The global industrial laser cleaning market is experiencing robust growth, driven by increasing demand for eco-friendly, precision-based surface treatment technologies across automotive, aerospace, and manufacturing sectors. According to a 2023 report by Mordor Intelligence, the market was valued at approximately USD 330 million in 2022 and is projected to grow at a CAGR of over 17% from 2023 to 2028. This surge is fueled by the phasing out of traditional cleaning methods—such as sandblasting and chemical treatments—due to environmental and safety concerns, and a shift toward automation in industrial maintenance. Laser cleaning offers non-abrasive, residue-free decontamination, making it ideal for critical applications in defense, heritage restoration, and nuclear facilities. With leading regions like North America and Asia-Pacific investing heavily in laser technology adoption, the competitive landscape is evolving rapidly. Below, we examine the top 10 industrial laser cleaner manufacturers at the forefront of innovation, scalability, and global market penetration.

Top 10 Industrial Laser Cleaner Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Netalux

Website: netalux.com

Key Highlights: Advanced laser cleaning technology for the world’s most demanding industries. Jango® industrial laser cleaning machine, in all-black design….

#2 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#3 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: we engineer and manufacture the most advanced—and most powerful—pulsed industrial laser cleaning systems on the market, built for both manual and automated ……

#4 Clean Laser Systems

Website: cleanlaser.de

Key Highlights: IPG | cleanLASER has been developing and producing high-precision laser systems for cleaning and industrial surface treatment for more than 20 years….

#5 Laser Photonics

Website: laserphotonics.com

Key Highlights: Laser Photonics manufactures reliable, safe, and eco-friendly Laser Cleaning, Laser Cutting, Laser Engraving, Laser Marking, and Laser Welding solutions….

#6 SFX Laser

Website: sfxlaser.com

Key Highlights: SFX Laser is a 20+ years professional laser equipment manufacturer including laser cleaning machine, laser welding machine, fiber laser engraver, fiber laser…

#7 SHARK P CL Industrial Laser Cleaning Machines (100

Website: pulsar-laser.com

Key Highlights: SHARK P CL is an industrial pulsed laser cleaning machine series by PULSAR Laser with outputs from 100 W to 1000 W, air-cooled up to 500 W….

#8 Argento Lux

Website: argentolux.com

Key Highlights: Our company provides state-of-the-art Industrial Laser Equipment Sales and Mobile Laser Cleaning Services for a wide range of applications and industries….

#9 IPG Photonics

Website: ipgphotonics.com

Key Highlights: IPG Photonics manufactures high-performance fiber lasers, amplifiers, and laser systems for diverse applications and industries. Discover your solution….

#10 Vytek Laser Systems

Website: vytek.com

Key Highlights: Vytek designs, builds, and sells a complete line of laser solutions for cleaning, engraving, marking, cutting, and welding, built to exacting standards….

Expert Sourcing Insights for Industrial Laser Cleaner

H2: Key 2026 Market Trends for Industrial Laser Cleaners

By 2026, the industrial laser cleaning market is poised for significant transformation, driven by technological advancements, expanding applications, and growing environmental and economic pressures. Here are the dominant trends shaping the sector:

-

Accelerated Adoption Driven by Environmental Regulations & Sustainability:

- H2: Stricter global regulations (e.g., REACH, RoHS, VOCs) will continue to phase out traditional cleaning methods like sandblasting, chemical solvents, and dry ice blasting due to their environmental hazards (dust, chemical waste, high energy consumption).

- H2: Laser cleaning’s inherent advantages – zero consumables, minimal waste (only vaporized contaminants), no secondary waste streams, and reduced water usage – will make it the preferred “green” technology for ESG (Environmental, Social, Governance) compliance. Industries facing scrutiny will prioritize laser adoption.

-

Significant Cost Reduction & Improved ROI:

- H2: Mass production, technological maturity, and increased competition will drive down the unit cost of laser cleaning systems (especially fiber lasers) and maintenance expenses.

- H2: The Total Cost of Ownership (TCO) will become increasingly favorable compared to traditional methods. Savings from eliminating consumables (abrasives, solvents), reduced waste disposal costs, lower labor requirements (faster cleaning), and extended asset lifespan (gentler on substrates) will solidify the compelling ROI, accelerating adoption beyond early adopters.

-

Technological Advancements Enhancing Performance & Usability:

- H2: Higher Power & Efficiency: Widespread availability of more powerful (multi-kW), yet more energy-efficient fiber lasers will shorten cleaning times for heavy-duty applications (e.g., shipbuilding, large-scale rust removal).

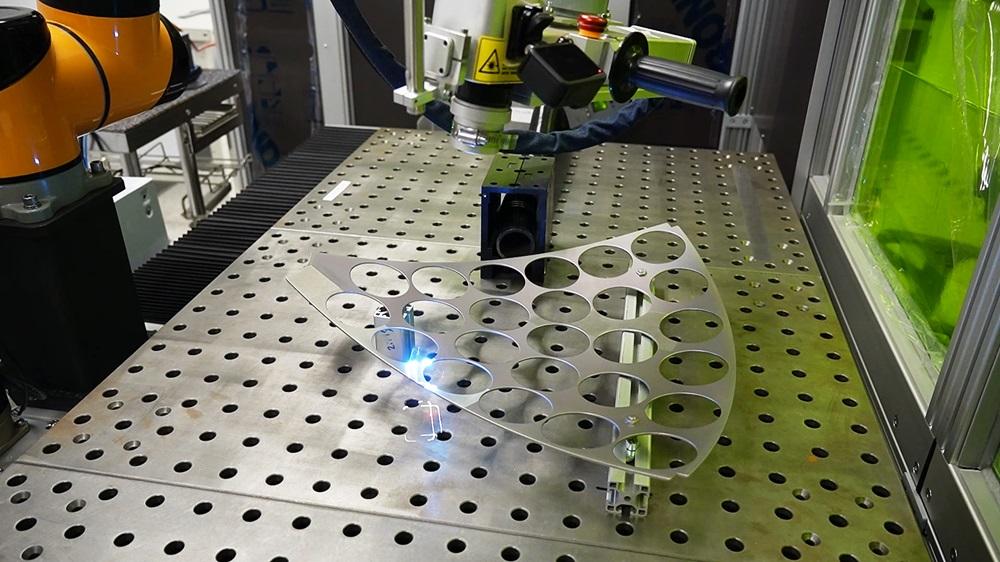

- H2: Improved Automation & Integration: Seamless integration with robotics (cobots and industrial robots) and production lines will become standard. Advanced motion control, real-time monitoring (sensors), and AI-driven process optimization will enable fully automated, consistent, and adaptive cleaning processes.

- H2: Enhanced Safety & Portability: Developments in fume extraction systems, beam enclosure designs, and safety interlocks will improve workplace safety. Simultaneously, lighter, more compact, and truly portable systems will expand applications to field maintenance and confined spaces.

- H2: Smarter Systems: Integration of IoT for remote monitoring, predictive maintenance, and data logging of cleaning parameters will improve process control, traceability, and asset management.

-

Expanding Application Scope Beyond Niche Use:

- H2: While core applications (mold cleaning, rust removal, paint stripping, weld preparation) remain strong, growth will surge in new sectors:

- Aerospace: Precision cleaning of turbine blades, composite surfaces, and delicate components.

- Automotive: Battery component cleaning (anodes/cathodes), EV motor maintenance, precision part cleaning in manufacturing.

- Nuclear: Safe and efficient decontamination of radioactive surfaces (a major growth driver).

- Cultural Heritage: Delicate restoration of artifacts, monuments, and artworks.

- Electronics: Cleaning sensitive components and circuit boards without damage.

- H2: The ability to selectively remove contaminants without damaging underlying substrates (metals, composites, ceramics) will unlock new processes.

- H2: While core applications (mold cleaning, rust removal, paint stripping, weld preparation) remain strong, growth will surge in new sectors:

-

Increased Market Competition & Diversification:

- H2: The market will see intensified competition, not only from established laser manufacturers but also from new entrants (including automation specialists and industrial tool companies) offering integrated solutions.

- H2: Product diversification will accelerate, with a broader range of systems: ultra-high power for heavy industry, mid-range for general manufacturing, compact portable units for maintenance, and highly specialized systems for niche applications (e.g., nuclear, art restoration).

-

Focus on Process Standardization & Qualification:

- H2: As adoption grows in highly regulated industries (aerospace, automotive, nuclear), there will be a strong push for standardized cleaning protocols, qualification procedures, and industry-specific certifications for laser cleaning processes. This will build trust and facilitate wider acceptance.

Conclusion for 2026:

By 2026, industrial laser cleaning will transition from a high-potential niche technology to a mainstream, cost-competitive solution across diverse manufacturing and maintenance sectors. Driven by environmental imperatives, falling costs, technological maturity (especially in automation and power), and expanding applications, the market will experience robust growth. Success will depend on vendors offering reliable, safe, integrated, and demonstrably cost-effective solutions that meet the specific needs of increasingly demanding industrial environments.

Common Pitfalls When Sourcing Industrial Laser Cleaners (Quality & IP)

Sourcing industrial laser cleaners presents unique challenges, particularly concerning product quality and intellectual property (IP) protection. Overlooking these aspects can lead to operational inefficiencies, safety risks, and legal complications. Below are key pitfalls to avoid:

Inadequate Quality Verification

Many suppliers, especially new or low-cost manufacturers, may overstate performance specifications. Buyers often discover discrepancies only after deployment, such as insufficient cleaning speed, inconsistent results on target materials, or premature component failure. Always request third-party test reports, conduct on-site demonstrations with your actual substrates, and verify compliance with safety standards (e.g., IEC 60825 for laser safety).

Lack of IP Due Diligence

Industrial laser cleaning technology often incorporates patented methodologies, software algorithms, or optical designs. Sourcing from manufacturers that infringe on existing IP exposes your company to legal risks, including import bans or litigation. Ensure your supplier can provide documentation confirming freedom to operate and ownership or licensing of critical technologies. Conduct patent landscape analysis if entering competitive markets.

Poor After-Sales Support and Training

High-performance laser systems require specialized maintenance and operator training. Some suppliers, particularly those based overseas, offer limited technical support or spare parts availability. This can result in extended downtime and increased total cost of ownership. Evaluate the supplier’s service network, spare parts lead times, and training programs before procurement.

Misalignment with Application Requirements

Laser cleaners vary significantly in power, wavelength, scanning systems, and automation integration. A common mistake is selecting a system based on price alone without matching technical specs to your specific use case—such as rust removal from steel, paint stripping from aerospace components, or delicate cleaning of electronics. Ensure the supplier conducts a thorough application assessment.

Ignoring Safety and Regulatory Compliance

Industrial lasers pose serious safety hazards. Non-compliant systems may lack proper enclosures, interlocks, or emission controls, risking workplace accidents and regulatory penalties. Verify that the laser cleaner meets regional safety certifications (e.g., CE, FDA, or GB standards in China) and includes comprehensive safety documentation.

By proactively addressing these pitfalls—prioritizing verified quality, ensuring IP integrity, and confirming technical and regulatory alignment—businesses can make informed sourcing decisions and achieve reliable, scalable laser cleaning operations.

H2: Logistics & Compliance Guide for Industrial Laser Cleaner

1. Product Classification & Regulatory Overview

Industrial laser cleaners are high-powered devices that use laser technology to remove rust, paint, oxides, and contaminants from metal surfaces. Due to their technical complexity and potential safety risks, they are subject to multiple international, national, and regional regulations.

- HS Code: Typically classified under 8515.21 (Laser machines for industrial purposes) or 8479.89 (Other machines with individual functions not specified elsewhere), depending on design and function. Confirm with local customs authorities.

- Regulated Components: Include laser diodes, power supplies, and cooling systems—each may have separate compliance requirements.

2. Safety & Laser Compliance Standards

Industrial laser cleaners must meet strict safety standards to prevent harm to operators and bystanders.

- IEC 60825-1: International standard for laser product safety. Classifies lasers by hazard level (Class 1 to Class 4). Most industrial laser cleaners fall under Class 4, requiring robust safety interlocks, warning labels, and protective housings.

- FDA/CDRH (U.S.): Requires manufacturers to file a Laser Product Report with the Center for Devices and Radiological Health. Includes product description, safety features, and variance requests if applicable.

- EN 60825-1 (EU): Harmonized standard under the Machinery Directive (2006/42/EC) and Low Voltage Directive (2014/35/EU). CE marking is mandatory.

- Laser Safety Officer (LSO): Recommended for workplaces using Class 3B or 4 lasers per ANSI Z136.1 (U.S.) or equivalent national standards.

3. Packaging & Transportation Logistics

A. Packaging Requirements

– Shock-resistant, moisture-proof packaging with internal cushioning to protect optical and electronic components.

– Clearly labeled with:

– “Fragile”

– “This Side Up”

– “Protect from Moisture”

– Laser warning symbol (IEC 60825)

– Include desiccants and humidity indicators for long-term or international shipping.

B. Transport Considerations

– Air Freight (IATA): Laser devices with Class 3B or 4 lasers may require special documentation. Batteries (if included) must comply with IATA Dangerous Goods Regulations (DGR).

– Sea Freight (IMO): No special classification unless batteries or hazardous materials are included.

– Land Transport: Follow ADR (Europe) or DOT (U.S.) regulations if transporting with high-capacity lithium-ion batteries or compressed cooling systems.

4. Import & Export Compliance

A. Export Controls

– ECCN (U.S. EAR): Check Commerce Control List. Lasers with specific power, wavelength, or pulse characteristics may fall under 6A003.b or 6A005, requiring an export license.

– Wassenaar Arrangement: Industrial lasers may be subject to dual-use controls. Verify with national export agencies.

– ITAR: Not typically applicable unless the laser is designed for defense or aerospace applications.

B. Import Requirements by Region

– European Union: CE marking, Declaration of Conformity, and technical file retention. Importers must register with customs and ensure compliance with RoHS and REACH.

– United States: FDA registration for laser products, FCC compliance (if device emits RF), and CBP entry filing with correct HTS code.

– China: Requires CCC certification for electrical safety if applicable, and registration with MIIT for certain electronic components.

– Other Markets (e.g., Canada, Australia, Japan): Check for local certification (e.g., ICES-003, RCM, PSE).

5. Documentation Checklist

Ensure the following documents are prepared and retained:

- Technical File (including risk assessment, design drawings, test reports)

- Declaration of Conformity (CE, UKCA, FCC, etc.)

- Laser Safety Report (IEC 60825-1 compliance)

- User Manual (in local language, including safety warnings and maintenance instructions)

- Packing List and Commercial Invoice

- Bill of Lading / Air Waybill

- Export License (if required)

- FDA Accession Number (U.S.)

- RoHS and REACH Compliance Statement

6. After-Sales & Maintenance Compliance

- Provide training for users on safe operation and emergency shutdown.

- Maintain service logs and calibration records.

- Ensure spare parts comply with original certifications.

- Monitor regulatory updates (e.g., changes in laser power thresholds or environmental standards).

7. Key Recommendations

- Engage a compliance consultant or legal expert for complex markets.

- Conduct a pre-shipment compliance audit.

- Label products clearly with laser class, wavelength, max output, and manufacturer details.

- Use certified logistics partners experienced in handling industrial laser equipment.

By adhering to this logistics and compliance guide, manufacturers and distributors can ensure safe, legal, and efficient global deployment of industrial laser cleaning systems.

Conclusion: Sourcing an Industrial Laser Cleaner

Sourcing an industrial laser cleaner requires a strategic and well-informed approach, considering the technology’s growing importance in achieving efficient, environmentally friendly, and precise surface cleaning solutions. After evaluating key factors such as cleaning performance, power requirements, automation compatibility, safety features, after-sales support, and total cost of ownership, it becomes clear that selecting the right supplier and system is critical to achieving long-term operational success.

Laser cleaning offers significant advantages over traditional methods—eliminating chemical usage, reducing waste, and minimizing surface damage—making it a sustainable and cost-effective solution for industries such as automotive, aerospace, manufacturing, and heritage restoration. However, the initial investment is substantial, and the technology demands proper training and integration planning.

To ensure optimal results, businesses should prioritize suppliers with proven industry experience, comprehensive technical support, and customizable solutions tailored to specific cleaning needs. Conducting pilot tests, reviewing case studies, and assessing service and warranty terms are essential steps in the sourcing process.

In conclusion, investing in an industrial laser cleaner is not merely a procurement decision but a strategic step toward modernizing maintenance processes and enhancing sustainability. With careful supplier selection and proper implementation, laser cleaning technology can deliver significant productivity gains, improved safety, and a strong return on investment over time.