The global industrial coatings market is experiencing robust expansion, driven by increasing demand from key end-use sectors such as automotive, construction, marine, and oil & gas. According to a 2023 report by Mordor Intelligence, the market was valued at USD 124.6 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2028, reaching an estimated USD 175.3 billion by the end of the forecast period. This growth is fueled by rising infrastructure development, stricter environmental regulations promoting low-VOC formulations, and technological advancements in protective coatings that enhance durability and corrosion resistance. As industries prioritize asset longevity and sustainability, the role of high-performance industrial coating services has become increasingly critical. In this evolving landscape, a select group of manufacturers are leading innovation, scalability, and global reach. Here’s a data-driven look at the top 10 industrial coating services manufacturers shaping the future of the industry.

Top 10 Industrial Coating Services Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 About

Domain Est. 1996

Website: ics-inc.com

Key Highlights: Our mission here at Industrial Coating Services, Inc. is to provide TOTAL FINISH QUALITY. To do this, we need to cover all three areas of the finishing ……

#2 Advanced Industrial Coatings

Domain Est. 1998

Website: aic-coatings.com

Key Highlights: AIC is a leading industrial coating services company, providing PTFE, Xylan and powder coatings for industrial, scientific and medical manufacturers….

#3 Global Industrial Coatings Leader

Domain Est. 1990

Website: ppg.com

Key Highlights: Offering Powder, liquid, pre-treatment, UV/EB, and e-coat. The world’s only total solution provider, PPG helps customers diversify offerings….

#4 About Us

Domain Est. 1993

Website: nordson.com

Key Highlights: Nordson Industrial Coating Systems offer precise application and curing of powder coatings, liquid paint, ambient temperature adhesives and sealants, ……

#5 Industrial Coating Services

Domain Est. 1997

Website: asbindustries.com

Key Highlights: We offer turnkey thermal spray and cold spray coatings, as well as secondary services like welding, machining, and grinding, to give our customers finished, ……

#6 Endura® Coatings: Industrial Coating Application Services

Domain Est. 1999

Website: enduracoatings.com

Key Highlights: Endura Coatings has been the leader in industrial coating application services with over 750 engineered coating solutions that don’t chip, crack or peel….

#7 Powder Coating & Industrial Painting

Domain Est. 2016

Website: ics-team1.com

Key Highlights: ICS provides cost effective solutions for any powder coating or industrial painting need. We also provide value added services allowing our customers to focus ……

#8 Industrial Coatings Services

Domain Est. 2017

Website: brandsafway.com

Key Highlights: Delivering safe, superior coatings services. BrandSafway understands your unique needs and offers high-quality, expert coatings solutions. We provide clients ……

#9 RPM Industrial Coatings Group

Domain Est. 2022

Website: rpmicg.com

Key Highlights: The RPM Industrial Coatings Group is home to 11 industry-leading coatings and finishing brands. Our dynamic portfolio includes liquid coatings, powder coatings ……

#10 American Coatings Association

Domain Est. 1995

Website: paint.org

Key Highlights: The American Coatings Association is a voluntary, nonprofit trade association working to advance the needs of the paint and coatings industry and the ……

Expert Sourcing Insights for Industrial Coating Services

H2: Market Trends in Industrial Coating Services for 2026

As we approach 2026, the global industrial coating services market is undergoing significant transformation driven by technological innovation, regulatory changes, sustainability imperatives, and shifting industrial demand patterns. This analysis highlights the key trends shaping the sector.

-

Increased Emphasis on Sustainable and Eco-Friendly Coatings

Environmental regulations are tightening worldwide, particularly in North America and Europe, pushing industrial coating providers to adopt low-VOC (volatile organic compound), water-based, and bio-based coatings. By 2026, the demand for environmentally compliant coatings is expected to grow at a CAGR exceeding 6%, as industries in automotive, aerospace, and heavy machinery prioritize green manufacturing. Regulatory frameworks such as the EU’s REACH and U.S. EPA standards are accelerating this shift. -

Adoption of Smart Coating Technologies

The integration of smart coatings—featuring self-healing, anti-corrosion sensors, and temperature-responsive properties—is gaining traction. These advanced materials, often embedded with nanotechnology, enable predictive maintenance and extended asset life. By 2026, smart coatings are projected to account for over 15% of high-value industrial applications, particularly in oil & gas, marine, and infrastructure sectors. -

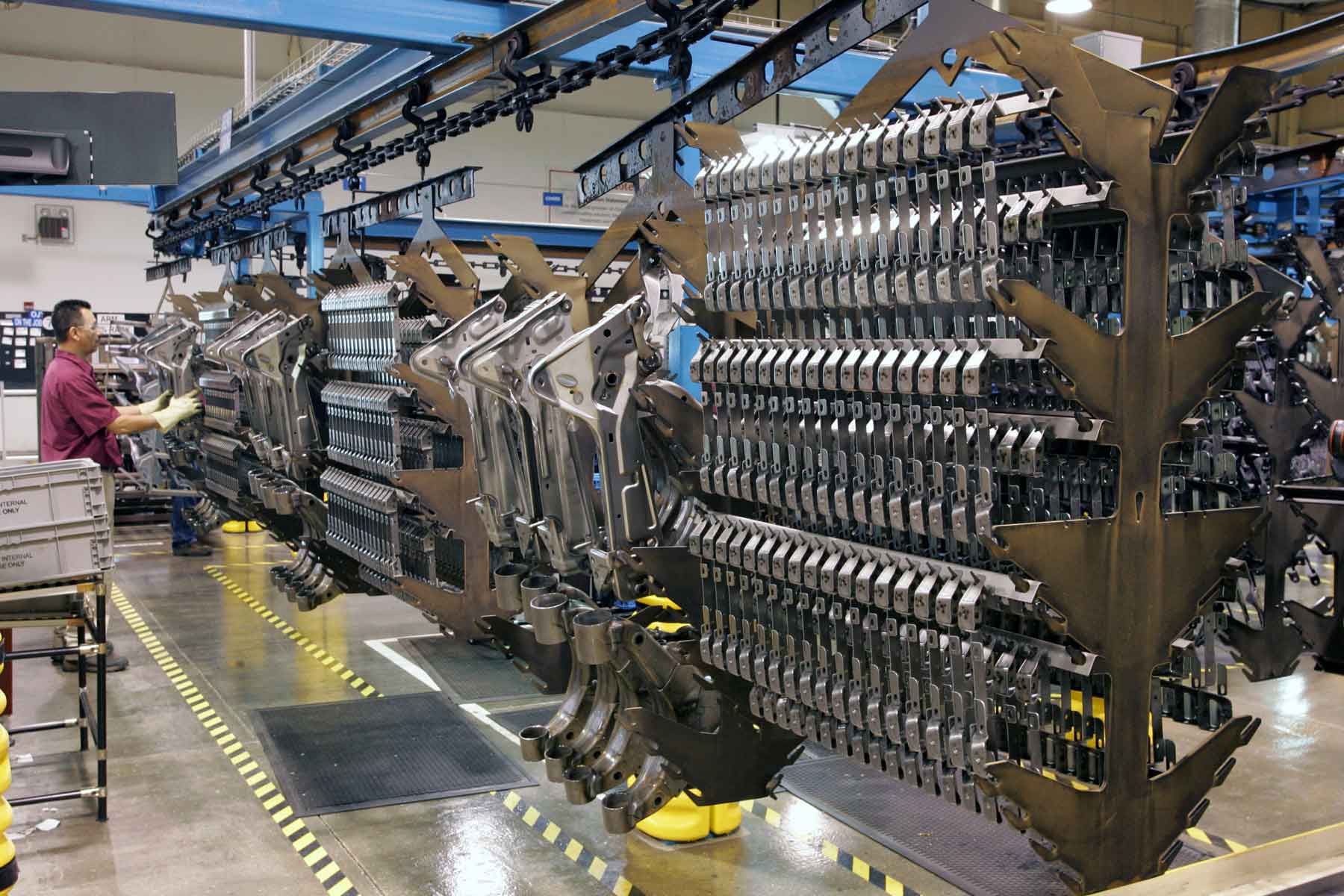

Rise of Automation and Digitalization in Application Processes

Industrial coating services are increasingly leveraging robotics, AI-driven quality control, and digital twin simulations to enhance precision, reduce waste, and improve efficiency. Automated spray systems and real-time monitoring platforms are becoming standard in large-scale manufacturing, especially in automotive and aerospace. This trend is expected to reduce labor costs by up to 20% while improving coating consistency. -

Growth in Protective Coatings for Renewable Energy Infrastructure

With global investments in wind, solar, and hydrogen infrastructure on the rise, there is heightened demand for durable protective coatings that resist harsh environmental conditions. Offshore wind turbines, in particular, require advanced anti-corrosion and anti-fouling solutions. By 2026, the renewable energy segment is forecasted to be one of the fastest-growing end-use markets for industrial coatings, with double-digit annual growth in coating service contracts. -

Regional Shifts and Supply Chain Localization

Geopolitical dynamics and supply chain resilience concerns are driving a trend toward regionalization of coating services. In Asia-Pacific—especially India and Southeast Asia—rapid industrialization is fueling local demand, leading to the expansion of coating service hubs. Meanwhile, nearshoring in North America and Eastern Europe is reducing dependency on long supply chains and enabling faster project turnaround. -

Consolidation and Strategic Partnerships

Market consolidation is accelerating as major players acquire niche coating technology firms to expand their service portfolios. Strategic alliances between coating service providers and equipment manufacturers are also rising, enabling integrated solutions. By 2026, the top 10 industrial coating service companies are expected to control over 35% of the global market share.

In summary, the 2026 industrial coating services landscape will be defined by sustainability, digital innovation, and specialization. Companies that invest in R&D, adopt circular economy principles, and align with evolving regulatory and industrial needs will be best positioned for long-term growth.

Common Pitfalls When Sourcing Industrial Coating Services (Quality & Intellectual Property)

Sourcing industrial coating services involves more than just comparing prices and lead times. Overlooking critical quality and intellectual property (IP) aspects can lead to product failures, regulatory issues, and significant legal or financial risks. Below are key pitfalls to avoid:

Inadequate Quality Control and Process Validation

Many suppliers claim adherence to industry standards, but without proper validation, processes may drift, leading to inconsistent coating performance. Pitfalls include accepting certifications at face value without audits, failing to define clear quality metrics in contracts, and not requiring documented process controls (e.g., ISO 9001, NADCAP). This can result in premature coating degradation, adhesion failures, or non-compliance with environmental or safety regulations.

Poor Material Traceability and Documentation

Industrial coatings often require strict traceability of raw materials, batch records, and application parameters—especially in regulated industries like aerospace, medical, or energy. Sourcing from vendors who lack robust documentation systems increases the risk of non-conformance, complicates root cause analysis during failures, and may hinder regulatory audits or customer certifications.

Insufficient Environmental and Safety Compliance

Coating processes may involve hazardous materials, volatile organic compounds (VOCs), or high-energy operations. Choosing a supplier without verified compliance with environmental regulations (e.g., EPA, REACH, RoHS) can expose your organization to liability, supply chain disruptions, or reputational damage. Ensure suppliers have current permits and follow safe handling and disposal practices.

Lack of Coating Performance Testing and Qualification

Relying solely on supplier assurances without independent performance testing is a major risk. Different substrates, environments, and service conditions demand specific coating properties (e.g., corrosion resistance, thermal stability, abrasion resistance). Failing to require qualification testing—such as salt spray, adhesion, or accelerated aging—can result in field failures and costly rework.

Inadequate Intellectual Property (IP) Protection

Industrial coating formulations and application techniques can be proprietary. When outsourcing, there’s a risk of unintentional IP disclosure or misappropriation. Pitfalls include not using non-disclosure agreements (NDAs), failing to define IP ownership in contracts, and allowing suppliers to use your proprietary processes or formulations without restrictions. This can lead to loss of competitive advantage or unauthorized use of your technology.

Ambiguous Ownership of Developed Coating Processes

When working collaboratively to develop custom coatings, unclear contractual terms can result in disputes over who owns the resulting IP. Without explicit agreements, suppliers may claim rights to innovations, limiting your ability to use or transfer the process. Always define IP ownership, usage rights, and confidentiality obligations before development begins.

Overlooking Supplier Longevity and Capacity

Choosing a coating provider solely on cost or proximity without assessing their financial stability, technical capabilities, or capacity can backfire. If the supplier lacks scalability or continuity, you risk production delays, inconsistent quality, or even business closure—jeopardizing your supply chain and long-term projects.

Failure to Audit and Monitor Supplier Performance

Once a supplier is selected, ongoing monitoring is essential. Neglecting regular audits, performance reviews, and quality data analysis can allow issues to go unnoticed until they escalate. Establish key performance indicators (KPIs) and conduct periodic supplier assessments to ensure sustained compliance and quality.

Avoiding these pitfalls requires thorough due diligence, clear contractual terms, and proactive management of both technical and legal aspects when sourcing industrial coating services.

Logistics & Compliance Guide for Industrial Coating Services

Ensuring smooth operations and adherence to regulatory standards is critical in industrial coating services. This guide outlines key logistics and compliance considerations to maintain safety, efficiency, and legal conformity.

Supply Chain Management

Effective supply chain management ensures the timely availability of raw materials, coating agents, and consumables. Establish relationships with reliable suppliers, maintain safety stock levels, and implement inventory tracking systems such as ERP software to monitor material usage and reorder points. Conduct regular audits of supplier compliance with environmental and quality standards.

Transportation and Material Handling

Transport hazardous coating materials (e.g., solvents, primers) in accordance with DOT (Department of Transportation) and ADR (European Agreement concerning the International Carriage of Dangerous Goods by Road) regulations. Use approved containers, proper labeling, and safety data sheets (SDS). Train personnel in safe handling, lifting techniques, and spill response procedures to prevent accidents and contamination.

Facility Compliance and Safety Standards

Maintain coating facilities in compliance with OSHA (Occupational Safety and Health Administration) and local occupational health regulations. Implement engineering controls such as ventilation systems, explosion-proof equipment, and fire suppression systems. Conduct routine safety inspections, provide personal protective equipment (PPE), and maintain documented training records for all employees.

Environmental Regulations

Adhere to EPA (Environmental Protection Agency) and equivalent regional environmental regulations, including those governing VOC (volatile organic compound) emissions, hazardous waste disposal, and air quality. Obtain necessary permits for coating operations and emissions. Implement pollution prevention measures, such as using low-VOC coatings and recycling solvents. Maintain detailed records of waste generation, storage, and disposal in compliance with RCRA (Resource Conservation and Recovery Act).

Quality Assurance and Documentation

Follow ISO 9001 and industry-specific standards (e.g., NACE, SSPC) for coating application and inspection. Document all coating processes, including surface preparation, application methods, film thickness, and curing conditions. Maintain quality control logs and inspection reports for traceability and customer compliance.

Regulatory Audits and Certifications

Prepare for and participate in scheduled audits by regulatory bodies or third-party certification agencies. Keep all compliance documentation—such as SDS, training records, emission reports, and permit renewals—up to date and readily accessible. Pursue certifications that enhance credibility, such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety).

Emergency Preparedness and Response

Develop and implement an emergency response plan for incidents such as chemical spills, fires, or equipment failure. Conduct regular drills, maintain spill kits and fire extinguishers, and ensure all personnel are trained in emergency procedures. Coordinate with local emergency services and report incidents as required by law.

By integrating these logistics and compliance practices, industrial coating service providers can ensure operational excellence, regulatory adherence, and long-term sustainability.

In conclusion, sourcing industrial coating services is a strategic decision that significantly impacts the durability, performance, and longevity of industrial assets. A thorough evaluation of service providers—considering factors such as technical expertise, compliance with industry standards, quality control processes, and experience in the specific sector—is essential to ensure optimal results. Investing time in selecting a reputable and reliable coating provider not only enhances corrosion protection and operational efficiency but also reduces long-term maintenance costs and downtime. By aligning with a capable partner, organizations can achieve superior surface protection, meet regulatory requirements, and maintain a competitive edge in demanding industrial environments.