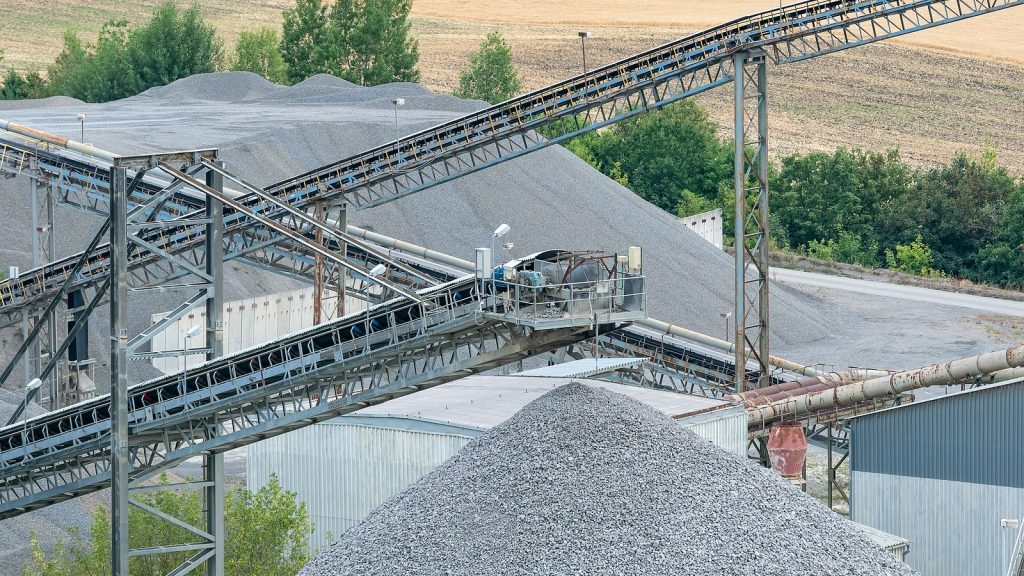

The global industrial conveyor belt market is experiencing robust expansion, fueled by rising automation across manufacturing, mining, and logistics sectors. According to a 2023 report by Mordor Intelligence, the market was valued at USD 6.8 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2028. This growth is further supported by Grand View Research, which highlights increasing demand for efficient material handling systems in e-commerce and food processing industries as a key market driver. As industries prioritize operational efficiency and supply chain optimization, conveyor belt manufacturers are responding with advanced, durable, and energy-efficient solutions. In this evolving landscape, the following ten companies have emerged as leaders, distinguished by innovation, global reach, and strong performance across critical industrial applications.

Top 10 Industrial Conveyor Belt Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Esbelt

Domain Est. 1996

Website: esbelt.com

Key Highlights: We are industrial conveyor belt manufacturer of lightweight thermoplastic conveyor belts for a wide range of applications, in food, agro, or industrial ……

#2 Ashworth Conveyor Belts

Domain Est. 1996

Website: ashworth.com

Key Highlights: The official site of Ashworth, a world leader in stainless steel, plastic, wire mesh, and spiral conveyor belts. Contact us for industrial applications, ……

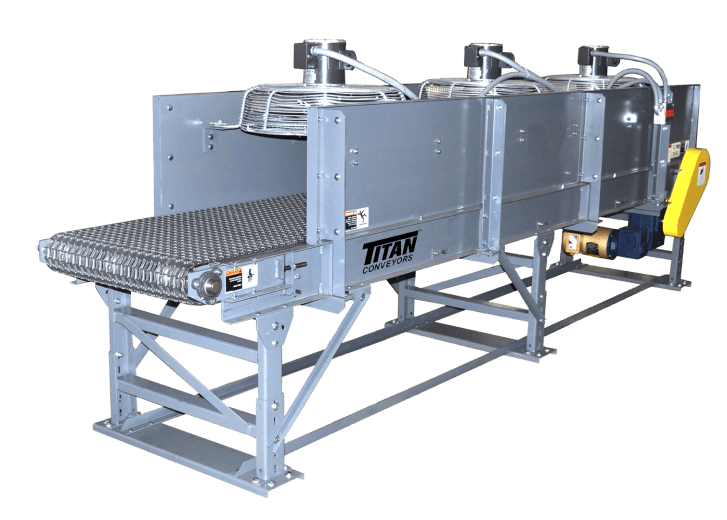

#3 Titan Conveyors

Domain Est. 1997

Website: titanconveyors.com

Key Highlights: Titan keeps North America moving with a full line of industrial conveyors including power rollers, chain driven live rollers, belt conveyors and more….

#4 QC Conveyors

Domain Est. 2013

Website: qcconveyors.com

Key Highlights: QC Conveyors is a trusted conveyor manufacturer providing custom systems for industrial and automation applications. Fast lead times and expert support….

#5 Dorner Conveyors

Domain Est. 2007

Website: dornerconveyors.com

Key Highlights: Dorner offers a wide variety of industrial, aluminum frame and sanitary, stainless steel frame conveyors. With fabric belt, modular belt, and flexible chain ……

#6 Conveyor Belts

Domain Est. 2011

Website: conveyor-belts.semperitgroup.com

Key Highlights: Semperit is a global provider of tailormade conveyor belt technology. Enhance your business with custom, innovative and reliable solutions….

#7 Beltservice Corporation

Domain Est. 1996

Website: beltservice.com

Key Highlights: Beltservice Corporation is a leading fabricator of custom conveyor belting. Every day, we stake our reputation on the durability, variety, and performance….

#8 Conveyor Belting

Domain Est. 1998

Website: beltpower.com

Key Highlights: Investing in high-quality conveyor belting is essential for maximizing operational efficiency and minimizing downtime….

#9 Volta Belting

Domain Est. 1999

Website: voltabelting.com

Key Highlights: Elevate your poultry processing operations with Volta Belting’s innovative conveyor belt solutions, designed for superior hygiene and efficiency….

#10 Conveyor Belt Systems

Domain Est. 2018

Website: continental-industry.com

Key Highlights: Conveyor belt solutions by Continental for a variety of tasks in machine and plant engineering make lifting, conveying and moving materials easier. Read more….

Expert Sourcing Insights for Industrial Conveyor Belt

2026 Market Trends for Industrial Conveyor Belt

The industrial conveyor belt market is poised for significant transformation by 2026, driven by advancements in automation, rising demand for efficient material handling, and the growing adoption of smart manufacturing technologies. As industries worldwide strive to enhance productivity, reduce operational costs, and improve supply chain resilience, conveyor systems are evolving beyond basic transport mechanisms into intelligent, integrated components of industrial ecosystems. This analysis explores key trends expected to shape the industrial conveyor belt market in 2026.

Increasing Demand from Manufacturing and Logistics Sectors

By 2026, the manufacturing and logistics sectors will remain dominant drivers of conveyor belt demand. The global expansion of e-commerce continues to place immense pressure on distribution centers and fulfillment operations, requiring faster, more reliable material handling solutions. Conveyor systems are being deployed at scale to automate sorting, packaging, and loading processes in warehouses and logistics hubs. Additionally, the reshoring and regionalization of supply chains—accelerated by geopolitical and pandemic-related disruptions—are prompting manufacturers to invest in automated production lines, further boosting conveyor belt adoption.

Integration with Industry 4.0 and Smart Technologies

A defining trend in 2026 will be the deep integration of conveyor belts with Industry 4.0 technologies. Smart conveyor systems equipped with sensors, IoT connectivity, and real-time data analytics are becoming standard in modern factories. These intelligent systems enable predictive maintenance, energy optimization, and seamless integration with warehouse management systems (WMS) and enterprise resource planning (ERP) platforms. AI-driven monitoring allows operators to detect wear, misalignment, or blockages before failures occur, minimizing downtime and extending equipment life.

Growth in Customization and Modular Designs

As industrial applications become more diverse, conveyor manufacturers are responding with highly customizable and modular solutions. By 2026, there will be a marked shift toward modular conveyor systems that can be easily reconfigured for different product sizes, weights, and production flows. This flexibility is particularly valuable in industries like food and beverage, pharmaceuticals, and electronics, where production lines frequently switch between product variants. Customization also extends to belt materials, with increased use of food-grade, anti-static, or high-temperature-resistant compounds.

Sustainability and Energy Efficiency

Environmental concerns and regulatory pressures are pushing the conveyor belt industry toward more sustainable practices. In 2026, energy-efficient motors, regenerative drives, and lightweight materials will be standard features in new conveyor systems. Manufacturers are also focusing on recyclable belt materials and longer product lifecycles to reduce waste. The circular economy model is gaining traction, with companies offering refurbishment and remanufacturing services for used conveyor components.

Regional Market Developments

Asia-Pacific will continue to lead the global conveyor belt market in 2026, fueled by rapid industrialization in countries like India, Vietnam, and Indonesia. China remains a major producer and consumer, particularly in heavy industries such as mining and cement. Meanwhile, North America and Europe are seeing growth driven by automation in automotive, aerospace, and high-tech manufacturing. Investments in smart factories under initiatives like the U.S. Advanced Manufacturing Partnership and Germany’s Industry 4.0 are accelerating conveyor system upgrades.

Technological Innovations in Belt Materials

Material science advancements are enabling stronger, lighter, and more durable conveyor belts. By 2026, high-performance polymers, composite materials, and nano-coated surfaces will be increasingly adopted to improve resistance to abrasion, heat, moisture, and chemicals. These innovations are critical in harsh environments such as mining, steel production, and chemical processing, where conveyor reliability directly impacts operational safety and efficiency.

Conclusion

By 2026, the industrial conveyor belt market will be characterized by intelligence, adaptability, and sustainability. The convergence of automation, digitalization, and environmental responsibility is reshaping the industry, creating opportunities for innovation and differentiation. Companies that embrace these trends—by offering smart, modular, and eco-friendly conveyor solutions—will be best positioned to lead in the evolving industrial landscape.

Common Pitfalls When Sourcing Industrial Conveyor Belts (Quality and Intellectual Property)

Sourcing industrial conveyor belts involves more than just selecting a size and material. Overlooking critical quality and intellectual property (IP) factors can lead to operational failures, safety hazards, legal risks, and unexpected costs. Below are key pitfalls to avoid:

Overlooking Material Specifications and Certifications

Choosing a belt based solely on price or availability without verifying material composition, certifications (e.g., FDA, USDA, UL, ISO), and resistance to heat, chemicals, or abrasion can result in premature failure. Using non-compliant belts in regulated industries (e.g., food processing, pharmaceuticals) can lead to contamination risks and regulatory penalties.

Ignoring Load, Speed, and Environmental Compatibility

A common mistake is selecting a belt that doesn’t match the operational demands. Failing to account for load capacity, conveyor speed, operating temperature, humidity, or exposure to oils and UV light can cause belt degradation, slippage, or breakdowns, increasing downtime and maintenance costs.

Assuming OEM Equivalency Without Verification

Some suppliers claim their belts are “OEM equivalent” but lack the engineering quality or durability. These belts may fit physically but underperform due to inferior tensile strength, splice integrity, or wear resistance. Always request performance data and third-party testing reports.

Neglecting IP and Trademark Infringement Risks

Purchasing belts that mimic branded designs (e.g.,仿制品 of Habasit, Fenner, or Ammeraal) without proper licensing may infringe on intellectual property rights. This exposes your company to legal action, shipment seizures, and reputational damage. Always verify supplier legitimacy and avoid “knock-off” products.

Skipping Due Diligence on Supplier Credibility

Working with unverified suppliers—especially from online marketplaces—increases the risk of receiving substandard or counterfeit belts. Lack of traceability, poor documentation, and absence of quality control processes are red flags. Always audit suppliers and request references.

Overlooking Splicing and Joining Quality

Poor splicing techniques or low-quality mechanical fasteners can compromise belt integrity, leading to joint failure and unplanned stoppages. Ensure the supplier provides certified splicing services or compatible joining solutions that match your system’s requirements.

Failing to Consider Total Cost of Ownership

Focusing only on upfront price often leads to higher long-term costs due to frequent replacements, energy inefficiency, or maintenance needs. High-quality belts may cost more initially but offer better durability, energy savings, and reduced downtime.

Not Securing Proper Documentation and Traceability

Lack of material test reports, batch traceability, or compliance documentation can hinder quality assurance and regulatory audits. Insist on full documentation to verify quality claims and support warranty claims if defects arise.

By recognizing and addressing these pitfalls, procurement teams can make informed decisions that ensure reliable performance, regulatory compliance, and protection against IP-related risks.

Logistics & Compliance Guide for Industrial Conveyor Belt

Overview

Industrial conveyor belts are critical components in manufacturing, mining, food processing, and distribution sectors. Proper logistics and compliance management ensures safe, efficient transport, installation, and operation while meeting regulatory standards.

Transportation and Handling

- Packaging and Protection: Conveyor belts must be shipped on robust spools or in protective wrapping to prevent damage from moisture, contaminants, or physical impact.

- Loading and Unloading: Use appropriate lifting equipment (e.g., forklifts with belt spool attachments). Avoid dragging or rolling belts on unprotected surfaces.

- Storage Conditions: Store in a dry, temperature-controlled environment away from direct sunlight, ozone sources (e.g., motors), and chemicals. Keep belts upright on spools and off the floor.

- Transport Mode Considerations:

- Road: Secure spools to prevent rolling; use tarps to protect from weather.

- Sea: Ensure waterproof packaging and moisture barriers; monitor humidity during long transit.

- Air: Confirm weight and dimensions comply with carrier restrictions; prioritize time-sensitive deliveries.

Regulatory Compliance

- International Standards:

- ISO 15236 Series: Specifies requirements for steel cord conveyor belts.

- ISO 21183-1: Covers lightweight conveyor belts for general use.

- EN 1284: European standard for textile conveyor belts.

- Regional Requirements:

- USA: Comply with OSHA 29 CFR 1910.219 (machine guarding) and MSHA (for mining applications). Belts used in food processing must meet FDA 21 CFR standards for food contact materials.

- EU: Adhere to the Machinery Directive (2006/42/EC) and REACH (chemical safety). Flame-resistant belts in underground mines must meet EN 14973.

- Australia: Comply with AS 1336 (safety in machinery) and AS 1604 (rubber conveyor belts).

- Fire Safety: Flame-resistant (FR) and anti-static properties are mandatory in mining and high-risk industrial environments. Certifications such as ISO 340 (flammability) and ISO 284 (electrical conductivity) may apply.

- Environmental Regulations: Ensure compliance with RoHS and REACH for restricted substances (e.g., heavy metals, phthalates).

Import and Export Documentation

- Commercial Invoice: Declares value, quantity, and description of conveyor belts.

- Packing List: Details weight, dimensions, and packaging method.

- Certificate of Origin: Required for preferential tariffs under trade agreements.

- Conformity Certificates: Include test reports verifying compliance with ISO, EN, or other applicable standards.

- Customs Classification: Use correct HS codes (e.g., 4010.31–4010.39 for rubber conveyor belts) to determine duties and restrictions.

Installation and Operational Compliance

- Safety Protocols: Follow lockout/tagout (LOTO) procedures during installation. Ensure emergency stop mechanisms and guarding are in place per OSHA or local regulations.

- Belt Tracking and Tensioning: Proper alignment reduces wear and prevents accidents. Document maintenance in accordance with ISO 5049 (belt conveyor safety).

- Worker Training: Operators and maintenance staff must be trained on belt handling, hazard recognition, and emergency procedures.

Maintenance and End-of-Life

- Inspection Schedule: Regularly inspect for wear, cracks, splice integrity, and contamination. Maintain logs for audit purposes.

- Sustainable Disposal: Recycle worn belts through certified rubber recycling programs. Comply with local waste disposal regulations (e.g., EPA guidelines in the U.S.).

- Reporting: Report any non-compliance issues or safety incidents to relevant authorities as required.

Conclusion

Effective logistics planning and strict adherence to compliance standards are essential for the safe and efficient use of industrial conveyor belts. Proactive documentation, staff training, and regulatory monitoring help minimize risk and ensure operational continuity across global supply chains.

In conclusion, sourcing industrial conveyor belt manufacturers requires a strategic approach that balances quality, cost, reliability, and technical capability. It is essential to evaluate potential suppliers based on their manufacturing expertise, product range, material quality, customization options, compliance with industry standards, and after-sales support. Conducting thorough due diligence—through site visits, reference checks, and sample testing—ensures that the selected manufacturer can consistently deliver durable and efficient conveyor belt solutions tailored to specific operational needs. By prioritizing long-term partnerships with reputable manufacturers, businesses can enhance productivity, reduce downtime, and achieve sustainable operational efficiency across their material handling systems.