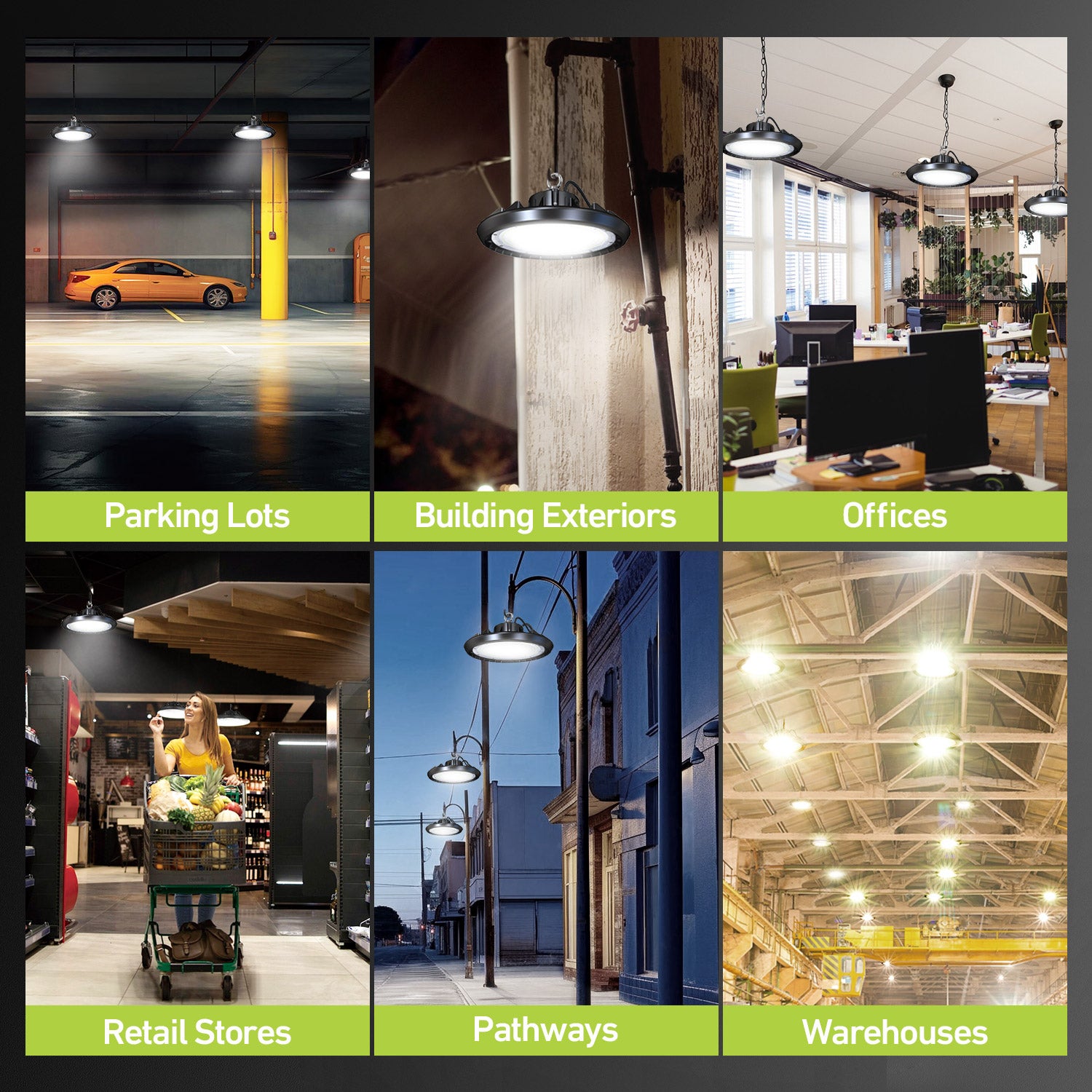

The global high bay lighting market is experiencing robust growth, driven by rising demand for energy-efficient lighting solutions across industrial and commercial sectors. According to a report by Mordor Intelligence, the Industrial LED Lighting Market was valued at USD 9.87 billion in 2024 and is projected to reach USD 14.23 billion by 2029, growing at a CAGR of 7.67% during the forecast period. This expansion is fueled by increasing industrial automation, stringent energy regulations, and the global shift toward sustainable infrastructure. High bay lights—particularly LED-based systems—are at the forefront of this transformation, offering superior luminous efficacy, longer lifespans, and lower maintenance costs compared to traditional lighting technologies. As industries modernize warehouses, manufacturing facilities, and distribution centers, the need for reliable, high-performance lighting has intensified. In this evolving landscape, a select group of manufacturers are leading innovation through advanced thermal management, smart controls integration, and energy savings exceeding 50%. The following list highlights the top 10 industrial high bay light manufacturers shaping the future of industrial lighting, based on market presence, technological innovation, product performance, and global reach.

Top 10 Industrial High Bay Light Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 LED High Bay Lights

Domain Est. 2014

Website: agcled.com

Key Highlights: As one of the leading industrial LED light manufacturers, AGC provides high quality LED high bay lights. We only put LED lights on the market after rigorous ……

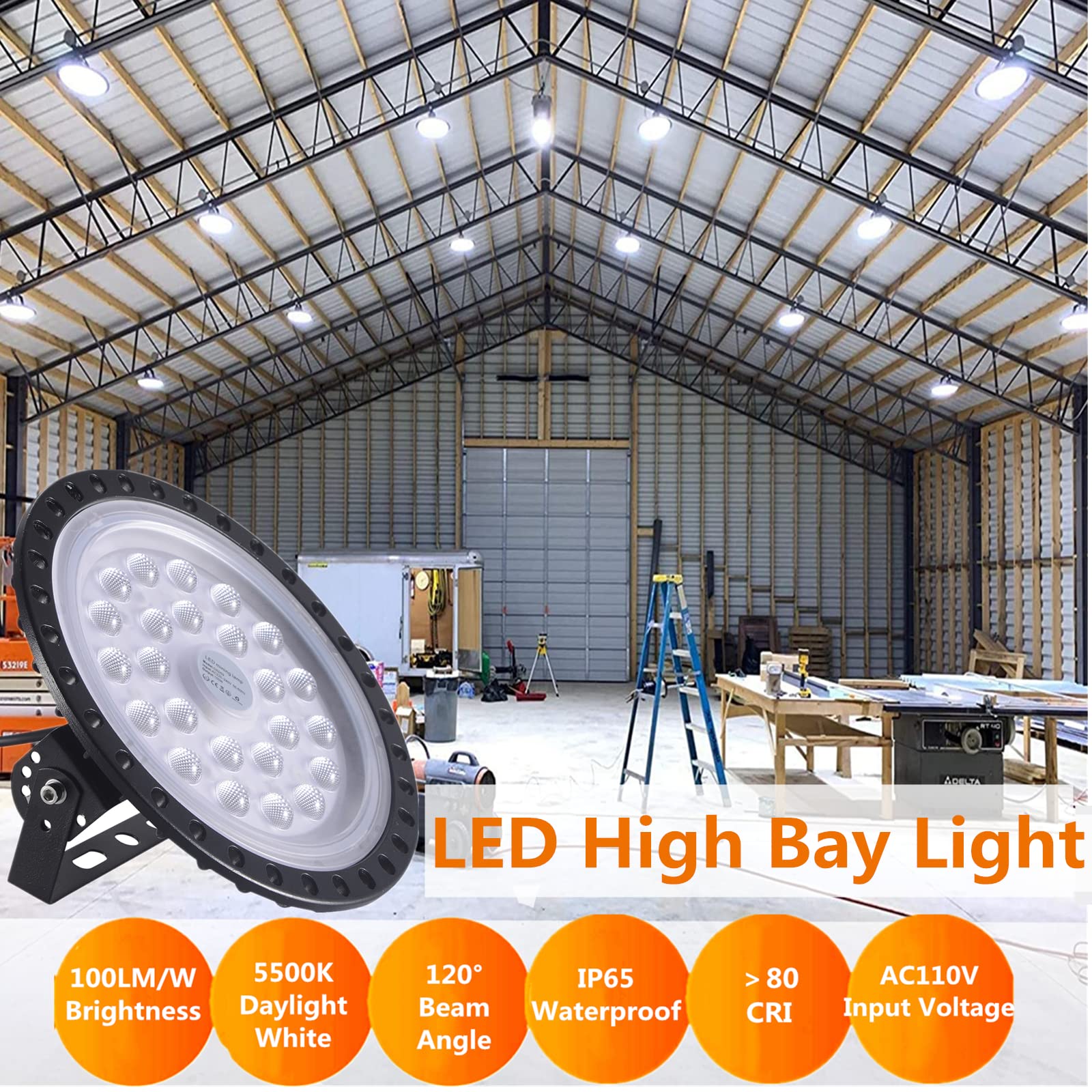

#2 LED High Bay Lights for Industrial & Warehouse Lighting

Domain Est. 2023

Website: jclgl-led.com

Key Highlights: Free delivery 30-day returnsThese indoor lighting fixtures use cutting-edge LED technology to provide bright eco-friendly illumination throughout an entire Warehouse and garage are…

#3 High-bay

Domain Est. 1996

Website: signify.com

Key Highlights: Our innovative, stylish, and easy to install high bay luminaires are suitable for use across a wide range of industrial indoor lighting applications, whether ……

#4 LED High Bay Lights

Domain Est. 2002

Website: e-conolight.com

Key Highlights: Free delivery over $500LED high bay lights are the perfect energy-efficient indoor lighting solution for industrial locations with high ceilings, like warehouses, gyms, barns, and …

#5 High Bay Warehouse Lighting Archives

Domain Est. 2017

Website: lsicorp.com

Key Highlights: Browse our wide variety of quality high-bay lighting options for a range of indoor industrial applications….

#6 High Powered High Bays

Domain Est. 2018

Website: commercialledlights.com

Key Highlights: 6-day deliveryOur high powered LED high bay fixtures for warehouse & industrial applications options are energy efficient and powerful. Shop our selection today….

#7 High-bay

Domain Est. 1987

Website: lighting.philips.com

Key Highlights: Free delivery · 30-day returnsDiscover Philips’ range of energy-efficient indoor high bay lights. Our innovative, stylish, and easy to install high bay luminaires are suitable for…

#8 LED High Bay Light Fixtures

Domain Est. 1997

Website: litetronics.com

Key Highlights: Litetronics has a wide selection of LED high bays to light up your large, open space. Learn more about our lighting solutions here….

#9 LED High Bay Lights

Domain Est. 2006

Website: hdled.com

Key Highlights: LED high bay lights are lighting fixtures specifically designed for illuminating spaces with high ceilings, delivering powerful and even illumination….

#10 Hyperlite LED Garage Lights

Domain Est. 2018

Expert Sourcing Insights for Industrial High Bay Light

H2: 2026 Market Trends for Industrial High Bay Lights

The industrial high bay lighting market is poised for significant transformation by 2026, driven by technological advancements, evolving energy regulations, and shifting industrial demands. Below is an analysis of key trends expected to shape the market in the coming years:

1. Dominance of LED Technology

By 2026, LED high bay lights are projected to maintain their dominance in the industrial lighting sector. Their superior energy efficiency, longer lifespan, and lower maintenance costs continue to displace traditional HID (High-Intensity Discharge) lighting. Innovations such as higher lumen outputs (up to 200 lm/W) and improved thermal management will further solidify LED’s position as the standard in industrial environments.

2. Integration of Smart Lighting Systems

Smart high bay lighting—equipped with sensors, IoT connectivity, and controls—is expected to see accelerated adoption. By 2026, a growing number of manufacturing plants, warehouses, and distribution centers will deploy intelligent lighting systems that support occupancy sensing, daylight harvesting, and remote monitoring. Integration with Building Management Systems (BMS) will enhance energy savings and operational efficiency.

3. Focus on Energy Efficiency and Sustainability

Global push for carbon neutrality and stricter energy codes (e.g., Title 24 in California, EU Ecodesign Directive) will drive demand for ultra-efficient high bay fixtures. Manufacturers will respond with ENERGY STAR-certified and DLC (DesignLights Consortium) listed products. The trend will also encourage circular economy practices, such as modular designs for easier repair and recycling.

4. Growth in Demand from Emerging Markets

Industrialization in regions like Southeast Asia, India, and parts of Africa will fuel market expansion. New warehouse constructions, logistics hubs, and smart factory initiatives in these regions will increase the need for reliable, high-performance lighting solutions, creating opportunities for global suppliers.

5. Rise of Human-Centric and Tunable Lighting

While traditionally focused on functionality, industrial lighting is beginning to incorporate human-centric design. By 2026, tunable white high bay lights that adjust color temperature to support worker alertness and well-being will gain traction, especially in facilities operating 24/7 or emphasizing worker productivity.

6. Consolidation and Innovation Among Suppliers

The competitive landscape will see further consolidation, with major players acquiring niche smart lighting or IoT technology firms. At the same time, innovation in materials (e.g., lightweight composites, improved optics) and product design (e.g., vapor-tight, explosion-proof variants for hazardous areas) will differentiate offerings in specialized industrial segments.

7. Impact of Automation and Industry 4.0

As factories adopt Industry 4.0 principles, high bay lights will increasingly serve dual roles—not only as illumination sources but also as nodes in connected industrial ecosystems. Embedded sensors in luminaires may support asset tracking, environmental monitoring, and predictive maintenance.

Conclusion

By 2026, the industrial high bay lighting market will be characterized by intelligence, efficiency, and integration. Success for manufacturers will depend on their ability to innovate, comply with global standards, and offer scalable, future-ready solutions tailored to the evolving needs of modern industrial spaces.

Common Pitfalls When Sourcing Industrial High Bay Lights

When procuring industrial high bay lights, businesses often encounter challenges that can compromise safety, performance, and long-term cost-efficiency. Avoiding these common pitfalls is crucial to ensuring reliable and effective lighting for warehouses, factories, and large commercial spaces.

Poor Quality Components and Build

One of the most frequent issues is selecting fixtures made with substandard materials and components. Low-cost high bay lights may use inferior LED chips, drivers, and heat sinks, leading to reduced lumen output, shorter lifespans, and premature failure. Poor thermal management can cause overheating, accelerating lumen depreciation and increasing maintenance costs. Always verify component specifications, request LM-79 or TM-21 photometric reports, and consider the reputation of the manufacturer.

Inadequate Ingress Protection (IP) Rating

Many industrial environments are exposed to dust, moisture, and chemical vapors. Choosing high bay lights with insufficient IP ratings—such as IP54 instead of IP65 or higher—can result in compromised performance and safety hazards. For example, in food processing or cold storage facilities, condensation and high humidity demand a minimum of IP65. Ignoring IP requirements may lead to water ingress, corrosion, electrical faults, and non-compliance with safety standards.

Overlooking Temperature and Environmental Ratings

Industrial settings often involve extreme temperatures, vibrations, and corrosive atmospheres. Sourcing lights not rated for the specific operating environment—such as failing to check operating temperature ranges or lack of anti-corrosion coatings—can lead to early degradation. Ensure the fixture is rated for the facility’s ambient conditions, including high bay areas with poor ventilation or exposure to outdoor elements.

Insufficient Light Distribution and Uniformity

Selecting high bay lights without analyzing beam angles and optical design can result in uneven illumination, dark spots, and glare. This affects worker productivity and safety. Fixtures must be matched to mounting height and layout requirements. Using lights with inappropriate optics (e.g., too narrow or too wide a beam) reduces efficiency and may require additional units, increasing overall costs.

Lack of Certifications and Compliance

Procuring lights without proper certifications—such as UL, CE, DLC, or local safety standards—poses safety risks and may lead to insurance or code compliance issues. Non-compliant products often bypass rigorous testing for electrical safety, thermal performance, and photometric accuracy. Always request certification documentation and verify authenticity with certification bodies.

Hidden Costs from Poor Energy Efficiency

While initial purchase price is a major factor, focusing solely on cost can lead to higher total cost of ownership. Low-efficiency fixtures consume more energy and generate more heat, increasing cooling loads and electricity bills. Look for high lumens-per-watt (lm/W) ratings and ENERGY STAR or DLC certification to ensure long-term savings and sustainability goals are met.

Inadequate Warranty and Support

Some suppliers offer attractive pricing but provide limited or non-transferable warranties with poor customer support. A short warranty (e.g., 2–3 years) may indicate low confidence in product durability. Ensure the warranty covers both parts and labor, and confirm the supplier’s responsiveness for technical support and replacements, especially for large-scale installations.

By carefully evaluating quality, IP rating, environmental suitability, optical performance, compliance, efficiency, and warranty support, buyers can avoid these pitfalls and select high bay lighting solutions that deliver reliable, safe, and cost-effective illumination for industrial applications.

Logistics & Compliance Guide for Industrial High Bay Lights

Ensuring smooth logistics and full compliance is essential when importing, distributing, or installing industrial high bay lights. This guide outlines key considerations across transportation, customs, safety standards, and regulatory requirements.

Transportation and Handling

Industrial high bay lights are often heavy and fragile, requiring careful packaging and handling during transit.

- Packaging Requirements: Units should be individually boxed with protective materials (e.g., foam, corner guards) to prevent damage. Bulk shipments must be palletized and secured with stretch wrap or strapping.

- Weight and Dimensions: Verify product specifications (length, width, height, weight) for accurate freight classification and container or truck loading planning.

- Fragility Labeling: Clearly mark packages as “Fragile,” “This Side Up,” and “Do Not Stack” where applicable to prevent mishandling.

- Storage Conditions: Store in a dry, temperature-controlled environment to protect electronic components from moisture and extreme temperatures.

Import and Export Compliance

International shipments must adhere to customs regulations and trade compliance protocols.

- HS Code Classification: Use Harmonized System (HS) code 9405.40 (Luminaires of lighting equipment) for customs declaration. Confirm local variations based on destination country.

- Commercial Documentation: Prepare accurate invoices, packing lists, and certificates of origin. Include product specifications (wattage, voltage, LED type).

- Duties and Tariffs: Research applicable import duties, VAT, and excise taxes in the destination market. Leverage free trade agreements if eligible.

- Restricted Substances: Ensure compliance with RoHS (Restriction of Hazardous Substances) and REACH regulations, especially for shipments to the EU.

Safety and Performance Standards

Industrial high bay lights must meet region-specific safety and performance certifications.

- North America (USA & Canada):

- UL 1598 / UL 8800: Standard for luminaires and LED lighting safety.

- cULus Certification: Required for both U.S. and Canadian markets; verifies compliance with UL and CSA standards.

-

DLC Certification (DesignLights Consortium): Required for utility rebates and energy efficiency programs.

-

European Union:

- CE Marking: Mandatory; includes compliance with:

- EN 60598-1: General safety for luminaires.

- EN 62471: Photobiological safety.

- EMC Directive (2014/30/EU): Electromagnetic compatibility.

- RoHS Directive (2011/65/EU): Restriction of hazardous substances.

-

ERP Directive (2009/125/EC): Energy-related products – mandates energy efficiency.

-

Other Regions:

- UKCA Marking: Required for the UK market post-Brexit (similar to CE).

- Australia/NZ: Comply with AS/NZS 60598.1 and obtain RCM (Regulatory Compliance Mark).

- China: CCC (China Compulsory Certification) may apply depending on product type.

Environmental and Energy Regulations

Energy efficiency and environmental impact are increasingly regulated.

- Energy Efficiency Labels: Include ENERGY STAR (U.S.) or EU Energy Label where required.

- WEEE Compliance (EU): Manufacturers/importers must register and provide take-back options for end-of-life disposal.

- Light Pollution Controls: Some regions require luminaires to meet IDA (International Dark-Sky Association) standards to minimize upward light spill.

Installation and Workplace Compliance

Ensure end-use installations meet local occupational safety and electrical codes.

- IP Rating: Verify Ingress Protection rating (e.g., IP65) for dust and moisture resistance in industrial environments.

- IK Rating: Confirm impact resistance (e.g., IK08) for high-traffic or hazardous areas.

- Electrical Codes: Installations must comply with local standards (e.g., NEC in the U.S., IEC 60364 internationally).

- Height and Spacing Guidelines: Follow manufacturer-recommended mounting heights and spacing to ensure optimal light distribution and safety.

Documentation and Recordkeeping

Maintain comprehensive records for audits and compliance verification.

- Technical Files: Retain product test reports, certification documents, and compliance declarations.

- Supply Chain Traceability: Keep records of suppliers, component origins, and batch numbers.

- Compliance Labels: Ensure each unit displays required certification marks and rating labels.

By adhering to this logistics and compliance framework, businesses can ensure the safe, legal, and efficient deployment of industrial high bay lighting systems globally.

Conclusion for Sourcing Industrial High Bay Lights

In conclusion, sourcing industrial high bay lights requires a comprehensive evaluation of several critical factors to ensure optimal performance, energy efficiency, durability, and cost-effectiveness. Key considerations include selecting appropriate brightness (measured in lumens), color temperature, energy efficiency (via high lumens per watt), and reliable LED technology for long-term savings and reduced maintenance. Compatibility with environmental conditions such as temperature, humidity, and potential exposure to dust or vibrations is essential for sustained operation in industrial settings.

Additionally, prioritizing luminaires with high IP ratings, robust construction, and certifications (such as DLC, UL, or CE) ensures safety and reliability. Engaging with reputable suppliers or manufacturers that offer strong warranties, technical support, and consistent product quality further mitigates risks and enhances return on investment.

Lastly, a lifecycle cost analysis—factoring in initial purchase price, energy consumption, maintenance, and lifespan—demonstrates that high-quality LED high bay lighting, though potentially higher in upfront cost, delivers significant long-term savings and operational benefits. By aligning technical specifications with facility requirements and sustainability goals, organizations can make informed sourcing decisions that enhance visibility, safety, and efficiency in industrial environments.