The global meat processing equipment market is experiencing robust growth, driven by rising demand for processed and shelf-stable meat products across both retail and foodservice sectors. According to Mordor Intelligence, the meat processing equipment market was valued at USD 31.2 billion in 2023 and is projected to grow at a CAGR of 5.8% through 2029, with industrial dehydration emerging as a critical segment due to its role in extending shelf life and ensuring food safety. Similarly, Grand View Research highlights an increasing focus on value-added meat products and sustainable preservation methods, further accelerating adoption of industrial-scale dehydrators. As manufacturers seek efficient, high-capacity solutions to meet consumer demand for jerky, dried sausages, and ready-to-eat protein snacks, innovation in temperature control, energy efficiency, and automation has become paramount. In this competitive landscape, leading industrial meat dehydrator manufacturers are distinguished by their technological capabilities, regulatory compliance, and global service networks—factors that are shaping the future of meat preservation.

Top 10 Industrial Meat Dehydrator Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 IKE

Domain Est. 2003

Website: ike.cn

Key Highlights: IKE is a professional heat pump food Dehydrator manufacturer. Food dryers produced by IKE are mainly used for commercial and industrial use….

#2 Commercial Food Dehydrator Collection

Domain Est. 2021

Website: hakkabros.com

Key Highlights: Free delivery 30-day returnsFood dehydrators by Hakka Brothers Corp for drying jerky, fruit, herbs, and food ingredients. Suitable for kitchen and commercial food prep use.Missing:…

#3 New Upgrade Food Dehydrator

Domain Est. 2022

Website: cercker.com

Key Highlights: Free deliveryFood-Dehydrator Machine 8 Stainless Steel Trays, 500W Dehydrator for Herbs, Jerky Dehydrator for Meat, 190ºF Mushroom Dehydrator, 24H Timer Fruits …Missing: industr…

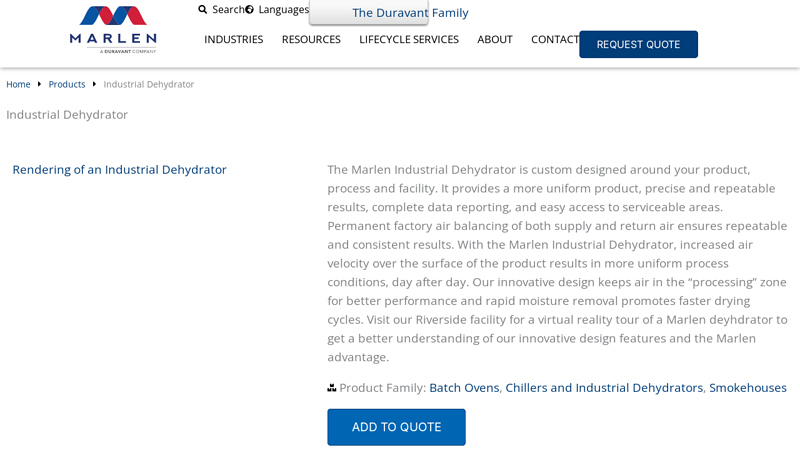

#4 Industrial Dehydrator

Domain Est. 1996

Website: marlen.com

Key Highlights: The Industrial Dehydrator from Marlen is high-quality and versatile. Ready for any Pet Food/Treat or Jerky recipes you may be dreaming of….

#5 Food dehydrators by American Harvest, Nesco, Excalibur

Domain Est. 1999

Website: pleasanthillgrain.com

Key Highlights: Free delivery over $75We’re a factory authorized dealer for every dehydrator we offer, and also carry a wide selection of appliances and cook’s tools….

#6 Commercial Dehydrators

Domain Est. 1998

Website: excaliburdehydrator.com

Key Highlights: 1–9 day delivery · 30-day returnsThese high-capacity machines are designed to handle substantial quantities of fruits, vegetables, herbs, and meats, making them ideal for restaura…

#7 Dehydrators

Domain Est. 2015

Website: westonbrands.com

Key Highlights: Free delivery over $200 Free 30-day returns…

#8 Dalle Food Dehydrator,Freeze Dryer,Citrus Juicer,Professional …

Domain Est. 2018 | Founded: 2018

Website: fsdalle.com

Key Highlights: Dalle company was founded in 2018, located in Foshan city, China. We have been professional food dehydrator and citrus juicer supplier for more than 6 ……

#9 Commercial Dehydrators America

Domain Est. 2019

Website: dehydratorsamerica.com

Key Highlights: Shopping for premium Commercial food dehydrators & Industrial Dehydrators? We offer free shipping, best prices, finance and offer 5-Yr Commercial Warranty….

#10 Dehydrators

Domain Est. 1996

Website: tribest.com

Key Highlights: Free delivery over $150Sedona® Supreme Commercial Food Dehydrator with Stainless Steel Trays. $599.95 ; Sedona® Express Food Dehydrator with Stainless Steel Trays….

Expert Sourcing Insights for Industrial Meat Dehydrator

2026 Market Trends for Industrial Meat Dehydrators

The global market for industrial meat dehydrators is poised for significant transformation by 2026, driven by shifting consumer preferences, technological innovation, and growing demand for sustainable and shelf-stable protein sources. As food production systems evolve to meet scalability and efficiency demands, industrial meat dehydration is emerging as a pivotal technology in the meat processing sector. This analysis explores the key trends shaping the industrial meat dehydrator market through 2026.

Rising Demand for Shelf-Stable and Portable Protein

One of the most influential trends driving the industrial meat dehydrator market is the increasing consumer demand for convenient, long-lasting protein products. With the growing popularity of ready-to-eat meals, outdoor recreation, and emergency preparedness supplies, dehydrated meat products such as jerky, meat bars, and protein crisps are gaining traction. Industrial dehydrators enable large-scale production of these items with consistent quality, reduced spoilage, and extended shelf life—critical for international distribution and retail scalability.

Advancements in Dehydration Technology

By 2026, industrial meat dehydrators are expected to incorporate smart technologies such as IoT-enabled monitoring, AI-driven process optimization, and energy-efficient heat pump systems. These innovations improve temperature and humidity control, reduce processing time, and lower energy consumption. Manufacturers are also integrating modular designs to allow quick changeovers between product types, enhancing flexibility for multi-product facilities. Such technological upgrades support higher throughput and improved food safety standards, aligning with regulatory requirements in major markets.

Expansion of Alternative and Cultivated Meat Processing

The rise of plant-based and cultivated (lab-grown) meats is creating new applications for industrial dehydration. As these alternative proteins enter mainstream markets, producers are using dehydration to improve texture, extend shelf life, and create novel snack formats. Industrial dehydrators are being adapted to handle sensitive non-animal proteins without compromising nutritional integrity. This diversification of input materials is broadening the scope of dehydrator applications and stimulating investment in specialized equipment.

Sustainability and Energy Efficiency Focus

Environmental concerns are pushing meat processors to adopt greener production methods. Industrial meat dehydrators with advanced heat recovery systems, solar-assisted drying, and reduced carbon footprints are gaining favor. Regulatory pressures and corporate sustainability goals are accelerating the shift toward energy-efficient models. By 2026, equipment manufacturers are expected to prioritize eco-design principles, offering closed-loop systems that minimize water and energy use while complying with global environmental standards.

Regional Market Growth and Emerging Economies

While North America and Europe remain dominant markets due to established meat snack industries and high automation rates, Asia-Pacific and Latin America are emerging as high-growth regions. Expanding middle-class populations, urbanization, and rising disposable incomes are fueling demand for value-added meat products. Countries like China, India, and Brazil are investing in modern meat processing infrastructure, creating new opportunities for industrial dehydrator suppliers. Localized production models supported by compact and scalable dehydrators are expected to proliferate in these regions.

Regulatory and Food Safety Standards

Food safety regulations are becoming more stringent worldwide, especially regarding pathogen control in low-moisture products like dried meat. Industrial dehydrators are being designed with integrated pasteurization stages, real-time microbiological monitoring, and compliance with HACCP and FDA guidelines. By 2026, regulatory alignment across regions will likely drive standardization in equipment design, improving interoperability and global market access for manufacturers.

Conclusion

By 2026, the industrial meat dehydrator market will be shaped by technological innovation, sustainability imperatives, and evolving consumer demands for convenient, safe, and diverse protein options. Companies that invest in smart, adaptable, and eco-friendly dehydration systems will be best positioned to capitalize on global growth opportunities in both traditional and alternative meat sectors.

Common Pitfalls When Sourcing an Industrial Meat Dehydrator (Quality & Intellectual Property)

Sourcing an industrial meat dehydrator involves significant investment and long-term operational impact. Falling into common traps related to quality and intellectual property (IP) can lead to costly failures, production downtime, legal disputes, and reputational damage. Here are the key pitfalls to avoid:

Overlooking Build Quality and Material Specifications

Many buyers focus solely on price or capacity, neglecting the construction details critical for food safety and durability. Using substandard stainless steel (e.g., non-food-grade 304 or 316), weak frame structures, or poorly sealed components can lead to corrosion, contamination, and frequent breakdowns. Always verify material certifications and demand third-party inspection reports before purchase.

Ignoring Compliance with Food Safety and Industry Standards

Assuming a machine is compliant without verification is a major risk. Industrial meat dehydrators must meet strict hygiene standards such as FDA, USDA, CE, or EHEDG. Sourcing from suppliers who cannot provide documented proof of compliance—or who modify designs to cut costs—can result in failed audits, product recalls, and regulatory penalties.

Falling for Counterfeit or Clone Equipment

Low-cost suppliers, especially from certain regions, may offer machines that mimic reputable brands but lack genuine engineering and safety protocols. These clones often infringe on IP rights and use inferior components. Purchasing such equipment exposes your business to legal liability, poor performance, and lack of technical support. Always conduct due diligence on the manufacturer’s legitimacy and original design ownership.

Underestimating the Importance of After-Sales Support and Spare Parts

A high-quality machine is only as reliable as the support behind it. Sourcing from manufacturers with limited regional presence or unclear IP ownership can mean long wait times for spare parts, lack of trained technicians, or refusal to service cloned units. Ensure the supplier offers a service network and guarantees parts availability for at least 10 years.

Neglecting Intellectual Property Verification

Using dehydrators that incorporate patented technology (e.g., airflow systems, control algorithms, or energy recovery mechanisms) without proper licensing can lead to infringement lawsuits. Always ask for IP documentation, especially if the machine offers advanced features. If the supplier cannot prove legitimate ownership or licensing, your operation could become entangled in legal disputes.

Relying on Inadequate Testing and Validation

Skipping factory acceptance tests (FAT) or on-site performance validation increases the risk of receiving a machine that doesn’t meet specifications. Poor temperature uniformity, inconsistent airflow, or high energy consumption may only become apparent after installation. Always include performance benchmarks in the contract and witness testing before shipment.

Failing to Secure Proper Licensing for Proprietary Technology

If the dehydrator includes proprietary software or process controls, ensure your usage rights are clearly defined in the contract. Some suppliers restrict modifications or data access, which can limit your ability to optimize production or integrate with other systems. Confirm licensing terms related to software updates, data ownership, and customization rights.

By proactively addressing these pitfalls—through rigorous supplier vetting, clear contractual terms, and independent verification—you can ensure the acquisition of a reliable, compliant, and legally sound industrial meat dehydrator that supports long-term operational success.

Logistics & Compliance Guide for Industrial Meat Dehydrator

Product Classification & Regulatory Oversight

Industrial meat dehydrators used in food processing are classified as food manufacturing equipment. They fall under the regulatory purview of food safety agencies such as the U.S. Food and Drug Administration (FDA) and the United States Department of Agriculture (USDA) for meat-specific processing. Compliance with food-grade standards, including materials of construction (e.g., stainless steel 304 or 316), is mandatory to prevent contamination and ensure cleanability.

Design & Manufacturing Standards

The dehydrator must be designed and manufactured in accordance with recognized standards such as NSF/ANSI 2, 3, or 14, which govern food equipment sanitation. Electrical components should meet National Electrical Code (NEC) requirements and carry UL or ETL certification for safety. Equipment must include features like smooth, weld-free interior surfaces, proper drainage, and accessibility for cleaning to support effective sanitation protocols.

Installation & Facility Requirements

Installation must comply with local building, fire, and mechanical codes. Adequate ventilation and exhaust systems are required to manage heat and moisture output. The facility must have appropriate utility connections (electrical, water, drainage) sized for the unit’s specifications. A hazard analysis and critical control points (HACCP) plan should be updated to include the dehydrator as a processing step, especially for pathogen reduction (e.g., Listeria, Salmonella).

Operational Compliance & Validation

Operators must validate that the dehydrator achieves and maintains time-temperature profiles necessary for safe meat processing, as defined by USDA-FSIS guidelines (e.g., 165°F internal temperature for a specified duration to achieve a 5-log reduction of pathogens in ready-to-eat products). Calibration of temperature sensors and recording devices must be performed regularly and documented. Routine cleaning and sanitation procedures (CIP or manual) must follow a master sanitation schedule compliant with Good Manufacturing Practices (GMPs).

Transportation & Import/Export Considerations

For international logistics, industrial dehydrators must comply with destination country regulations, including CE marking for the European Union or CCC certification for China. Documentation such as a Certificate of Conformity, electrical schematics, and user manuals in the local language may be required. Shipping must account for the unit’s weight, dimensions, and fragility—crated securely on pallets with protective wrapping. Insurance and Incoterms (e.g., FOB, CIF) should be clearly defined in purchase agreements.

Maintenance & Recordkeeping

A preventive maintenance program must be established per manufacturer recommendations, including inspection of heating elements, fans, door seals, and control systems. All maintenance, calibration, and sanitation activities must be recorded and retained as part of food safety audits (e.g., SQF, BRCGS, or FDA inspections). Records should be stored securely and made available for regulatory review upon request.

Environmental & Disposal Regulations

End-of-life disposal of the dehydrator must comply with local environmental regulations regarding electronic waste (e-waste) and refrigerant (if applicable). Components such as motors, circuit boards, and insulation materials may be subject to specific recycling or hazardous waste handling protocols. Facilities should partner with certified e-waste recyclers to ensure proper decommissioning and documentation.

In conclusion, sourcing an industrial meat dehydrator requires careful consideration of several key factors, including production capacity, energy efficiency, temperature control, build quality, and compliance with food safety standards. Evaluating suppliers based on reputation, after-sales support, and cost-effectiveness ensures a long-term, reliable investment. Additionally, selecting a dehydrator that aligns with your specific processing needs—such as batch size, product type, and throughput—will optimize operational efficiency and product quality. By conducting thorough research and due diligence, businesses can secure a robust, scalable solution that supports growth and maintains consistency in producing high-quality dried meat products.