA requirements. To learn more about our swing gates ……

#6 Mezzanine Safety Gates (MEZZ)

Domain Est. 1998

Website: vestil.com

Key Highlights: The Mezzanine Safety Gate provides an OSHA required 42-3/8″ high handrail, 21″ high mid-rail, and 4″ high toe board for mezzanines without sacrificing load ……

#7 Beacon World Class

Domain Est. 1998

Website: beacontechnology.com

Key Highlights: In stockThe Mezzanine Safety Gates provide essential fall protection from high platforms and mezzanines. These units feature a 4″-high kick plate, a 21″ midrail, ……

#8 Mezzanine Safety Gates for Workplace

Domain Est. 1999

Website: caisafety.com

Key Highlights: Discover CAI Safety’s comprehensive range of mezzanine safety gate systems, featuring vertical, horizontal, pallet, and self-closing models….

#9 Mezzanine Safety Gates

Domain Est. 2010

Website: mezzgate.com

Key Highlights: Mezzanine safety gates designed for OSHA-compliant fall protection on elevated work platforms, pallet drop areas, loading docks, and lifts….

Expert Sourcing Insights for Industrial Safety Gates Mezzanine

H2: Emerging Market Trends for Industrial Safety Gates and Mezzanine Systems in 2026

As industrial automation, warehouse optimization, and workplace safety regulations continue to evolve, the market for Industrial Safety Gates and Mezzanine Systems is poised for significant transformation by 2026. Driven by technological advancements, regulatory pressures, and shifting logistics demands, several key trends are shaping the future of this sector.

-

Increased Adoption of Smart Safety Gate Technologies

By 2026, smart industrial safety gates integrated with IoT sensors, RFID, and real-time monitoring systems are expected to dominate the market. These intelligent systems enhance operational safety by detecting gate position, load weight, and unauthorized access, sending alerts to facility managers via centralized dashboards. The integration with Building Management Systems (BMS) and Warehouse Management Systems (WMS) allows for predictive maintenance and improved compliance tracking. -

Growth in E-Commerce and Automated Warehousing

The continued expansion of e-commerce is driving demand for multi-level storage solutions, including mezzanine floors in distribution centers. As space optimization becomes critical, mezzanine systems equipped with automated safety gates—especially those compatible with robotic picking and automated guided vehicles (AGVs)—are becoming standard. This trend is accelerating the development of modular, customizable gate systems that support seamless integration with automation infrastructure. -

Stricter Global Safety Regulations

Regulatory bodies such as OSHA (U.S.), HSE (UK), and ISO are expected to enforce stricter standards for fall protection and access control on elevated work platforms by 2026. This will increase demand for compliant mezzanine safety gates, including interlocked and self-closing systems that meet ANSI/ASSE A1264.1 and other international standards. Manufacturers will need to prioritize certifications and provide detailed documentation to meet procurement requirements. -

Sustainability and Modular Design

Sustainability is becoming a key purchasing criterion. By 2026, there will be a growing preference for recyclable materials and modular safety gate systems that can be reconfigured or relocated as facility layouts change. This reduces waste and supports circular economy principles. Steel and aluminum composites with powder-coated, non-toxic finishes are expected to gain favor due to their durability and low environmental impact. -

Rise of Customization and Turnkey Solutions

Industrial facilities are increasingly seeking turnkey mezzanine safety solutions tailored to specific operational needs. Providers offering end-to-end services—from design and engineering to installation and training—are gaining competitive advantage. Customization in gate height, opening width, load capacity, and integration with existing racking systems will be critical differentiators in the market. -

Expansion in Emerging Markets

Regions such as Southeast Asia, India, and Latin America are witnessing rapid industrialization and growth in manufacturing and logistics sectors. These regions represent high-growth opportunities for safety gate and mezzanine system providers. Localized manufacturing and partnerships with regional distributors are expected to expand market reach by 2026.

In summary, the 2026 market for Industrial Safety Gates and Mezzanine Systems will be defined by innovation, compliance, and integration. Companies that invest in smart technology, regulatory alignment, and flexible design will be best positioned to lead in this evolving landscape.

Common Pitfalls When Sourcing Industrial Safety Gates for Mezzanines (Quality & Intellectual Property)

Sourcing industrial safety gates for mezzanines requires careful attention to both product quality and intellectual property (IP) compliance. Overlooking these aspects can lead to safety hazards, legal risks, and long-term operational inefficiencies. Below are key pitfalls to avoid:

Poor Quality Materials and Construction

Many low-cost suppliers use substandard materials such as thin-gauge steel, inferior welds, or non-compliant hardware. This compromises structural integrity, leading to gate failure under load or frequent maintenance issues. Always verify material specifications, third-party certifications (e.g., ANSI, OSHA, CE), and demand test reports for load capacity and cycle durability.

Lack of Compliance with Safety Standards

Safety gates must meet regional and industry-specific regulations (e.g., OSHA 1910.23 in the U.S. or EN ISO 14122 in Europe). Sourcing non-compliant gates exposes facilities to fines, shutdowns, and liability in case of accidents. Ensure suppliers provide documentation proving conformance to applicable standards.

Inadequate Design for Mezzanine Applications

Generic safety gates may not suit mezzanine environments, where space constraints, load dynamics, and fall protection are critical. Pitfalls include improper swing radius, insufficient gate height, or lack of self-closing mechanisms. Confirm the design is purpose-built for mezzanine use and integrates seamlessly with existing guardrails.

Counterfeit or IP-Infringing Products

Some suppliers copy patented gate designs, mechanisms, or branding without authorization. Purchasing such products can expose your company to legal action, especially in international markets. Verify the supplier’s original design rights and avoid deals that seem too good to be true—IP infringement often correlates with lower-quality knockoffs.

Absence of Manufacturer Traceability and Support

Reputable suppliers provide serial-numbered components, clear documentation, and accessible technical support. Sourcing from anonymous or offshore manufacturers with no after-sales service can result in installation challenges, unavailability of spare parts, and unresolved warranty claims.

Insufficient Testing and Certification Documentation

Reliable safety gates undergo rigorous testing for cycle life, impact resistance, and corrosion. Beware of suppliers who cannot provide independent lab reports or certifications. Lack of verifiable testing data is a red flag for poor quality and potential IP issues.

Hidden Costs from Frequent Maintenance or Downtime

Low initial cost often comes with higher lifecycle expenses. Poorly made or non-compliant gates may require frequent repairs or replacements, disrupting operations. Evaluate total cost of ownership, including durability, warranty terms, and supplier reliability.

Neglecting Supplier Due Diligence

Failing to audit suppliers—especially overseas ones—can result in receiving counterfeit, substandard, or non-compliant products. Conduct factory audits, request references, and verify business credentials to mitigate IP and quality risks.

By addressing these pitfalls proactively, buyers can ensure they source mezzanine safety gates that are both high-quality and legally sound, protecting personnel, operations, and organizational integrity.

Logistics & Compliance Guide for Industrial Safety Gates Mezzanine

Product Overview and Purpose

Industrial safety gates for mezzanines are engineered barriers designed to prevent falls from elevated platforms during material handling operations. These gates ensure worker safety at loading/unloading points and comply with occupational health and safety regulations. Proper logistics planning and adherence to compliance standards are essential for effective installation, operation, and long-term safety.

Regulatory Compliance Requirements

Safety gates must meet specific national and international standards to ensure workplace safety. Key regulatory frameworks include:

– OSHA 1910.23: Mandates guardrails and fall protection on open-sided floors and platforms over 4 feet high.

– ANSI/ASSE A1264.1: Provides specifications for safety gate design, including load capacity and structural integrity.

– International Building Code (IBC): Requires proper railing systems on mezzanines exceeding defined height thresholds.

– Local Jurisdiction Codes: Always verify regional requirements, as municipalities may impose additional safety provisions.

Ensure all safety gates are certified, labeled, and accompanied by documentation proving compliance with applicable standards.

Design and Installation Standards

Safety gates must be designed and installed according to best engineering practices:

– Gates should maintain continuous fall protection—no open gaps during operation.

– Hinges, latches, and pivot mechanisms must withstand repeated industrial use.

– Load ratings must exceed anticipated forces (typically 200+ lbs concentrated load).

– Installation must follow manufacturer specifications, including proper anchoring to structural steel or reinforced concrete.

– Self-closing and self-latching features are recommended to minimize human error.

Engage qualified personnel for installation and validate alignment with mezzanine structural design.

Transportation and Handling Logistics

Proper handling ensures product integrity during shipping and site delivery:

– Gates are typically shipped via freight carriers in crated or palletized form.

– Use material handling equipment (e.g., forklifts, pallet jacks) for unloading; avoid dragging or impact.

– Store in a dry, level area to prevent warping or corrosion, especially for steel components.

– Confirm delivery dimensions and access routes (doorways, elevators, mezzanine access) prior to shipment.

Coordinate with suppliers to ensure timely delivery aligned with installation schedules.

Site Preparation and Access

Before installation, verify the following:

– Mezzanine structural supports are rated to bear the added gate weight and dynamic loads.

– Floor and railing interfaces are level and properly prepped for mounting.

– Adequate workspace is available for assembly and equipment maneuvering.

– Power tools and lifting gear are available and certified for use.

Conduct a pre-installation site survey with engineers or safety officers to identify potential obstacles.

Inspection and Certification Protocol

After installation:

– Perform a full operational test of opening, closing, and latching mechanisms.

– Verify that no gaps exceed OSHA’s 1910.23 maximum of 19 inches.

– Conduct load testing if required by local code or internal safety policy.

– Document inspection results and retain records for compliance audits.

– Affix compliance labels and operational instructions near the gate.

Schedule recurring inspections (e.g., quarterly) to maintain safety integrity.

Training and Operational Compliance

Ensure all personnel are trained on:

– Proper use of safety gates during loading/unloading operations.

– Reporting malfunctions or damage immediately.

– Adherence to lockout/tagout (LOTO) procedures during maintenance.

– Understanding fall hazards and emergency protocols.

Maintain training records as part of your safety management system.

Maintenance and Recordkeeping

Implement a preventive maintenance plan:

– Lubricate moving parts monthly.

– Inspect for wear, corrosion, or structural damage quarterly.

– Replace damaged components with manufacturer-approved parts.

– Keep logs of all inspections, repairs, and modifications.

Retention of compliance documentation supports audits and insurance requirements.

Conclusion

Effective logistics and strict compliance with safety standards are critical when deploying industrial mezzanine safety gates. From procurement and transport to installation and ongoing use, every phase must align with regulatory requirements and best practices to ensure worker protection and operational continuity.

Conclusion: Sourcing Industrial Safety Gates for Mezzanines

Sourcing industrial safety gates for mezzanine levels is a critical step in ensuring workplace safety, regulatory compliance, and operational efficiency in industrial and warehouse environments. Selecting the right safety gates involves careful consideration of factors such as load capacity, gate type (e.g., vertical rise, swing, or telescopic), material durability, ease of operation, and adherence to OSHA, ANSI, or other regional safety standards.

Partnering with reputable suppliers who offer certified, high-quality products and comprehensive installation support is essential. Automated or self-closing gates can enhance safety by minimizing human error, while custom solutions may be necessary to accommodate unique mezzanine layouts or operational workflows.

Ultimately, investing in reliable mezzanine safety gates not only protects personnel from fall hazards but also contributes to a safer, more productive work environment. Proactive sourcing—prioritizing safety, quality, and long-term value—ensures compliance and supports sustainable facility operations.